Corrosion Prevention

Diunggah oleh

Mujahid Haddad0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

43 tayangan53 halamanMethods of preventing corrosion

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPT, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniMethods of preventing corrosion

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

43 tayangan53 halamanCorrosion Prevention

Diunggah oleh

Mujahid HaddadMethods of preventing corrosion

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 53

J ordan University of Science and Technology

Department of Chemical Engineering

CORROSION PREVENTION

CORROSION PREVENTION

METALS AND ALLOYS

Stainless steel is not stainless, it is not the

most corrosion-resistant material, and it is

not a specific alloy.

( from 11.5 to 30% chromium and from zero

to 22% nickel, together with other alloy

additions).

In chloride-containing mediums and stressed

structures, stainless steels are less resistant

than ordinary structural steel.

Stainless steel alloys are more susceptible to

localized corrosion such as intergranular

corrosion, stress-corrosion cracking, and

pitting attack than ordinary structural steels.

Stainless steels represent a class of highly

corrosion-resistant materials of relatively low

cost that should be carefully used.

NATURAL (METAL-CORROSIVE) COMBINATIONS:

The maximum amount of corrosion

resistance for the least amount of money:

Stainless steels - nitric acid.

Nickel and nickel alloys caustic soda.

Monel hydrofluoric acid.

Hastelloys (Chromites) hot hydrochloric

acid.

Lead dilute sulfuric acid.

Aluminum no staining atmospheric

exposure.

Tin distilled water

Titanium hot strong oxidizing solutions.

Tantalum ultimate resistance.

Steel concentrated sulfuric acid.

Tantalum is resistant to most acids at all

concentrations and temperatures and is

generally used under conditions where

minimal corrosion is required, such as

implants in human body.

Both tantalum and glass are resistant to

virtually all mediums except hydrofluoric

acid and caustic solutions.

Manufacturers of glass-lined equipment use

tantalum plugs to seal defects since this

material matches the resistance of glass.

For reducing or non-oxidizing environments,

such as air-free acids and aqueous solutions,

nickel, copper, and their alloys are employed.

For oxidizing conditions, chromium-

containing alloys are used.

For extremely powerful oxidizing conditions,

titanium and its alloys have shown superior

resistance.

METAL PURIFICATION

Pure metals are usually expensive and

relatively soft and weak, but more

corrosion resistant.

Pure aluminum (99.5%+) is used for handling

hydrogen peroxide, where the presence of

other elements may cause decomposition

because of catalytic effects.

Arc-melted zirconium is more resistant than

induction-melted zirconium because of more

impurities in the latter. Therefore, it is used in

an atomic-energy applications where a little

corrosion is too much.

NON-METALLICS

Rubber, natural and synthetic.

Plastics.

Ceramics.

Carbon and graphite.

Wood.

Rubbers and plastics, as compared with

metals and alloys, are much weaker, softer,

more resistant to chloride ions and HCl, less

resistant to strong sulfuric acid and oxidizing

acids such as nitric, less resistant to solvents,

and have relatively low temperature

limitations (170 oF to 200 oF for most).

Ceramics possess excellent corrosion and

high-temperature resistant.

Carbon show good corrosion resistance,

electrical and heat conductivity, but they are

fragile.

Wood is attacked by aggressive environments.

ALTERATION OF ENVIRONMENT

** Changing Mediums:

Lowering temperature, decreasing velocity,

removing oxygen or oxidizers and changing

concentration.

Boiling seawater is less corrosive than hot

seawater because of the decrease in oxygen

solubility with temperature.

Metals and alloys that passivate (e.g., st.st.),

generally have better resistance to flowing

mediums than stagnant solutions.

Very high velocities cause erosion-corrosion

effects.

Nickel-molybdenum alloys (Hastelloy B,

chlorimet 2) posses excellent resistance in

pure hydrochloric acid.

HCl containing ferric chloride as an oxidizer

impurity (called muriatic acid), rapidly

corrodes nickel-molybdenum alloys.

Dearation is not recommended for active-

passive metals or alloys.

