Manufacturing Technology

Diunggah oleh

sharmashnDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Manufacturing Technology

Diunggah oleh

sharmashnHak Cipta:

Format Tersedia

INTRODUCTION

Manufacturing is the industrial activity that changes the form of raw materials to create

products or in other word manufacturing has been accurately defined as the activities that

are performed in the conversion of stuff to useful thing (product). It is the application

of physical and chemical processes to alter the geometry, property and/or appearances of

given starting material to make part or product.

The derivation of the word manufacture reflects its original meaning: to make by hand. As

the power of the hand tool is limited, manufacturing is done largely by machinery today.

Manufacturing technology constitutes all methods used for shaping the raw metal materials

into a final product.

The development of new tool materials opened a new era for the machining industry in

which machine tool development took place.

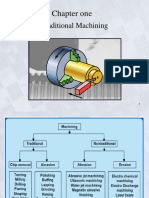

CLASSIFICATION OF MANUFACTURING PROCESSES

METAL MACHINING

Machining is the removal of the unwanted material (machining allowance) from the

work piece (WP), so as to obtain a finished product of the desired size, shape, and

surface quality. The practice of removal of machining allowance through cutting

techniques was first adopted using simple handheld tools made from bone, stick, or

stone, which were replaced by bronze or iron tools. Water, steam, and later electricity

were used to drive such tools in power-driven metal cutting machines (machine tools).

The importance of machining processes can be emphasized by the fact that every

product use in our daily life has undergone this process either directly or indirectly. It

is important to understand the metal cutting process in order to make the best use of

it.

METAL MACHINING (.CONT.)

In the metal working industries work piece of different shape, dimension and

materials are worked. The various working processes to make these fall into two

groups :

Metal Working

Chip-less Process (Metal

Forming) e.g. forging,

pressing , drawing etc.

Chip Forming Process

(Metal Cutting) e.g.

turning, drilling, milling

etc.

METAL MACHINING (.CONT.)

A Cutting tool may be used either for cutting apart, as with a knife, or for removing

chips. Part are produced by removing metal mostly in the form of small chips.

All cutting tools can be divided into two groups they are:

1) Single point cutting tools

2) Multi-Point cutting tools

Single point cutting tool having a wedge like action find, a wide application on lathe,

and slotting machine. Multi point cutting tools are merely two or more single point

tools arrange together as a unit.

TYPE OF CUTTING TOOLS

METAL MACHINING (.CONT.)

SINGLE POINT CUTTING TOOLS FOR LATHE MACHINE

METAL MACHINING (.CONT.)

MULTI POINT CUTTING TOOLS

METAL MACHINING (.CONT.)

MULTI POINT CUTTING TOOLS

METAL MACHINING (.CONT.)

MECHANICS OF CUTTING AND CHIP FORMATION

In figure tool is considered stationary, and the work-piece moves to the right.

The metal is severely compressed in the area in the front of cutting tool. The

metal in front of the tool rake face gets immediately compressed, first elastically

and plastically. This zone is traditionally called shear zone.

METAL MACHINING (.CONT.)

CHIP F0RMATION

The metal in front of the tool rake face gets

immediately compressed first elastically and

then plastically.

The actual separation of the metal starts as a

yielding or fracture, depending upon the

cutting conditions, starting from the cutting

tool tip.

The chip after sliding over the tool rake face

would be lifted away from the tool, and the

resultant curvature of the chip is termed as

chip curl.

METAL MACHINING (.CONT.)

Mechanics of cutting and Chip

Formation

Metal cutting as a slide of card which would slide over one

another as the wedge shape tool moves under these cards

as shown in figure.

TYPE OF CHIPS

The chip is variable both in size and shape in actual manufacturing practice.

Study of chip is one of the most important things in metal cutting.

TYPE OF CHIP (.CONTD.)

FOUR BASIC TYPES OF CHIP IN MACHINING

Whether the cutting condition can be, the chip produced may belong to one of the

following type :

1. Discontinuous chip

2. Continuous chip

3. Continuous chip with Built-up Edge (BUE)

4. Serrated chip

TYPE OF CHIP (.CONTD.)

