CHAPTER 3 - Water Supply

Diunggah oleh

Mazliah Zainal Abidin100%(2)100% menganggap dokumen ini bermanfaat (2 suara)

216 tayangan76 halamanThe document discusses water supply and treatment in Malaysia. It notes that Malaysia receives 324 billion m3 of rainfall per year, but only 20 billion m3 becomes groundwater. Meeting future water demand will be challenging due to uneven rainfall distribution, degradation of catchment areas, and pollution of rivers. In 1998, Klang Valley experienced its worst water crisis due to development not keeping pace with urbanization. Common water sources in Malaysia include rivers, lakes and reservoirs. Conventional treatment plants are typically used to treat surface water sources via processes like coagulation, flocculation, sedimentation and filtration.

Deskripsi Asli:

environmental engineering

Judul Asli

CHAPTER 3- Water Supply

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPT, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThe document discusses water supply and treatment in Malaysia. It notes that Malaysia receives 324 billion m3 of rainfall per year, but only 20 billion m3 becomes groundwater. Meeting future water demand will be challenging due to uneven rainfall distribution, degradation of catchment areas, and pollution of rivers. In 1998, Klang Valley experienced its worst water crisis due to development not keeping pace with urbanization. Common water sources in Malaysia include rivers, lakes and reservoirs. Conventional treatment plants are typically used to treat surface water sources via processes like coagulation, flocculation, sedimentation and filtration.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

100%(2)100% menganggap dokumen ini bermanfaat (2 suara)

216 tayangan76 halamanCHAPTER 3 - Water Supply

Diunggah oleh

Mazliah Zainal AbidinThe document discusses water supply and treatment in Malaysia. It notes that Malaysia receives 324 billion m3 of rainfall per year, but only 20 billion m3 becomes groundwater. Meeting future water demand will be challenging due to uneven rainfall distribution, degradation of catchment areas, and pollution of rivers. In 1998, Klang Valley experienced its worst water crisis due to development not keeping pace with urbanization. Common water sources in Malaysia include rivers, lakes and reservoirs. Conventional treatment plants are typically used to treat surface water sources via processes like coagulation, flocculation, sedimentation and filtration.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 76

WATER SUPPLY

Environmental Engineering Sem1 2012/2013 1

INTRODUCTION

Environmental Engineering Sem 1 2012/2013

2

Malaysia was reported to receive rainfall of 324billion m

3

/year in year 2000

1

. It

distributed to surface runoff and evapo-transpiration about 152 billion m

3

/year

respectively and only 20 billion m

3

/year becomes groundwater.

Malaysias water status are diverse, increase and competing needs. However the

future forecast ( done by SMHB) indicated that water supply demand cannot be met

in many locations due to

uneven rainfall distribution, temporally or spatialy

degradation in the raw water supply catchments, because of Un-control opening of

forested areas (logging, roads, urbanizations) resulting in massive sedimentation

flow into rivers

Pollution in rivers as it passes urban areas, reaches between raw water source

catchment/storages & downstream water supply intake

1 -Ir Salmah Zakaria (2008) , Water Resources and Global Warming: Focus, Water Supply , Meeting of Water Supply

Senior Officer, Equatorial Hotel, KL.

INTRODUCTION

Environmental Engineering Sem 1 2012/2013

3

Humans are defending on water supply for the daily

basis routine. . Therefore we should not keep

throwing everything into the river. Consequently, the

cost of water treatment will be higher and not

affordable any longer. Freshwater is finite and water

should be treated as a commodity.

We should learn from other on what they have been

doing to have a sustainable water supply.

A Singapore Success Story

On 27 February 1977, at the opening of the

Upper Pierce Reservoir, the prime Minister,

Lee KuanYew said It should be a way of life

to keep the waters clean .. In ten years let us

have fishing in the Singapore River and in the

Kallang River.In October 1977, The Ministry

of the Environment , submitted an Action

Plan to the Prime Minister

Singapore River and in Kallang Basin

How did they do it?

-5,000 hawkers were relocated into food

centres

-26,000 squatter families were resettled to

HDB flats

-Moved factories to JTC, then only

-Removed more than 200 tonnesof rubbish

-Upgrade the riverside walkway along the

river

-Upgrade parking lots along rivers

-Developed recreational areas along rivers

-Sand was brought in to form beaches for

recreation

INTRODUCTION

Environmental Engineering Sem 2 2011/2012 4

In Malaysia, the worst water crisis happen in year 1998 for Klang Valley

residents. The main reasons for the water crisis were due:

development of the resource and treatment facilities could not meet the rapid

pace of urbanisation and industrialisation;

a prolonged drought causing the reduction of flows in the rivers and the

subsequent decrease in the reservoir levels;

the low flows in the rivers were insufficient to dilute the pollutant loads

resulting frequent closures of water treatment plants and

High water losses due to leakages in the distribution systems and pilferages

WATER QUANTITY REQUIREMENT

Environmental Engineering Sem 2 2011/2012 5

Water supply is required for domestic and industrial, agriculture, environment and Bio-

Diversity, hydropower, transportation and recreation.

In Malaysia at year 2007

2

, about 14,278 MLD water treated from 462 numbers of water

treatment plants. The water demand is 12,330 MLD, most serves for urban area

compared to rural .The water being used by 27 Million people.

2 -Ir Noor Azahari Zainal (2008) , Operational Aspects of WaterDemand Management- For Domestic & Industrial Use, Meeting of

Water Supply Senior Officer, Equatorial Hotel, KL.

WATER QUANTITY REQUIREMENT

Environmental Engineering Sem 2 2011/2012 6

WATER QUANTITY REQUIREMENT

Environmental Engineering Sem 2 2011/2012 7

2000 2010 2020 2030 2040 2050

Domestic &

Industrial

(mil m

3

/yr)

3483 5579 7423 8937 10268 11544

Irrigation

(mil m

3

/yr)

7350 6517 6517 6132 6132 6132

Total

(mil m

3

/yr)

10833 12086 13940 15069 16400 17676

Most of treated water was used for domestic and industrial besides agricultural. At year

2010 (Table 3. 1), the water consumption is slightly higher for irrigation, However by the

year 2020 to 2050, more treated water will be used for domestic and industrial activity.

Table 3.1: Water Demand for Malaysia from 2000 to 2050

WATER SOURCES

Environmental Engineering Sem 2 2011/2012 8

Groundwater Surface water

constant

composition

high mineral content

low turbidity

low color

low or no D.O.

CO

2

, H

2

S may be

present

high hardness

high Fe, Mn

variable composition

low mineral content

high turbidity

colored

D.O. present

low hardness

taste and odor

Clay, silt, NOM

Seawater

Groundwater

shallow wells

deep wells

Surface water

rivers

lakes

Reservoirs

Groundwater Vs Surface water

WATER TREATMENT

9

In practice, all public water supplies undergo some form of treatment, with the degree

of the treatment being dependent on the quality of the raw water supply.

The quality of treated water is now almost standardized in the developed world, with

treatment facilities having to satisfy many water quality parameters on a frequent

monitoring basis.

The aim of water treatment is to produce water;

That is palatable

esthetically pleasing

presence of chemicals does not pose a threat to human health

includes chloride, color, corrosivity, iron, manganese, taste and odor

That is potable

Safe to drink protective of human health

Not necessarily esthetically pleasing

That meets regulatory criteria/standards

Without interruption

At reasonable cost.

