PUMPS

Diunggah oleh

praSHANT2331100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

196 tayangan28 halamanPumps

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPT, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniPumps

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

196 tayangan28 halamanPUMPS

Diunggah oleh

praSHANT2331Pumps

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 28

PUMPS

Engineering Solutions . . . Delivering Results

Introduction

Pumps are a mechanical device that forces a fluid to move from one

position to another.

This is achieved by supplying energy or head to a flowing liquid in

order to overcome head losses due to friction, pipe work and also, if

necessary, to raise the liquid to a higher level.

Engineering Solutions . . . Delivering Results

Classification of Pumps

Engineering Solutions . . . Delivering Results

Centrifugal pump

Centrifugal pump

Its purpose

The energy changes

Engineering Solutions . . . Delivering Results

Centrifugal pump

Engineering Solutions . . . Delivering Results

Reciprocating pump

Piston plunger pump is simplest

form

Prime movers

The capacity of a pump is

determined by the number of plungers

or pistons and the size of these

elements (bore and stroke).

Engineering Solutions . . . Delivering Results

Reciprocating pump

Engineering Solutions . . . Delivering Results

Features of different pump

Engineering Solutions . . . Delivering Results

Pump Types-Comparison and Selection Guide

Yes Yes No Self-priming

Constant Constant Variable Variable or

Constant Flow

Smooth Pulsating Smooth Smooth or

Pulsating Flow

Yes Yes No Requires Relief

Valve

2.81 X 10

6

+ kg/m

2

7.03 X 10

6

+ kg/m

2

4.23 X 10

4

+ kg/m

2

Maximum Pressure

Yes Yes No Low Flow Rate

Capability

2271.2 + m

3

/hr 2271.2 + m

3

/hr 27276.6 + m

3

/hr Maximum Flow

Rate

Low/Medium

Capacity,

Low/Medium

Pressure

Low Capacity,

High Pressure

Medium/High

Capacity,

Low/Medium

Pressure

Optimum Flow and

Pressure

Applications

Rotary Pumps Reciprocating Pumps Centrifugal Pumps Parameter

Engineering Solutions . . . Delivering Results

Calculation

Suction pressure

Suction pressure is the pressure at the upstream of the pump. This is given

by

Suction pressure = source press. + static head del p in pump suction

BTL

Pump centre line

Vessel

Source pressure Source pressure pressure

above the liquid level

Static head static pressure

difference due to the liquid

between pump centre line

and vessel BTL

Del P losses in the pump

suction line

Pump

Engineering Solutions . . . Delivering Results

NPSH Net Positive Suction Head

NPSHa is the net remaining pressure at the suction flange of the

pump after subtracting all negative forces that restrict liquid from

getting into the pump.

A similar term NPSHr is used by pump manufactures to describe the

energy losses that occur within many pumps as the fluid volume is

allowed to expand within the pump body. This energy loss is

expressed as a head of fluid.

Engineering Solutions . . . Delivering Results

NPSHa Calculation

The NPSHa is calculated from:

Fluid surface pressure + positive

head pipework friction loss

fluid vapour pressure

Or

Fluid surface pressure negative

head pipework friction loss

fluid vapour pressure

Engineering Solutions . . . Delivering Results

Cavitation

Vapour pressure

Local boiling

Gas bubbles collapse

Reduce the flow of delivered fluid.

Vibrations, damage to the pipework system or the pump. This

effect is known as cavitation.

Engineering Solutions . . . Delivering Results

Understanding NPSHa and NPSHr

Engineering Solutions . . . Delivering Results

In a system where the fluid needs to be lifted to the pump inlet , the negative

head reduces the motive force to move the fluid to the pump.

Engineering Solutions . . . Delivering Results

Discharge pressure

Discharge pressure is pressure at the downstream of the pump

This is given by

Discharge pressure = Destination pressure + static head + del p in

pump discharge circuit + contingency

Where,

Destination pressure Operating pressure of the destination

vessel/column, etc.

Static head static pressure difference due to the liquid head

between final destination point and grade.

Del p line losses in the discharge line.

Contingency This is kept to take care of any unforeseen

additional requirement of del p in the discharge

circuit.

