X - All Nadasdi1 - Synthetics Are Not The Same Presentation

Diunggah oleh

Ray Cepeda Mena0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

40 tayangan20 halamanSynthetic lubricating oils have developed a reputation for working in the most extreme conditions. The evolution of mineral oil processing has led to the introduction of new families of products. These "newer" synthetics are based on severely hydroprocessed mineral oils.

Deskripsi Asli:

Judul Asli

X - All Nadasdi1 - Synthetics Are Not the Same Presentation

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPT, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniSynthetic lubricating oils have developed a reputation for working in the most extreme conditions. The evolution of mineral oil processing has led to the introduction of new families of products. These "newer" synthetics are based on severely hydroprocessed mineral oils.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

40 tayangan20 halamanX - All Nadasdi1 - Synthetics Are Not The Same Presentation

Diunggah oleh

Ray Cepeda MenaSynthetic lubricating oils have developed a reputation for working in the most extreme conditions. The evolution of mineral oil processing has led to the introduction of new families of products. These "newer" synthetics are based on severely hydroprocessed mineral oils.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 20

1 of 20

2006 Exxon Mobil Corporation. All rights reserved.

All Synthetic Oils

Are Not The Same

Dr. T. Tim Nadasdi

Dr. Jim T. Carey

Dr. Angela Galiano-Roth

2 of 20

2006 Exxon Mobil Corporation. All rights reserved.

Introduction

Synthetic lubricating oils have developed a reputation for

working in the most extreme conditions. They have been

associated with superior performance

thermal and oxidative stability

shear stability

low temperature performance

low frictional properties

The evolution of mineral oil processing has recently led to the

introduction of new families of products, marketed as

synthetic lubricants

based on severely hydroprocessed mineral oils

This presentation will provide some insight into:

fundamental characteristics of these newer synthetics compared to

traditional synthetic oils

effects that these base oils have on finished lubricant/grease performance

3 of 20

2006 Exxon Mobil Corporation. All rights reserved.

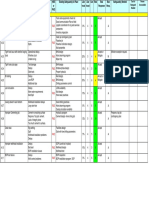

API Basestock Classifications

API Basestock Classification

Physical Specifications

Group

VI Sulfur % wt. Saturates % wt

Manufacturing

Process

I 80-120 >0.03 <90

Conventional (solvent

refining)

II 80-120 <0.03 >90

Require

Hydrocracking/dewaxing

III >120 <0.03 >90

Requires severe

Hydrocracking/dewaxing

IV >140 0.00 >90

Chemical Synthesis -

PAO

V

All other synthetics -

esters, polyglycols,

phosphate esters...

4 of 20

2006 Exxon Mobil Corporation. All rights reserved.

Parameter Group I Group II Group III Group IV

Comparison of Basestock Properties

Oxidation

Stability

Volatility

Additive Solvency of

basestock

Low Temperature

capability

Efficiency / Traction

Relative costs

1 1.1-1.2 1.5 4 to 10

Viscosity range at 40

deg C (in cSt)

Up to 500 Up to 120 Up to 40 Up to 50,000

Direction of arrow indicates improved performance

Generalized Comparison of Base Stock

Properties

5 of 20

2006 Exxon Mobil Corporation. All rights reserved.

Mineral Oil Molecular Make-Up

Presentation

Symbol

Chemical Advantage in a

Lubricant

Disadvantage in a

Lubricant

Short Chain

Paraffins

High volatility

Low flash Pt.

Medium Chain

Paraffins

Higher VI

Therm. & oxid. stability

Low solvency

Long Chain

Paraffins

High VI

Therm. & oxid. stability

Low solvency

Waxy

Aromatics High solvency

High viscosity

Poor oxid. stability

Low VI

Heteroatomic

Molecules (S, N)

Sometimes oxidative

stability

Can affect other

properties (foam,

Demuls, oxidation)

Saturated Rings Better low temp.