Raw Water

(average)

Treated

Water

Parameters Unit

pH 5.8 -6.9 6.5 - 9

Iron < 1.0 < 0.3

Turbidity 300 < 5

DO 4 - 7 8 -10

Manganese < 0.2 < 0.1

Suspended Solid 100 -

Color < 15

Aluminium < 0.1 < 0.2

Fluoride < 1.5 0.5 0.7

pH

mg/l

NTU

ppm

mg/l

mg/l

TCU

mg/l

ppm

Res. Chlorine - 1.5 2.5 ppm

300

Ammonia - < 1.5 ppm

Environmental Engineering Sem 2 2011/2012 10

TREATED WATER QUALITY STANDARD*

* SAJ Holdings Sdn Bhd

TYPES OF WATER TREATMENT PLANT

Environmental Engineering Sem 2 2011/2012 11

Objective: to remove turbidity and color from surface water

Plant : Filtration Plant /Coagulation Plant/Conventional Plant

TYPES OF WATER TREATMENT PLANT

Environmental Engineering Sem 2 2011/2012 12

Objective: to remove the hardness of the mineral

Plant : Softening Plant

TYPES OF WATER TREATMENT PLANT

Environmental Engineering Sem 2 2011/2012 13

Objective: to remove sulfide

Plant : Groundwater Plant

Well

Aeration

Air

CO

2

H

2

S

Storage P

Disinfectant

Environmental Engineering Sem 2 2011/2012 14

THE GENERAL PURPOSE OF WATER TREATMENT

PROCESS

Pre chlorination - used for disinfection of the raw water only if it does not result in

formation of thrihalomethane.

Pre sedimentation - To reduce silt and settleable organic matter prior to chemical

treatment

Coagulation - alum/ other chemicals are added to water to form tiny sticky

particle called floc.

Flocculation - is the process of the aggregation of the destabilized particles and

precipitation products.

Sedimentation - To remove the particles and precipitate by gravitational settling.

Filtration - To remove even smaller particles.

Flouridation - Fluoride is added into water to prevent incident in dental caries.

Disinfection - Chrorine/disinfectant is added to kill any bacteria or

microorganism that may be in the water.

Post Chlorination - To form and remain the residual chlorine in the distribution

system.

Activated Carbon - To remove odor and taste producing compound.

Environmental Engineering Sem 2 2011/2012 15

WATER TREATMENT PROCESSES

Water treatment processes are depending on the water sources. There are 4

classes of water treatment as shown in Table 3.2. The treatment processes may

be difference from one to another as shown in Table 3.3. The typical water

treatment process is shown in Figure 3.2.

Table 3.2 Classes of Water Treatment

Class Description Source

A

B

C

D

No treatment

Disinfection only

Standard Water Treatment

Special Water Treatment

Some borehole water

Occasional upland water

Some borehole water

Occasional upland water

Lowland rivers and reservoirs

Some rural supplies (Fe and Mn), Colour removal

Trace element removal, Industrial Water

Electronics industry requirement, Algae removal

Organic removal

Environmental Engineering Sem 2 2011/2012 16

WATER TREATMENT PROCESSES

Treatment

Categorization

Groundwater

Supply Class B

Standard Water Treatment

Class C

Special Water Treatment

Class D

Intake Intake Intake

Pre treatment Aeration Coarse screening, Fine

Screening,Pumping ,

Storage,Equalization,

Neutralization,Aeration

Chemical pre-treatment

Screening, Pumping,

Storage, Equalization

Neutralization, Aeration

Softening, Algae removal

Primary

Treatment

Coagulation and mixing

Flocculation, Sedimentation

Coagulation and mixing,

Flocculation,Sedimentation

Secondary

treatment

Filtration Filtration

Disinfection Disinfection Disinfection Disinfection

Advance

Treatment

Adsorption,Activated

carbon,Membrane Process

Halogenated compound

removal, Fe and Mn removal

Fluoridation Fluoridation Fluoridation Fluoridation

Distribution

network

Yes Yes Yes

Table 3.3 Flow Chart Outline of Water Treatment Processes

Environmental Engineering Sem 2 2011/2012 17

What are the common raw

water sources used in

Malaysia?

As an engineer, you are

asked to select the

appropriate water

treatment plant.

What will be your

selection? Why?

List the primary treatment.

What are the common raw water sources

used in Malaysia?

Answer : River water and lake

As an engineer, you are asked to select the

appropriate water treatment plant.

What will be your selection?

Answer : Coagulation plant/ Conventional plant ( Refer Slide 19,

the common practice in Malaysia)

Why?

Answer : We use the river water as an intake

List the primary treatment.

Answer: Coagulation and mixing Flocculation, Sedimentation

Environmental Engineering Sem 2 2011/2012 18

Clean Water Tank

Disinfection

& Re-adjustment

Hydrated Lime

Chlorine

Flouride

Environmental Engineering Sem 2 2011/2012 19

Filtration

Flocculation

Tank

Consumer

Pump station

Balancing Tank

Aerator

Distribution Tank Distribution Tank

Consumer

Chemical

Pre-Treatment

Chemical Dosage

Hydrated Lime-Softening

Alum- Coagulation

Raw water source

Intake

Sedimentation

Tank

- - - Our concern

Environmental Engineering Sem 2 2011/2012 20

Raw water intakes withdraw water from a

river, lake, or reservoir ( surface water source)

over a predetermined range of pool levels.

Intake site selections depend on :

Water quality

Water depth

Stream or current velocities

Access

Power availability

Proximity to water treatment plant

Environmental impact

Hazard to navigate

Raw water intake structures control

withdrawal of raw water from a surface water

source. Intake structure contains gates,

screens, control valves, pumps, chemical

feeders, flow meters, offices and machine

shop.

Intake design consideration;

Intake velocity

High velocities head loss,

entrain suspended matter, trap

fish, and other aquatic animals.

Velocity below 8 cm/s allows

aquatic animal to escape, and

minimize the suspended matter

Intake-port location- Water

quality in each stratum may vary.

To achieve, multiple intake ports

set at various levels are generally

provided

Top intake less than 2 m below

normal level.

Bottom intake least 1 m above

the bottom

Gates - Usually sluice gates .

Large cast iron gates that slide

vertically on a guide track.

INTAKE

Environmental Engineering Sem 2 2011/2012 21

Environmental Engineering Sem 2 2011/2012 22

Types of intake structures; floating intake ( Figure 3.3), submerged intake,

pier intake, tower intake ( Figure 3.4), exposed or tower intake and shore

intake

Figure 3.4: Tower intake

Figure 3.3 Floating intake

INTAKE

Environmental Engineering Sem 2 2011/2012 23

AERATION

To create turbulence to provide for the maximum contact between water and air

to achieve desired dissolved oxygen content at ambient temperature and

pressure .

It can be a simple mechanical process of spraying water into the air and allowing

it to fall over a series of cascades (waterfalls) ( Figure 3.5), multiple platform

aerator- tray ( Figure 3.6) venturi aerator, draft-tube aerator while absorbing or

desorbing oxygen in its journey.

Figure 3.5 Cascade Figure 3.6 Tray

Environmental Engineering Sem 2 2011/2012

24

To supply of O

2

from the atmosphere to water to effect beneficial changes

in the water quality.

To release excess H

2

S gas which may cause undesirable tastes and odor.

To release excess CO

2

which may have corrosive tendencies on concrete

materials.

To increase the O

2

content of water which may have negative taste, color

and stain properties due to the presence of Fe and Mn in solution ( Mostly

for groundwater) . The addition of oxygen assists the precipitation of Fe and

Mn as following:

AERATION

4Fe

2+

+ O

2

+ 10 H

2

0 4 Fe(OH)

3

(s)

+ 8H

+

2Mn

2+

+ O

2

+ 2 H

2

0 2 MnO

2

(s)

+ 4H

+

Environmental Engineering Sem 2 2011/2012 25

AERATION

Example

Parit Raja Water Treatment Plant has a plant capacity of 60 MLD. Calculate

the required water surface area of a cascade used for aeration.

Solution:

To calculate exposed water surface area, we used design criteria of 10 m

2

of

exposed water surface for every 50L/s of design flow.

Design capacity = 10 m

2

of exposed water surface

50 L/s of designed flow

Water surface area = 10 m

2

x 60 MLD

50 L/s

= 10 m

2

x 60 x 10

6

L/D

50 L x 60 s x 60 min x 24 hr

s min hr day

= 10 m

2

_x 60 x 10

6

L/D

4320000 L/D

= 138.8 ~ 140 m

2

Environmental Engineering Sem 2 2011/2012 26

SOFTENING

The removal of ions that cause hardness is called SOFTENING. This process is

common for groundwater source.

