E&I

Diunggah oleh

chirayutrivediJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

E&I

Diunggah oleh

chirayutrivediHak Cipta:

Format Tersedia

Bhavna

What is refining?

Oil or petroleum refinery.

Refining of oil by fractional distillation.

What is refining?

Refining is the process of purification of a substance

or a form by removing impurities or unwanted

elements typically as a part of an industrial process.

Broadly speaking refining of liquids is often

accomplished by distillation or fractionation, gases

by extraction and some solids by growing crystals in a

solution.

Oil Refinery

An oil refinery or petroleum refinery is an industrial

processing plant where crude oil is refined and processed

into more useful products such as petroleum, gasoline,

kerosene, diesel fuel, LPG etc.

An oil refinery is considered an essential part of the

downstream side of petroleum industry.

Oil refineries also produce various intermediate products

like hydrogen, light hydrocarbons, reformate and pyrolysis

gasoline.

Contd.

Oil refineries have extensive pipelines running

through them which carry streams of fluids between

large chemical units.

The crude oil feedstock is typically processed by an

oil production plant.

There is usually an oil depot at or near an oil refinery

for the storage of incoming crude oil feedstock as

well as bulk liquid products.

Difference between oil refinery and

petrochemical plant

A refinery processes crude oil into different

components such as kerosene, gasoline, diesel, LPG

etc.

A petrochemical plant is a chemical plant that will

use a petroleum based feedstock, such as LPG or

other products from a petroleum refinery to produce

a chemical product, such as plastic for example.

Operation

Fractional Distillation is the main operation in an oil

refinery.

Fractional distillation is the process of separation of a

mixture into its component parts or fractions by heating

it at a very high temperature.

The fractions at the top of the fractionating column have

boiling points lower than the fractions at the bottom.

The heavy bottom fractions are often cracked into

lighter, more useful products.

Contd.

However, the lighter elements form explosive vapours in

the fuel tanks and are hazardous.

Thus the hundreds of different hydrocarbon molecules in

crude oil are separated in the refineries into components

which can be used as fuels , lubricants etc in

petrochemical processes.

These processes produce products like plastics,

detergents , solvents and fibers like nylon, polyesters etc

A Fractional Distillation Column

APOORV

Oil Refining Process: Fractional Distillation

Uses of petroleum products

Petroleum derived products used in other

industries

The Oil Refining Process

What is fractional distillation?

Fractional distillation is the separation of a mixture into its

component parts or fractions.

The different hydrocarbon components of crude oil are its

fractions.

Fractional distillation is based on the principle that

different substances boil at different temperatures.

For example, crude oil contains kerosene and naphtha,

which are useful fractions. When you evaporate the

mixture of kerosene and naphtha, and then cool it, the

kerosene condenses at a higher temperature than the

naphtha. As the mixture cools, the kerosene condenses

first, and the naphtha condenses later.

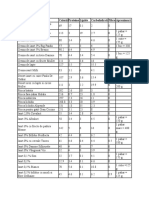

Products of Fractional Distillation

Light

Distillates

Middle

Distillates

Heavy

Distillates

Gases (1-4)

Petrol (7-9)

Naphtha (6-11)

Kerosene (12-16)

Heating oil (15-18)

Petrodiesel (15-18)

Lubricating oil (18-25)

Heavy fuel oil (20-27)

Greases & Wax (25-30)

Bitumen (above 35)

* Figures in brackets indicate number of carbon atoms

per molecule

Uses of Petroleum Products

Gases- Used in making Liquefied Petroleum Gas

(LPG)

Gasoline (Petrol)- Used as Motor fuel.

Naphtha- Used to make solvents & also used in

making high octane petrol.

Kerosene- Used to make ATF (Air Turbine Fuel).

Heating Oil- Used for industrial & domestic

heating.

Petrodiesel- Widely used as a fuel in cars, trains

& military vehicles.

Contd.

Lubricating oil- Lubricants have thousands of uses, from

fixing squeaky doors to oiling industrial machines and

automotive engines.

Heavy fuel oil- These are used in large industrial boilers, in

power stations for example, and to raise steam to drive

turbines on ships. It is also known as Bunker oil.

Greases- Used for lubrication purposes.

Wax- Used to make candles, electrical insulation and

waterproof coverings for food cartons.

Bitumen- This is the heaviest product from the refinery.

When heated, it can be used in road construction and as a

waterproofing material for roofs.