Better solvency

Adds some viscosity

Poor oxidative

stability

A

H

R

Group I oils are a mixture of

many different molecules

with different properties

R

R

R

H

H

H

H

H

A

A

A

A

A

A

6 of 20

2006 Exxon Mobil Corporation. All rights reserved.

Mineral Oil Group I - Group III Processing

Hydroprocessing

Further

Hydroprocessing

R

R

R

H

H

H

H

H

A

A

A

A

A

A

GP I

R

R

R

R

R

R

R

R

GP II

R

R

R

GP III

Polyalphaolephin (PAO)

Viscosity controlled by molecular design

7 of 20

2006 Exxon Mobil Corporation. All rights reserved.

Basestock Summary

The processes used to manufacture Group II and

Group III oils limit their viscosity to ~120 and 40 cSt

at 40

o

C, respectively

Group II and Group III base oils require liquid

thickening agents to meet the viscosity

requirements of many industrial applications

PAO oils achieve their high viscosity through

molecular design and do not require liquid thickening

agents for typical industrial applications

8 of 20

2006 Exxon Mobil Corporation. All rights reserved.

0

50

100

150

200

250

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Year

C

a

p

a

c

i

t

y

(

1

0

0

0

B

B

L

/

d

a

y

)

1990 1991 1992

1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004

Group II

Group I

Total Capacity

86%

14%

29%

71%

51%

49%

North American Base Oil Capacity Change

9 of 20

2006 Exxon Mobil Corporation. All rights reserved.

Market Changes

1999 ruling by the National Advertising Division of the Better

Business Bureau has expanded the meaning of the word synthetic

relative to lubricants

Synthetic base oil compositions may include a variety of base oils

that have been chemically altered and when formulated properly

deliver the performance standards expected from a synthetic

lubricant

GP II, GP III and white oils may fit the new criteria for synthetics

Increased North American market capacity for GP II & III oils

Practical Result - the meaning of the term synthetic has been

expanded and can no longer be just associated with the performance

strengths and chemistry of GP IV/V stocks.

10 of 20

2006 Exxon Mobil Corporation. All rights reserved.

Lets Look at 3 Synthetic Gear Oils

All 3 oils are considered synthetic hydrocarbons

The difference in the oils is in the blend of PAO,

Polyisobutylene (PIB) and Group III base stocks

All other additives in the oils are the same

11 of 20

2006 Exxon Mobil Corporation. All rights reserved.

Three Synthetic Gear Oils

1. The same commercial premium gear oil additive package in all oils

2. The same commercially available ester in all oils

The oils differ ONLY in their base stock composition

Oil A Oil B Oil C

Hydrocarbon Type PAO PAO/PIB GP III/PIB

Viscosity ISO 460 ISO 460 ISO 460

Viscosity Index 164 150 145

PAO 88 51

Polyisobutylene (PIB) 37 37

Group III Oil 51

Gear Oil Additive Package

1

2 2 2

Ester

2

10 10 10

Total 100 100 100

12 of 20

2006 Exxon Mobil Corporation. All rights reserved.

Test Regiment

Bulk Oil Oxidation Test

- This test is run for 24 hours at 375

o

F. Air is bubbled though the test oil

which contains a metal catalyst. Viscosity increase and TAN are measured.

Worm Gear Test

- This test involves running oils in a worm gear at various loads. It is run for

48hrs during which time the oil temperature and gear box efficiency are

monitored. The used oil is tested for shear stablity (viscosity loss) and wear

metals.

Test Method Relation to Lubricant Performance

Pour Point ASTM D97

In general, lower pour points indicate better low

temperature performance

Brookfield Visc ASTM D5133

Related to flowability and pumpability of oil at lower

temperatures

Bulk Oil Oxidation See Below Estimation of oxidation stability and oil life

Worm Gear Test See Below Shows lubricant performance in a real worm gear box

13 of 20

2006 Exxon Mobil Corporation. All rights reserved.

Low Temperature Results - Pour Point

Even with PPD concentration optimized for lowest pour point, Oil C

still has a pour point that is 9

o

C higher than PAO or PAO/PIB

blends

Oil A

(PAO)

Oil B

(PAO/PIB)

Oil C

(GP III/PIB)