Hardness in natural waters comes from the dissolution of minerals from geologic

formation that contain calcium and magnesium . Two common minerals are calcite and

dolomite. The natural process by which water become hard is shown below.

Environmental Engineering Sem 2 2011/2012 27

SOFTENING

Hardness is a term often used to characterize the ability of a water to:

ocause soap scum

Ca

2+

+ (Soap)

-

Ca(Soap)

2

(s)

oincrease the amount of soap needed

ocause scaling on pipes

ocause valves to stick due to the formation of calcium carbonate crystals

oleave stains on plumbing fixtures

Description Hardness range (mg/L as CaCO

3

)

Extremely soft 0 - 50

Very soft 50 100

Moderately

hard

100 150

Hard 150 - 300

Very hard > 300

Total Hardness (TH)

Technically - the sum of

all polyvalent cations

Practically - the amount

of calcium and

magnesium ions (the

predominant minerals in

natural waters)

(TH = Ca

2+

+ Mg

2+

)

It is divided into

carbonate (CH) and

noncarbonate hardness

(NCH), (TH = CH + NCH)

Environmental Engineering Sem 2 2011/2012 28

SOFTENING

Carbonate Hardness (CH)

associated with HCO

3

-

, CO

3

2-

CH = TH or Total alkalinity, whichever is less

Often called "temporary hardness" because heating the water will remove

it. When the water is heated, the insoluble carbonates will precipitate and

tend to form bottom deposits in water heaters.

Ca

2+

+ 2HCO

3

-

CaCO

3(s)

+ CO

2(g)

+ H

2

O

Non-Carbonate Hardness

NCH = TH - CH

If Alkalinity > Total hardness, then NCH = 0

Called permanent hardness because it is not removed when the water is

heated. It is much more expensive to remove non-carbonate hardness than

carbonate hardness.

Ca

2+

, Mg

2+

associated with other ions, Cl

-

, NO

3

-

, SO

4

2-

Environmental Engineering Sem 2 2011/2012 29

SOFTENING

Ion Conc.

mg/L

M.W.

mg/mmol

(n(

Eq. Wt.

mg/meq

Conc.

meq/L

(ion conc. / EW)

Conc.

mg/L as

CaCO

3

Ca

2+

40.0 40.1 2 20.05 1.995 99.8*

Mg

2+

10.0 24.3 2 12.15 0.823 41.2

Na

+

11.8 23.0 1 23.0 0.510 25.7

K

+

7.0 39.1 1 39.1 0.179 8.95

HCO

3

-

110.0 61.0 1 61.0 1.800 90.2

SO

4

2-

67.2 96.1 2 48.05 1.400 69.9

Cl

-

11.0 35.5 1 35.5 0.031 15.5

Example

A sample of water having a pH of 7.2 has the following concentrations of ions

Ca

2+

40 mg/L

Mg

2+

10 mg/L

Na

+

11.8 mg/L

K

+

7.0 mg/L

HCO

3

-

110 mg/L

SO

4

2-

67.2 mg/L

Cl

-

11 mg/L

Calculate the TH, CH, NCH, Alkalinity, and construct a bar chart of the constituents

Solution

*Sample Calculation: Concentration of Ca

2+

in mg/L as CaCO

3

= (Concentration in meq/L) *

(Equivalent Weight of CaCO

3

) = (1.995 meq/L) X (50 mg/meq) = 99.8 mg/L as CaCO

3

Environmental Engineering Sem 2 2011/2012 30

SOFTENING

Check Solution

E(Cation)s = E(Anion)s

175.6 = 175.6

Note: to within 10% mg/L as CaCO

3

Total Hardness

= E of multivalent cations

= (Ca

2+

) + (Mg

2+

)

= 99.8 + 41.2

= 141 mg/L as CaCO

3

Alkalinity = (HCO

3

2-

) + (CO

3

2-

) + (OH

-

) - (H

+

)

Since pH = 7.2 (neutral pH, OH

-

& H

+

are negligible)

Alkalinity ~ (HCO

3

2-

) = (1.80 x 10

-3

) eq/L

Alkalinity = (1.80 x

10

-3

eq/L)(50 g/eq)(1000 mg/g)

= 90.1 mg/L as CaCO

3

Carbonate Hardness (the portion of the hardness associated with

carbonate or bicarbonate)

Alkalinity = 90.1 mg/L as CaCO

3

TH = 141 mg/L as CaCO

3

CH = 90.1 mg/L as CaCO

3

(Note: if TH < Alk then CH = TH; and NCH = 0 )

Non-carbonate Hardness

NCH = TH - CH = 141 - 90.1 =50.9 mg/L as CaCO

3

Environmental Engineering Sem 2 2011/2012 31

SOFTENING

Softening can be accomplished by the lime soda process, ion exchange,

nanofiltration and reverse osmosis. Lime soda softening is discussed in this chapter.

Lime-Soda Softening

-it is possible to calculate the chemical doses necessary to remove hardness

-hardness precipitation is based on the following two solubility reaction:

Ca

2+

+ HCO

3

2-

CaCO3 (s)

Objective: to percipitate calcium as

CaCO

3

.In order to percipitate,

the water must pH 10.3

Mg

2+

+ 2OH

-

MgOH2 (s)

In order to percipitate,

The water must pH 11

To supply hydroxyl ions, the

economic way is to buy LIME ( CaO)

, then mix with water to produce

Ca(OH)

2

(hydrated lime)

Environmental Engineering Sem 2 2011/2012 32

SOFTENING

Softening Reactions

The softening reactions are regulated by controlling the pH.

FIRST any free acids are neutralized

THEN- pH is raised to precipitate the CaCO

3

; if necessary

- pH is raised further to remove Mg(OH)

2

FINALLY if necessary, CO

3

2-

is added to precipitate the noncarbonate hardness

1

2

3

4

5

6

Six important softening reactions

are shown.

In each case, the chemical that has

been added to the water is printed

in bold type.

Designation (s) is for solid, hence

indicates that the substance has

been removed from the water.

In reality they occur

simultaneously.

Environmental Engineering Sem 2 2011/2012 33

SOFTENING

Magnesium is MORE EXPENSIVE to remove than calcium, then we leave as much Mg

2+

as

possible in the water.

The removal of noncarbonate hardness is MORE EXPENSIVE , because we must add the

CO

3

2-

( in term of SODA) therefore we leave as much noncarbonate hardness as possible

in the water.

Traditionally, the final total hardness is set of 75 to 120 mg/L as CaCO

3

, however due to

the economic constraints, many utilities will operate at total hardness of 140 -150 mg/L

as CaCO

3.

Concurrent removal of other species

Natural Organic Matter (NOM)

Turbidity

Other metals

Limitation

Because of the solubility of CaCO3 (s) and

MgOH2 (s), ideal mixing is prohibited some

hardness ions remain in solution

insufficient time for reactions

Minimum Ca hardness ~ 30 mg/L as CaCO

3

Minimum Mg hardness ~ 10 mg/L as CaCO

3

(1) NEUTRALIZATION OF CARBONIC ACID(H

2

CO

3

)

- Add lime

- To neutralize any free acids ( acid carbonic) that may be present in the water

- NO hardness is removed in this step

CO

2

+ Ca(OH)

2

CaCO

3(s)

+ H

2

O

Environmental Engineering Sem 2 2011/2012 34

SOFTENING

(2) PRECIPITATION OF CARBONATE HARDNESS DUE TO CALCIUM

-add lime

-pH must be raised up to 10.3 to percipitate the calcium carbonate

-To achieve this pH , convert all of the bicarbonate to carbonate

-The carbonate then serves as common ion for percipitation reaction

Ca

2+

+ 2HCO

3

-

+ Ca(OH)

2

2CaCO

3(s)

+ 2H

2

O

With the aid of chemical

equation, show the

formation of carbonic acid

Environmental Engineering Sem 2 2011/2012 35

Environmental Engineering Sem 2 2011/2012 36

SOFTENING

(3) Precipitation of carbonate hardness due to magnesium

Must add more lime to achieve a pH about 11.

