Concrete Bridge

Diunggah oleh

kepvinDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Concrete Bridge

Diunggah oleh

kepvinHak Cipta:

Format Tersedia

CONCRETE BRIDGE

Submitted to:

Engr. Reden Hernandez

Submitted by:

Jerome C. Gatchalian

Victoriano Macalino

John Kepvin Viray

Guio Feliciano

Jojo Marin

Norben Sigua

HISTORY

It was in the 18th Century that bridge design began

to develop into a science, led by an engineering

school founded in Paris.

Its director, Jean Perronet, perfected the masonry

arch, with its low sweeping curve and slender piers.

Soon afterwards, attention switched to England

where the invention of the steam locomotive called

for stronger bridges.

In 1794, iron was first used for the chain cables of a

suspension bridge over the River Tees and 1779 saw the

first all-iron bridge over the Severn at Coalbrookdale. This

arch bridge, spanning 100ft, is still in service.

Just when the masonry arch bridge was reaching its peak

around the beginning of the 20th Century, reinforced

concrete arrived on the scene. Since then, it has become

the major construction material for bridges as it has for

most structural and civil engineering applications, with

its intrinsic versatility, design flexibility and, above all,

natural durability.

Concrete

Concrete is characterized by the type of aggregate or

cement used, by the specific qualities it manifests, or

by the methods used to produce it.

Bridges

More bridges are built using concrete than any other

material worldwide, demonstrating continued

confidence in the materials performance and

durability. Concrete bridges worldwide have a clear

track record of flexibility and versatility in terms both

of final forms and methods of construction that is

hard to match.

Benefits

Function and elegance

Durability

Versatility

Speed and build ability

Sustainability

Economy

Types of Concrete

Bridges

Arch Bridges

Reinforced Slab Bridges

Beam and Slab Bridge

Box Girder Bridge

TECHNIQUES

Techniques of construction vary according to the

actual design and situation of the bridge, there being

three main types:

Incrementally launched

Span-by-span

Balanced cantilever

Incrementally launched

Span-by-Span

Balanced Cantilever

Integral Bridges

Cable-Stayed Bridges

Suspension Bridges

Widening of Gapan

San Fernando- Olongapo (GSO) Road

and Emergency Dredging Project

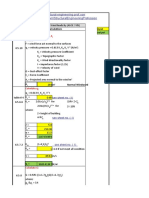

DESIGN SPECIFICATION

DESIGN METHODOLOGY

Pre-casting method

Cofferdam

-Bored pile method

PRECAST CONCRETE BRIDGE

I Beams & Super Tees

-Standard beam can be pre and or post tensioned.

-Cast on site or in existing PC yard

Advantages

-Cheap

-Simple to erect

Disadvantages

-Limited in length (lat torsion buckling)

-Less efficient

COFFERDAMS

A cofferdam is defined as a temporary structure

which is constructed so as to remove water and/ or

soil from area and make it possible to carry on the

construction work under reasonably dry condition.

REQUIREMENTS OF A COFFERDAM

The cofferdams should be reasonably watertight.

It should be noted that absolute water tightness is

desired in a cofferdam.

The cofferdams should be designed for the maximum

water level and other destructive force so as to make

it stable against bursting, overturning and sliding.

The water to be excluded by a cofferdam may be either

ground water or water lying above ground level.

The materials used in the construction of a cofferdam are

earth, timber, steel and concrete.

The cofferdam is generally constructed at site of work.

The type of construction for cofferdam is depended up

on the depth, soil conditions, fluctuations in the water

level, availability of material, etc.

The cofferdams are constructed with advantage where a

large area of site is to be enclosed and the hard bed is at

reasonable depth.

USES OF COFFERDAMS

To facilitate pile driving operation

To place grillage and raft foundation

To construct foundations for piers and abutments of

bridge, dams, locks, etc;

To enclose a space for the removal of sunken vessels

To provide a working platform for the foundation of

building when water is met with; and

To provide space for carrying out the foundation work

without disturbing or damaging the adjoining structure

such as buildings, pipelines, sewers, etc.

BORED PILE METHOD

Bored pile is used for those tall buildings or massive

industrial complexes, which require foundations that

can bear the load of thousands of tons, most

probably in unstable or difficult soil conditions.

