En 15085 Class

Diunggah oleh

0502raviDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

En 15085 Class

Diunggah oleh

0502raviHak Cipta:

Format Tersedia

Company Certification

Standards in

Welding

What is a code:

A systematic collection of regulations and rules of procedure

IPC Indian Penal Code - It is a comprehensive code, intended to

cover all substantive aspects of criminal law.

IBR Indian Boiler regulation - Regulations in respect of

materials, design and construction, inspection and testing of

boilers and boiler components for compliance by the

manufacturer's and users of boilers in the country.

ASME BPVC Section IX - Welding and Brazing Qualifications

What is a standard:

A Standard can be defined as a set of technical definitions

and guidelines that function as instructions for designers,

manufacturers, operators, or users of equipment.

Different standards adopted :

American Welding Society Standards (AWS)

American petroleum institute standards (API)

Australian / New zealand standards (AS/NZS)

British Standards (BS)

International Organisation for standardisation (ISO)

European Union Standards (EN)

German Standards (DIN)

Bureau of Indian Standards (BIS)

Difference between a code and a

standard

A code is a model, a set of rules that knowledgeable people

recommend for others to follow. It is not a law, but can be

adopted into law.

A standard tends be a more detailed elaboration, the nuts

and bolts of meeting a code.

A standard becomes a Code when it has been adopted by

one or more governmental bodies and is enforceable by law,

or when it has been incorporated into a business contract.

SOME OF THE MANAGEMENT

STANDARD.

ISO 900O -QMS

ISO 14000 -EMS

ISO 18000-Occupational Health and Safety

Management System (OH& S MS) And

International Standard

OHSAS 18001:1999

ISO 27000-ISO/IEC 27002 provides best

practice recommendations on IS security

management systems (ISMS).

EMERGING STANDARDS

ISO-3834 Quality

requirements for fusion

welding of metallic materials.

EN -15085- Welding of

railway vehicles and

components.

IRIS- International Railway

Industry Standard

Welding is a Special Process-Why

7 - Product realization

7.5 Production and service provision

7.5.2 Validation of processes for production and

service provision

The organization shall validate any processes for

production and service provision where the resulting

output cannot be verified by subsequent monitoring or

measurement and as a consequence, deficiencies

become apparent only after the product is in use or the

service has been delivered.

What is ISO-3834&EN 15085

It is an international standard created by the

welding professionals.

ISO 9001 defines requirements for quality

management system

ISO 3834 also defines the quality

requirements, only welded products.

EN 15085 for railway applications.

What is ISO-3834&EN 15085(contd)

The standard specifies the requirements

relating only to the welded structure.

The standard can also be used as a production

control system.

ISO 3834 is not a product standard, but it is

often cited as a requirement of various

products to ensure good practice in the

welding and to prevent premature failures.

What is ISO-3834&EN 15085(contd)

The standards provides details of how to

control the various welding and welding-

related operations to achieve the desired

quality consistently

The company that is certified according to this

standard gains an advantage when competing

with other companies in European and World

wide markets.

What is ISO-3834&EN 15085(contd)

Fusion welding processes are widely used in

many products. In some companies it is a key

manufacturing process. Products may be both

simple and complex, for example, Pressure

vessels, domestic and agricultural equipment,

cranes, bridges, railway transport and other

facilities.

What is ISO-3834&EN 15085(contd)

These processes have a significant impact on

production costs and product quality. It is

important to ensure that these processes are

carried out in the most efficient manner and

that all transactions are properly controlled.

What is ISO-3834&EN 15085(contd)

It is noted that ISO 3834 is not quality

management system standard, which replaces

ISO 9001:2000,

but it may be beneficial to producers in the

application of ISO 9001:2000.

Description of the quality requirements of

welding processes is important as the quality of

these processes is not easy to verify,

because they belong to the ISO 9000:2000 for

special processes.

ISO 3834 part-1 to 4

ISO 3834-1-General requirements

ISO 3834-2- Comprehensive quality

requirement

ISO 3834-3- Standard quality requirement

ISO 3834-4 -elementary quality requirement

ISO 3834-2- Comprehensive quality

requirement

Constructions in which the failure of welds may

lead to

total product failure

with significant financial consequences

Major injury.