Brittle work materials

Low cutting speeds

Large feed and depth of cut

High tool-chip friction

DISCONTINUOUS CHIPS

TYPE OF CHIP (.CONTD.)

DISCONTINUOUS CHIPS

Discontinuous Chip

When brittle materials like cast iron are

cut, the deformed material gets fractured

very easily and thus the chip produced is in

the form of discontinuous segments.

Cutting force becomes unstable with the

variation coinciding with the fracturing

cycle.

Higher depths of cut (large chip thickness),

low cutting speeds and small rake angles

are likely to produce discontinuous chips.

TYPE OF CHIP (.CONTD.)

Ductile work materials

High cutting speeds

Small feeds and depths

Sharp cutting edge

Low tool-chip friction

CONTINUOUS CHIPS

TYPE OF CHIP (.CONTD.)

CONTINUOUS CHIPS

Continuous chips are usually formed at high rake

angles and/or high cutting speeds.

A good surface finish is generally produced.

Continuous chips are not always desirable, particularly

in automated machine tools,

Tend to get tangled around the tool

Operation has to be stopped to clear away the chips.

TYPE OF CHIP (.CONTD.)

CONTINUOUS CHIP FORMATION

CONTINUOUS WITH BUE

Ductile materials

Low-to-medium cutting speeds

Tool-chip friction causes portions of

chip to adhere to rake face

BUE forms, then breaks off,

cyclically

CONTINUOUS WITH BUE

BUE consists of layers of material from the workpiece that are

gradually deposited on the tool.

BUE then becomes unstable and eventually breaks up

BUE material is carried away on the tool side of the chip

The rest is deposited randomly on the workpiece surface.

BUE results in poor surface finish

Reduced by increasing the rake angle and therefore decreasing the

depth of cut.

SERRATED CHIPS

Semi continuous - saw-tooth

appearance

Cyclical chip forms with alternating

high shear strain then low shear

strain

Associated with difficult-to-machine

metals at high cutting speeds

CHIPS PRODUCED IN TURNING

Various chips produced in turning: (a) tightly curled chip; (b) chip hits workpiece and

breaks; (c) continuous chip moving away from workpiece; and (d) chip hits tool shank

and breaks off. Source

THIN AND THICK SHEAR MODEL

METHODS OF MACHINING

There are method of metal cutting, depending upon the arrangement of the cutting

edge with respect to the direction of relative work-tool motion:

1. Orthogonal cutting or two dimensional cutting

2. Oblique cutting or three dimensioning cutting

Orthogonal cutting take place when the cutting face of the tool is 90 to the line of

action or path of the tool. If, however, the cutting face is inclined at an angle less than

(other than 90) 90 to the path of tool, the cutting action is known as oblique.

Orthogonal cutting or two

dimensional cutting

METHODS OF MACHINING

In orthogonal cutting, the cutting edge of the cutting tool is

arrange perpendicular to the cutting velocity (V), where in

oblique cutting, it set at some angle other than 90 to the

cutting velocity (v), which gives an inclination angle . The

analysis of oblique cutting being very complex, the relatively

simple arrangement of orthogonal cutting is, therefor, widely

used in theoretical and experimental work

Oblique cutting is more practical while orthogonal cutting is

convenient for analysis.

METHODS OF MACHINING (CONTD.)

METHODS OF MACHINING (CONTD.)

Orthogonal Cutting Model

Simplified 2-D model of machining that describes the

mechanics of machining fairly accurately

Chip Thickness Ratio

c

o

t

t

r

where r = chip thickness ratio; t

o

= thickness of the chip prior to chip formation; and

t

c

= chip thickness after separation

Chip thickness after cut always greater than before, so chip ratio always

less than 1.0

METHODS OF MACHINING (CONTD.)

=

=

Chip Thickness Ratio

c

o

t

t

r

Based on the geometric parameters of the orthogonal

model, the shear plane angle can be determined as:

sin

cos

tan

r

r

1

where r = chip ratio, and = rake angle

MECHANICS OF ORTHOGONAL CUTTING

The current analysis is based on Merchant's

thin shear plane model considering the

minimum energy principle.

This model would be applicable at very

high cutting speeds, which are generally

practiced in production

ASSUMPTIONS

The tool is perfectly sharp and no contact along the clearance

face.