Decreasing corrosive concentration is usually

effective.

Many acids such as H2SO4 and H3PO4 are

virtually inert at high concentrations at

moderate temperatures.

INHIBITORS:

Adsorption-Type Inhibitors:

These are organic compounds which

adsorbed on the metal surface and suppress

metal dissolution and reduction reactions.

They affect both the anodic and cathodic

processes. (organic amines).

Hydrogen-Evolution Poisons:

Arsenic and antimony ions, retard the

hydrogen-evolution reaction.

They are effective in acid solutions but are

ineffective in environments where other

reduction processes such as oxygen reduction

are the controlling cathodic reactions.

Scavengers:

These substances act by removing corrosive

reagents from sol;ution.

Na2SO3 + O2 2Na2SO4

N2H4 + O2 N2 + 2H2O

Sodium sulfate and hydrazine will not be

effective in strong acid solution, because

oxygen reduction is not the controlling

corrosion cathodic reaction.

Oxidizers:

They inhibit the corrosion of metals and

alloys that demonstrate active-passive

transitions (i.e., iron and its alloys and

stainless steels).

Chromate, nitrate and ferric salts are

oxidizers inhibitors.

Vapor-Phase Inhibitors:

They are usually used in closed spaces such as

inside packages or on the interior of

machinery during shipment, because they are

transferred by sublimation and condensation

to the metal surface.

Inhibitors should be added in excess and their

concentration checked periodically, because

less inhibiting agents accelerate corrosion.

When two or more inhibiting substances are

added to a corrosive system, the inhibiting

effect is sometimes greater than that which

would be achieved by either of the two (or

more) substances alone. This is called a

synergistic effect.

Many inhibitors are toxic, and their

application is limited to those mediums that

will not be used directly or indirectly in the

preparation of food or other products that

will come in contact with humans.

Arsenic salts exert a powerful inhibiting

effect in strong acids, but toxic.

Inhibitors generally rapidly loss their

effectiveness as the concentration and

temperature of the environment increase.

Design

Mechanical design of a component should be

based on the material of construction.

** Wall Thickness

The wall thickness is usually made twice the

thickness that would give the desired life, to

allow for some variation in the depth of

penetration during uniform corrosion, which

is not always uniform.

The wall thickness must meet mechanical

requirements such as pressure, weight, and

stress considerations.

The bottom portion may have more corrosion

allowance than the upper.

Weld rather than rivet tanks and other

containers to avoid crevice corrosion.

Design tanks and other containers for easy

draining and easy cleaning.

(steel tank H2SO4 +air adsorb

moisture dilution rapid attack).

Design systems for easy replacement of

components that are expected to fail rapidly

in service.

Avoid excessive mechanical stresses in

components exposed to corrosive mediums to

avoid stress-corrosion cracking.

Avoid galvanic electrical contact between

dissimilar metals to prevent galvanic

corrosion.

Avoid sharp bends in piping systems when

high velocities and/or solids in suspension are

involved to avoid erosion-corrosion cracks.

Provide thicker structures to take care of

impingement effects.

Make sure materials are properly selected.

Avoid spots during heat-transfer operations

to avoid local heating and high corrosion

rates and stress-corrosion failures.

Design to exclude air, except for active-

passive metals and alloys, such as stainless

steel and titanium.

Avoid heterogeneity: Dissimilar metals, vapor

spaces, uneven heat and stress distributions.

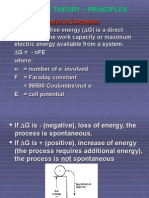

Anodic Protection

It is the prevention of corrosion by

impressed anodic current.

The potential of the structure can be

maintained constant by a constant

potential device called a potentiostat.

At the corrosion potential, applied current

density is zero, and the corrosion rate is 100

A/cm2.

Since Mixed-potential theory requires

charge conservations, then iapp=ia-ic

If the potential increased to E1 with a

potentiostat, an iapp of 999 A/cm2 is

required.

o At E2, iapp=9999 A/cm2.

o At E3, iapp=0.9 A/cm2.

o At the optimum potential E4, iapp= 1 A/cm2,

which is equal to the corrosion rate at this

potential

o Anodic protection is much more efficient

than cathodic protection.