The product may be subject to dynamic

loading

In addition to high static loading.

ISO 3834-3- Standard quality

requirement

Constructions in which failure of welds

impair the intended use of construction.

Normal safety risk

Financial losses not extreme.

ISO 3834-4 elementary quality

requirement

Constructions in which failure of welds

Not fundamentally impair the intended use.

No adverse effects on safety of people

Minor financial consequences.

EN 15085

Railway applications Welding of

railway vehicles and components

Part 1: General

Part 2: Quality requirements and certification

of welding manufacturer

Part 3: Design requirements

Part 4: Production requirements

Part 5: Inspection, testing and documentation

EN 15085 Part 1: General

EN 15085 Part 1 provides an overview and

scope of the 15085 series of standards and

how it applies to the welding of metallic

materials in the manufacture and

maintenance of railway vehicles and their

parts.

EN 15085 Part 2: Quality requirements and

certification of welding manufacturer

EN 15085 Part 2 of the standard defines the

certification and quality requirements for the

welding manufacturer to undertake for new

fabrication and repair work.

It then provides an essential link

between performance requirements defined

during design to achieve the appropriate

quality welds during production and the

demonstration of the required quality by

inspection

EN 15085 Part 3: Design requirements

EN 15085 Part 3 defines weld performance

class during design, which is based on safety

and stress factors relevant to railway

operation.

Quality levels of imperfections are assigned to

weld performance classes to ensure a certain

level of performance intended during design

EN 15085 Part 4: Production

requirements

Based on the weld performance classes,

certification levels for production, as well as

inspection and testing and qualifications for

welding personnel of the manufacturer are

specified.

EN 15085 Part 5: Inspection, testing and

documentation

This standard deals with inspections and

testing to be executed on the welds,

destructive as well as non-destructive tests to

be performed and necessary documentation

to issue to declare the conformity of the

products.

The EN 15085 series of standards does not

deal with product qualification

Some important terms used in

EN15085:

Certification level (CL): It is level to classify

the welded railway vehicle or the welded

component depending on the weld

performance class (CP)

The certification level is abbreviated by CL

CERTIFICATION LEVEL -1(CL-1)

This level applies to welding manufacturers

which manufacture welded railway vehicles or

their welded parts with welded joints

classified in weld performance classes CP A

to CP D.

Certification level CL 2 to CL 4 is included.

Examples Of CL -1 level manufacturers.

Bogie frames and bolsters;

Body shell components (e.g. under frames, structures);

Buffers and draw gear;

Wheel set components (e.g. wheel set mountings,

axle boxes, spring supports);

Brake equipment (e.g. magnetic track brake, brake

rods, brake triangles, brake cylinders, brake cross

beams);

Examples Of CL -1 level manufacturers

welded components for drag transmission from

bogie to vehicle;

Vibration dampers and their link between bogie

and vehicle or between vehicles;

supporting frames for heavy components (e.g.

traction units, pantographs);

finishing welding of castings within components

indicated above;

External fuel tanks

CERTIFICATION LEVEL -2(CL-2)

This level applies to welding manufacturers which

manufacture welded parts of railway vehicles with

welded joints classified in weld performance classes

CP C2 to CP D.

Welded joints classified in weld performance class CP

C1 are included if these welds are checked

according to weld inspection class CT 1 according to EN

15085-5:2007, Table 1. Certification level CL 4 is only

included according to welded

joints of certification level CL 2 or CL 3.

CERTIFICATION LEVEL -3(CL-3)

This level applies to welding manufacturers

which manufacture welded parts of railway

vehicles with welded joints classified in

weld performance class CP D.

This level applies to manufacturers which do

not weld but design railway vehicles and parts

of rail vehicles or buy and assemble or sell

them. Certification not required for welding

works of certification level CL 3.

Weld performance class(CP)

It is performance requirements of the welded

joint as defined by the stress category and the

safety category of the welded joint.

Note: The weld performance class is

abbreviated by CP (class of performance).