The reaction may be considered to occur in two

stages.

First stage occurs when we convert all of the

bicarbonate to carbonate

Mg

2+

+ 2HCO

3

-

+ Ca(OH)

2

MgCO

3

+ CaCO

3(s)

+ 2H

2

O

It is SOLUBLE.so

the hardness of

water did not

CHANGE

Second stage- addition of more lime

Mg

2+

+ CO

3

2-

+ Ca(OH)

2

MgOH

2(s)

+ CaCO

3(s)

4) Removal Of Noncarbonate Hardness Due To Calcium

NO further increase in pH is required.

Provide additional carbonate in the form of soda ash

Ca

2+

+ Na

2

CO

3

CaCO

3(s)

+ 2Na

+

Environmental Engineering Sem 2 2011/2012 37

SOFTENING

5) Removal Of Noncarbonate Hardness Due To Magnesium

-First add lime

Mg

2+

+ Ca(OH)

2

MgOH

2(s)

+ Ca

2+

not much changes

in hardness . We

still HAVE Ca

2+

-to eliminate Ca

2+

, add soda

Ca

2+

+ Na

2

CO

3

CaCO

3(s)

+ 2Na

+

Environmental Engineering Sem 2 2011/2012 38

SOFTENING

Flow

diagram for

solving

softening

problem

( all

addition as

mg/L as

CaCO

3

)

Environmental Engineering Sem 2 2011/2012 39

SOFTENING

Example

From the water analysis presented below, determine the amount of lime and soda (mg/L

as CaCO

3

)

to soften the water to 120 mg/L as CaCO

3

.

Water composition (mg/L as CaCO

3

)

Ca

2+

= 149.2

CO

2

= 29.3

HCO

3

-

= 185.0

Mg

2+

= 65.8

SO

4

2-

=29.8

Na

+

= 17.4

Cl

-

= 17.6

Solution

1) Plot the bar chart as shown below

149.2 + 65.8

185 + 29.8

2) From the bar chart , we note

following

TH = 215 mg/L as CaCO

3

CH = 185 mg/L as CaCO

3

HOW??

if TH > alk CH = Alk

NCH = 30 mg/L as CaCO

3

HOW??

NCH = TH -CH

Environmental Engineering Sem 2 2011/2012 40

SOFTENING

3) Follow the logic of Figure in Slide 38, calculate the lime dose as follows

Step Dose (mg/L as CaCO

3

)

Lime = CO

2

29.3

Lime = HCO

3

-

185.0

Lime = Mg

2+

- 40 = 65.8 - 40

25.8

Lime = excess

25.8

TOTAL = 265.9

4) Calculate NCH

left

and NCH

removed

NCH

left

= final desired hardness 40 NCH

removed

= NCH NCH

left

Therefore,

NCH

left

= 120 40 = 80 mg/L

NCH

removed

= 30 80 = -50 ( negative is indicating there is no need to

remove NCH, no SODA required )

WHY COLLOIDS ARE

SUSPENDED IN SOLUTION

HOW TO REMOVE COLLOIDS

????

Environmental Engineering Sem 2 2011/2012 41

Environmental Engineering Sem 2 2011/2012 42

COAGULATION and FLOCCULATION

Surface water contains organic and inorganic particles.

Particle such as clay, and colloids remain in suspension without aggregating for

long periods of time. Consequently the particle cannot be removed by

sedimentation in a reasonable amount of time.

Majority of ions in surface water consist of negatively charged particle/colloids

which are stable in nature( stable = existing in ionized form) .

They repel other colloidal particles

before they collide with one

another. The colloids are

continually involved in Brownian

movement.

Environmental Engineering Sem 2 2011/2012 43

COAGULATION and FLOCCULATION

How to destabilize the particles???

Neutralize the charge by addition of an ion opposite to it ( Destabilization)

Destabilization (Coagulation)

( refer slide 29)

Particles

Flocculation

(Refer slide 30)

Al(OH)

3 (s)

@ Fe(OH)

3 (s)

Settle down at the bottom of

the flocculation tank

Al

3+

/

Fe

3+

Al

3+

/

Fe

3+

Environmental Engineering Sem 2 2011/2012 44

COAGULATION and FLOCCULATION

Coagulation process utilizes what is known as a chemical coagulant is mixed

thoroughly with the water and various species of the positively charged particles

adsorb to the negatively charged colloids such as colour, clay, turbidity and other

particles through the processes of charge neutralisation to produce microfloc.

Once the charge is neutralized, the small suspended particles are capable of sticking

together. The slightly larger particles, formed through this process and called

microflocs, are not visible to the naked eye.

The water surrounding the newly formed microflocs should be clear. If it is not, all the

particles' charges have not been neutralized, and coagulation has not been carried to

completion. More coagulant may need to be added.

Microfloc itself is not yet settleable , then flocculation process takes place.

Environmental Engineering Sem 2 2011/2012 45

COAGULATION and FLOCCULATION

Flocculation is the process in which the destabilised particles are

bound together by hydrogen bonding of Van der Waals forces to form larger

particle flocs.

High molecular weight

polymers, called coagulant

aids, may be added during

this step to help bridge,

bind, and strengthen the

floc, add weight, and

increase settling rate.

Once the floc has reached

it optimum size and

strength, the water is ready

for the sedimentation

process.

Environmental Engineering Sem 2 2011/2012 46

COAGULATION and FLOCCULATION

COAGULANT:

is the substance (chemical) that is added to the water to destabilize particles

and accomplish coagulation

PROPERTIES OF COAGULANT

o Trivalent cations

o Nontoxic: obvious for the production of safe water

o inexpensive

o Insoluble in the neutral pH. The coagulant that is added must percipitate out

of solution so that high concentration of the ion are not left in the water.

Such precipitation greatly influenced the colloidal removal process

Types of coagulant commonly used

Environmental Engineering Sem 2 2011/2012 47

Coagulant type examples

Inorganic metallic

coagulant

Aluminium sulfate (Al

2

(SO

4

)

3

14H

2

O, sodium

aluminate, aluminium chloride, ferric sulfate and

ferric chloride

Prehydrolyzed metal

salts

Made from alum and iron salts and hydroxide under

controlled condition; polyaluminium chloride (PAC)

Organic polymers Cationic polymers, anionic polymers, and nonionic

polymers

Natural plant-based

materials

Opuntia spp. And Moringa Oleifera (used in many

parts of the world esp. developing country.

COAGULATION and FLOCCULATION

Environmental Engineering Sem 2 2011/2012 48

COAGULATION and FLOCCULATION

How does alum works?

In sufficient alkalinity in the water

1Al

2

(SO

4

)

3

14H

2

O + 6HCO

3

-

2Al(OH)

3

3H

2

O(s) + 6CO

2

+8H

2

O + 3SO

4

2-

1 mole of alum added uses 6 moles of alkalinity and produces 6 moles of CO2

Alum sludge , settle in the

flocculation tank

The above reaction shifts the

carbonate equilibrium and

decreases the pH

However, as long as sufficient

alkalinity is present and CO

2

(g) is

allowed to evolve, the pH is not

drastically reduced and is

generally not an operational

problem

HCO

3

-

+ H

+

= H

2

CO

3

(Acid Carbonic)

Environmental Engineering Sem 2 2011/2012 49

COAGULATION and FLOCCULATION

Example

Calculate the amount of alum sludge produced and alkalinity (HCO

3

-

) consumed when 1 mg/L alum was used.