Engineering Solutions . . . Delivering Results

Differential pressure = Discharge pressure Suction pressure

Differential head = [(Diff. pressure in Kg/cm

2

) / (Density in Kg/m

3

)]

X 10

4

Shut off pressure = Max suction pressure + Max diff. pressure

where, Max suction press. = Max source press + Static head

Max diff. pressure:

for centrifugal pump = 1.2 X Diff. pressure

for positive displacement pump = 1.1 X Diff. pressure

Pump power consumption (kw) = (Flow rate in m

3

/hr X Diff.

pressure in Kg/cm

2

) / (36 X efficiency)

Engineering Solutions . . . Delivering Results

Typical characteristic curve for centrifugal pump

Engineering Solutions . . . Delivering Results

Proportioning pump efficiency

Engineering Solutions . . . Delivering Results

Example

Engineering Solutions . . . Delivering Results

Required flow rate Q = 200 l/s(given)

Pressure at the Suction side of pump

Source pressure = 3.0 mgiven

Pressure loss in suction line = 50 kpa

= 50 X 10.33 = 5.10 m of water

therefore, pressure at pump suction

= 3.0 5.10 = -2.10 m of water

Required Discharge pressure

Static head to be overcome = 25.0 m of water

Line losses to be overcome = 250 kpa

= 250 X 10.33 = 25.5 m of water

Total pressure required at the discharge of pump

= 25.0 + 25.5 = 50.5 m of water

Thus, head to be added by pump = 50.5 (-2.1)

= 52.6 m of water

Engineering Solutions . . . Delivering Results

Operating point lies in the

operating Envelop as such this

pump can supply the required

head at the required flow rate.

Pump will operate at around

1040 rpm

Required NPSH is 6.5 m of

water

Efficiency at the operating

point can be seen to be about

66 %

Engineering Solutions . . . Delivering Results

NPSH Calculation

NPSHa = Height of liquid in tank above pump suction + Atmospheric

pressure - Pressure losses in suction piping - Vapour pressure of liquid

Atmospheric pressure = 10.33 m of water

Vapour pressure of water @ 60 deg. C = 149.4 mm Hg

= (149.4 / 760) X 10.33 = 2.0 m of water

NPSHa = 3.0 + 10.33 5.10 2.0

= 6.23 m of water

From this we can see NPSHr > NPSHa which is not feasible and hence

cavitation will occur.

Therefore this pump is not suitable for this application

We will calculate the power requirements, as an example of how to do this.

Pump power consumption kw = (Flow rate in m

3

/hr X Diff. pressure in

Kg/cm

2

) / (36 X efficiency)

= (720 X 5.26) / (36 X 0.66)

= 160 kw

Engineering Solutions . . . Delivering Results

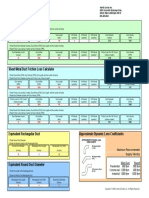

Excel Sheet

Pump Calculation.xls

Engineering Solutions . . . Delivering Results

THANK YOU

Engineering Solutions . . . Delivering Results

Engineering Solutions . . . Delivering Results

RP

Engineering Solutions . . . Delivering Results

RP

Anda mungkin juga menyukai

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineDari EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazinePenilaian: 5 dari 5 bintang5/5 (1)

- The Axial Flow Compressor CompromiseDokumen8 halamanThe Axial Flow Compressor Compromisekincandia100% (4)

- Cavitation and Pump NPSHRDokumen39 halamanCavitation and Pump NPSHRRicardo BarrosBelum ada peringkat

- Pumping Control Methods and Their Impact On System EfficiencyDokumen16 halamanPumping Control Methods and Their Impact On System EfficiencyWahidHamedBelum ada peringkat

- Chapter 2 Centrifugal PumpsDokumen96 halamanChapter 2 Centrifugal PumpsMichael MesfinBelum ada peringkat

- Positive Displacement PumpsDokumen6 halamanPositive Displacement PumpsVignesh DuraiBelum ada peringkat

- Dry Vacuum Pump Cobra Busch enDokumen2 halamanDry Vacuum Pump Cobra Busch enJessica ChandlerBelum ada peringkat

- Pump Notes PDFDokumen25 halamanPump Notes PDFUsman KhalidBelum ada peringkat

- Thermodynamics PDFDokumen125 halamanThermodynamics PDFAnonymous ffje1rpaBelum ada peringkat

- Gas Jet Pump Paper Oct03 Ipa03 e 059Dokumen11 halamanGas Jet Pump Paper Oct03 Ipa03 e 059kglorstadBelum ada peringkat

- A1 Management & Technical Consultant Pune: Training Program On Reciprocating CompressorDokumen14 halamanA1 Management & Technical Consultant Pune: Training Program On Reciprocating CompressorSandeep KocharBelum ada peringkat

- Compressors: Me7313 Industrial Automation and ControlDokumen13 halamanCompressors: Me7313 Industrial Automation and ControlNuwan DinushaBelum ada peringkat

