Managing Quality in Decentralised Manufacturing

Diunggah oleh

Manish Gupta0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

48 tayangan17 halamanquality management

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPT, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Iniquality management

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

48 tayangan17 halamanManaging Quality in Decentralised Manufacturing

Diunggah oleh

Manish Guptaquality management

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 17

Quality in Small Scale Industry:

Fashion Industry Perspective

Importance of Quality

All of us know it

Needs no debate

Most of us are here to share our

experiences on Quality

Many organizations represented

here have an ongoing Quality

program

Journey Towards Total Quality

and ISO 9000

A well-defined milestone in the endless

journey towards Total Quality

Credibility Brought in by third party

certification

Quality in SSI:

May be most used term But it is least

understood

Commonsense that is not common

It is like ten blind men describing an

elephant

Presentation by Rajesh Bheda , GMT,NIFT at WCTQ 1999

Key Concerns of International

Apparel Buyers

Product Quality

Dependable Delivery

Competitive Price

Better Quality at lower price

I ncreasing Quality Expectations Among

Apparel I mporters and Retailers

Consumers Quality Expectations have

gone up

Consumer is too busy to come back to

complain

Not Interested in Taking Special Care of the

Product

Reduced Consumer Spending on Apparel

Stores Cant Afford a Dissatisfied Customer

Working With Non-quality Vendors Costly

Consumers perception of

Quality

A recently conducted research

concludes that Quality of

Apparel sold in the US market

has declined

Presentation by Rajesh Bheda , GMT,NIFT at WCTQ 1999

Apparel Industry:

Order quantities are reducing continually

Highly labor intensive processes

Labor controlled, not machine controlled processes

Varied raw material

Seasonal products with low shelf life

Largely decentralized manufacturing

Reserved for SSI

Q: Why do you face quality

problems?

A: We have no problems but our

suppliers dont understand

quality

sub-contractors are not bothered

about quality

Key to Quality in Apparel

Industry :Process Capability

Without Process capability Quality can not

be expected

It is the responsibility of top management to

ensure the process capability of different

process groups

Presentation by Rajesh Bheda , GMT,NIFT at WCTQ 1999

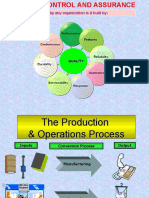

PLANT & MACHINERY

TRAINING

MOTIVATED PEOPLE

KNOW-HOW

SKILLS

QUALITY

INPUT

=

RAW MATERIAL

+

SPECIFICATIONS

QUALITY

OUTPUT

=

PROCESSED

COMPONENT

OR

GARMENTS

PROCESS MODEL FOR SEWING

Presentation by Rajesh Bheda , GMT,NIFT at WCTQ 1999

Team Working: An Asset for

Process Capability

The Process Model

Organic / Flexible

Non-hierarchical

Self Learning & Self

Correcting

Knowledge Driven

Presentation by Rajesh Bheda , GMT,NIFT at WCTQ 1999

INPUT

PROCESS CHAIN

OUTPUT

=

PROCESS A PROCESS B

Output of previous process becomes input to next process.

No substandard input to be given to any process.

No process shall allow sub standard output to come out.

The Benefits

Promotes Knowledge Workers

Right first time

Reduced Inspection

Increased Flexibility

Minimum Repairs and Rejects

Increased Productivity

Reasons for Failure

Belief that Quality starts with inspection and ends with inspection

Mainly quantity driven targets for the departments

Departmental goals may not synergise with organizational goal

Have no idea about the Cost of Quality in their organization

Do not have a clear quality policy nor do they demonstrate

commitment to quality

Employees of these organizations are well aware of the Chalta Hai

approach of the management

To the extent possible they would like to blame others for the quality

problems of their merchandise

Choice is yours!