Solution

Chemical reaction

Al

2

(SO

4

)

3

14H

2

O + 6HCO

3

-

2Al(OH)

3

(s) + 6CO

2

+ 8 H

2

O + 3SO

4

2-

+ 14H

2

O

Molecular weight( MW)

MW

alum

= 594 g/mole

MW

alkalinity

= 61 g/mole

MW

alum sludge

= 78 g/mole

Solid removed when 1 mg/L alum was used,

1 mg/L = 1.684 x 10

-6

moles/L

( 594 g/mole)(1000 mg/g)

Known that 1 mole/L alum yield 2 mole/L of alum sludge, therefore

Solid removed = 2 (1.684 x 10

-6

moles/L) ( 78 g/mole)

= 2.63 x 10

-4

g/L

= 0.26 mg/L

Alkalinity consumed when 1 mg/L alum was used,

Known that 1 mole/L alum yield 6 mole/L of alkalinity, therefore

Alkalinity removed = 6 (1.684 x 10

-6

moles/L) ( 61 g/mole)

= 61.6 mg/L HCO

3

-

Expressed in CaCO

3

= 61.6 mg/L HCO

3

-

x EW CaCO

3

EW HCO

3

-

= 61.6 mg/L HCO

3

-

x 50 g/eq

61 g/eq

= 50 .5 mg/L HCO

3

-

as CaCO

3

Environmental Engineering Sem 2 2011/2012 50

COAGULATION and FLOCCULATION

Example

A 50 mg/L alum dose is used to coagulate a turbid surface water. Calculate the amount of the

floc ( alum sludge) produces ( kg/d)

if the flow is 0.04 m

3

/s.

Solution

= 156 ( 50 g/m

3

)(0.04 m

3

/s) (24 x 3600 s/d) ( 1 kg/1000g)

594

= 45.4 kg/d

From chemical equation: Al

2

(SO

4

)

3

14H

2

O + 6HCO

3

-

2Al(OH)

3

(s) +

6CO

2

+ 8 H

2

O + 3SO

4

2-

+ 14H

2

O

Why trivalent cations

considered as good

coagulant?

Environmental Engineering Sem 2 2011/2012 51

Environmental Engineering Sem 2 2011/2012 52

Environmental Engineering Sem 2 2011/2012 53

COAGULATION and FLOCCULATION

Therefore, coagulation and flocculation designed to remove

Microorganisms and colloids that caused turbidity

Toxic compounds that are sorbed to particles

NOM (precursor of DBPs)

JAR test (Figure 3.6) is a laboratory works to illustrate the coagulation and

flocculation concepts associated to nature water. From this experiment the

optimal pH, coagulant dose ,and coagulant aid could be determined.

Environmental Engineering Sem 2 2011/2012 54

COAGULATION and FLOCCULATION

Example

A typical test is conducted by first dosing each jar with the same alum dose and varying the pH in each

jar. The result s are shown in below. Find the optimal pH, coagulant dose, and the theoretical amount of

alkalinity that would be consumed at the optimal dose.

Environmental Engineering Sem 2 2011/2012 55

COAGULATION and FLOCCULATION

Solution

1) Conduct the second jar test with pH 6.0 for six beakers ( Why 6? Refer to the jar which has the

lower turbidity in jar test 1). The results are shown below

2) Construct the graph

turbidity remaining vs alum

Dose

3) From the graph, the

optimal alum dosage was

estimated to be 12.5 mg/L

Environmental Engineering Sem 2 2011/2012 56

COAGULATION and FLOCCULATION

4) theoretical amount of alkalinity that would be consumed at the optimal dose.

TRY YOURSELF !!!!

REFER to SLIDE 50-51

Answer: 6.31 mg/L HCO

3

-

as CaCO

3

Environmental Engineering Sem 2 2011/2012 57

COAGULATION and FLOCCULATION

Effectiveness of

Coagulation

The crux of efficient

coagulation is the efficiency

of MIXING the coagulant

with the raw water.

Coagulation happens in two

mechanisms;

Adsorption/destabilization

of the soluble hydrolysis

species on the colloid and

destabilization

Sweep coagulation where

the colloid is trapped in the

hydroxide precipitate

Environmental Engineering Sem 2 2011/2012 58

COAGULATION and FLOCCULATION

Mixing equipment is need in coagulation. Why?

To dispersion of the coagulant into the raw water.

-Dispersion of the coagulant into water is called flash mixing or rapid mixing.

-Rapid mixing aims to produce the high G.

Common alternatives for mixing when the mechanism of coagulation is

adsorption/destabilization are;

Diffusion mixing by pressured water jets

In line mechanical mixing

In line static mixing

Common alternatives for mixing when the mechanism of coagulation is sweep

coagulation are;

Mechanical mixing in stirred tanks

Diffusion by pipe grid

Hydraulic mixing

Environmental Engineering Sem 2 2011/2012 59

COAGULATION and FLOCCULATION

Efficiency of MIXING is depending on the 1) velocity gradient and 2) mixing time

Velocity gradient, G

G , can be thought as the amount of shear taking place;

For coagulation, G must be higher enough. When chemical be added, the

different G should e take into the consideration.

Adsorption/destabilization: 3000 s

-1

< G < 5000 s

-1

, t = 0.5 s

Sweep coagulation : 600 s

-1

< G < 1000 s

-1

, 1 s < t < 10 s

Different chemicals require different velocity gradients

Power of mixture imparted to water could be calculated;

Power = G

2

Vu

where,

G = velocity gradient, s

-1

V = volume in m

3

u = dynamic viscosity of water, Pa.s

Environmental Engineering Sem 2 2011/2012 60

COAGULATION and FLOCCULATION

Mixing Time

The time that a fluid remains in the reactor and affects the degree to

which the reaction goes to completion.

In the ideal reactor,

t = V/Q

where ,

t = time ( in second)

V = volume ( m

3

)

Q = flowrate ( m

3

/s)

Adsorption/destabilization: t = 0.5 s

Sweep coagulation : 1 s < t < 10 s

note : real reactor do not behave as ideal reactor because of density

difference due to temperature or other causes.

Environmental Engineering Sem 2 2011/2012 61

COAGULATION and FLOCCULATION

Example

A rapid mixer is used for the dispersion of the coagulant to achieve the

adsorption/destabilization reaction. If the water ( temperature 17

0

C) flows at

300 MLD, determine the volume of coagulation tank. Calculate the power.

Given ; velocity gradient, G = 2000 s

-1

Solution

For the adsorption/destabilization reaction, t should be fixed as 0.5 s.

Volume = Q t

= ( 300 x 10

6

L) ( 0.5 s x d x hr x min )

d 24 hr 60 min 60 s

= 1740 L x m

3

1000L

= 1.74 m

3

Refer to water properties, dynamic viscosity of water @17

0

C =1.081 x 10

-3

Pa.s

Power = G

2

Vu

= (2000)

2

(1.74) (1.081 x 10

-3

)

= 7524 Watt

Note: recalculate the power by assuming the temperature of water is 25

0

C. Give

comment.

Environmental Engineering Sem 2 2011/2012 62

COAGULATION and FLOCCULATION

Effectiveness of Flocculation

The crux of efficient flocculation is the efficiency of MIXING to bring the particles into

contact with one another so that they will collide, stick together and grow to a size

that will readily settle. The mixing to to flocculate the coagulated water.

For flocculation, high enough to cause particles contact and keep the floc from

settling but low enough to prevent the floc from tearing apart.

Mixing Time

For conventional treatment where settling follows flocculation, the flocculation

times ranges from 20 -40 minutes.

Efficiency of MIXING is depending on the 1) velocity gradient and 2)mixing time.

Velocity gradient, G

Environmental Engineering Sem 2 2011/2012 63

COAGULATION and FLOCCULATION

Flocculation is normally accomplished with

1) paddle flocculator or 2) baffled chamber

2) baffled chamber

Coagulation Flocculation Sedimentation

Environmental Engineering Sem 2 2011/2012 64

COAGULATION and FLOCCULATION

The Recommended Standards for Water Works Great Lakes Upper Missisippi River

Board of State Sanitary Engineers ( GLUMRB) recommended the criteria for

flocculation tank.

1. Inlet and outlet design shall prevent short circuiting and destruction of floc

2. Minimum flow-through velocity shall not be less than 2.5 to 7.5 mm/s with the

detention time for floc formation of at least 30 min.