- Centrifugal Compressor HorsepowerDokumen9 halamanCentrifugal Compressor HorsepowerCurtis DookieBelum ada peringkat

- Increasing Pump CapacityDokumen3 halamanIncreasing Pump Capacitydk4monjureBelum ada peringkat

- Reciprocating Compressor PDFDokumen28 halamanReciprocating Compressor PDFmoBelum ada peringkat

- 6 Konitzer2Dokumen32 halaman6 Konitzer2mchramziBelum ada peringkat

- Principle of Centrifugal PumpsDokumen13 halamanPrinciple of Centrifugal Pumpsvisitabhinav100% (3)

- High Pressure Pump For Water Jet CuttingDokumen15 halamanHigh Pressure Pump For Water Jet Cuttingktpcoeo0% (1)

- Hydraulic Resevoir Design Criteria PDFDokumen10 halamanHydraulic Resevoir Design Criteria PDF2345421Belum ada peringkat

- Positive Displacement CompressorsDokumen46 halamanPositive Displacement CompressorsMahendra PuguhBelum ada peringkat

- Study of The Centrifugal Pump Efficiency at Throttling and Speed ControlDokumen4 halamanStudy of The Centrifugal Pump Efficiency at Throttling and Speed ControlHassan SouleymanBelum ada peringkat

- Hydraulic Pumps Lec NotesDokumen30 halamanHydraulic Pumps Lec NotesDarsh MenonBelum ada peringkat

- PumpsDokumen45 halamanPumpsMehmood Ul Hassan100% (1)

- Course2a-Energy Efficiency PDFDokumen59 halamanCourse2a-Energy Efficiency PDFNazaruddin SinagaBelum ada peringkat

- DGS - 2. JCDokumen15 halamanDGS - 2. JCfjafarvand100% (1)

- Vaneless DiffuserDokumen8 halamanVaneless Diffuseramir_karimiBelum ada peringkat

- Presentation of PumpDokumen46 halamanPresentation of PumpArindam SamantaBelum ada peringkat

- b3311 722-2Dokumen7 halamanb3311 722-2Arnaldo BenitezBelum ada peringkat

- Separator: A Streamlined Organization Dedicated To Technology and Excellence in ExecutionDokumen64 halamanSeparator: A Streamlined Organization Dedicated To Technology and Excellence in ExecutionSyed Hussain AbbasBelum ada peringkat

- T II P Training Program On Basic Process Engineering PracticesDokumen26 halamanT II P Training Program On Basic Process Engineering PracticesAsmita AndaniBelum ada peringkat

- The Affinity Laws of Centrifugal PumpsDokumen8 halamanThe Affinity Laws of Centrifugal PumpsArunkumar SubramanianBelum ada peringkat

- Mep All QuestionsDokumen79 halamanMep All QuestionsbabaBelum ada peringkat

- 5 Reciprocating Compressor SelectionDokumen27 halaman5 Reciprocating Compressor SelectionHazem RamdanBelum ada peringkat

- 3-Day Gen Open 112003 5a (Compatibility Mode)Dokumen111 halaman3-Day Gen Open 112003 5a (Compatibility Mode)api-3703348100% (1)

- Gas TreatmentDokumen106 halamanGas TreatmentKarthik MuruganBelum ada peringkat

- Guide To Measure Rotating EquipmentDokumen18 halamanGuide To Measure Rotating EquipmentMDRBelum ada peringkat

- Reciprocating Air Compressors: Compression RatioDokumen25 halamanReciprocating Air Compressors: Compression RatioRichardt LootsBelum ada peringkat

- JIP Compressor FoulingDokumen3 halamanJIP Compressor FoulinglvicencioaBelum ada peringkat

- Pumps in Parallel or Serial ConnectionDokumen7 halamanPumps in Parallel or Serial Connectionyarzar17Belum ada peringkat

- Mopico: Product Overview: Segment Gas Storage and Sealed TechnolgyDokumen18 halamanMopico: Product Overview: Segment Gas Storage and Sealed Technolgyhernan plazasBelum ada peringkat

- Turbo Machines Lab: Centrifugal and Reciprocating CompressorsDokumen38 halamanTurbo Machines Lab: Centrifugal and Reciprocating CompressorsUpendra SravanBelum ada peringkat

- Hoer CT Valve 2Dokumen5 halamanHoer CT Valve 2Tu PhamBelum ada peringkat

- Centrifugal Compressor Construction and TestingDokumen10 halamanCentrifugal Compressor Construction and Testingmusaveer0% (1)

- Jet Pump Technical DataDokumen11 halamanJet Pump Technical DataIdelia Cutipa Yauri100% (1)