The surface where shear is occurring is a plane.

The cutting edge is a straight line extending perpendicular to the

direction of motion and generates a plane surface as the work

moves past it.

The chip does not flow to either side or no side spread.

Uncut chip thickness is constant.

Width of the tool is greater than the width of the work.

A continuous chip is produced without any BUE.

Work moves with a uniform velocity.

The stresses on the shear plane are uniformly distributed

FORCES AND MECHANICS OF CUTTING

Why should we know?

Power requirement for the machine tool can be

calculated

Design of stiffness, etc. for the machine

tolerances

Whether work piece can withstand the cutting

force

Fs = force which is the resistance to shear of the metal in forming the chip. It acts along

the shear plane.

Ns = Normal to the shear plane. This is the backup force on the chip provided by the work

piece.

N = force at the tool tip interface acting normal to the cutting face of the tool and is

provided by the tool

F = Is the frictional resistance of the tool acting on the chip. It act downward against the

motion of the chip as it glides upward along the tool face.

R and R are equal in magnitude and opposite in direction.

Fig. a

MERCHANT CIRCLE

The two orthogonal component (horizontal and vertical) FH and FV of the resultant force

R can be measure by using dynamometer. The horizontal component is the cutting force

FH and the vertical component is the thrust force Fv.

All these force can be represented with the help of a circle known as Merchant force

circle

Fig, b

MERCHANT CIRCLE

Here the two force triangle have been superimpose by placing the two

equal force R and R together. In the figure, is the angle of friction. In this

diagram, for the convenience the resultant force have been moved to the

point of the tool. Since the force FH and Fv are at right angle to each other,

their intersection lies on a circle diameter R. The force F and N may be

placed in the diagram as shown to form the circle diagram.

Now : firm fig. b and c

Fig. c

Force Fs and Ns are right angle to each other

1.

.2

..3

from Fig. d

Fv

N

F

4

..................

5

.6

7

.8

Putting the value of Ns (from eq. 3) in this both equations (7 and 8)

...9

.

10

1

1

MINIMUM ENERGY CONDITION

2 2

45

Or

WHAT THE MERCHANT EQUATION TELLS US

To increase shear plane angle

Increase the rake angle

Reduce the friction angle (or coefficient of friction)

Effect of Higher Shear Plane Angle

Higher shear plane angle means smaller shear plane which means lower

shear force, cutting forces, power, and temperature

2 2

45

Effect of shear plane angle : (a) higher with a resulting lower shear plane area; (b) smaller

with a corresponding larger shear plane area. Note that the rake angle is larger in (a), which tends

to increase shear angle according to the Merchant equation

POWER AND ENERGY RELATIONSHIPS

Where: D= Dia. Of job

N= Velocity of job or tool rev/min

Anda mungkin juga menyukai

- Unit-I Theory of Metal CuttingDokumen73 halamanUnit-I Theory of Metal CuttingSarvesh Kumarasamy100% (1)

- Material Removal Process (Metal Machining Process) : Theory of Metal CuttingDokumen129 halamanMaterial Removal Process (Metal Machining Process) : Theory of Metal CuttingIjanSahrudinBelum ada peringkat

- CH 2 Metal Cutting ToolsDokumen19 halamanCH 2 Metal Cutting ToolsAlex AdmasBelum ada peringkat

- CD 5291 Computer Aided Tools For ManufactiringDokumen2 halamanCD 5291 Computer Aided Tools For ManufactiringGnaneswaran Narayanan63% (8)

- Tool Life & Tool Wear PPT by Ankit & VikramDokumen23 halamanTool Life & Tool Wear PPT by Ankit & VikramAnkit Nayak100% (5)

- Thermal Aspects of Machining Module 1Dokumen75 halamanThermal Aspects of Machining Module 1Libin AbrahamBelum ada peringkat

- Merchant's Circle NotsDokumen5 halamanMerchant's Circle NotsSaravanan MathiBelum ada peringkat

- Manufacturing Technology-Fundamentals of MachiningDokumen33 halamanManufacturing Technology-Fundamentals of MachiningDhanis ParamaguruBelum ada peringkat