MATERIALS

1. AUGER

2. BORING MACHINE

KELLY BAR

SERVICE CRANE

THE END

Anda mungkin juga menyukai

- Smart FTK - Leyte - Mahaplag - Cuatro de Agosto1Dokumen21 halamanSmart FTK - Leyte - Mahaplag - Cuatro de Agosto1anthonyBelum ada peringkat

- General Construction Notes: Drawing IndexDokumen1 halamanGeneral Construction Notes: Drawing IndexEdzon Lacay0% (1)

- Visayas State University: College of EngineeringDokumen5 halamanVisayas State University: College of EngineeringDanielaBelum ada peringkat

- Igneous RocksDokumen64 halamanIgneous RocksNishitaBelum ada peringkat

- Hydraulic EquationsDokumen9 halamanHydraulic EquationsJohn Michael CampitanBelum ada peringkat

- 09 Mi BLDG 1Dokumen663 halaman09 Mi BLDG 1LeahBelum ada peringkat

- Notes On Coordinate SystemsDokumen96 halamanNotes On Coordinate SystemsMargie Cording100% (1)

- Room Aircon Heat Load Estimate FormDokumen3 halamanRoom Aircon Heat Load Estimate FormMena G. El NimrBelum ada peringkat

- Igneous Rocks: Edited By: Syamsidar Sutan Geofisika Fmipa Mulawarman UniversityDokumen40 halamanIgneous Rocks: Edited By: Syamsidar Sutan Geofisika Fmipa Mulawarman UniversityVendy Mediannoor100% (2)

- Affidavit of Consent: Epublic OF THE HilippinesDokumen1 halamanAffidavit of Consent: Epublic OF THE Hilippines9746957Belum ada peringkat

- One Way Slab ExampleDokumen20 halamanOne Way Slab ExampleRixer PrietoBelum ada peringkat

- GB Code Checklist - Architectural - 27apr2017Dokumen27 halamanGB Code Checklist - Architectural - 27apr2017ajBelum ada peringkat

- Type of Coordinate System and Its ApplicationsDokumen21 halamanType of Coordinate System and Its ApplicationsMahmoud MahmoudmBelum ada peringkat

- Principles of LawDokumen22 halamanPrinciples of LawNorrisson Sanggau100% (1)

- Leaflet - IDEA StatiCa ConcreteDokumen2 halamanLeaflet - IDEA StatiCa ConcretepgyzBelum ada peringkat

- Samson FootingDokumen7 halamanSamson FootingJoseph Cloyd L. LamberteBelum ada peringkat

- Chapter5 - Shear and Diagonal Tension in BeamsDokumen9 halamanChapter5 - Shear and Diagonal Tension in BeamsYo FangirlsBelum ada peringkat

- Moment Distribution Method On Structural MemberDokumen98 halamanMoment Distribution Method On Structural MemberPaul Henry Trono CunananBelum ada peringkat

- Dfu WsfuDokumen1 halamanDfu Wsfuren salazarBelum ada peringkat

- Wind Loads Calculations by ASCE7 05 For Any BuildingDokumen12 halamanWind Loads Calculations by ASCE7 05 For Any BuildingShara Mae de MesaBelum ada peringkat

- Ar443 Building Frames Lecture Notes PDFDokumen23 halamanAr443 Building Frames Lecture Notes PDFsaleemm_2Belum ada peringkat

- Length Excavated (M) Width Excavated (M) Depth Excavated (M)Dokumen15 halamanLength Excavated (M) Width Excavated (M) Depth Excavated (M)anthonyBelum ada peringkat

- Swimming Pool MandyDokumen80 halamanSwimming Pool MandyRENZZ IRVIN DELA TORREBelum ada peringkat

- Module 002 CE ELECT 5S-Structural Framing Concepts and Preliminary SizingDokumen13 halamanModule 002 CE ELECT 5S-Structural Framing Concepts and Preliminary SizingCeasar MerialesBelum ada peringkat

- Wharf - Dock Fender Design Manual-ENDokumen56 halamanWharf - Dock Fender Design Manual-ENSteven SebastianBelum ada peringkat

- Design CriteriaDokumen44 halamanDesign CriteriaJonniel De GuzmanBelum ada peringkat

- LECTURE 4 - Design of Singly Reinforced Beams (Design)Dokumen29 halamanLECTURE 4 - Design of Singly Reinforced Beams (Design)Howell TungolBelum ada peringkat

- Power Point Presentation Pequonnock River Watershed Management Plan Power Point PresentationDokumen57 halamanPower Point Presentation Pequonnock River Watershed Management Plan Power Point PresentationBridgeportCTBelum ada peringkat

- MIKE 213 Coupled Model FMDokumen50 halamanMIKE 213 Coupled Model FM'Seta' Prastya BayuBelum ada peringkat

- Structural Analysis 222Dokumen5 halamanStructural Analysis 222ome hinigaran0% (1)

- Review QuestionsDokumen31 halamanReview QuestionsGerby PaaBelum ada peringkat

- Concrete Design Flowcharts 3-14-17Dokumen19 halamanConcrete Design Flowcharts 3-14-17AbinashBelum ada peringkat