Petroleum derived products used in

other industries

Agriculture- One of the most important uses of

petroleum is in the production of ammonia to be

used as the nitrogen source in agricultural

fertilizers. Pesticides are almost all produced from

oil.

Plastics- Plastic is a staple of modern life. Nylon,

which is in everything from stockings to

mechanical gears and even in car engines, is the

most successful petroleum-based plastic to date.

Most plastics come from olefins, which include

ethylene and propylene.

Contd.

Tires- Synthetic rubber is used for car tires and

rubber soles on shoes. The demand for synthetic

rubber is four times greater than that for natural

rubber.

Pharmaceuticals- Mineral oil and petrolatum are

petroleum by-products used in many creams and

topical pharmaceuticals. Acetylsalicylic acid

(ASA), the active ingredient in many pain reliever

medicines, is manufactured from petrochemicals.

Other Products

One 42-gallon barrel of oil creates 19.4 gallons

of gasoline. The rest is used to make things

like:

Sports items- Basketballs, footballs, golf bags,

golf balls, skiis, roller skates etc.

Consumer products- Shampoo, deodorant,

lipstick, cold creams, shaving creams etc.

Sports car bodies, dashboards & Car enamel.

Cassettes, CD players & Movie films.

Contd.

Plastic wood

Rubber Cement

Antifreeze

Artificial limbs

Anesthetics

Solvents

Linoleum

Abhishek

Refineries

Gross Refining Margin

GRM is the difference between crude oil price

and total value of petroleum products produced by

the refinery.

One of the major parameters to evaluate the

performance of a refinery .

If a refinery receives $80 from the sale of the

products refined from a barrel of crude oil that

costs $70/bbl, then the Refinery Gross Margin is

$10/bbl.

Now suppose if the operating cost of the

refinery and the other accounting losses are

$2/bbl then margin is $8/bbl.

Example

Factors affecting GRM

Cost of sourcing the crude oil.

Manufacturing Reliability and Efficiency

Ability to transport quality fuels.

Nelson complexity.

Customs Duty Structure

Nelson Complexity

The Nelson Index is a measure of the complexity of

an oil refinery. Refineries that are higher on the

Nelson Index are valued higher relative to their

peers.

For example, high Nelson Index refineries may be

able to refine lower quality crude oil, or be capable

of producing higher value end products.

And higher the valuable products higher is the GRM.

How customs duty affects ?

For petro products manufactured in India, oil

refineries in India are paid the import parity

price, the international price plus the insurance

and freight cost plus the customs duty.

Thus, higher the customs duty, higher will be the

gross refining margin.

GRMs of some companies:-

Reliance:- $8.1/bbl ( 4 th quarter of 2013-2014)

BPCL:- $4.7/bbl

IOCL:-$4.24/bbl

Essar Oil :- $7.7/bbl

HPCL:- $3.71/bbl

AZLAAN

The 10 biggest refining countries

1. USA

2. China

3. Russia

4. Japan

5. India

6. South Korea

7. Italy

8. Saudi Arabia

9. Germany

10. Canada

United States possesses the largest refinery

capacity in the world with refinery capacity of 17.38

million barrels per day approximately 18.8% of the

world's total refinery capacity

India holds the world's fifth largest refinery capacity

with 4.1Mbd in 2012, claiming 4.4% of the global

refinery capacity per day. India refined 894,000

barrels of crude oil.

Refining capacity

Shell 4 million barrels/day

ExxonMobile : 1.95 million barrels/day

British petroleum ; 92,531 barrels/day

Global refinery sector this year

The global refining and marketing industry will

continue to see pockets of earnings growth over the

next year, but flat conditions overall, with product

demand expected to increase modestly this year by

1.2 million b/d, according to a recent report from

Moodys. That demand increase will be roughly in

line with net global capacity additions, Moodys said.

The outlook reflects Moodys expectations for the

fundamental business conditions in the industry over

the next 12-18 months, during which time it expects

the R&M sectors earnings before interest, taxes,

depreciation, and amortization (EBITDA) to remain

volatile but to rise by about 8% through mid- to late-

2015

Indias refining capacity;

215.066 MMTPA at present, Comprising-

22 refineries

17 under Public Sector,

3 under private sector

2 in Joint Venture (JV)

INDIAN REFINERY SECTOR -

REFINING CAPACITIES :

IOCL :- 65.7 Million Metric Tonnes per Annum

(MMTPA)

HPCL :- 14.8 Million Metric Tonnes per Annum

(MMTPA).