- 4 Sheet MetalDokumen54 halaman4 Sheet MetalShashank PansariBelum ada peringkat

- HIDDEN SURFACE REMOVAL ALGORITHMSDokumen8 halamanHIDDEN SURFACE REMOVAL ALGORITHMSAshok KumarBelum ada peringkat

- Production Engg Lab Manual (V Semester) Lathe Tool DynamometerDokumen4 halamanProduction Engg Lab Manual (V Semester) Lathe Tool Dynamometerpsmonu54Belum ada peringkat

- Anna University Exam Paper Theory of Metal Cutting: Production EngineeringDokumen3 halamanAnna University Exam Paper Theory of Metal Cutting: Production EngineeringAkash Kumar DevBelum ada peringkat

- Presses & Press WorkDokumen43 halamanPresses & Press WorkSahil ShethBelum ada peringkat

- Press Working TerminologyDokumen16 halamanPress Working TerminologyAadrika UmashankarBelum ada peringkat

- Amie Fundamentals of Design and Manufacturing DesignDokumen3 halamanAmie Fundamentals of Design and Manufacturing DesignAhmed Abotoor50% (6)

- Theory of Metal Cutting ExplainedDokumen2 halamanTheory of Metal Cutting ExplainedShivanshu shekhar100% (1)

- Stretch Forming JomyDokumen33 halamanStretch Forming JomyJoBelum ada peringkat

- 3-Classification of CUTTING DIESDokumen5 halaman3-Classification of CUTTING DIESGurdeepBelum ada peringkat

- Production Engineering I (Meng 3191) : Cutting ForceDokumen53 halamanProduction Engineering I (Meng 3191) : Cutting ForceFasil GetachewBelum ada peringkat

- Sheet Metal Working: Unit No. VDokumen67 halamanSheet Metal Working: Unit No. VMahesh SalotagiBelum ada peringkat

- Books:: Machining Technology & MetrologyDokumen8 halamanBooks:: Machining Technology & MetrologyaritraBelum ada peringkat

- Types of Drawing Process-Wire Drawing, Rod Drawing and Tube DrawingDokumen12 halamanTypes of Drawing Process-Wire Drawing, Rod Drawing and Tube DrawingMr.N.S. NateshBelum ada peringkat

- Theory of Metal Cutting: Submitted To MR. GURPREET SINGH Submitted byDokumen39 halamanTheory of Metal Cutting: Submitted To MR. GURPREET SINGH Submitted byamitBelum ada peringkat

- Plastic Metal Forming of Metals and PowdersDokumen20 halamanPlastic Metal Forming of Metals and Powdersيوسف عادل حسانينBelum ada peringkat

- Sheet Metal WorkingDokumen23 halamanSheet Metal WorkingSujit MishraBelum ada peringkat

- Machining ProcessesDokumen44 halamanMachining Processesregassa rajiBelum ada peringkat

- Ch21 Fundamentals of Cutting2Dokumen70 halamanCh21 Fundamentals of Cutting2manojc68Belum ada peringkat

- Types of Press Tools Classified and ExplainedDokumen24 halamanTypes of Press Tools Classified and ExplainedAvula VinayBelum ada peringkat

- MP-I - Unit 5 - Sheet Metal WorkingDokumen60 halamanMP-I - Unit 5 - Sheet Metal WorkingTirumala Height Phase-IBelum ada peringkat

- Water Jet Machining: Recent DevelopmentDokumen36 halamanWater Jet Machining: Recent Developmentrmehfuz60% (5)

- Strip LayoutDokumen35 halamanStrip LayoutJay PatelBelum ada peringkat

- Lecture 8 Sheet Metal Working PDFDokumen6 halamanLecture 8 Sheet Metal Working PDFluisimtzBelum ada peringkat

- Mechanism of Metal CuttingDokumen88 halamanMechanism of Metal CuttingAndriya Narasimhulu50% (2)

- Selection of Material and Hardware Used in Press ToolDokumen22 halamanSelection of Material and Hardware Used in Press ToolVipul MetaBelum ada peringkat

- Metal Casting Guide: Risers, Solidification Times & MoreDokumen8 halamanMetal Casting Guide: Risers, Solidification Times & MoreYash DesaaiBelum ada peringkat