- Magsalay Seismic Loading AnalysisDokumen2 halamanMagsalay Seismic Loading AnalysisKarl HelbiroBelum ada peringkat

- InterDiagram ColumnInterDiagram ColumnInterDiagram ColumnInterDiagram ColumnInterDiagram ColumnInterDiagram ColumnInterDiagram ColumnDokumen5 halamanInterDiagram ColumnInterDiagram ColumnInterDiagram ColumnInterDiagram ColumnInterDiagram ColumnInterDiagram ColumnInterDiagram ColumnVicenteRocabadoBelum ada peringkat

- Reinforced Concrete DesignDokumen29 halamanReinforced Concrete DesignChristian Angelo ButacBelum ada peringkat

- Design of Truss Malika Ali BSCE-5ADokumen78 halamanDesign of Truss Malika Ali BSCE-5AUdat Hakeem Malang AmirBelum ada peringkat

- Motorpool 2 2021Dokumen1 halamanMotorpool 2 2021Darren ValienteBelum ada peringkat

- IntrodutionDokumen32 halamanIntrodutionsatydevsinghnegiBelum ada peringkat

- Bacao Bridge Revetment Design Report (Revised) PDFDokumen19 halamanBacao Bridge Revetment Design Report (Revised) PDFAngelo MoralBelum ada peringkat

- ESC Steel Philippines Brochure - Oct 2019 PDFDokumen12 halamanESC Steel Philippines Brochure - Oct 2019 PDFCarlos_CriticaBelum ada peringkat

- Arup Vietnam: Waist Landing Strength of MaterialsDokumen1 halamanArup Vietnam: Waist Landing Strength of MaterialsChhour CEBelum ada peringkat

- Catubig Project - Technical SpecificationsDokumen176 halamanCatubig Project - Technical SpecificationsLeo CalejaBelum ada peringkat

- Manual: ShoreDokumen164 halamanManual: Shorenonopimentel100% (1)

- Republic of The Philippines: Kalinga State UniversityDokumen5 halamanRepublic of The Philippines: Kalinga State UniversityJoan AntonioBelum ada peringkat

- Gen. Luna ST., Iloilo City, Philippines Department of ArchitectureDokumen19 halamanGen. Luna ST., Iloilo City, Philippines Department of ArchitectureCloe Dianne SillaBelum ada peringkat

- Lecture 4 - Reinforced Concrete - Bond, Development LengthDokumen55 halamanLecture 4 - Reinforced Concrete - Bond, Development LengthChristopher PaladioBelum ada peringkat

- How To Generate Your Own Column Interaction DiagramDokumen81 halamanHow To Generate Your Own Column Interaction DiagramMarlo AristorenasBelum ada peringkat

- Design of Highway Surface DrainageDokumen3 halamanDesign of Highway Surface DrainageVin GaragiBelum ada peringkat

- Proposed 1 Storey Car Display and Repair Shop-PlumbingDokumen1 halamanProposed 1 Storey Car Display and Repair Shop-Plumbingmichael jan de celisBelum ada peringkat

- Coastal Engineering Analysis and Design of A Mound Breakwater For A Protected Beach Resort DevelopmentDokumen6 halamanCoastal Engineering Analysis and Design of A Mound Breakwater For A Protected Beach Resort Developmentcatherine faithBelum ada peringkat

- Types of Coastal StructuresDokumen18 halamanTypes of Coastal StructuresMourad Nadeer100% (1)

- Regional Office Iv-B: Itemized Quantities and Cost Estimates On Other SheetDokumen50 halamanRegional Office Iv-B: Itemized Quantities and Cost Estimates On Other SheetKevin Suerte CanillaBelum ada peringkat

- Erosion & ScourDokumen8 halamanErosion & ScourOswald OsBelum ada peringkat

- Ra 9200Dokumen4 halamanRa 9200HeartfigliaBelum ada peringkat

- Chapter - 3 Load On Bridge.Dokumen13 halamanChapter - 3 Load On Bridge.Assefa NigussieBelum ada peringkat

- Lecture of Civil EngineeringDokumen52 halamanLecture of Civil EngineeringhassanBelum ada peringkat

- CofferdamDokumen46 halamanCofferdamPreeti 1026100% (1)

- Underwaterconstruction 1july23Dokumen21 halamanUnderwaterconstruction 1july23Pavan NadgoudaBelum ada peringkat

- Building Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksDari EverandBuilding Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksBelum ada peringkat

- A Guide to Some of the Equations used in Constructing a Suspension BridgeDari EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeBelum ada peringkat

- Guidance and Special Education 1Dokumen53 halamanGuidance and Special Education 1kepvinBelum ada peringkat