Promote Process

Capability in the Total

Supply Chain

Or

Wait for the Disaster

Anda mungkin juga menyukai

- TQM and Quality DefinitionsDokumen50 halamanTQM and Quality DefinitionssiddharthtiroleBelum ada peringkat

- 4 3 Achieving Quality ProductionDokumen2 halaman4 3 Achieving Quality Productionaboudd30Belum ada peringkat

- OM Chapter FiveDokumen67 halamanOM Chapter FiveLakachew GetasewBelum ada peringkat

- Quality Management Highlights and DefinitionsDokumen23 halamanQuality Management Highlights and DefinitionsakshaynnaikBelum ada peringkat

- ASQ Six SigmaDokumen536 halamanASQ Six Sigmadmrpanda9940100% (2)

- Experiment:-4: Topic:-Total Quality ManagementDokumen21 halamanExperiment:-4: Topic:-Total Quality ManagementAniket A. MestryBelum ada peringkat

- 12 - Project Quality Management 2Dokumen36 halaman12 - Project Quality Management 2Aftab AhmedBelum ada peringkat

- World Class Quality Management: Group:AlphaDokumen11 halamanWorld Class Quality Management: Group:AlphaKripa NairBelum ada peringkat

- MNG6102 - OM - Session 7 - Lecture Slides - Quality Management and Quality Control - Case StudyDokumen59 halamanMNG6102 - OM - Session 7 - Lecture Slides - Quality Management and Quality Control - Case Studyhenry brandonBelum ada peringkat

- Introduction to SPCDokumen20 halamanIntroduction to SPCComputer Maintainance Hardware and softwareBelum ada peringkat

- Session 1Dokumen19 halamanSession 1Avantika SinghBelum ada peringkat

- Chapter 17 Implementing Quality ConceptsDokumen14 halamanChapter 17 Implementing Quality ConceptsCelestaire LeeBelum ada peringkat

- TQM ReportDokumen22 halamanTQM ReportMarco LacapBelum ada peringkat

- Dasar TQMDokumen27 halamanDasar TQMIzzati WindaBelum ada peringkat

- Quality Management EssentialsDokumen59 halamanQuality Management EssentialsKentDemeterio100% (7)

- Quality ManagementDokumen59 halamanQuality ManagementminisonyBelum ada peringkat

- Chapter 9Dokumen33 halamanChapter 9Denise BaterinaBelum ada peringkat

- MMZG 522 Total Quality Management: BK RoutDokumen97 halamanMMZG 522 Total Quality Management: BK Routsudar1477Belum ada peringkat

- HistoryDokumen12 halamanHistoryChristine SalazarBelum ada peringkat

- Lean Production & Quality Management - DONEDokumen32 halamanLean Production & Quality Management - DONEradhikaiyerBelum ada peringkat

- Understanding Total Quality Management (TQM) Perspectives and EvolutionDokumen10 halamanUnderstanding Total Quality Management (TQM) Perspectives and Evolutionpatricia navasBelum ada peringkat

- Total Quality ManagementDokumen97 halamanTotal Quality ManagementRodiemerBelum ada peringkat

- BSE TQM Review Material 09oct2021Dokumen37 halamanBSE TQM Review Material 09oct2021Maria MiguelBelum ada peringkat

- Quality Philosophies and StandardsDokumen50 halamanQuality Philosophies and StandardsAsim QayyumBelum ada peringkat

- TQM MidtermDokumen51 halamanTQM MidtermcutierineeeBelum ada peringkat

- TQM in Service SectorDokumen21 halamanTQM in Service SectorPushkar MathureBelum ada peringkat

- Quality l1Dokumen22 halamanQuality l1api-53255207Belum ada peringkat

- Quality, Quality Control and Quality ManagementDokumen91 halamanQuality, Quality Control and Quality Managementsaurabh das100% (1)

- Lesson 1 Overview of TQMDokumen30 halamanLesson 1 Overview of TQMGlycel GayatinBelum ada peringkat

- Operation ManagementDokumen129 halamanOperation ManagementVishwanath SN100% (1)

- TQM3Dokumen10 halamanTQM3Rio Aristo BirawaBelum ada peringkat

- Business IG Section 4.3 Achieving Quality Production, Section 4.4 Location Decisions, Section 5.1 Business Finance - Neeeds and SourcesDokumen17 halamanBusiness IG Section 4.3 Achieving Quality Production, Section 4.4 Location Decisions, Section 5.1 Business Finance - Neeeds and SourcesJuné MaraisBelum ada peringkat

- TQM Total Quality Management Concepts and ImplementationDokumen37 halamanTQM Total Quality Management Concepts and ImplementationAshutosh SrivastavaBelum ada peringkat