- Production Technology-I Unit No. 1: Cutting ToolDokumen15 halamanProduction Technology-I Unit No. 1: Cutting ToolPankaj ChhabraBelum ada peringkat

- Micro Machining Prof V K JainDokumen70 halamanMicro Machining Prof V K JainJayant Kumar0% (1)

- Unit Iii Visual RealismDokumen59 halamanUnit Iii Visual RealismJabin JoeBelum ada peringkat

- Solidification ShrinkageDokumen16 halamanSolidification ShrinkageSherif El-soudyBelum ada peringkat

- Metal FormingDokumen49 halamanMetal FormingtejasBelum ada peringkat

- Machining Forces and Merchant's Circle Diagram (MCD)Dokumen40 halamanMachining Forces and Merchant's Circle Diagram (MCD)AswinBelum ada peringkat

- Metal Cutting Theory and MechanismDokumen75 halamanMetal Cutting Theory and Mechanismnishantdubey1183Belum ada peringkat

- Fabrication of Microelectronic Devices Final - 2 PDFDokumen30 halamanFabrication of Microelectronic Devices Final - 2 PDFAdarsh BarnwalBelum ada peringkat

- Basic Mechanical Engineering: Manufacturing ProcessesDokumen49 halamanBasic Mechanical Engineering: Manufacturing Processespritam goleBelum ada peringkat

- PATTERN ALLOWANCE AND CASTING PROCESS FUNDAMENTALSDokumen19 halamanPATTERN ALLOWANCE AND CASTING PROCESS FUNDAMENTALSimamuddeen100% (3)

- 15mec243 - Tool Design: VII Semester - Elective Mechanical EngineeringDokumen17 halaman15mec243 - Tool Design: VII Semester - Elective Mechanical Engineeringvignesh100% (1)

- Metal Cutting: Machining & Machining Tools Unit-1Dokumen90 halamanMetal Cutting: Machining & Machining Tools Unit-1Joao PedroBelum ada peringkat

- Introduction to Machine Tool DesignDokumen13 halamanIntroduction to Machine Tool DesignAshok Kumar0% (2)

- Mercant CircleDokumen7 halamanMercant CircleKavi ArasuBelum ada peringkat

- Broaching MachineDokumen10 halamanBroaching MachineVinayakNerkarBelum ada peringkat

- Theory of Metal Cutting ProcessesDokumen46 halamanTheory of Metal Cutting ProcessesRaju MathewBelum ada peringkat

- Fitting Models: Semi Circular JointDokumen2 halamanFitting Models: Semi Circular Jointsubba reddyBelum ada peringkat

- Question Bank - All UnitsDokumen11 halamanQuestion Bank - All UnitsParamasivam Veerappan100% (1)

- Sheet Metal Shop GuideDokumen37 halamanSheet Metal Shop Guideeafz111Belum ada peringkat

- Sheet Metal OperationsDokumen63 halamanSheet Metal OperationsDilip ShenoyBelum ada peringkat

- CH03. Sheet Metal ProcessesDokumen73 halamanCH03. Sheet Metal ProcesseshizanorhudaBelum ada peringkat

- Principle Angle Single Point Cutting ToolsDokumen16 halamanPrinciple Angle Single Point Cutting ToolsSoumik DasBelum ada peringkat

- Theory of Metal Machining ProcessesDokumen111 halamanTheory of Metal Machining ProcessesYuvraaj Singh100% (1)

- Production Engineering Lecture 2Dokumen16 halamanProduction Engineering Lecture 2AINAMANI AMOSBelum ada peringkat

- Metal Cutting Meaning, History and Principles MetallurgyDokumen21 halamanMetal Cutting Meaning, History and Principles MetallurgyJackson SichingaBelum ada peringkat

- Power Plant Economics and TarrifsDokumen36 halamanPower Plant Economics and TarrifssharmashnBelum ada peringkat

- Hydro and Nuclear Power PlantDokumen40 halamanHydro and Nuclear Power PlantsharmashnBelum ada peringkat

- Heat Pump CycleDokumen25 halamanHeat Pump CycleDario Rajmanovich100% (1)