Weld performance classes

Stress categories

Safety

High Medium Low

High CP A (*) CP B CP C2

Medium CP B b CP C2 CP C3

Low CP C1 d CP C3 CP D

CP A (*) - Weld performance class CP A is a special class which applies only for

welds with full penetration and full accessibility for inspection in production and

maintenance

Weld inspection class(CT):

defines the inspections to be carried out for a

given weld with respect to the weld

performance class.

NOTE The weld inspection class is

abbreviated by CT (class of testing).

Correspondence between weld

performance classes and inspection

classes

Stress category:category determined by the

stress factor

Stress factor: It is ratio of the calculated

fatigue stress to the admissible fatigue stress

of the joint type, adjusted by the appropriate

safety factor

Safety categories

The safety category defines the consequences of failure of the single

welded joint in respect to the effects on persons, facilities and the

environment.

The safety categories are differentiated as follows:

Low: Failure of the welded joint does not lead to any direct

impairment of the overall function.Consequential events with personal

injuries are unlikely.

Medium: Failure of the welded joint leads to an impairment of the

overall function or can lead to consequential events with personal

injuries.

High: Failure of the welded joint leads to consequential events with

personal injuries and breakdown of the overall function

Relationship between

Stress category.

Safety category.

Weld performance class.

Quality levels for imperfections.

Inspection class and testing.

Given In Next Slide.

Stress

categor

y

Safety

categor

y

Weld

performa

nce

class

Quality

levels for

imperfect

ions EN

ISO 5817

Inspectio

n class

Volumet

ric tests

RT or

UT

Surface

tests

MT or PT

Visual

examination

VT

High High CP A see Table

5 or

Table 6

CT 1 100% 100 % 100 %

High Medium CP B B CT 2 10% 10 % 100 %

High Low CP C2 C CT 3 Not

required

Not

required

100 %

REQUIREMENTS TO IMPLEMENT

ISO 3834&EN 15085

MEN

MATERIAL

METHOD

MACHINE

MONEY

Welding personnel(Men)

Welders and welding operators

Welding co-ordination personnel

Inspection & testing personnel

Welding inspection personnel

Non-destructive testing personnel

Welder qualification standards

American

standards

ISO/EURO INDIAN

ASME/Sec IX

AWS D1.1

BS EN 287

ISO 9606

IS 817

IS 7318

IS7310

EN 287-Part-1 -2011

QUALIFICATION TEST OF WELDERS

FUSION WELDING

PART-1- STEEL

Validity Of Approval

Valid for 2years, providing

that the welders supervisor

can confirm that at every six

month period the welder has

been working within his

range of qualification.

Job knowledge for welders as per en 287

Job knowledge test shall comprise:

identification of the range of qualification based on the current

qualification test,

properties and identification of parent materials within the material

groups or sub-groups of the test pieces,

properties and identification of parent materials within the material

groups or

sub-groups covered by the range of the qualification certificate to be

issued,

characteristic features of the welding process being the subject of the

qualifica- tion test,

properties and identification of welding consumables used for the

particular welding process,

the principles of edge preparation for welding and pre-welding

assembly,

the principles of selecting proper welding parameters,

the principles of pre-heating and pre-heating control,

proper interpass temperatures and their control,

weld imperfections and their causes,

method of repair of the welds below the acceptance level.

Visual Testing

Each test piece shall be subjected to visual testing (VT):

after the root run of the butt weld has been performed in the test piece,

after completion of the test piece.

Visual testing and its recording shall comply with the guidelines contained in

EN ISO 17637.

The quality level of the test pieces, based on type and size of imperfections, shall be assessed in

accordance with EN ISO 5817 for steel test pieces and EN ISO

10042 for the test pieces of aluminium or its alloys.

Surface imperfections of the test piece shall be within quality level B.

Only the following types of imperfections in quality level C are permitted:

excess butt weld metal (502),

excess fillet weld metal (503),

excess throat of the fillet weld (5214),

excessive penetration (504),

incorrect weld toe (505),

undercuts (501).

The reference numbers given in brackets are in accordance with EN ISO 6520-1. In the assessment of the

root run of the butt weld test piece welded from both

sides, weld root removed, surface imperfections shall not exceed limits for imper fections within quality

level D.

