10 Scavenge Fires

Diunggah oleh

Bhupender Ramchandani0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

24 tayangan6 halamanmarine

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPT, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inimarine

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

24 tayangan6 halaman10 Scavenge Fires

Diunggah oleh

Bhupender Ramchandanimarine

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 6

Scavenge fires

Oily carbon deposits build up in the scavenge

trunking during normal operation of the engine.

Drains are provided in order to remove such

deposits and so help keep the scavenge

trunking reasonably clean. Under certain

conditions the deposits may dry out and ignite.

Piston blow past due to sticking or broken

piston rings, or even excessive liner wear, is a

major cause of the problem. Faulty combustion

due to late injection or incorrect atomisation

may also be responsible as may blow back

through the scavenge ports caused by a

restriction in the exhaust.

In all cases the increased temperature

leads to a drying out of the oily deposits in

the air box and subsequently ignition takes

place. A scavenge fire can cause serious

damage to the piston rod diaphragm gland

as well as leading to possible distortion of

the air box and cracking of the liner. Tie

rod tension will almost certainly be

affected.

B&W and other engine builders

recommend that in the event of a

fire the engine should be slowed as

soon as possible and preferably

stopped. The turning gear should

be put in and the engine

continuously turned to prevent

seizure. Air supply should be cut off

by enclosing the turbocharger

inlets, for mechanically operated

exhaust valves the gas side should

also be operated, (hydraulically

operated exhaust valves will self

close after a few minutes). The

individual isolating valves on the

scavenge drains line are close to

prevent the fire transferring to other

boxes. Boundary cooling may be

employed.

Fixed extinguishing mechanism

should be used at the earliest

possible time. When the fire is

extinguished the air box is allowed

to cool, then the air boxes should

be well cleaned, the tie-rod tension

checked. The causes of the fire

should be ascertained and

remedied.

Fire fighting media

Carbon dioxide- will put out a fire but supply is

limited. Susceptible to loss if dampers do not

effective prevent air flow

Dry powder- will cover the burning carbon and

oil but is messy. As the fire may still smoulder

below the powder care must be taken when the

scavenge doors are removed as the powder

layer may be blown away.

Steam-plentiful and effective

Water spray- perhaps the ideal solution giving

quick effective cooling effect to the fire.

Indications that a fire is imminent are a reduction

in flow through the drains and a temperature rise

in the scavenge. This temperature rise can be

detected by temperature wires or mats.

When a fire is in progress there is a slow down

of the engine with the turbocharger surging as

the fire consumes the oxygen. Sparks are seen

issuing from the drains and there is a

temperature rise in the scavenge space.

Scavenge belt relief door

Fitted to both ends of

the scavenge belt and

set to lift slightly

above the maximum

normal working

scavenge air pressure

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Assignment 4Dokumen2 halamanAssignment 4Komal SinghBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Marine Engineering Study Materials: Videocon d2h HD OfferDokumen7 halamanMarine Engineering Study Materials: Videocon d2h HD OfferBhupender RamchandaniBelum ada peringkat

- Isps CodeDokumen10 halamanIsps CodeBhupender RamchandaniBelum ada peringkat

- Marine Engineering Study Materials: Videocon d2h HD OfferDokumen6 halamanMarine Engineering Study Materials: Videocon d2h HD OfferBhupender RamchandaniBelum ada peringkat

- Marine Engineering Study Materials: EFC InternationalDokumen5 halamanMarine Engineering Study Materials: EFC InternationalBhupender RamchandaniBelum ada peringkat

- Marine Engineering Study Materials: Wall Paints in HD ShadesDokumen7 halamanMarine Engineering Study Materials: Wall Paints in HD ShadesBhupender RamchandaniBelum ada peringkat

- P 57Dokumen7 halamanP 57Bhupender RamchandaniBelum ada peringkat

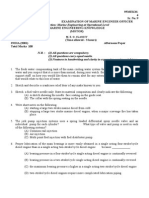

- 95 MEKM4 SR No2Dokumen2 halaman95 MEKM4 SR No2Bhupender RamchandaniBelum ada peringkat

- 95MEP 4 Sr. No. 1Dokumen2 halaman95MEP 4 Sr. No. 1Bhupender RamchandaniBelum ada peringkat