- Total Quality Management (TQM) Definition and Customer SatisfactionDokumen30 halamanTotal Quality Management (TQM) Definition and Customer SatisfactionnalinijevalBelum ada peringkat

- Quality Management 010Dokumen70 halamanQuality Management 010Muhammad AsfarBelum ada peringkat

- QUALITY CONTROL ASSURANCEDokumen117 halamanQUALITY CONTROL ASSURANCENarendra100% (1)

- Quality Management EssentialsDokumen62 halamanQuality Management EssentialsShishir GyawaliBelum ada peringkat

- PresntDokumen193 halamanPresntSrinidhikumar KumarBelum ada peringkat

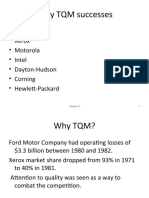

- Early TQM Successes: - Nashua - Xerox - Motorola - Intel - Dayton-Hudson - Corning - Hewlett-PackardDokumen31 halamanEarly TQM Successes: - Nashua - Xerox - Motorola - Intel - Dayton-Hudson - Corning - Hewlett-Packardrocks tusharBelum ada peringkat

- Day1 - Course IntroductionDokumen12 halamanDay1 - Course IntroductionPaul StarkBelum ada peringkat

- AV Feigenbaum1Dokumen34 halamanAV Feigenbaum1Manju SebastianBelum ada peringkat

- Unit - 1Dokumen55 halamanUnit - 1Puneeth RajBelum ada peringkat

- Topic 1 - Total Quality in OrganizationDokumen28 halamanTopic 1 - Total Quality in OrganizationCBelum ada peringkat

- Ch1 TQM DR Hesham For OaklandDokumen20 halamanCh1 TQM DR Hesham For OaklandAnum Nadeem GillBelum ada peringkat

- Total Quality Management Chapter 1Dokumen49 halamanTotal Quality Management Chapter 1Princess Ria Generalao OhinaBelum ada peringkat

- Quality Management and EthicsDokumen67 halamanQuality Management and EthicsRajabBelum ada peringkat

- WK7 QualityDokumen33 halamanWK7 QualityKohi BangBelum ada peringkat

- 1foundations of Quality ManagementDokumen80 halaman1foundations of Quality ManagementmiguelBelum ada peringkat

- Quality Control and Quality AssuranceDokumen22 halamanQuality Control and Quality Assurancearun231187Belum ada peringkat

- QualityDokumen25 halamanQualitygsidhu156276Belum ada peringkat

- 5.3 Lean Production and Quality MNGDokumen71 halaman5.3 Lean Production and Quality MNGfm017225Belum ada peringkat

- Quality assurance and control ensure high standardsDokumen16 halamanQuality assurance and control ensure high standardsmuhibBelum ada peringkat

- Unit Iv: Continuous Improvement: by N.GunasekaranDokumen26 halamanUnit Iv: Continuous Improvement: by N.GunasekaranAravind GiriBelum ada peringkat

- BASIC CONCEPTS OF QUALITY MANAGEMENTDokumen65 halamanBASIC CONCEPTS OF QUALITY MANAGEMENTShery Butt67% (6)

- Managing Quality and Reducing CostsDokumen50 halamanManaging Quality and Reducing CostsTrung Trần ĐứcBelum ada peringkat

- Unit 1quality ConceptsDokumen27 halamanUnit 1quality ConceptsManish PakhideBelum ada peringkat

- Introduction to Quality Definitions and ConceptsDokumen19 halamanIntroduction to Quality Definitions and ConceptsAmim FatmiBelum ada peringkat

- Systems and Techniques Used in Production Management: Topic 5Dokumen21 halamanSystems and Techniques Used in Production Management: Topic 5Frank Eric ZombokoBelum ada peringkat

- Seven Essentials of Supplier Quality Management A Concise Guide: A systematic approach in managing supplier towards delivering zero-defect material consistentlyDari EverandSeven Essentials of Supplier Quality Management A Concise Guide: A systematic approach in managing supplier towards delivering zero-defect material consistentlyPenilaian: 4 dari 5 bintang4/5 (2)

- Critical Path MethodDokumen31 halamanCritical Path MethodManish GuptaBelum ada peringkat