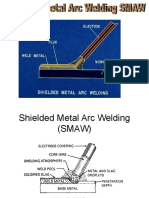

Welder qualification designation

standard Welding

process

Prod

uct

type

Weld

type

Material

group

Weldi

ng

consu

mable

s

Material

thickness

Pipe out

side

diameter

Welding

position

Weld

details

EN 287

-1

111 P BW 1.1 B 10 mm D 60 PA ss nb

1-Steel SMAW PLATE Butt

Weld

Steel with

steel

classified

based on

yield

strength

Basic

coated

electro

de.

plate

thickness

out side

dia

down

hand

single

side

with no

backing

BS EN ISO 5817 -2007

Welding-fusion welded joints in steel

,nickel,titanium and their alloys( beam

welding excluded).

Quality levels for imperfections

Different quality levels.

Three quality levels are given

Quality level C -stringent

Quality level C- Intermediate

Quality level D- Moderate.

BS EN ISO 4063-2009

WELDING AND ALLIED PROCESSES

NOMENCLATURE OF PROCESSES AND

REFRENCE NUMBERS.

ISO 4063

Process number

1 arc welding 2- resistance

welding

3- gas welding 5 beam

welding

8- cutting

&gouging

52

Laser welding

81 oxy fuel

cutting

83

Plasma

cutting

833 air

plasma

cutting

84

Laser beam

welding

1 arc welding

111- SMAW/MMAW

12- Sub merged welding.(SAW)

121- sub merged arc welding with solid wire

electrode.

13- GMAW

131- MIG welding with solid wire

135-MAG welding with solid wire

136- MAG welding with flux core wire.

14- GTAW.

141- TIG welding with solid filler material.

142- Autogenous welding.

15-PLASMA ARC WELDING

Resistance Welding

2- Resistance welding

21- resistance spot welding.

211- indirect spot welding

212- DIrect Spot Welding.

22 Resistance seam welding

225- foil butt seam welding

Beam welding

5- beam welding

52- laser beam welding

521- solid state laser welding

522-gas laser welding

523- diode laser welding

Gas cutting and gouging

81- oxy fuel/flame /oxygen cutting.

83- plasma cutting.

831- plasma cutting with oxidising gas.

832- plasma cutting with out oxidising gas.

833- air plasma cutting.

84-laser beam cutting

86- flame gouging

Please stay on track

Thank you for you attention

56

THE QUALITY LADDER

Zero

Defect

Prevent

Act in such

a way that

the problem

does not occur

Think

3rd Ladder

Eliminate cause

of the problem

Improve

Take corrective

action, analyse

Establish causes

Temporary

elimination

Solve for

limited period

I am responsible

2nd Ladder

Rationalise

I dont

have time

Accuse

It is others

fault

It is not

true

Ignore

Dont

know

1st ladder

Quality ladder defined

Is a overall picture of steps an Organization goes

through while climbing a Quality Ladder for reaching

peak performances.

The peak performance is like the peak to be climbed.

This peak has 3 plateau. Each plateau has to be

climbed using the Quality ladder. At the top of each

plateau the Organization has some respite before

starting up the next ladder to climb up the next

plateau.

The first ladder is the rightmost ladder. Each step in the

ladder is like an obstacle the organization has to

overcome.

Quality ladder defined

The first obstacle is in the dont know

barrier.

People in the Organization use this term to

give a reason for not involving themselves in a

new concept.

Quality ladder defined(Contd)

If this barrier is overcome the Organization

enters the barrier ignore.

People may learn about a new concept but

then they tend to ignore it.

Quality ladder defined(Contd)

If this barrier is over come then the next

barrier is it is not true barrier.

In other words I know about the new

concept, I dont want to ignore it but I do not

believe it, it is not true, I am not prepared to

accept it.

Quality ladder defined(Contd)

If this barrier is overcome the next barrier is

the scapegoat culture.

Somebody else is to be blamed for all failures

in the Organization and accuse others.

Quality ladder defined(Contd)

If this barrier is overcome and people are planned to

accept that they are at fault, they take shelter under

the most popular excuse

I dont have time. I am too busy.