A potentiostat is an electronic device that

maintains a metal at a constant potential

with respect to a reference electrode.

The optimum potential for protection is

determined by electrochemical

measurements.

Anodic protection is limited to passive metals

or alloys.

It is used in extremely corrosive

environments and requires low current.

Cathodic protection is achieved by

supplying electrons to the metal structure

to be protected.

The addition of electrons to the structure

will tend to suppress metal dissolution

and increase the rate of hydrogen

evolution.

CATHODIC PROTECTION

If current is considered to be flow from

(+) to (-), as in conventional electrical

theory, then a structure is protected if

current enters it from the electrolyte and

vice versa.

There are two ways to cathodically

protect a structure

1. by an external power supply

2. by appropriate galvanic coupling

The anode is usually surrounded by backfill

consisting of coke breeze, gypsum, or

bentonite , soil to improve electric contact

between the anode and surrounding soil.

Cathodic protection using sacrificial anodes

can also be used to protect buried pipe

lines.

Protective currents are usually determined

empirically

The anodes are spaced along the pipe to

ensure uniform current distribution

1

In such cases , trial and error adjustment of

anode size or applied current can be made

until satisfactory protection is achieved.

A more accurate and less time

consuming approach is to be measure

the potential of the protected

structure with a suitable reference

electrode.

The reference-electrode is placed in

the ground or on a sponge in brine to

make electrical contact.

If a metallic object is placed in a strong

current field, a potential difference

develops across it and accelerated

corrosion occurs at points where current

leaves the object and enters the soil.

Steel structure exposed to soils, fresh

and brackish water, and seawater are

protected if they are polarized to 0.85

volts versus a copper-copper sulfate

reference electrode.

Anda mungkin juga menyukai

- Mujahid v1904Dokumen3 halamanMujahid v1904Mujahid HaddadBelum ada peringkat

- Che 452 General Approach To Model Formulation and Problem SolvingDokumen1 halamanChe 452 General Approach To Model Formulation and Problem SolvingMujahid HaddadBelum ada peringkat

- ReactionDokumen14 halamanReactionMujahid HaddadBelum ada peringkat

- Chapter 5 Leaching PDFDokumen13 halamanChapter 5 Leaching PDFrosesahawnehBelum ada peringkat

- General Introduction: Chapter Four ExtractionDokumen19 halamanGeneral Introduction: Chapter Four ExtractionMujahid HaddadBelum ada peringkat

- Chapter6 Material ScienceDokumen12 halamanChapter6 Material ScienceMujahid HaddadBelum ada peringkat

- Chapter Seven Water Cooling TowersDokumen5 halamanChapter Seven Water Cooling TowersMujahid HaddadBelum ada peringkat

- Modern Theory of CorrosionDokumen98 halamanModern Theory of CorrosionMujahid HaddadBelum ada peringkat

- Principles of CorrosionDokumen15 halamanPrinciples of CorrosionMujahid HaddadBelum ada peringkat

- Chapter1 - Introduction and Basic ConceptsDokumen36 halamanChapter1 - Introduction and Basic ConceptsMujahid HaddadBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Chemistry 2nd Edition Tro Test BankDokumen27 halamanChemistry 2nd Edition Tro Test BankHandugan Quinlog NoelBelum ada peringkat

- Ncert Sol For Cbse Class 9 Sci Chapter 4 Structure of The AtomDokumen18 halamanNcert Sol For Cbse Class 9 Sci Chapter 4 Structure of The AtomShah RukhBelum ada peringkat

- Libro de Calculos MetalurgicosDokumen718 halamanLibro de Calculos Metalurgicosjoegb2919Belum ada peringkat

- Toxicologiacal Fluorides PDFDokumen404 halamanToxicologiacal Fluorides PDFMoisés MotaBelum ada peringkat