- Focus On LanguageDokumen65 halamanFocus On LanguagekepvinBelum ada peringkat

- Focus On LanguageDokumen65 halamanFocus On LanguagekepvinBelum ada peringkat

- Focus On LanguageDokumen65 halamanFocus On LanguagekepvinBelum ada peringkat

- V-Tac 221008Dokumen47 halamanV-Tac 221008Petrisor FilipBelum ada peringkat

- Percentage Boq: Validate Print HelpDokumen9 halamanPercentage Boq: Validate Print HelpBlitheBelum ada peringkat

- ODU, CHB Wall Fence & CYclone Rebar CostingDokumen4 halamanODU, CHB Wall Fence & CYclone Rebar Costinghenjie mirasolBelum ada peringkat

- ARC01016-Building Data SheetDokumen12 halamanARC01016-Building Data SheetCamilo CastilloBelum ada peringkat

- Reymundos Glass QuotationDokumen1 halamanReymundos Glass QuotationTRISTAN JAN JERICHO ALMEROBelum ada peringkat

- VIN LED Lighting E-Catalogue VER 2.12Dokumen88 halamanVIN LED Lighting E-Catalogue VER 2.12poonam_ranee3934Belum ada peringkat

- Bsc071 - Glamz - Civil - Submittal LogDokumen16 halamanBsc071 - Glamz - Civil - Submittal Logقاسم ابرار محمدBelum ada peringkat

- SOS Children's Village Aqaba, JordanDokumen24 halamanSOS Children's Village Aqaba, JordanSadia SamiBelum ada peringkat

- IBC - ABC BuildingDokumen51 halamanIBC - ABC BuildingNadaa28Belum ada peringkat

- Construction Techniques and Equipment PracticesDokumen4 halamanConstruction Techniques and Equipment PracticeskalpanaBelum ada peringkat

- ISEO IDEA Kw12816 (Base - AntiGerm - DoP - Certifire - CE0497)Dokumen16 halamanISEO IDEA Kw12816 (Base - AntiGerm - DoP - Certifire - CE0497)31863192Belum ada peringkat

- ASPDokumen27 halamanASPFarhanBelum ada peringkat

- H3107ADokumen1 halamanH3107AExile PeachBelum ada peringkat

- Thomas Wright, Grotesque ArchitectureDokumen48 halamanThomas Wright, Grotesque ArchitectureBeornn McCarthy100% (1)

- GR1 - StrongholdsDokumen126 halamanGR1 - StrongholdsYiğit Ünsay67% (3)

- 1948-Architectural Catalogue 2012 EZDokumen41 halaman1948-Architectural Catalogue 2012 EZGkou DojkuBelum ada peringkat

- Dipping TanksDokumen8 halamanDipping TanksSaid Ahmed SalemBelum ada peringkat

- Designers' Show House 2011Dokumen23 halamanDesigners' Show House 2011Courier JournalBelum ada peringkat

- Method Statement of Concreting Pile Cap Rev02Dokumen3 halamanMethod Statement of Concreting Pile Cap Rev02Mohd Hafizul Hj Tanalol75% (4)

- Lighting of Railway Premises PDFDokumen14 halamanLighting of Railway Premises PDFAnuar PadeliBelum ada peringkat

- What Is Stairs ?Dokumen38 halamanWhat Is Stairs ?rajeshBelum ada peringkat

- Evolution of BricksDokumen44 halamanEvolution of BricksHari KaranBelum ada peringkat

- BAIYILED TGC LED FloodlightDokumen2 halamanBAIYILED TGC LED FloodlightBAIYILED EUROPE B.V.Belum ada peringkat

- Bhaskar Homes: Good Buildings Come From Good People and All Problems Are Solved by Good DesignDokumen6 halamanBhaskar Homes: Good Buildings Come From Good People and All Problems Are Solved by Good DesignRajaGopal ReddyBelum ada peringkat

- Report Office FoundationDokumen11 halamanReport Office FoundationMochammad ShokehBelum ada peringkat

- Laurie Baker IntroductionDokumen73 halamanLaurie Baker Introductionnonie09ashna100% (1)

- Dawood Rebar CoDokumen32 halamanDawood Rebar Cocbala_2006Belum ada peringkat

- The Illustrated Guide To The Houses of AmericaDokumen280 halamanThe Illustrated Guide To The Houses of AmericaHamza Mihoub100% (1)

- Senior Five End of Term One Examinations, 2015 Building Drawing P720/2 Time: 3 Hours InstructionsDokumen5 halamanSenior Five End of Term One Examinations, 2015 Building Drawing P720/2 Time: 3 Hours InstructionsEremu ThomasBelum ada peringkat

- Latihan Autocad KIMI-A2 - PlanDokumen1 halamanLatihan Autocad KIMI-A2 - PlanMuhd HakimieBelum ada peringkat