Tugas Casing Seat Selection

Diunggah oleh

Debbya Debora SariHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Tugas Casing Seat Selection

Diunggah oleh

Debbya Debora SariHak Cipta:

Format Tersedia

Casing Seat Selection

FUNCTIONS OF CASING

To keep the hole open and to provide a support for weak,

or fractured formations.

To isolate porous media with different fluid/pressure

regimes from contaminating the pay zone

To provide a passage for hydrocarbon fluids; most

production operations are carried

To provide a suitable connection for the wellhead

connection

Introduction

TYPES OF CASING

1. Stove pipe (Marine Conductor or foundation pile for

offshore rigs)

Run to prevent wash out of unconsolidated surface

formation

Run to provide a circulation system for drilling fluids and

to ensure the stability of the ground under the rig

Does not carry wellhead equipment

Can be driven into ground with a pile driver (26 in to 42 in

per pile)

Introduction

2. Conductor pipe

Run from surface to some shallow depth to protect nearsurface

unconsolidated formation

Provide a circulation for the drilling mud to protect foundation of the

platform

May be connecting of BOP or cut at surface or diverter connection

Sizes from 18 5/8 in to 20 in

3. Surface casing (13 3/8 in.)

Run to prevent caving of week formation encountered at shallow depths

Should be set in competent rock like limestone: to ensure that the

formation will not fractured at the casing shoe by high mud weight used

later in the next hole

Protect against shallow blow-out, thus BOPs are connected to top

TYPES OF CASING

Introduction

TYPES OF CASING

Introduction

4. Intermediate casing (9 5/8 in.)

Usually set in the transition zone below or above

pressured formation (salt and/or caving shale)

Need good cementing o prevent communication

behind the casing between zones; multistage

cementing may be used for long strings

5. Production casing (7 in.)

Isolate production zones

Provide reservoir fluid control

Permit selective production in multi zones production

6. Liner casing

A string of casing that does not reach to the surface

Hang on the intermediate casing, by use of suitable

packer and slips called liner hanger

Introduction

To obtain the most economical design, casing strings often consist of

multiple sections of different steel grade, casing depths, wall

thickness, and coupling types. Such a casing string is called a

combination string. Additional cost savings sometimes can be

achieved by the use of liner combination strings instead of full strings

running from the surface to the bottom of the hole. However, the

potential savings must be weighted against the additional risks and

costs of a successful, leak-free tieback operation as well as the

additional casing wear that results from a longer exposure of the

upper casing to rotation and translation of the drill string.

Selection of Casing Setting

Depths

The selection of the number of casing strings and their setting

depths generally is based on a consideration of the pore pressure

gradients and fracture gradients of the formations to be penetrated.

The pore pressure and fracture pressure are expressed as an

equivalent density and are plotted vs. depth. A line representing the

planned-mud-density program also is plotted. The mud densities are

chosen to provide an acceptable trip margin above the anticipated

formation pore pressure to allow for reductions in mud weight

caused by upward pipe movement during tripping operation. A

commonly used trip margin is 0.5 lbm/gal or one that will provide 200-

500 psi of excess bottomhole pressure over the formation pore

pressure.

Selection of Casing Setting

Depths

Selection of Casing Setting

Depths

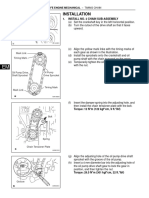

Point a: to prevent the formation fluid into the well

and to reach the desired depth.

Point b: to prevent the fracture of formation -->

intermediate casing need to run at this depth.

Point c: Fluid density is reduced until it reaches to

margin of the curve

Point d: casing shoe of the surface casing

Example

A well is being planned for a location in Jefferson Parish, LA. The

intended well completion requires the use of 7 production casing set

at 15,000 ft. Determine the number of casing strings needed to reach

this depth objective safely, and select the casing setting depth of each

string. Pore pressure and fracture gradient, and lithology data from

logs of nearby wells are given in Fig 7.21. allow a 0.5 lbm/gal trip

margin, and a 0.5 lbm/gal kick margin when making the casing seat

selections. The minimum length of surface casing required to protect

the freshwater aquifers is 2000ft. Approximately 180 ft of conductor

casing generally is required to prevent washout on the outside of the

conductor. It is general practice in this are to cement the casing in

shale rather than in sandstone.