Rationalization of the situation is the next barrier to

overcome. If this barrier is overcome the Organization

reaches the first plateau and there is some respite

before you start climbing the second ladder.

The second and third ladders are self explanatory.

Any questions

Anda mungkin juga menyukai

- EN15085 IntroductionDokumen89 halamanEN15085 IntroductionSubramanian R33% (3)

- En 15085 - 1 & 2Dokumen34 halamanEn 15085 - 1 & 20502ravi100% (4)

- En 15085 Design ModuleDokumen89 halamanEn 15085 Design Module0502ravi100% (1)

- BS en 15085 - 2quality Requirements For ManufcturersDokumen48 halamanBS en 15085 - 2quality Requirements For ManufcturersSubramanian R0% (1)

- A Quick Guide to Welding and Weld InspectionDari EverandA Quick Guide to Welding and Weld InspectionPenilaian: 4.5 dari 5 bintang4.5/5 (16)

- ISO 3834 by SelvaDokumen83 halamanISO 3834 by Selvaaravindan100% (11)

- En 15085Dokumen6 halamanEn 150850502ravi0% (1)

- Industrial radiography A Complete Guide - 2019 EditionDari EverandIndustrial radiography A Complete Guide - 2019 EditionBelum ada peringkat

- 1143 EWF IIW Diploma Overview - August 2013Dokumen2 halaman1143 EWF IIW Diploma Overview - August 2013Sean ฌอนBelum ada peringkat

- En15085 Guideline-Part2 2017-11Dokumen22 halamanEn15085 Guideline-Part2 2017-11Quality MSIPLBelum ada peringkat

- WPS & PQR - 2021Dokumen82 halamanWPS & PQR - 2021Subramanian RBelum ada peringkat

- BS en 15085-2Dokumen22 halamanBS en 15085-2Gnana MoorthyBelum ada peringkat

- IIW SyllabusDokumen31 halamanIIW SyllabusAbhishek AnandBelum ada peringkat

- Quality Technology HandbookDari EverandQuality Technology HandbookR S SharpeBelum ada peringkat

- Steps To CE Mark According To EN 1090-1 Version 1.1Dokumen1 halamanSteps To CE Mark According To EN 1090-1 Version 1.1CE_WizardBelum ada peringkat

- IIW/EWF Diploma in Welding QualificationDokumen8 halamanIIW/EWF Diploma in Welding Qualificationreezman100% (1)

- EN ISO 9606-1 (2013) (E) CodifiedDokumen0 halamanEN ISO 9606-1 (2013) (E) Codifiedvimal_mech1230% (1)

- Quality Requirements - Fusion Welding of Metalic MaterialDokumen8 halamanQuality Requirements - Fusion Welding of Metalic MaterialStatus whatsapp status100% (2)

- En Iso 15609Dokumen2 halamanEn Iso 15609Parminder SinghBelum ada peringkat

- EN 15085-4 2007, Railway Applications - Welding of Railway Vehicles and Components - Part 4 Production RequirementsDokumen18 halamanEN 15085-4 2007, Railway Applications - Welding of Railway Vehicles and Components - Part 4 Production RequirementsJerzy RistujczinBelum ada peringkat

- List of NDT Standards 10 2015 CorrDokumen16 halamanList of NDT Standards 10 2015 CorrAymeeen100% (2)

- IIW Guidance For 3834Dokumen20 halamanIIW Guidance For 3834Necati Dayı80% (5)

- Iiw Welding GuidelinesDokumen95 halamanIiw Welding Guidelinestomychalil100% (2)

- EN 15085 Program Evaluation TestDokumen2 halamanEN 15085 Program Evaluation TestSatish KeskarBelum ada peringkat

- Non-Destructive TestingDari EverandNon-Destructive TestingJ. BoogaardPenilaian: 4 dari 5 bintang4/5 (7)

- Certification Guideline for Welding Manufacturers of Railway VehiclesDokumen50 halamanCertification Guideline for Welding Manufacturers of Railway Vehiclesrameshqc100% (1)