- CarburetorsDokumen10 halamanCarburetorssharmashnBelum ada peringkat

- What Are Heat Exchangers For?Dokumen33 halamanWhat Are Heat Exchangers For?captainhassBelum ada peringkat

- Risk Management Strategies For Beginning and Small Farmers and Ranchers ConferenceDokumen37 halamanRisk Management Strategies For Beginning and Small Farmers and Ranchers ConferencesharmashnBelum ada peringkat

- Unified Mechanical Engineering Lab-2Dokumen38 halamanUnified Mechanical Engineering Lab-2sharmashnBelum ada peringkat

- Belachew Renewable JourDokumen25 halamanBelachew Renewable JoursharmashnBelum ada peringkat

- Biodiesel Distillation Temperature, Cetane Number, and Viscosity vs. Fatty Acid ProfileDokumen2 halamanBiodiesel Distillation Temperature, Cetane Number, and Viscosity vs. Fatty Acid ProfilesharmashnBelum ada peringkat

- Biodiesel Fuel at UconnDokumen22 halamanBiodiesel Fuel at UconnsharmashnBelum ada peringkat

- T13 Introduction To Gear TrainsDokumen17 halamanT13 Introduction To Gear TrainsAli El-GazzarBelum ada peringkat

- Assignement 1Dokumen1 halamanAssignement 1sharmashnBelum ada peringkat

- Material Science Phase Diagrams MCQsDokumen3 halamanMaterial Science Phase Diagrams MCQsPrince AbhishekBelum ada peringkat

- DOE Fundamentals Handbook, Mechanical Science, Volume 1 of 2Dokumen122 halamanDOE Fundamentals Handbook, Mechanical Science, Volume 1 of 2Bob VinesBelum ada peringkat

- Hydraulic CircuitDokumen17 halamanHydraulic CircuitPrashanth PrakashBelum ada peringkat

- Test 1Dokumen2 halamanTest 1sharmashnBelum ada peringkat

- MosfetDokumen12 halamanMosfetsharmashnBelum ada peringkat

- Test 1Dokumen1 halamanTest 1sharmashnBelum ada peringkat

- EdmDokumen5 halamanEdmsharmashnBelum ada peringkat

- Assignment 2Dokumen1 halamanAssignment 2sharmashnBelum ada peringkat

- CavitationDokumen39 halamanCavitationzfrl100% (1)

- 19 Introduction To Design of Helical SpringsDokumen12 halaman19 Introduction To Design of Helical SpringsPRASAD326100% (3)

- LMMEC355PDokumen15 halamanLMMEC355PsharmashnBelum ada peringkat

- Static Force AnalysisDokumen26 halamanStatic Force AnalysissharmashnBelum ada peringkat

- Laboratory Manual MEC-325 Thermo Fluid Engineering LaboratoryDokumen36 halamanLaboratory Manual MEC-325 Thermo Fluid Engineering LaboratoryArpit Kumar Jain100% (1)

- Brakes and DynamometersDokumen16 halamanBrakes and DynamometerssharmashnBelum ada peringkat

- Injection SystemDokumen19 halamanInjection SystemsharmashnBelum ada peringkat

- Basic hydraulic and pneumatic circuit design conceptsDokumen20 halamanBasic hydraulic and pneumatic circuit design conceptssharmashnBelum ada peringkat

- Gas Turbine Power PlantDokumen18 halamanGas Turbine Power Plantsharmashn100% (1)

- Keywords: Consumer, Packing, RecycleDokumen8 halamanKeywords: Consumer, Packing, RecycleDr.K.BaranidharanBelum ada peringkat

- Oleochem Chap 1Dokumen47 halamanOleochem Chap 1lolahonez100% (4)

- Reliance 380PG Pharmaceutical Grade Washer Technical DataDokumen7 halamanReliance 380PG Pharmaceutical Grade Washer Technical DataNirbhayBelum ada peringkat

- Excel Flowsheeting TutorialDokumen2 halamanExcel Flowsheeting TutorialYoga Anugrah PratamaBelum ada peringkat

- 2011specific Kobelco BookDokumen169 halaman2011specific Kobelco Bookmas_munir7174Belum ada peringkat