Example

Selection of Casing Sizes

To enable the production casing to be placed in the well,

the bit size used to drill the last interval of the well must be

slightly larger than the OD of the casing connectors.

The selected bit size should provide sufficient clearance

beyond the OD of the coupling to allow for mud cake on

the borehole wall and for casing appliances, such as

centralizers and scratchers. The bit used to drill the lower

portion of the well also must fit inside the casing string

above.

Selection of Casing Sizes

CASING SPESIFICATION

Casing is specified by: grade, weight per unit

length, outside diameter and wall thickness, type

of coupling, and length of joint.

API defines three types of casing weight

Nominal weight: normally based on the

calculation, not exact, use for design and given in

tables.

Plain end weight: the weight of casing joint

without inclusion of threads and couplings

Threads and coupled weight

Selection of Weight, Grade, and

Couplings

In general, each casing string is designed to withstand the most

severe loading conditions anticipated during casing placement

and the life of the well. The loading conditions that are always

considered are burst, collapse, and tension. Because the loading

conditions in a well tend to vary with depth, it is often possible to

obtain a less expensive casing design with several different

weights, grades, and couplings.

The casing design usually is based on an assumed loading

condition. the assumed design load must be severe enough that

there is a very low probability of a more severe situation actually

occurring and causing casing failure.

Selection of Weight, Grade, and

Couplings

The high-internal pressure loading condition used for the

burst design is based on a well control condition assumed

to occur while circulating out a large kick.

The high-external pressure loading condition used for the

collapse design is based on a severe lost-circulation

problem.

The high-axial tension loading condition is based on an

assumption of stuck casing while the casing is run into the

hole before cementing operations.

Selection of Weight, Grade, and

Couplings

Selection of Weight, Grade, and Couplings

The burst design should ensure that formation fracture pressure at the

casing seat will be exceed before the burst pressure is reached. Thus,

this design uses formation facture as a safety pressure release

mechanism to ensure that casing rupture will not occur at the surface.

The pressure with the casing is calculated assuming that only

formation gas is in the casing.

The external pressure outside the casing that helps resist burst is

assumed to be equal to the normal formation pore pressure for the

area.

Burst Design

Selection of Weight, Grade, and

Couplings

The collapse design is based either on the most

severe lost-circulation problem that is felt to be

possible or on the most severe collapse loading

anticipated when the casing is run. For both cases, the

maximum possible external pressure that tends to

cause casing collapse results from the drilling fluid that

is in the hole when the casing is placed and cemented.

Collapse Design

Selection of Weight, Grade, and Couplings

If a severe lost circulation zone is encountered near the bottom of the next

interval of hole and no other permeable formations are present above the lost

circulation zone, the fluid level in the well can fall until the BHP is equal to the

pore pressure of the lost circulation zone.

lc p m lc

D D D 052 . 0 052 . 0

max

where D

lc

is the depth of the lost circulation zone; g

p

is the pore-

pressure gradient of the lost circulatio zone; r

max

is the maximum mud

density anticipated in drilling to D

lc

; and D

m

is the depth to which the

mud level will fall.

Collapse Design

Anda mungkin juga menyukai

- Drilling Supervisor: Passbooks Study GuideDari EverandDrilling Supervisor: Passbooks Study GuideBelum ada peringkat

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Dari EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Penilaian: 5 dari 5 bintang5/5 (2)

- Casing Setting Depth Optimisation Based On Well Control Considerations by Lek Chun HouDokumen6 halamanCasing Setting Depth Optimisation Based On Well Control Considerations by Lek Chun HouLek Chun Hou100% (1)

- Air and Gas Drilling Manual: Applications for Oil, Gas, Geothermal Fluid Recovery Wells, Specialized Construction Boreholes, and the History and Advent of the Directional DTHDari EverandAir and Gas Drilling Manual: Applications for Oil, Gas, Geothermal Fluid Recovery Wells, Specialized Construction Boreholes, and the History and Advent of the Directional DTHBelum ada peringkat

- AOO Personal Information FDokumen8 halamanAOO Personal Information FOdhiambo OwinoBelum ada peringkat

- Casing DesignDokumen65 halamanCasing DesignRizwan FaridBelum ada peringkat

- CasingDokumen31 halamanCasingsouthliBelum ada peringkat

- Casing DesignDokumen8 halamanCasing DesignJason Bash100% (1)