- ArticrlDokumen9 halamanArticrlBhupender RamchandaniBelum ada peringkat

- Function: Marine Engineering at Operational LevelDokumen3 halamanFunction: Marine Engineering at Operational LevelBhupender RamchandaniBelum ada peringkat

- Function: Marine Engineering at Operational LevelDokumen2 halamanFunction: Marine Engineering at Operational LevelBhupender RamchandaniBelum ada peringkat

- Mek 2001 Jan 95 SR - No.1Dokumen3 halamanMek 2001 Jan 95 SR - No.1Bhupender RamchandaniBelum ada peringkat

- ArticlDokumen11 halamanArticlBhupender RamchandaniBelum ada peringkat

- Function: Marine Engineering at Operational LevelDokumen2 halamanFunction: Marine Engineering at Operational LevelBhupender RamchandaniBelum ada peringkat

- Function: Marine Engineering at Operational LevelDokumen3 halamanFunction: Marine Engineering at Operational LevelBhupender RamchandaniBelum ada peringkat

- Function: Marine Engineering at Operational LevelDokumen2 halamanFunction: Marine Engineering at Operational LevelBhupender RamchandaniBelum ada peringkat

- Function: Marine Engineering at Operational LevelDokumen3 halamanFunction: Marine Engineering at Operational LevelBhupender RamchandaniBelum ada peringkat

- 95 MEKM4 SR No4Dokumen3 halaman95 MEKM4 SR No4Bhupender RamchandaniBelum ada peringkat

- 95 MEKM4 SR No5Dokumen3 halaman95 MEKM4 SR No5Bhupender RamchandaniBelum ada peringkat

- 95 MEKM4 SR No5Dokumen3 halaman95 MEKM4 SR No5Bhupender RamchandaniBelum ada peringkat

- 95 MEKM SR No.3Dokumen3 halaman95 MEKM SR No.3Bhupender RamchandaniBelum ada peringkat

- Function: Marine Engineering at Operational LevelDokumen4 halamanFunction: Marine Engineering at Operational LevelBhupender RamchandaniBelum ada peringkat

- 95MEKM4 SrNo10Dokumen3 halaman95MEKM4 SrNo10Bhupender RamchandaniBelum ada peringkat

- Function: Marine Engineering at Operational LevelDokumen3 halamanFunction: Marine Engineering at Operational LevelBhupender RamchandaniBelum ada peringkat

- 95 MEKM4 SR No.7Dokumen3 halaman95 MEKM4 SR No.7Bhupender RamchandaniBelum ada peringkat

- 95MEKM4 SrNo8Dokumen3 halaman95MEKM4 SrNo8Bhupender RamchandaniBelum ada peringkat

- Function: Marine Engineering at Operational LevelDokumen4 halamanFunction: Marine Engineering at Operational LevelBhupender RamchandaniBelum ada peringkat

- Function: Marine Engineering at Operational LevelDokumen3 halamanFunction: Marine Engineering at Operational LevelBhupender RamchandaniBelum ada peringkat

- 95MEKM4 SrNo6Dokumen3 halaman95MEKM4 SrNo6Bhupender RamchandaniBelum ada peringkat

- 95MEKM4 SrNo2Dokumen3 halaman95MEKM4 SrNo2Bhupender RamchandaniBelum ada peringkat

- Om en A: F in Ite D Iffe Ren Ce-B Ase DN Um Eri Ca L M Eth Od SDokumen426 halamanOm en A: F in Ite D Iffe Ren Ce-B Ase DN Um Eri Ca L M Eth Od SPrateek Kumar PandeyBelum ada peringkat

- 1.rle Rubrics For Case PresentationDokumen2 halaman1.rle Rubrics For Case PresentationKhristine EstosoBelum ada peringkat

- ZTE V4 RNC Commissioning and Integration TrainingDokumen2 halamanZTE V4 RNC Commissioning and Integration TrainingBeena SinghBelum ada peringkat

- Beamforming For 4.9G/5G Networks: Exploiting Massive MIMO and Active Antenna TechnologiesDokumen12 halamanBeamforming For 4.9G/5G Networks: Exploiting Massive MIMO and Active Antenna TechnologiesAymen Ben zinebBelum ada peringkat