- Project ManagementDokumen29 halamanProject ManagementManish GuptaBelum ada peringkat

- Feasibilty ReportDokumen30 halamanFeasibilty ReportManish GuptaBelum ada peringkat

- Standard Costs & Variance-AnalysisDokumen33 halamanStandard Costs & Variance-AnalysisManish GuptaBelum ada peringkat

- Is Youth Brand ConsciousDokumen6 halamanIs Youth Brand ConsciousManish GuptaBelum ada peringkat

- SEO-Optimized Title for Konkan Railway Project Management DocumentDokumen30 halamanSEO-Optimized Title for Konkan Railway Project Management DocumentManish GuptaBelum ada peringkat

- Production ManagementDokumen15 halamanProduction ManagementManish GuptaBelum ada peringkat

- Joint Venture & AcquisitionDokumen18 halamanJoint Venture & AcquisitionManish GuptaBelum ada peringkat

- Linear ProgrammingDokumen19 halamanLinear ProgrammingManish GuptaBelum ada peringkat

- Jurnal 3 Lingkungan BisnisDokumen18 halamanJurnal 3 Lingkungan BisnisGladys GanestyaBelum ada peringkat

- ErpDokumen6 halamanErpManish GuptaBelum ada peringkat

- Production and Operations ManagementDokumen21 halamanProduction and Operations ManagementGaurav218100% (4)

- Krishna Mishra (07) Manish Kumar (11) B.F.Tech - 6 (2011-15) : Prepared byDokumen16 halamanKrishna Mishra (07) Manish Kumar (11) B.F.Tech - 6 (2011-15) : Prepared byManish Gupta100% (3)

- Maintenance Management: Key Performance Indicators: Measuring and Managing The Maintenance FunctionDokumen19 halamanMaintenance Management: Key Performance Indicators: Measuring and Managing The Maintenance FunctionManish Gupta100% (5)

- Labor CostDokumen20 halamanLabor CostManish GuptaBelum ada peringkat

- Joint Venture & AcquisitionDokumen18 halamanJoint Venture & AcquisitionManish GuptaBelum ada peringkat

- Sewing MachineDokumen243 halamanSewing MachineRAHUL1639840% (5)

- Maintenance ManagementDokumen27 halamanMaintenance ManagementManish GuptaBelum ada peringkat

- Apparel Quality ManagementDokumen24 halamanApparel Quality ManagementManish GuptaBelum ada peringkat

- Line Balancing PresentationDokumen42 halamanLine Balancing PresentationGlenn RebelloBelum ada peringkat

- Banswara GarmentsDokumen14 halamanBanswara GarmentsManish GuptaBelum ada peringkat

- Preperatory ProcessesDokumen47 halamanPreperatory ProcessesManish GuptaBelum ada peringkat

- Improvingtheproductivityandintroducingtheworkstudy 130827160702 Phpapp02Dokumen27 halamanImprovingtheproductivityandintroducingtheworkstudy 130827160702 Phpapp02Manish GuptaBelum ada peringkat

- Project ManagementDokumen29 halamanProject ManagementKumar AnkurBelum ada peringkat

- BA 117 Strategy, Balanced Scorecard CaseDokumen23 halamanBA 117 Strategy, Balanced Scorecard CaseFrancisCzeasarChuaBelum ada peringkat

- BA 117 Strategy, Balanced Scorecard CaseDokumen23 halamanBA 117 Strategy, Balanced Scorecard CaseFrancisCzeasarChuaBelum ada peringkat

- Leadtimereductionintextileindustry 120207225943 Phpapp01Dokumen20 halamanLeadtimereductionintextileindustry 120207225943 Phpapp01Manish GuptaBelum ada peringkat

- Grey Room OperationDokumen58 halamanGrey Room OperationNahid KhannaBelum ada peringkat

- Armand Vallin FeigenbaumDokumen9 halamanArmand Vallin FeigenbaumManish GuptaBelum ada peringkat

- Reinvigorate Gordon's Gin with "InnervigorationDokumen26 halamanReinvigorate Gordon's Gin with "InnervigorationnanapokuahBelum ada peringkat