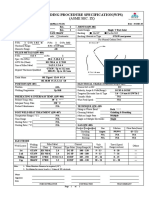

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Dokumen3 halamanWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- BAS Castings - Ni Resist CA..Dokumen3 halamanBAS Castings - Ni Resist CA..vijay2bhagyaBelum ada peringkat

- History of The Periodic Table (G8)Dokumen30 halamanHistory of The Periodic Table (G8)pipznraviBelum ada peringkat

- The Chemistry Name GameDokumen18 halamanThe Chemistry Name GameBrandon Baxter100% (1)

- Metals and AlloysDokumen7 halamanMetals and Alloysjovi manabatBelum ada peringkat

- Lab Report: Experiment 2: Understand The Changes in Terms of Chemical and Physical PropertiesDokumen2 halamanLab Report: Experiment 2: Understand The Changes in Terms of Chemical and Physical PropertiesAriful IslamBelum ada peringkat

- Classification Tests For Hydroxyl and Carbonyl Containing CompoundsDokumen5 halamanClassification Tests For Hydroxyl and Carbonyl Containing CompoundsAcener Padua100% (1)

- Economic Aspects of Carbonatites of India: P. Krishnamurthy, S.Q. Hoda, R.P. Sinha, D.C. Banerjee, K.K. DwivedyDokumen7 halamanEconomic Aspects of Carbonatites of India: P. Krishnamurthy, S.Q. Hoda, R.P. Sinha, D.C. Banerjee, K.K. DwivedyPritam RajBelum ada peringkat

- Salt Analysis: Test For AnionsDokumen7 halamanSalt Analysis: Test For AnionshellozahranBelum ada peringkat

- Properties of Metals StructureDokumen10 halamanProperties of Metals StructureCyril Cauilan50% (2)

- Determination of Ascorbic AcidDokumen4 halamanDetermination of Ascorbic AcidRVV SatyanarayanaBelum ada peringkat

- FittingDokumen16 halamanFittingLALIT 318Belum ada peringkat

- Her DrearyDokumen3 halamanHer DrearyMiera Yushira Yusoff67% (6)

- Qualitative Inorganic Analysis: A New Physico-Chemical ApproachDokumen376 halamanQualitative Inorganic Analysis: A New Physico-Chemical ApproachFrederik RareBelum ada peringkat

- Salt AnalysisDokumen6 halamanSalt AnalysisARTHUR BALAJI RBelum ada peringkat

- FR 1 (E6)Dokumen5 halamanFR 1 (E6)JR CastorBelum ada peringkat

- Aqa Chm6x QP Jun12Dokumen12 halamanAqa Chm6x QP Jun12Georgiana CrivatBelum ada peringkat

- AQA A2 CHEMISTRY TOPIC 5.4 TRANSITION METALS PART 1 COMPLEX IONSDokumen12 halamanAQA A2 CHEMISTRY TOPIC 5.4 TRANSITION METALS PART 1 COMPLEX IONSAdnan ChowdhuryBelum ada peringkat

- US4851160Dokumen7 halamanUS4851160Argo Rizky Kusuma 2007110716Belum ada peringkat

- Chemistry FinalDokumen19 halamanChemistry FinalSarnendu Chattopadhyay100% (1)

- Earth Materials and ProcessesDokumen1 halamanEarth Materials and ProcessesJemarjo SalandananBelum ada peringkat

- Answers/Solutions For Part 1Dokumen3 halamanAnswers/Solutions For Part 1yesBelum ada peringkat

- Classifying Hazardous WastesDokumen8 halamanClassifying Hazardous WastesSirhc ZialcitaBelum ada peringkat

- Soal PISA (Fisika Dan Kimia)Dokumen12 halamanSoal PISA (Fisika Dan Kimia)ristawaniBelum ada peringkat

- A Study On Sulfuric AcidDokumen3 halamanA Study On Sulfuric AcidChing BanKai XiangBelum ada peringkat

- SCIENCE 10 Q4 Module 5 Balancing Chemical EquationsDokumen25 halamanSCIENCE 10 Q4 Module 5 Balancing Chemical EquationsPatrick GalmanBelum ada peringkat