- Competitive Solutions For Joining TechnologyDokumen19 halamanCompetitive Solutions For Joining Technologyjy12bhuBelum ada peringkat

- GMAW Practical Slide Show - FINALDokumen36 halamanGMAW Practical Slide Show - FINALDanem HalasBelum ada peringkat

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDokumen3 halamanWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLEBelum ada peringkat

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDari Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuidePenilaian: 3.5 dari 5 bintang3.5/5 (7)

- IWE SubjectsDokumen2 halamanIWE SubjectsAdnan Rana100% (3)

- Weld Plan D00651285Dokumen14 halamanWeld Plan D00651285sandeepBelum ada peringkat

- ISO 3834 Evaluation TestDokumen2 halamanISO 3834 Evaluation TestSatish KeskarBelum ada peringkat

- Din en 15085 2Dokumen24 halamanDin en 15085 2David Hoffman100% (1)

- CE Marking of StructuralDokumen31 halamanCE Marking of StructuralRavi ValiyaBelum ada peringkat

- Filler Materials TestingDokumen34 halamanFiller Materials TestingSunilBelum ada peringkat

- AWS A4.4 Standard Procedure For Determination of Moisture Content of Welding Fluxes and Welding Electrode Flux CoveringDokumen33 halamanAWS A4.4 Standard Procedure For Determination of Moisture Content of Welding Fluxes and Welding Electrode Flux CoveringJairo ContrerasBelum ada peringkat

- ISO 9606-1 Interpretations 2019-04-10Dokumen5 halamanISO 9606-1 Interpretations 2019-04-10alevent100% (1)

- LEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories Non Fixed Load Lifting Attachments - Version 2 - Feb 2015Dokumen17 halamanLEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories Non Fixed Load Lifting Attachments - Version 2 - Feb 2015Ulviyye ElesgerovaBelum ada peringkat

- Aws A2.4 - 1998 PDFDokumen118 halamanAws A2.4 - 1998 PDFLongTuanBelum ada peringkat

- Guideline Welding Coordination For ISO 1090-2Dokumen33 halamanGuideline Welding Coordination For ISO 1090-2apostolidis83100% (1)

- Terms in Welding Standard en 15085Dokumen6 halamanTerms in Welding Standard en 150850502raviBelum ada peringkat

- Requirements ISO 3834Dokumen76 halamanRequirements ISO 3834mdasifkhan2013100% (7)

- 112 Ewf 652r1 11 Sv00 Ewf Guideline Welding Coordination 1090 October 2011Dokumen33 halaman112 Ewf 652r1 11 Sv00 Ewf Guideline Welding Coordination 1090 October 2011Carlos Nombela PalaciosBelum ada peringkat

- LR Weld Certification Guide v1.3 SubscribeDokumen24 halamanLR Weld Certification Guide v1.3 SubscribeSergio Jesus SanjurjoBelum ada peringkat

- Asme Sec 9 - ADokumen144 halamanAsme Sec 9 - Anidhinchandranvs67% (3)

- API 1104 WQTRDokumen2 halamanAPI 1104 WQTRalisyalalaBelum ada peringkat

- Dimensions Tolerenaces On Weld and PositionsDokumen14 halamanDimensions Tolerenaces On Weld and PositionsDILIP VELHAL100% (3)

- Repair Dvs Supplement PDFDokumen6 halamanRepair Dvs Supplement PDFGnana MoorthyBelum ada peringkat

- Course Fully Sponsored By: (W International Institute of Welding (IIW) Diploma of International Welding Specialist (IWS)Dokumen8 halamanCourse Fully Sponsored By: (W International Institute of Welding (IIW) Diploma of International Welding Specialist (IWS)SanthaKumar Muthu ThankaveluBelum ada peringkat

- Welding Procedure Standards and Qualification CodesDokumen4 halamanWelding Procedure Standards and Qualification CodesBalkishan DyavanapellyBelum ada peringkat

- Certified Welding EngineerDokumen4 halamanCertified Welding Engineerjunidomar100% (1)

- Welding Coordination Tasks ISO 14731Dokumen1 halamanWelding Coordination Tasks ISO 14731Ion Plesa100% (1)