- Casing and TubingDokumen16 halamanCasing and TubingAli Aliiev100% (1)

- Casing Design - Jimmy WangDokumen160 halamanCasing Design - Jimmy Wangjuanett¿¿¿¿67% (3)

- Tubing Design FactorsDokumen11 halamanTubing Design FactorsandreaBelum ada peringkat

- Part 2 Well DesignDokumen12 halamanPart 2 Well DesignAbdelaziz Mohamed Abdelmoaty ArafaBelum ada peringkat

- Lesson 8b Introduction To UBDDokumen57 halamanLesson 8b Introduction To UBDbon1ngBelum ada peringkat

- Casing DesignDokumen48 halamanCasing Designdrillinganaco60% (5)

- Tubing DesignDokumen12 halamanTubing Designakshitppe11Belum ada peringkat

- Oil Well DesigningDokumen15 halamanOil Well DesigningShashank SacamuriBelum ada peringkat

- Casing ExerciseDokumen9 halamanCasing ExerciseYesar Bin Mustafa AlmalekiBelum ada peringkat

- Basic Tubing ForcesDokumen21 halamanBasic Tubing ForcesOzzie GonzalezBelum ada peringkat

- Rig DesginDokumen25 halamanRig DesginImam PranadipaBelum ada peringkat

- Balanced Cement Plug CalculationDokumen7 halamanBalanced Cement Plug CalculationAlejandro ViscarraBelum ada peringkat

- 26 Mill-EZ Composite Bridge PlugDokumen2 halaman26 Mill-EZ Composite Bridge PlugzbhdzpBelum ada peringkat

- 5.1-Casing DesignDokumen23 halaman5.1-Casing DesignnabeelkhanBelum ada peringkat

- Well Control FdreDokumen27 halamanWell Control FdreKhairi OmarBelum ada peringkat

- Part 1 Introduction New PDFDokumen12 halamanPart 1 Introduction New PDFRanim HishamBelum ada peringkat

- Reaming OperationDokumen5 halamanReaming Operationsorangel_123Belum ada peringkat

- 20 in Surf - 94 PPFDokumen12 halaman20 in Surf - 94 PPFAnonymous XbmoAFtIBelum ada peringkat

- 12 - Horizontal Well CompletionDokumen21 halaman12 - Horizontal Well CompletionMaximiliano GonzalezBelum ada peringkat

- Casing Design PrinciplesDokumen18 halamanCasing Design PrinciplesANISAHBelum ada peringkat

- Chapter 06 Pressure Losses in The Circulating SystemDokumen22 halamanChapter 06 Pressure Losses in The Circulating SystemAbrar HassanBelum ada peringkat

- Spe 30364 Seebty Ofpotrebum Endnws: Platform Concept OutlineDokumen12 halamanSpe 30364 Seebty Ofpotrebum Endnws: Platform Concept Outlinebr_fdm1604100% (1)

- Casing CalculationsDokumen10 halamanCasing CalculationsKimiko ShopBelum ada peringkat

- Well PlanningDokumen4 halamanWell PlanningSibte Hassan ButtBelum ada peringkat

- Chevron: Wellcap Plus Practice Test Surface/SubseaDokumen13 halamanChevron: Wellcap Plus Practice Test Surface/SubseaBoedi SyafiqBelum ada peringkat

- Advanced Drill Pipe M Jellison Et AlDokumen9 halamanAdvanced Drill Pipe M Jellison Et AlIepuras RaduBelum ada peringkat

- Lecture2-Well CompletionDokumen43 halamanLecture2-Well CompletionRamy MaamounBelum ada peringkat

- Aerated DrillingDokumen10 halamanAerated DrillingDen YogaBelum ada peringkat

- Well CompletionDokumen22 halamanWell CompletionRobot100% (1)

- Perforation GeometryDokumen10 halamanPerforation GeometryJawaid HussainBelum ada peringkat

- Casing DesignDokumen43 halamanCasing DesignAdvait DeshmukhBelum ada peringkat

- Analysis, Comparison and Application of CWD Against Conventional Drilling OperationsDokumen104 halamanAnalysis, Comparison and Application of CWD Against Conventional Drilling Operationsprakharmathur14100% (1)

- Tubing Length Change CalculationsDokumen33 halamanTubing Length Change CalculationsOmer Khalid100% (2)