- Motor Yanmar l48v6 Compactador Mvh-150d2Dokumen64 halamanMotor Yanmar l48v6 Compactador Mvh-150d2Mas Inyeccion ElectronicaBelum ada peringkat

- Assignment AASDokumen2 halamanAssignment AASdean016026Belum ada peringkat

- Test FireDokumen11 halamanTest FireMario UyBelum ada peringkat

- BTS Ac SystemDokumen40 halamanBTS Ac Systemmohsinaliqureshi02Belum ada peringkat

- 2013 Tuckwell Roberts toolemeraDokumen282 halaman2013 Tuckwell Roberts toolemeracrm102bBelum ada peringkat

- Weight Optimization of Buck Stays Using PDFDokumen4 halamanWeight Optimization of Buck Stays Using PDFIvan Fernando MosqueraBelum ada peringkat

- Traction CONTROLDokumen18 halamanTraction CONTROLkiransideasBelum ada peringkat

- Machine Glass Thermometers Model 32, V-Form: ApplicationsDokumen5 halamanMachine Glass Thermometers Model 32, V-Form: ApplicationschauBelum ada peringkat

- Lgi Tungsten Tube Bulb Array Reflector Shield / Device For 16 Tube Holders Model - Lgi 16.05.2017ad, 03.45amDokumen7 halamanLgi Tungsten Tube Bulb Array Reflector Shield / Device For 16 Tube Holders Model - Lgi 16.05.2017ad, 03.45amPierre Le GrandeBelum ada peringkat

- Case Study-Corrosion ProtectionDokumen25 halamanCase Study-Corrosion ProtectionAjeng Fadillah100% (1)

- PDFDokumen48 halamanPDFDental LabBelum ada peringkat

- IRTracer 100 Brochure C103 E091Dokumen28 halamanIRTracer 100 Brochure C103 E091Mariela VeraBelum ada peringkat

- PDK 205481 KW26-S5-FSE-4Q enDokumen83 halamanPDK 205481 KW26-S5-FSE-4Q enRoberto SacotoBelum ada peringkat

- Machinist Hammers and Tools Product ListingDokumen34 halamanMachinist Hammers and Tools Product ListingFJH ALZBelum ada peringkat

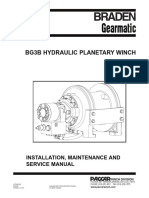

- Braden Bga06 Manual de PartesDokumen24 halamanBraden Bga06 Manual de PartesMauricio Ariel H. OrellanaBelum ada peringkat

- dgr10 2020 07 01Dokumen16 halamandgr10 2020 07 01Data CentrumBelum ada peringkat

- A Review of Hydrogen UsageDokumen12 halamanA Review of Hydrogen UsageRonnie GenezBelum ada peringkat

- TCL - Split System - AC - Owners - ManualDokumen39 halamanTCL - Split System - AC - Owners - ManualNicole WintBelum ada peringkat

- Igcse e Electricity With MSCDokumen94 halamanIgcse e Electricity With MSCaliBelum ada peringkat

- Plan Your Visit PDFDokumen6 halamanPlan Your Visit PDFiyer34Belum ada peringkat

- Laboratory Apparatus For Evaluating Slurry Pipeline Wear (Cooke, Johnson & Goosen)Dokumen17 halamanLaboratory Apparatus For Evaluating Slurry Pipeline Wear (Cooke, Johnson & Goosen)Engr Sakher100% (1)

- AS 2187 - Terminology PDFDokumen29 halamanAS 2187 - Terminology PDFkrainaoz2011Belum ada peringkat

- Hitachi Shirokuma floor-mounted air conditioner features and benefitsDokumen2 halamanHitachi Shirokuma floor-mounted air conditioner features and benefitsCristian TopalaBelum ada peringkat

- Optimization of Kerf Quality During Pulsed Laser Cutting of Aluminium Alloy SheetDokumen7 halamanOptimization of Kerf Quality During Pulsed Laser Cutting of Aluminium Alloy SheetSyafril AbdillahBelum ada peringkat

- Overhead InsulatorsDokumen17 halamanOverhead InsulatorskpchakralaBelum ada peringkat