- Weld Performance Class (CP) en 15085Dokumen7 halamanWeld Performance Class (CP) en 150850502ravi100% (1)

- WELDABILITY of SteelDokumen41 halamanWELDABILITY of Steel0502ravi100% (1)

- CANFAN Airzon BLDC Super Efficient Fans - ICF PeramburDokumen13 halamanCANFAN Airzon BLDC Super Efficient Fans - ICF Perambur0502raviBelum ada peringkat

- Weld DefectsDokumen6 halamanWeld Defects0502raviBelum ada peringkat

- Icf-Pioneering in A Changing Economic EnvironmentDokumen18 halamanIcf-Pioneering in A Changing Economic Environment0502raviBelum ada peringkat

- E1648-01 Aluminum Fusion WeldsDokumen3 halamanE1648-01 Aluminum Fusion Welds0502raviBelum ada peringkat

- To CNC Machines & RobotsDokumen29 halamanTo CNC Machines & Robots0502raviBelum ada peringkat

- Welding VisualDokumen25 halamanWelding Visual0502ravi100% (1)

- Is-16003-2012-Specification and Qualification of WeldingDokumen23 halamanIs-16003-2012-Specification and Qualification of WeldingvijaykumarnBelum ada peringkat

- 7310 - 1 - 1974Dokumen12 halaman7310 - 1 - 19740502raviBelum ada peringkat

- SmawDokumen11 halamanSmaw0502raviBelum ada peringkat

- Fmea 1Dokumen22 halamanFmea 10502raviBelum ada peringkat

- I So AwarenessDokumen32 halamanI So Awareness0502raviBelum ada peringkat

- Time StudyDokumen28 halamanTime Study0502raviBelum ada peringkat

- WELDABILITY of SteelDokumen41 halamanWELDABILITY of Steel0502ravi100% (1)

- DIN 6700-2 Standard for Welding of Rail VehiclesDokumen27 halamanDIN 6700-2 Standard for Welding of Rail Vehicles0502ravi100% (1)

- Wps 15614 TemplateDokumen2 halamanWps 15614 Template0502raviBelum ada peringkat

- GR ExercisesDokumen10 halamanGR Exercises0502raviBelum ada peringkat

- Terms in Welding Standard en 15085Dokumen6 halamanTerms in Welding Standard en 150850502raviBelum ada peringkat

- Welding ConsumablesDokumen31 halamanWelding Consumables0502raviBelum ada peringkat

- Welding Defect PhotoDokumen14 halamanWelding Defect Photo0502raviBelum ada peringkat

- Stainless Steel DefectsDokumen30 halamanStainless Steel Defects0502ravi100% (1)

- Welding ElectrodesDokumen19 halamanWelding ElectrodesVijayan MunuswamyBelum ada peringkat

- WPSPQRDokumen11 halamanWPSPQR0502raviBelum ada peringkat

- Ss WeldingDokumen12 halamanSs Welding0502ravi100% (1)

- EN 1011 welding standards for stainless steelDokumen25 halamanEN 1011 welding standards for stainless steel0502ravi100% (1)

- Advanced welding techniques for joining metalsDokumen11 halamanAdvanced welding techniques for joining metals0502ravi100% (1)

- WELDABILITY of SteelDokumen41 halamanWELDABILITY of Steel0502ravi100% (1)

- Welding DefectsDokumen47 halamanWelding Defects0502raviBelum ada peringkat

- Iso 3834Dokumen11 halamanIso 38340502ravi100% (1)

- Welding of Stainless SteelsDokumen11 halamanWelding of Stainless Steels0502raviBelum ada peringkat

- The CongoDokumen3 halamanThe CongoJoseph SuperableBelum ada peringkat

- FP-XH PGRG eDokumen936 halamanFP-XH PGRG ebvladimirov85Belum ada peringkat

- Virchow TriadDokumen6 halamanVirchow Triadarif 2006Belum ada peringkat

- Patent for Fired Heater with Radiant and Convection SectionsDokumen11 halamanPatent for Fired Heater with Radiant and Convection Sectionsxyz7890Belum ada peringkat