- Tariff 2013Dokumen398 halamanTariff 2013scribd99190Belum ada peringkat

- Countable Uncountable NounsDokumen1 halamanCountable Uncountable NounsMaría Verónica Salinas56% (9)

- A Project Report On Leisure WearDokumen20 halamanA Project Report On Leisure WearBratesh PradhanBelum ada peringkat

- LogisticsDokumen15 halamanLogisticskruzipBelum ada peringkat

- Eden Harvest Festival and Souced Pilchads Sardines and SanjayDokumen2 halamanEden Harvest Festival and Souced Pilchads Sardines and SanjayProsenjit76Belum ada peringkat

- Cabana Catering MenuDokumen12 halamanCabana Catering MenuMax DrinkerBelum ada peringkat

- Factors Affecting Mayur Suitings SalesDokumen88 halamanFactors Affecting Mayur Suitings SalesSwapnil KadamBelum ada peringkat

- Supply Chain ExamplesDokumen3 halamanSupply Chain Examplesmano555Belum ada peringkat

- Kimberly-Clark Company Case Assign4Dokumen3 halamanKimberly-Clark Company Case Assign4Ahmad Elsayed MohammedBelum ada peringkat

- Portwest Hats PS53Dokumen2 halamanPortwest Hats PS53Arun RavindranBelum ada peringkat

- SWOT Analysis: StrengthsDokumen4 halamanSWOT Analysis: Strengthsassign hub100% (1)

- Dishwasher Manual SummaryDokumen29 halamanDishwasher Manual Summaryandreea_vornicu25Belum ada peringkat

- West African TextilesDokumen33 halamanWest African TextilesDaniel Shivas100% (1)

- AC V For Fast Food RestaurantsDokumen4 halamanAC V For Fast Food Restaurantselijah namomoBelum ada peringkat

- Din/Fem: Tower Crane / Grue À Tour / Gru A Torre Guindaste de Torre Grúa TorreDokumen6 halamanDin/Fem: Tower Crane / Grue À Tour / Gru A Torre Guindaste de Torre Grúa Torremanuelfer1985Belum ada peringkat

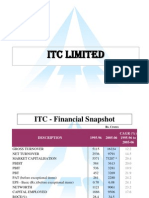

- ITCDokumen47 halamanITCHarshit KatwalaBelum ada peringkat

- Requiem For A Dream (2000)Dokumen114 halamanRequiem For A Dream (2000)Rohan Bhasin100% (1)

- Project IN Practical Research 1: Grade 11 - Abm 1 Group 2Dokumen20 halamanProject IN Practical Research 1: Grade 11 - Abm 1 Group 2Justin100% (1)

- Group Project on E-Commerce in IndiaDokumen53 halamanGroup Project on E-Commerce in IndiaAmit Singh100% (2)

- Management Thesis of Customer Perception On PantaloonDokumen60 halamanManagement Thesis of Customer Perception On PantaloonSaurav GoyalBelum ada peringkat

- Jess' Recipe BookDokumen67 halamanJess' Recipe Bookmvrettas23Belum ada peringkat

- Wc565176@ssu - Edu: Bob & Dorie Sheldon 420 Walker Road Great Falls, VA 22066 703-819-7515 Cell/textDokumen3 halamanWc565176@ssu - Edu: Bob & Dorie Sheldon 420 Walker Road Great Falls, VA 22066 703-819-7515 Cell/textDaniel FioreBelum ada peringkat

- TLE 6 First Quarter Summative With TOSDokumen9 halamanTLE 6 First Quarter Summative With TOSjuvy0% (1)

- Li & Fung LTDDokumen7 halamanLi & Fung LTDSai VasudevanBelum ada peringkat

- Business PlanDokumen16 halamanBusiness PlanHamid Asghar100% (1)

- Novapol TF 0338 e NovaDokumen2 halamanNovapol TF 0338 e NovaJulio GarcíaBelum ada peringkat

- Product MixDokumen16 halamanProduct Mixvinod_auraBelum ada peringkat

- Physical AppearanceDokumen4 halamanPhysical AppearanceAntonella Saenz OrbegosoBelum ada peringkat

- MM Case StudyDokumen5 halamanMM Case StudyPurushottam NanjappaBelum ada peringkat