Oil C

+ PPD

-35

-30

-25

-20

-15

-10

-5

0

1 2 3 4

D

e

g

r

e

e

C

e

l

s

i

u

s

-33

o

C

-24

o

C

-18

o

C

14 of 20

2006 Exxon Mobil Corporation. All rights reserved.

0

100,000

200,000

300,000

400,000

500,000

600,000

-10 -20 -30

Temperature

o

C

V

i

s

c

o

s

i

t

y

i

n

c

P

Oil A

(PAO)

Oil B

(PAO/PIB)

Oil C

(GP III/PIB)

Low Temperature Results - Brookfield Viscosity

Oil A shows significantly better

flow characteristics at lower

temperatures

15 of 20

2006 Exxon Mobil Corporation. All rights reserved.

Bulk Oil Oxidation Results

Both TAN and viscosity increase indicate that Oil C

undergoes the highest oxidation

0

5

10

15

20

25

% Change in Viscosity 7 7 23

Change in TAN (mg

KOH/g)

0.4 2.6 3.2

Oil A

(PAO)

Oil B

(PAO/PIB)

Oil C

(GP III/PIB)

V

i

s

c

o

s

i

t

y

C

h

a

n

g

e

(

%

)

T

A

N

C

h

a

n

g

e

(

m

g

K

O

H

/

g

)

16 of 20

2006 Exxon Mobil Corporation. All rights reserved.

Testing in a Worm Gear Box

Worm Gear

(Steel)

Bearings

(Steel)

Driven Gear

(Cu/Sn alloy)

17 of 20

2006 Exxon Mobil Corporation. All rights reserved.

Gear Box Efficiency (%)

Oil A (PAO) has an average efficiency benefit of 6% over Oil C (GP III/PIB)

70

71

72

73

74

75

76

77

78

79

80

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Hours

Oil A

(PAO)

Oil B

(PAO/PIB)

Oil C

(GP III/PIB)

E

f

f

i

c

i

e

n

c

y

(

%

)

Worm Gear Test Results

18 of 20

2006 Exxon Mobil Corporation. All rights reserved.

Sump Temperature (

o

F)

165

170

175

180

185

190

195

200

205

210

215

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Hours

T

e

m

p

e

r

a

t

u

r

e

(

o

F

)

Oil A

(PAO)

Oil B

PAO/PIB)

Oil C

GpIII/PIB)

Oil A Oil B Oil C

Hydrocarbon Type PAO PAO/PIB GpIII/PIB

Viscosity Change - 1.8% - 4.8% - 5.9%

Cu, ppm 70 320 1100

Sn, ppm 25 42 160

Fe, ppm 1 2 8

Used Oil Data

Worm Gear Test Results

19 of 20

2006 Exxon Mobil Corporation. All rights reserved.

Oil Summary

Group II oils are limited to ~120 cSt and Group III to

~40cSt

Group II and Group III base oils require thickening

agents to meet the viscosity requirements of many

industrial applications

Synthetic industrial lubricants made with Group II/III

oils MAY have different performance properties

than lubricants made with PAO alone

Selection of synthetic lubricants should focus on

product performance, application requirements,

and field experience

All synthetics ARE NOT the same

20 of 20

2006 Exxon Mobil Corporation. All rights reserved.

Considerations for Greases

Performance differences seen in oils will likely

translate to greases

Need to understand grease lubrication regimes and

determine which type of synthetic oil will perform

best in the intended application

Different types of synthetic oils will likely interact

differently with grease thickeners

Effect on bleed rate?

Effect on shear stability?

Effect on thickener reaction?

Effect on low temperature properties?