- Bibliography and FootnotesDokumen2 halamanBibliography and FootnotesHannah de VeraBelum ada peringkat

- Studi Tentang Pelayanan Terhadap Kapal Perikanan Di Pelabuhan Perikanan Pantai (PPP) Tumumpa Kota ManadoDokumen9 halamanStudi Tentang Pelayanan Terhadap Kapal Perikanan Di Pelabuhan Perikanan Pantai (PPP) Tumumpa Kota ManadoAri WibowoBelum ada peringkat

- Evolis User ManualDokumen28 halamanEvolis User ManualIonmadalin1000Belum ada peringkat

- Labour Law Assignment - Gross NegligenceDokumen6 halamanLabour Law Assignment - Gross NegligenceOlaotse MoletsaneBelum ada peringkat

- 93c3 Document 3Dokumen14 halaman93c3 Document 3NONON NICOLASBelum ada peringkat

- A C Engines and Jet Propulsion1Dokumen16 halamanA C Engines and Jet Propulsion1Mukesh KumarBelum ada peringkat

- Accommodating Expansion of Brickwork: Technical Notes 18ADokumen13 halamanAccommodating Expansion of Brickwork: Technical Notes 18AWissam AlameddineBelum ada peringkat

- Olympiad Problem 2Dokumen3 halamanOlympiad Problem 2Đạt Nguyễn BáBelum ada peringkat

- Concession Project List Excel 02-Aug-2019Dokumen15 halamanConcession Project List Excel 02-Aug-2019Vishal BansalBelum ada peringkat

- G20 SolutionDokumen11 halamanG20 SolutionAbidemi Benjamen AttehBelum ada peringkat

- SFN ProfileDokumen4 halamanSFN Profiledinesh panchalBelum ada peringkat

- ICorr CED CT01 InspectionAndTestingOfCoatings Issue1-2Dokumen13 halamanICorr CED CT01 InspectionAndTestingOfCoatings Issue1-2AlineMeirelesBelum ada peringkat

- Can Snails Become Habituated To A StimulusDokumen2 halamanCan Snails Become Habituated To A StimulusSachitra Wijethunga100% (1)

- Re 150821Dokumen2 halamanRe 150821francis puthuserilBelum ada peringkat

- Laser Diffraction Physics Project: Submitted By, Disha DineshDokumen11 halamanLaser Diffraction Physics Project: Submitted By, Disha DineshNidaleeBelum ada peringkat

- I. You'll Hear A Conversation Between Two People. Listen and Fill in The Blanks (10 PTS) This Is The VOA Special English Agriculture ReportDokumen7 halamanI. You'll Hear A Conversation Between Two People. Listen and Fill in The Blanks (10 PTS) This Is The VOA Special English Agriculture ReportTHỌ NGUYỄN VĂNBelum ada peringkat

- Full TextDokumen167 halamanFull Textjon minanBelum ada peringkat

- Which Will Weigh The Least Without AnswerDokumen7 halamanWhich Will Weigh The Least Without AnswerumeshBelum ada peringkat

- Wish Upon A STAR: Presented By: Daulo, Eunice R. III - Block 3Dokumen17 halamanWish Upon A STAR: Presented By: Daulo, Eunice R. III - Block 3nhyce18Belum ada peringkat

- Ultraviolet Flame Detector: Omniguard Model 660Dokumen2 halamanUltraviolet Flame Detector: Omniguard Model 660carlosBelum ada peringkat

- 2022 Cement Lime Manufacturing Ehs Guidelines enDokumen39 halaman2022 Cement Lime Manufacturing Ehs Guidelines enSamiBelum ada peringkat

- Relations Between Lean Management and Organizational StructuresDokumen12 halamanRelations Between Lean Management and Organizational StructuresRENE JAVIER PACHECO SALASBelum ada peringkat

- Chapter 6 SBLDokumen4 halamanChapter 6 SBLbrave manBelum ada peringkat

- Contractor Hse Management ProgramDokumen12 halamanContractor Hse Management ProgramAhmed IbrahimBelum ada peringkat

- Electromechanical Instruments: Permanent-Magnet Moving-Coil InstrumentsDokumen13 halamanElectromechanical Instruments: Permanent-Magnet Moving-Coil InstrumentsTaimur ShahzadBelum ada peringkat