- Clean Milk ProductionDokumen19 halamanClean Milk ProductionMohammad Ashraf Paul100% (3)

- Progibb LV Plus PGR - Low Voc FormulationDokumen2 halamanProgibb LV Plus PGR - Low Voc FormulationDodik Novie PurwantoBelum ada peringkat

- Private Schools Provide Better EducationDokumen2 halamanPrivate Schools Provide Better EducationcitraBelum ada peringkat

- Laser Surface Treatment ProcessesDokumen63 halamanLaser Surface Treatment ProcessesDIPAK VINAYAK SHIRBHATEBelum ada peringkat

- Diia Specification: Dali Part 252 - Energy ReportingDokumen15 halamanDiia Specification: Dali Part 252 - Energy Reportingtufta tuftaBelum ada peringkat

- Chapter 10 AP GP PDFDokumen3 halamanChapter 10 AP GP PDFGeorge ChooBelum ada peringkat

- CAT Ground Engaging ToolsDokumen35 halamanCAT Ground Engaging ToolsJimmy Nuñez VarasBelum ada peringkat

- DR-M260 User Manual ENDokumen87 halamanDR-M260 User Manual ENMasa NourBelum ada peringkat

- Traffic Violation Monitoring with RFIDDokumen59 halamanTraffic Violation Monitoring with RFIDShrëyãs NàtrájBelum ada peringkat

- Taking Back SundayDokumen9 halamanTaking Back SundayBlack CrowBelum ada peringkat

- WK 43 - Half-Past-TwoDokumen2 halamanWK 43 - Half-Past-TwoKulin RanaweeraBelum ada peringkat

- Organizing Small Items with Glass Bottle OrganizersDokumen70 halamanOrganizing Small Items with Glass Bottle OrganizersDy SaiBelum ada peringkat

- Cost Analysis and Financial Projections for Gerbera Cultivation ProjectDokumen26 halamanCost Analysis and Financial Projections for Gerbera Cultivation ProjectshroffhardikBelum ada peringkat

- Placenta Previa Case Study: Adefuin, Jay Rovillos, Noemie MDokumen40 halamanPlacenta Previa Case Study: Adefuin, Jay Rovillos, Noemie MMikes CastroBelum ada peringkat

- SECTION 303-06 Starting SystemDokumen8 halamanSECTION 303-06 Starting SystemTuan TranBelum ada peringkat

- Detection and Attribution Methodologies Overview: Appendix CDokumen9 halamanDetection and Attribution Methodologies Overview: Appendix CDinesh GaikwadBelum ada peringkat

- 5125 w04 Er PDFDokumen14 halaman5125 w04 Er PDFHany ElGezawyBelum ada peringkat

- Material and Energy Balance: PN Husna Binti ZulkiflyDokumen108 halamanMaterial and Energy Balance: PN Husna Binti ZulkiflyFiras 01Belum ada peringkat

- Direct From: 1St Quarter 2020Dokumen23 halamanDirect From: 1St Quarter 2020JeanBelum ada peringkat

- Flexibility Personal ProjectDokumen34 halamanFlexibility Personal Projectapi-267428952100% (1)

- TutorialDokumen324 halamanTutorialLuisAguilarBelum ada peringkat

- Interpreting Piping and Instrumentation DiagramsDokumen41 halamanInterpreting Piping and Instrumentation DiagramsFredric Tun100% (2)

- (Razavi) Design of Analog Cmos Integrated CircuitsDokumen21 halaman(Razavi) Design of Analog Cmos Integrated CircuitsNiveditha Nivi100% (1)

- IS 4991 (1968) - Criteria For Blast Resistant Design of Structures For Explosions Above Ground-TableDokumen1 halamanIS 4991 (1968) - Criteria For Blast Resistant Design of Structures For Explosions Above Ground-TableRenieBelum ada peringkat

- 2 - Soil-Only Landfill CoversDokumen13 halaman2 - Soil-Only Landfill Covers齐左Belum ada peringkat

- Smart Grid Standards GuideDokumen11 halamanSmart Grid Standards GuideKeyboardMan19600% (1)