3. Agitators shall be drivenby variable speed drives with the peripheral speed of

paddles ranging from 0.15 to 0.91 m/s

4. Flocculation and sedimentation basin shall be asa close together as possible

1) In flocculation tank, flow-through

velocity is normally to 2.5 - 75

mm/s. Explain what will be happen

if the velocity is less than 2.5 mm/s

and more than 7.5 mm/s.

1) In designing a flocculation tank,

which one of the following

parameters take more priority:

horizontal /flow through veloccity

or detention time?

2) Flocculation and settling tanks

should be as close as possible .

Why?

Environmental Engineering Sem 2 2011/2012 65

Environmental Engineering Sem 2 2011/2012 66

SEDIMENTATION

oSedimentation basin =

clarifier = settling tank

oWater flows into the

settling basins, where the

flow is almost devoid of

turbulence.

oThe water resides here for

time periods ranging from 2

to 8 hours and flocculated

particles settle out as

sludge

oThe sludge is mechanically

removed periodically

oSedimentation basin are

usually rectangular or

circular with either a radial

or upward water flow

pattern.

The key parameters and typical values in the design

of settling tank are:

- surface over flow rate 20- 35 m

3

/day/m

2

- detention times 2-8 h

- weir overflow rate 150 300 m

3

/day/m

Either

rectangular or

circular ,

normally 1

unit

sedimentation

system

comprises of 2

tanks

Environmental Engineering Sem 2 2011/2012 67

SEDIMENTATION

oThe design can be divided into

four zones: inlet, settling, outlet

and sludge storage

Inlet zone - to evenly distribute

the flow and suspended

particles across the section of

the settling zone*

Sludge storage zone- depends

upon the method of cleaning,

the frequency of cleaning and

the quantity of sludge

estimated to be produced.

Outlet zone- to remove the

settled water from the basin

with out carrying away any of

the floc particles

Zones of sedimentation: (a) horizontal flow

clarifier , (b) upflow clarifier

*

*

Environmental Engineering Sem 2 2011/2012 68

SEDIMENTATION

Three classes of sedimentation

Types Description Example

Water treatment Wastewater treatment

I Settling as discrete

particles at a

constant

settling velocity

No flocculation

during

sedimentation

1. Pre-sedimentation

2. in filter bed after

backwashing

1. grit chamber

II Particles that

aggregated or

flocculate during

sedimentation

Sedimentation after

alum or iron

coagulation

1. Primary

sedimentation

2. In settling tanks

after trickling

filtration

3. In upper portions of

secondary clarifiers

after activated

sludge treatment

Environmental Engineering Sem 2 2011/2012 69

SEDIMENTATION

Ty

pes

Description Example

Water treatment Wastewater treatment

III Particles settle as a

zone or blanket

Usually have a clear

interface between the

settling sludge and the

clarified effluent

settling in lime soda

ash sedimentation

1. activated sludge

sedimentation

2. sludge thickeners

Environmental Engineering Sem 2 2011/2012 70

SEDIMENTATION

Ideal sedimentation basins (Type 1)- UPFLOW CLARIFIER

settling velocity, v

s

of the particle to be removed

Velocity of water decreases as the water flows upward (overflow rate = v

o

,

hydraulic surface loading)

Velocity of the particle remains unchanged

If v

s

> v

o

, then 100% of particles remain in tank

If v

s

< v

o

, then 0% of particles remain in tank

Environmental Engineering Sem 2 2011/2012 71

SEDIMENTATION

Example

The settling velocity of calcium carbonate floc formed during flocculation is 2.1

mm/s. If the detention time in the settling zone is 1.0 h and upflow rate is 1.75

GPM/sq ft, what is the minimum depth of water required to ensure removal of

the floc by gravity settling. Given, I ft = 0.3048 m, 1.0 US gal =3.785L

Solution

1.75 GPM/ ft

2

= 1.18 mm/s

AV = 2.1 -1.18 mm/s

= 0.92 mm/s

Velocity = depth/ hour

Depth = (velocity )( hour)

=( 0.92 mm/s) ( 1 h)

= 3.3 m

Environmental Engineering Sem 2 2011/2012 72

SEDIMENTATION

Example

Calculate the diameter and depth of a circular clarifier for a design flow of 3800 m

3

/d and an

overflow rate of 0.00024 m/s and a detention time of 3 h. Calculate the weir loading rate by

assuming the total effluent weir is 20 m.

Solution

Volume , V = Qt

= (3800 m

3

/d) ( 3/24)

= 475 m

3

Q = 3800 m

3

/d = 0.044 m

3

/s

Surface overflow rate = Q/A

0.00024 m/s = 0.044 m

3

/s

A m

2

Area, A = 183.3 m

2

Volume, V = AD

D =V/A

= 475 m

3

/183.3 m

2

= 2.59 m

Diameter = 15.3 m

Weir loading rate = Q/ L

w

= 3800 m

3

/d

20 m

= 190 m

3

/day.m ( OK!)

Environmental Engineering Sem 2 2011/2012 73

SEDIMENTATION

Ideal sedimentation basins (Type 1)- REGTANGULAR BASIN

Particle removal is dependent on

the overflow rate, v

0

In order for particle to be removed

settling velocity , v

s

must be

sufficient so that it reaches the

bottom during the time the water

resides in the tank (t

d

).

If V

s

= V

o

, then

v

s

> v

0

, 100 %

particles should be

easily removed

v

s

= v

0

, 100 %

particles

removed

v

s

< v

0

,

some fraction of the particles will be removed P = 100 v

s

v

0

Environmental Engineering Sem 2 2011/2012 74

SEDIMENTATION

Example

A water treatment plant has a horizontal flow sedimentation tank with an

overflow rate of 17 m3/d. m2 and wishes to remove particles that have settling

velocities of 0.1 mm/s. What percentage of removal should be expected for each

particle in an ideal sedimentation tank?

Solution

v

s

= 0.1 mm/s

v

0

= 17 m3/d. m2 = ? mm/s, ( do the conversion so, v

0

= 0.2 mm/s

Note that

v

s

< v

0

,

P = 100 v

s

/ v

o

= 100 ( 0.1)/(0.2) = 50%

Recalculate by considering v

0

are

0.2 mm/s and 1 mm/s respectively.

Environmental Engineering Sem 2 2011/2012 75

SEDIMENTATION

Example

Determine the surface area of a sedimentation tank . The design

flow is 0.044 m

3

/s. Use a design overflow rate of 20 m / day.

Find the depth of the sedimentation for the given overflow rate

and detention time.

Solution:

1)Find the surface area.

First change the flow rate to compatible units.

(0.044 m

3

/ s)(86,400 s / day) = 3801.6 m

3

/day

The surface area is = 3801.6 m

3

/day

20 m/ day

=190.m

2

2) Find the length to width dimension

Common length-to-width , L: W ratios ( 2:1 < L:W < 5:1 , and

lengths seldom exceed 100 m. A minimum of two tanks is always

provided.

use two tanks, each with a width of 5 m, a total surface area of

190 m

2

,

Length = 190 m

2

/(2 tanks)(5 m wide) = 19 m

meet our length-to-width ratio of 3.8 : 1 ( OK!)

Tank 1 Tank 2

Flocculation tank

S

e

d

i

m

e

n

t

a

t

i

o

n

t

a

n

k

S

e

d

i

m

e

n

t

a

t

i

o

n

t

a

n

k

Tank 1

L= 19m,

W = 5 m

Tank 2

L= 19m,

W = 5 m

Q = 3801.6 m

3

/day

Environmental Engineering Sem 2 2011/2012 76

SEDIMENTATION

3) Find the tank depth.

Rule of thumb that the detention time should be 2-8 h.

Assumed the detention time of 120 min

Q = V/t

V = Q t

V = (1900.8 m

3

)(120 min)( d ) = 158 m

3

d 1440 min

Depth= 158 m

3

=1.684 m,= 1.7 m

95 m

2

The final design would then be two tanks, each having the following dimensions:

5 m wide x 19 m long x 1.7 m deep plus sludge storage depth.