Anda mungkin juga menyukai

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Mobil Planned Engineering Service: This Is Your Legacy This Is Your BrandDokumen19 halamanMobil Planned Engineering Service: This Is Your Legacy This Is Your BrandRay Cepeda MenaBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- 2 - SyntheticsDokumen57 halaman2 - SyntheticsRay Cepeda Mena100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Mobil Grease 28Dokumen7 halamanMobil Grease 28Ray Cepeda MenaBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Porres - XOM Open Gear InspectionsDokumen30 halamanPorres - XOM Open Gear InspectionsRay Cepeda Mena100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- 3 - Syntetic Pocket GuideDokumen9 halaman3 - Syntetic Pocket GuideRay Cepeda MenaBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- X - Hydraulic Fluids Electronic HandoutDokumen41 halamanX - Hydraulic Fluids Electronic HandoutRay Cepeda Mena100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Waxrex 2405 - Msds - EnglishDokumen8 halamanWaxrex 2405 - Msds - EnglishRay Cepeda MenaBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Porres - XOM Open Gear InspectionsDokumen30 halamanPorres - XOM Open Gear InspectionsRay Cepeda Mena100% (1)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- 2 Airl 1Dokumen21 halaman2 Airl 1Ray Cepeda MenaBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Mobilgear 600 XP SeriesDokumen3 halamanMobilgear 600 XP SeriesRay Cepeda MenaBelum ada peringkat

- X - Lubricación en Motores PequeñosDokumen39 halamanX - Lubricación en Motores PequeñosRay Cepeda MenaBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- 2 Airl 1Dokumen21 halaman2 Airl 1Ray Cepeda MenaBelum ada peringkat

- PCC - Costos ComponentesDokumen66 halamanPCC - Costos ComponentesRay Cepeda MenaBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Mobil Planned Engineering Service: This Is Your Legacy This Is Your BrandDokumen19 halamanMobil Planned Engineering Service: This Is Your Legacy This Is Your BrandRay Cepeda MenaBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- F200aet 2006Dokumen88 halamanF200aet 2006Ray Cepeda MenaBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- X - Grease Electronic HandoutDokumen47 halamanX - Grease Electronic HandoutRay Cepeda MenaBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Limites - MonitorDokumen5 halamanLimites - MonitorRay Cepeda MenaBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Motor de Moto PDFDokumen38 halamanMotor de Moto PDFAnninha Sud AlvesBelum ada peringkat

- Yamaha Ft50cehdx 2007Dokumen80 halamanYamaha Ft50cehdx 2007Ray Cepeda MenaBelum ada peringkat

- Marcol 82 MSDSDokumen7 halamanMarcol 82 MSDSRay Cepeda MenaBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Atlas Copco Seri Xa 60-70-80-120-160 DD y Nueva Serie Deutz Xas DDDokumen36 halamanAtlas Copco Seri Xa 60-70-80-120-160 DD y Nueva Serie Deutz Xas DDRay Cepeda Mena100% (5)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Motor de Moto PDFDokumen38 halamanMotor de Moto PDFAnninha Sud AlvesBelum ada peringkat

- 2806C-E18+workshop+manual pdf+CATERPILLAR+C18Dokumen192 halaman2806C-E18+workshop+manual pdf+CATERPILLAR+C18Jhon Hever Benitez100% (27)

- Yamaha Ft50cehdx 2008Dokumen72 halamanYamaha Ft50cehdx 2008Ray Cepeda MenaBelum ada peringkat

- F100betl 2004Dokumen78 halamanF100betl 2004Ray Cepeda MenaBelum ada peringkat

- F100betl 2004Dokumen78 halamanF100betl 2004Ray Cepeda MenaBelum ada peringkat

- Sj700B-E Sj700B-E Mj-Sj700 '06: Superjet 700Dokumen0 halamanSj700B-E Sj700B-E Mj-Sj700 '06: Superjet 700Ray Cepeda MenaBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- L200aetx 2007Dokumen75 halamanL200aetx 2007Ray Cepeda MenaBelum ada peringkat

- F100betl 2005Dokumen78 halamanF100betl 2005Ray Cepeda MenaBelum ada peringkat

- Diagnostic Study of Excessive Water Production in Aswad Oilfield, LibyaDokumen7 halamanDiagnostic Study of Excessive Water Production in Aswad Oilfield, LibyaAlmakhzanjiBelum ada peringkat

- Carbon Capture Utilization and Storage CCUS - The Energy Source of The FutureDokumen5 halamanCarbon Capture Utilization and Storage CCUS - The Energy Source of The Futuredaljeet.kaurBelum ada peringkat