- 2012 Paper Screw CompressorsDokumen25 halaman2012 Paper Screw CompressorsravisankarBelum ada peringkat

- 00-Superior Compressor Student Guide-ToCDokumen1 halaman00-Superior Compressor Student Guide-ToCTu PhamBelum ada peringkat

- 5.7 Centrifugal PumpsDokumen8 halaman5.7 Centrifugal PumpsSaleem Chohan100% (1)

- CT2 2012 Poor Pump Design ConsiderationsDokumen2 halamanCT2 2012 Poor Pump Design ConsiderationsKroya HunBelum ada peringkat

- Trico Catalog May 09Dokumen120 halamanTrico Catalog May 09Wong DaBelum ada peringkat

- How To Read Pump CurveDokumen4 halamanHow To Read Pump CurvenghiemvhBelum ada peringkat

- Full Load Test ExpanderDokumen8 halamanFull Load Test Expanderdhanu_aquaBelum ada peringkat

- Skills Workshop: Centrifugal PumpDokumen3 halamanSkills Workshop: Centrifugal PumpchayanunBelum ada peringkat

- Impeller - KSBDokumen6 halamanImpeller - KSBEd0% (1)

- C Module-5 Reciprocating Air Compressors. Reciprocating Compressors - Construction - WorkingDokumen48 halamanC Module-5 Reciprocating Air Compressors. Reciprocating Compressors - Construction - WorkingJasraj Gill100% (1)

- Flow Profile For Reciprocating Pumps - Chemical Engineering ProcessingDokumen3 halamanFlow Profile For Reciprocating Pumps - Chemical Engineering ProcessingVILLANUEVA_DANIEL2064Belum ada peringkat

- DVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L IDokumen6 halamanDVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L Imiguel hernandezBelum ada peringkat

- How Liquid Ring Vacuum Pumps Work - EnggcyclopediaDokumen3 halamanHow Liquid Ring Vacuum Pumps Work - EnggcyclopediaJAGADEESHBelum ada peringkat

- Pumps and Seals PDFDokumen1.024 halamanPumps and Seals PDFBung TromixBelum ada peringkat

- Very Usefully CourseDokumen174 halamanVery Usefully CourseSudhakar Rao100% (1)

- Flow in Circular Pipes: ObjectiveDokumen35 halamanFlow in Circular Pipes: ObjectivemamunruetBelum ada peringkat

- Evaporator 1Dokumen41 halamanEvaporator 1praSHANT2331Belum ada peringkat

- Evaporation Is The Vaporization of A LiquidDokumen15 halamanEvaporation Is The Vaporization of A LiquidpraSHANT2331Belum ada peringkat

- CV SizingDokumen27 halamanCV SizingpraSHANT2331Belum ada peringkat

- ValvesDokumen18 halamanValvespraSHANT2331Belum ada peringkat

- ValvesDokumen18 halamanValvespraSHANT2331Belum ada peringkat

- PumpsDokumen26 halamanPumpspraSHANT2331Belum ada peringkat

- Distillation DesignDokumen30 halamanDistillation Designfdc20062340100% (2)

- Distillation ColumnDokumen37 halamanDistillation ColumnpraSHANT2331Belum ada peringkat

- Rotating EquipmentDokumen235 halamanRotating EquipmentpraSHANT2331100% (5)

- Chemical PotentialDokumen19 halamanChemical PotentialpraSHANT2331Belum ada peringkat

- How To Select A Pump-By Majid HamedyniaDokumen72 halamanHow To Select A Pump-By Majid Hamedyniamajid100% (2)

- 1.6a Line Sizing SlidesDokumen24 halaman1.6a Line Sizing SlidesPhani Raj M100% (1)

- Fluid Mechanics and Pressure DropDokumen48 halamanFluid Mechanics and Pressure DroppraSHANT2331Belum ada peringkat

- 1.6a Line Sizing SlidesDokumen24 halaman1.6a Line Sizing SlidesPhani Raj M100% (1)

- ValvesDokumen18 halamanValvespraSHANT2331Belum ada peringkat

- TIMAS-PR-PI-005 - Piping Pressure Test, Flushing, BLW & Reinstate ProcedureDokumen16 halamanTIMAS-PR-PI-005 - Piping Pressure Test, Flushing, BLW & Reinstate ProcedureMechanical Static WRKBelum ada peringkat

- Testing Blind Plate TableDokumen5 halamanTesting Blind Plate TableKyaw Kyaw Aung77% (13)