Anda mungkin juga menyukai

- Density&Viscosity CalculatorDokumen19 halamanDensity&Viscosity CalculatorRanjit RjtBelum ada peringkat

- Water Quality Standards and ParametersDokumen142 halamanWater Quality Standards and Parametersnazatussimaz100% (2)

- CHAPTER 3 - Sedimentation StudentDokumen80 halamanCHAPTER 3 - Sedimentation StudentlundingBelum ada peringkat

- Thesis Water Treatment PDFDokumen34 halamanThesis Water Treatment PDFAzlyn SyafikahBelum ada peringkat

- CPI - Lesson 3ADokumen24 halamanCPI - Lesson 3AKarla Joy P. SucgangBelum ada peringkat

- Presentation 1Dokumen14 halamanPresentation 1suhail4uBelum ada peringkat

- IE208-L4-Water TreatmentDokumen57 halamanIE208-L4-Water TreatmentKristine Mae CabreraBelum ada peringkat

- Chapter - 1: 1.1 Water - Its Significance and SourcesDokumen22 halamanChapter - 1: 1.1 Water - Its Significance and Sourcesdalton2003Belum ada peringkat

- Study of Groundwater Quality at Dindigul Town, Tamilnadu, IndiaDokumen6 halamanStudy of Groundwater Quality at Dindigul Town, Tamilnadu, IndiaSadhika S FarzanaBelum ada peringkat

- 1 s2.0 S2212371722000014 MainDokumen12 halaman1 s2.0 S2212371722000014 MainRodrigo Alvim HudsonBelum ada peringkat

- Unesco - Eolss Sample Chapters: Industrial WaterDokumen9 halamanUnesco - Eolss Sample Chapters: Industrial WaterCarlos Castillo San RomanBelum ada peringkat

- Design of Water Treatment Plant at PonukDokumen9 halamanDesign of Water Treatment Plant at PonukPilu RaneBelum ada peringkat

- Cve423 Environmental - EngineeringDokumen36 halamanCve423 Environmental - EngineeringGideon IdehenBelum ada peringkat

- ENE-101 Lec 4 IncompDokumen34 halamanENE-101 Lec 4 IncompMaheen HayatBelum ada peringkat

- Analysis and Investigation of Sugar Industrial Waste WaterDokumen4 halamanAnalysis and Investigation of Sugar Industrial Waste WaterJournalNX - a Multidisciplinary Peer Reviewed JournalBelum ada peringkat

- 01 1230 Jerry RoweDokumen40 halaman01 1230 Jerry RoweJaime MercadoBelum ada peringkat

- Water Quality Assignment A - Blessed Sibanda (N01519451G)Dokumen7 halamanWater Quality Assignment A - Blessed Sibanda (N01519451G)Blessed SibandaBelum ada peringkat

- Chemistry-PBL-Project Report-1Dokumen16 halamanChemistry-PBL-Project Report-1Soumya ChaphaleBelum ada peringkat

- Piped Services-Water Supply SystemDokumen58 halamanPiped Services-Water Supply SystemtsuichinghongBelum ada peringkat

- Eap215 - Design AssignmentDokumen35 halamanEap215 - Design AssignmentyogadarshiniBelum ada peringkat

- G2PRESENTATIONDokumen28 halamanG2PRESENTATIONLily QuiBelum ada peringkat

- Ahmed Al 2000Dokumen14 halamanAhmed Al 2000Gustavo TaquichiriBelum ada peringkat

- Irrigation Water Quality: January 2018Dokumen20 halamanIrrigation Water Quality: January 2018Tejas CjBelum ada peringkat

- CPI - Lesson 3Dokumen16 halamanCPI - Lesson 3Kim Tracey LadagaBelum ada peringkat

- WR 230: Water Treatment Engineering: Instructor: Ms. AlexanderDokumen31 halamanWR 230: Water Treatment Engineering: Instructor: Ms. AlexanderGerald MagingaBelum ada peringkat

- Reduction of Turbidity of Water Using Locally Available Natural Coagulants 2020-2021Dokumen12 halamanReduction of Turbidity of Water Using Locally Available Natural Coagulants 2020-2021gowtham gowdaBelum ada peringkat

- Water Pollution in MinesDokumen23 halamanWater Pollution in MinesAbhishek VaidyaBelum ada peringkat

- Membranes 12 00923 v2Dokumen10 halamanMembranes 12 00923 v2Elizabeth BennetBelum ada peringkat

- By-Vikas Kumar Reg-11MEE0038Dokumen9 halamanBy-Vikas Kumar Reg-11MEE0038Vikas PoddarBelum ada peringkat

- Water PDFDokumen40 halamanWater PDFAnjney100% (1)

- Seawater Distillation Using Vacuum Pumps and UltraDokumen8 halamanSeawater Distillation Using Vacuum Pumps and UltraEsposito EspositoBelum ada peringkat

- Review On Recent Advances in Synthesis of Black TiO2Dokumen13 halamanReview On Recent Advances in Synthesis of Black TiO2International Journal of Innovative Science and Research TechnologyBelum ada peringkat

- CHAPTER7 WaterqualityforirrigationDokumen33 halamanCHAPTER7 WaterqualityforirrigationKarim MegherfiBelum ada peringkat

- DELFUORIDATIONDokumen8 halamanDELFUORIDATIONLe Ngoc DungBelum ada peringkat

- Water PurificationDokumen22 halamanWater PurificationChinmay PapnaiBelum ada peringkat

- Water Pollution: 1st Semester 2012-2013Dokumen11 halamanWater Pollution: 1st Semester 2012-2013Jeric Gader BriosoBelum ada peringkat

- Drinking Water Treatment Process Flow DiagramDokumen3 halamanDrinking Water Treatment Process Flow DiagramMemory Nyasha MZTN100% (1)

- Nallakukkala 2021Dokumen24 halamanNallakukkala 2021VishnuShantanBelum ada peringkat

- Soft and Hard Water, Temporary and PERMANENT HARDNESS, Treatments of WaterDokumen27 halamanSoft and Hard Water, Temporary and PERMANENT HARDNESS, Treatments of WaterPradnyesh VishwasraoBelum ada peringkat

- Water Treatment ProcessDokumen32 halamanWater Treatment Processmiraflorcomia65Belum ada peringkat

- ScienceDokumen8 halamanScienceTanveer RobiulBelum ada peringkat

- Name - Dushyant Class - Xith A Roll No. - 01 Subject - Chemistry Project OnDokumen22 halamanName - Dushyant Class - Xith A Roll No. - 01 Subject - Chemistry Project OnManavBelum ada peringkat

- Water PurificaitonDokumen13 halamanWater PurificaitonbekkuBelum ada peringkat

- 1 s2.0 S2214714419316903 MainDokumen18 halaman1 s2.0 S2214714419316903 MainLuciano MagalhãesBelum ada peringkat

- Chapter 40 Water Treatment PlantDokumen7 halamanChapter 40 Water Treatment PlantKrishna KantiBelum ada peringkat

- Design Parameters of Sand Filtration Systems in Wastewater Treatment ProcessDokumen9 halamanDesign Parameters of Sand Filtration Systems in Wastewater Treatment ProcessMi doremiBelum ada peringkat

- Sources of Irrigation Water and QualityDokumen6 halamanSources of Irrigation Water and QualityRotich VincentBelum ada peringkat

- A Review of Current Desalination Technologies in Developing and Developed CountriesDokumen62 halamanA Review of Current Desalination Technologies in Developing and Developed Countriesrksiva2009Belum ada peringkat

- Water Treatment and Plant Design PDFDokumen87 halamanWater Treatment and Plant Design PDFFatih100% (4)

- Asian Journal of Advances in ResearchDokumen12 halamanAsian Journal of Advances in ResearchOnline JobBelum ada peringkat

- Design of Water Treatment Plants CourseDokumen47 halamanDesign of Water Treatment Plants CourseAnonymous M0tjyW100% (1)