- Work Permit SystemDokumen42 halamanWork Permit SystemDamien Gracious K.D100% (2)

- Ansi Aga B109 1 2000Dokumen43 halamanAnsi Aga B109 1 2000Ihab El-SaftawiBelum ada peringkat

- Natural Gas Engineering: S.M. Farouq AliDokumen48 halamanNatural Gas Engineering: S.M. Farouq AlirickBelum ada peringkat

- BREF Ceramic Manufacturing Industry enDokumen260 halamanBREF Ceramic Manufacturing Industry enTeodora89100% (3)

- Manual Aparat de Aer Conditionat Samsung Wind Free PDFDokumen36 halamanManual Aparat de Aer Conditionat Samsung Wind Free PDFPerfectreviewBelum ada peringkat

- UMD ProfileDokumen2 halamanUMD ProfileGregg GarbesiBelum ada peringkat

- CO2 Recovery Plant To Urea Production in Abu Dhabi: Back To Projects DatabaseDokumen2 halamanCO2 Recovery Plant To Urea Production in Abu Dhabi: Back To Projects DatabaserajachemBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Práctica de Laboratorio #6-CronometrajeDokumen3 halamanPráctica de Laboratorio #6-CronometrajeJoselynBelum ada peringkat

- Risk Assesment 1Dokumen1 halamanRisk Assesment 1Leon MonsalveBelum ada peringkat

- Flammable Vapor Release Hazards in Congested AreasDokumen1 halamanFlammable Vapor Release Hazards in Congested AreasNc Bean100% (1)

- Global Greenhouse Gas Emissions Data - US EPADokumen10 halamanGlobal Greenhouse Gas Emissions Data - US EPAToastBelum ada peringkat

- The Case For Methanol As A Green H2 CarrierDokumen2 halamanThe Case For Methanol As A Green H2 Carrierdavid limBelum ada peringkat

- Heat PumpsDokumen15 halamanHeat Pumpsanony210Belum ada peringkat

- Case Study ONGCDokumen15 halamanCase Study ONGCRaavi SinghBelum ada peringkat

- Erreesse SRL - BrochureDokumen32 halamanErreesse SRL - BrochureEduardo VasquezBelum ada peringkat

- Data Base PlanttsDokumen6 halamanData Base Planttsharshad_19832589Belum ada peringkat

- 13.09 Stream A TopsoeDokumen20 halaman13.09 Stream A TopsoeJorge Ariel QuipildorBelum ada peringkat

- 1 Primary Recovery Drive Mechanisms PDFDokumen37 halaman1 Primary Recovery Drive Mechanisms PDFmd khatriBelum ada peringkat

- Deepwater DrillingDokumen39 halamanDeepwater DrillingLorenzo Jefry Taolin100% (1)

- Floating SolarDokumen22 halamanFloating SolarNrj100% (1)

- DesuperHeating PDFDokumen8 halamanDesuperHeating PDFJason LeeBelum ada peringkat

- Section 2.2 - Gas Piping SystemDokumen90 halamanSection 2.2 - Gas Piping SystemPDPPPMAT0621 Ruhilin Binti NasserBelum ada peringkat

- LNG Myanmar Projects 2019Dokumen5 halamanLNG Myanmar Projects 2019Maung OoBelum ada peringkat

- Mexico Burgos Basin PresentationDokumen18 halamanMexico Burgos Basin PresentationCarlos PereaBelum ada peringkat

- Sunrise Systems Pipenet Vision: Detailed Demonstration AND Discussion of ApplicationsDokumen77 halamanSunrise Systems Pipenet Vision: Detailed Demonstration AND Discussion of ApplicationsIjaz FazilBelum ada peringkat

- Chevron Tombua LandanaDokumen2 halamanChevron Tombua LandanaHASHMI MAHMOODBelum ada peringkat

- FinancialTimesUSA 18february2023Dokumen54 halamanFinancialTimesUSA 18february2023hangchi songBelum ada peringkat

- Geothermal Handbook: Planning and Financing Power GenerationDokumen29 halamanGeothermal Handbook: Planning and Financing Power GenerationPhan Trong HuanBelum ada peringkat