- Pertemuan 3Dokumen53 halamanPertemuan 3Arif Pradana WIbowoBelum ada peringkat

- XF Series Dripline Chart Sell - Sheet 051122Dokumen1 halamanXF Series Dripline Chart Sell - Sheet 051122YASSER SHAALANBelum ada peringkat

- Hydraulic Pumps: Quality With Value GuaranteedDokumen9 halamanHydraulic Pumps: Quality With Value GuaranteedAlaa said100% (2)

- Aerothermal Performance Measurements and AnalysisDokumen8 halamanAerothermal Performance Measurements and Analysisraul19rsBelum ada peringkat

- Advance Fluid Mechanics TurorialDokumen2 halamanAdvance Fluid Mechanics Turorialpinakramanuj11150% (2)

- Lab ManualDokumen11 halamanLab ManualSujith SurapaneniBelum ada peringkat

- Flexible Duct Friction Loss CalculatorDokumen1 halamanFlexible Duct Friction Loss CalculatorThinh TranBelum ada peringkat

- Vane Fluture Si AdaptoareDokumen32 halamanVane Fluture Si Adaptoarebotas georgianaBelum ada peringkat

- Torque Values For DEFENDER, Isoguard and Isomate Sealing Gaskets/Flange Isolation KitsDokumen2 halamanTorque Values For DEFENDER, Isoguard and Isomate Sealing Gaskets/Flange Isolation KitsPranpath NarupantawartBelum ada peringkat

- Energy Loss in PipesDokumen37 halamanEnergy Loss in Pipestimothyatambo383Belum ada peringkat

- Chapter 21. Hydraulics: by Brian BomanDokumen10 halamanChapter 21. Hydraulics: by Brian BomanLao ZhuBelum ada peringkat

- Enerpac PATG1102NDokumen72 halamanEnerpac PATG1102NAnonymous G6ceYCzwtBelum ada peringkat

- AE 301 - Aerodynamics I - Spring 2015 Problem Set 2: Assigned: Friday, January 23, 2015 Due: Friday, January 30, 2015Dokumen2 halamanAE 301 - Aerodynamics I - Spring 2015 Problem Set 2: Assigned: Friday, January 23, 2015 Due: Friday, January 30, 2015TheTannedFishBelum ada peringkat

- Cl605 Hydraulic SystemDokumen13 halamanCl605 Hydraulic SystemMirko NovakovicBelum ada peringkat

- LESSON 8 - Shell Momentum BalanceDokumen66 halamanLESSON 8 - Shell Momentum BalancePamela MendozaBelum ada peringkat

- Distorted ModelDokumen23 halamanDistorted ModelSwarna Rk100% (1)

- Course (PIPING SYSTEMS - MECHANICAL DESIGN AND SPECIFICATION - ME-41)Dokumen3 halamanCourse (PIPING SYSTEMS - MECHANICAL DESIGN AND SPECIFICATION - ME-41)Ahmed FitryMusaBelum ada peringkat

- DuPont Welding Quality Manual PDFDokumen54 halamanDuPont Welding Quality Manual PDFRodolfoMarínBelum ada peringkat

- Kitesurf Sail Design Comparison by CFD Analysis Ran in Solidworks 1. Design 1 1.1. Geometric CharacteristicsDokumen10 halamanKitesurf Sail Design Comparison by CFD Analysis Ran in Solidworks 1. Design 1 1.1. Geometric CharacteristicsSergioBelum ada peringkat

- Centrifugal Pumps: Cast Iron & Bronze ModelsDokumen8 halamanCentrifugal Pumps: Cast Iron & Bronze Modelsudrogono2Belum ada peringkat

- Pump Head CalculationDokumen14 halamanPump Head CalculationSolymanElsayedSolymanBelum ada peringkat

- Relief Valve - TypesDokumen2 halamanRelief Valve - Typesyushveer002Belum ada peringkat

- Non Newtonian FluidsDokumen2 halamanNon Newtonian FluidsChristian FernandezBelum ada peringkat

- Monoblock Directional Control Valve: Key Valve Features Technical DataDokumen8 halamanMonoblock Directional Control Valve: Key Valve Features Technical DataDark CenobiteBelum ada peringkat

- Chemical Engineering Graduate Transport - HW 3Dokumen3 halamanChemical Engineering Graduate Transport - HW 3Luthfir RahmanBelum ada peringkat

- Coull Hodson Design PDFDokumen12 halamanCoull Hodson Design PDFSimone CastagnoBelum ada peringkat

- Fluid 12Dokumen193 halamanFluid 12Charanpreet KaurBelum ada peringkat

- Features of Asme b31.3Dokumen11 halamanFeatures of Asme b31.3Ignacio OñateBelum ada peringkat