BPCL :- 20.0 Million Metric Tonnes per Annum

(MMTPA)

Reliance:- 60.0 Million Metric Tonnes per Annum

(MMTPA)

Essar:- 20.0 Million Metric Tonnes per Annum

(MMTPA)

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Presentation 1 of 3pl and 4plDokumen34 halamanPresentation 1 of 3pl and 4plGajendra Behera100% (1)

- 027-ITP For Pre - Cast Concrete PDFDokumen11 halaman027-ITP For Pre - Cast Concrete PDFKöksal Patan75% (4)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Chapter 1 - Traffic VolumeDokumen18 halamanChapter 1 - Traffic VolumeIsuru BiyanwilaBelum ada peringkat

- HMT Deckmaster REV 2 1508 - BrochureDokumen2 halamanHMT Deckmaster REV 2 1508 - BrochureILya KryzhanovskyBelum ada peringkat

- Tabel Calorii LactateDokumen14 halamanTabel Calorii LactateDorina StăetuBelum ada peringkat

- By Order of The Secretary of The Air Force Air Force Instruction 11-2C-130 23 APRIL 2012 Flying Operations C-130 Operations ProceduresDokumen310 halamanBy Order of The Secretary of The Air Force Air Force Instruction 11-2C-130 23 APRIL 2012 Flying Operations C-130 Operations ProceduresAriawan D RachmantoBelum ada peringkat

- BCA 1B - Code of Practice On Buildability-2015 PDFDokumen75 halamanBCA 1B - Code of Practice On Buildability-2015 PDFdelciogarciaBelum ada peringkat

- INS-P-006-Procedure For Inspection of PlatesDokumen4 halamanINS-P-006-Procedure For Inspection of PlatesDeepak100% (1)

- Certificado Classic Ei2 60 1HDokumen20 halamanCertificado Classic Ei2 60 1HenriquefamBelum ada peringkat

- Cause Inefficiency Bus Operation Flow at The Larkin Bus TerminalDokumen61 halamanCause Inefficiency Bus Operation Flow at The Larkin Bus TerminalohferhanisabellaBelum ada peringkat

- Buckingham - BrochureDokumen3 halamanBuckingham - BrochureScott MydanBelum ada peringkat

- Road CoastingDokumen145 halamanRoad CoastingBhavsar NilayBelum ada peringkat

- Aluminum 2024 t351 Sheet SuppliersDokumen13 halamanAluminum 2024 t351 Sheet Supplierssanghvi overseas incBelum ada peringkat

- Data Excel SheetDokumen7 halamanData Excel SheethiteshcparmarBelum ada peringkat

- Container PDFDokumen48 halamanContainer PDFRobertLouisNoyaBelum ada peringkat

- Paper Cup Machine DetailsDokumen7 halamanPaper Cup Machine DetailsTushar NakhateBelum ada peringkat

- Countersink, Counterbore & SpotfaceDokumen8 halamanCountersink, Counterbore & SpotfaceŤhe Đûke100% (1)

- SOP Slump TestDokumen2 halamanSOP Slump TestLloyd R. PonceBelum ada peringkat

- Adhesive TechniquesDokumen12 halamanAdhesive TechniquesNildo TrindadeBelum ada peringkat

- Professional Indemnity InsuranceDokumen20 halamanProfessional Indemnity InsurancevihangimaduBelum ada peringkat

- A Lesson On Tank Gauging On ShipsDokumen29 halamanA Lesson On Tank Gauging On ShipsTJames Paulin100% (1)

- Imperial TubingtoolsntDokumen32 halamanImperial TubingtoolsntvovobossBelum ada peringkat

- Cmci Cmci: Euco-Guard S-40Dokumen2 halamanCmci Cmci: Euco-Guard S-40pravi3434Belum ada peringkat

- 016655Dokumen2 halaman016655James O'SullivanBelum ada peringkat

- Transfennica FleetDokumen18 halamanTransfennica FleetP12321Belum ada peringkat

- HALDIRAM'SDokumen18 halamanHALDIRAM'SRashi KukrejaBelum ada peringkat

- 4 Quality in WeldingDokumen7 halaman4 Quality in WeldingAlaaBelum ada peringkat

- Krishak Bazar at Tehatta-I Block Seed Farm2 (Unhide)Dokumen18 halamanKrishak Bazar at Tehatta-I Block Seed Farm2 (Unhide)Hironmoy DashBelum ada peringkat

- EASA Part-66 Module 7Dokumen5 halamanEASA Part-66 Module 7Prince Sky100% (2)