- Treatment For Drinking Water ProductionDokumen13 halamanTreatment For Drinking Water ProductionmanjunathBelum ada peringkat

- Production of Clay Filters For Waste Water TreatmeDokumen11 halamanProduction of Clay Filters For Waste Water TreatmePaolaBelum ada peringkat

- Water TreatmentDokumen19 halamanWater TreatmentAnonymous 8ooQmMoNs1Belum ada peringkat

- Project Review2.Dokumen22 halamanProject Review2.Jasthi HarishaBelum ada peringkat

- Characterization of Industrial EffluentDokumen12 halamanCharacterization of Industrial Effluentnajie89Belum ada peringkat

- Water PurificationDokumen17 halamanWater PurificationsimonaBelum ada peringkat

- Basic Water 1Dokumen21 halamanBasic Water 1Hani ZahraBelum ada peringkat

- Microbiological Aspects of Pollution Control: Fundamental Aspects of Pollution Control and Environmental ScienceDari EverandMicrobiological Aspects of Pollution Control: Fundamental Aspects of Pollution Control and Environmental ScienceBelum ada peringkat

- Chapter 1 Part 1Dokumen31 halamanChapter 1 Part 1Mazliah Zainal AbidinBelum ada peringkat

- Hazard Identification, Risk Assessment & Risk Control: by Hera Singh Scientific Officer Pusat Pengajian Sains KesihatanDokumen26 halamanHazard Identification, Risk Assessment & Risk Control: by Hera Singh Scientific Officer Pusat Pengajian Sains KesihatanJefry M SidiqueBelum ada peringkat

- Sand Replacement MethodDokumen19 halamanSand Replacement MethodMazliah Zainal Abidin100% (1)

- Water Efficiency: © Rahmat Muslim 2010Dokumen57 halamanWater Efficiency: © Rahmat Muslim 2010Mazliah Zainal AbidinBelum ada peringkat

- Chapter 4b - Wastewater Treatment 2Dokumen105 halamanChapter 4b - Wastewater Treatment 2Mazliah Zainal AbidinBelum ada peringkat

- Jurutera Dan MasyarakatDokumen5 halamanJurutera Dan MasyarakatMazliah Zainal AbidinBelum ada peringkat

- Nota Keusahawanan Week 2 (Environment Screening) Edited 20 Sep 2012Dokumen16 halamanNota Keusahawanan Week 2 (Environment Screening) Edited 20 Sep 2012Mazliah Zainal AbidinBelum ada peringkat

- 1.0 Objective: A A B BDokumen20 halaman1.0 Objective: A A B BMazliah Zainal AbidinBelum ada peringkat

- Chapter 1 - Introduction To RCDokumen46 halamanChapter 1 - Introduction To RCMazliah Zainal AbidinBelum ada peringkat

- Permeability Test: A. Constant HeadDokumen13 halamanPermeability Test: A. Constant HeadAdron LimBelum ada peringkat

- Nota Keusahawanan Week 1 (Introduction)Dokumen20 halamanNota Keusahawanan Week 1 (Introduction)Mazliah Zainal AbidinBelum ada peringkat

- Omtex Classes: Greenhouse EffectDokumen12 halamanOmtex Classes: Greenhouse EffectAMIN BUHARI ABDUL KHADERBelum ada peringkat

- Comments Matrix D3 Liquica - PICDokumen7 halamanComments Matrix D3 Liquica - PICHanaBelum ada peringkat

- Piping Fabrication, Installation, Flushing and Testing L-CR-004 Annex B Rev. 1, January 1996Dokumen2 halamanPiping Fabrication, Installation, Flushing and Testing L-CR-004 Annex B Rev. 1, January 1996NaBelum ada peringkat

- Vishveshwaraya Technical University Jana Sangama, Belgavi: Interlinking of Indian RiversDokumen25 halamanVishveshwaraya Technical University Jana Sangama, Belgavi: Interlinking of Indian RiversNaveenBelum ada peringkat

- Hand Pump - WikipediaDokumen13 halamanHand Pump - WikipediaSrinivas DsBelum ada peringkat

- COC Ar30 40L 02-02-XII-14Dokumen1 halamanCOC Ar30 40L 02-02-XII-14Tirtana PrasetiaBelum ada peringkat

- Science10 q4 Mod1 Boyleslaw v5Dokumen18 halamanScience10 q4 Mod1 Boyleslaw v5Vicente SazilBelum ada peringkat

- Liquefaction of Carbon Dioxide With Ammonia Absorption Chiller System and Its Energy ReductionDokumen5 halamanLiquefaction of Carbon Dioxide With Ammonia Absorption Chiller System and Its Energy ReductionSamuel DotouBelum ada peringkat

- Solids Liquids & Gases PDFDokumen16 halamanSolids Liquids & Gases PDFWalterViaBelum ada peringkat

- Sahara Regenerative Air DryersDokumen29 halamanSahara Regenerative Air DryersNaveen KumarBelum ada peringkat

- Ac System Parts Id SK-KD 19Dokumen89 halamanAc System Parts Id SK-KD 19Louise LucassicBelum ada peringkat

- r050210801 Fluid Mechanics For Chemical EngineeringDokumen7 halamanr050210801 Fluid Mechanics For Chemical EngineeringSrinivasa Rao GBelum ada peringkat

- Specifications - Instructions and Operation: Mark II Series Molded Plastic ManometersDokumen4 halamanSpecifications - Instructions and Operation: Mark II Series Molded Plastic ManometerssikuripBelum ada peringkat

- Set 5Dokumen2 halamanSet 5Olliver Ceni de OliveiraBelum ada peringkat

- White Paper: Introduction To ISO Compressed Air Quality StandardsDokumen16 halamanWhite Paper: Introduction To ISO Compressed Air Quality StandardsjoadBelum ada peringkat

- NRECA Water BalanceDokumen54 halamanNRECA Water BalanceGneis Setia GrahaBelum ada peringkat

- AFT Fathom - Sep 20, 2014Dokumen9 halamanAFT Fathom - Sep 20, 2014Sami UllahBelum ada peringkat

- Higg Index-Water Module: - Why It Is Used As Business Tool and - How To Score in ItDokumen36 halamanHigg Index-Water Module: - Why It Is Used As Business Tool and - How To Score in Itshahed81Belum ada peringkat

- Grade 10 - GasesDokumen35 halamanGrade 10 - GasesVictoria Lowman0% (1)

- Chemical Process Principles TestsDokumen2 halamanChemical Process Principles Testsnp484Belum ada peringkat

- Osmosis Manual EnglishDokumen46 halamanOsmosis Manual EnglishIacob Daniel100% (1)

- 8 Fundamental Equation of Fluid FlowDokumen70 halaman8 Fundamental Equation of Fluid FlowKit Meng LimBelum ada peringkat

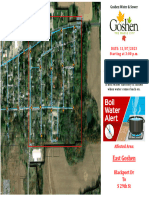

- Boil Order - East GoshenDokumen2 halamanBoil Order - East GoshenWNDUBelum ada peringkat

- Natural Gas Pipeline Flow Calculations Course Content 2 23 16Dokumen32 halamanNatural Gas Pipeline Flow Calculations Course Content 2 23 16Aravind100% (1)

- Chapter 2 - Fluid StaticsDokumen30 halamanChapter 2 - Fluid StaticsاشرفاللساميBelum ada peringkat

- IV Dam Outlet Work1Dokumen33 halamanIV Dam Outlet Work1hailish100% (1)

- Karnaphuli Water Supply Project Phase 2: Factory Inspection Report On ChlorinatorDokumen7 halamanKarnaphuli Water Supply Project Phase 2: Factory Inspection Report On ChlorinatorJahangir AlamBelum ada peringkat

- Inch Dia Inch MeterDokumen6 halamanInch Dia Inch MeterRadhakrishnan SreerekhaBelum ada peringkat

- Picket Plott DevelopmentDokumen7 halamanPicket Plott DevelopmentFalza WihdanyBelum ada peringkat