- Api5ct MTRLSDokumen2 halamanApi5ct MTRLSSundar KumarBelum ada peringkat

- Off-Bottom Drilling PracticesDokumen3 halamanOff-Bottom Drilling PracticesAdel Ahmed AlkhaligyBelum ada peringkat

- DRILLING FLUIDS HandoutDokumen10 halamanDRILLING FLUIDS HandoutHans SamBelum ada peringkat

- CT Operations ExerciseDokumen20 halamanCT Operations ExerciseMohammed Anis FortasBelum ada peringkat

- LinerDokumen19 halamanLinerHakan Özkara100% (1)

- Well Control EquipmentDokumen60 halamanWell Control EquipmentDinesh MehtaBelum ada peringkat

- Offshore Well Construction - Casing DesignDokumen77 halamanOffshore Well Construction - Casing DesigntduyhaoBelum ada peringkat

- 19 Well ControlDokumen133 halaman19 Well ControlAvazdordi SadriBelum ada peringkat

- 1 API Introduction StandardsDokumen29 halaman1 API Introduction StandardsImam MalikBelum ada peringkat

- 477 - 7in TOL Inflow Test ProgramDokumen4 halaman477 - 7in TOL Inflow Test Programciucalata88100% (1)

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsDari EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsBelum ada peringkat

- Streamline Numerical Well Test Interpretation: Theory and MethodDari EverandStreamline Numerical Well Test Interpretation: Theory and MethodBelum ada peringkat

- Offshore Gas Hydrates: Origins, Development, and ProductionDari EverandOffshore Gas Hydrates: Origins, Development, and ProductionBelum ada peringkat

- Measurement While Drilling: Signal Analysis, Optimization and DesignDari EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignBelum ada peringkat

- Microbial Enhancement of Oil Recovery - Recent AdvancesDari EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesBelum ada peringkat

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersDari EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersBelum ada peringkat

- Plotting in MatlabDokumen7 halamanPlotting in Matlabpride3351Belum ada peringkat

- Fire Protection Engineering Summer 2001Dokumen33 halamanFire Protection Engineering Summer 2001Hany RifaatBelum ada peringkat

- Lab Manual No 13Dokumen3 halamanLab Manual No 13Hammad JawadBelum ada peringkat

- WRO 2018 WeDo RegularDokumen14 halamanWRO 2018 WeDo RegularAlaas AlvcaszaBelum ada peringkat

- TDS 9-11SA Mechanical TroubleshootingDokumen34 halamanTDS 9-11SA Mechanical Troubleshootingahmed.kareem.khanjerBelum ada peringkat

- Sincronizacion de Motor Toyota 2az-FeDokumen12 halamanSincronizacion de Motor Toyota 2az-FeWilliams NavasBelum ada peringkat

- Materi Safety Riding Honda TangerangDokumen26 halamanMateri Safety Riding Honda TangerangKusuma Cheep Liiss100% (2)

- Sand Reclamation - Standard Devices: Shake Out MachinesDokumen2 halamanSand Reclamation - Standard Devices: Shake Out MachinesKaarthicNatarajanBelum ada peringkat

- Collaborative Filtering and Inference Rules For Context-Aware Learning Object RecommendationDokumen11 halamanCollaborative Filtering and Inference Rules For Context-Aware Learning Object RecommendationDaniel LemireBelum ada peringkat

- Introduction To Surveying PDFDokumen27 halamanIntroduction To Surveying PDFArseni MaximBelum ada peringkat

- Ht-Discharge Pipes and Fittings (PPS) : KunststoffeDokumen35 halamanHt-Discharge Pipes and Fittings (PPS) : Kunststoffeluis eduardo ramos rebataBelum ada peringkat

- IPCR Part 2 2017Dokumen4 halamanIPCR Part 2 2017RommelBelum ada peringkat

- 4 - 5.1 - Fluid Action On Surfaces (Plane Surface)Dokumen16 halaman4 - 5.1 - Fluid Action On Surfaces (Plane Surface)Jacky CagampanBelum ada peringkat

- Starter MP EecDokumen21 halamanStarter MP EecIshan 96Belum ada peringkat

- Canalta Parts CatalogueDokumen25 halamanCanalta Parts Cataloguellando1Belum ada peringkat

- Water Tank Seat Slab DesignDokumen2 halamanWater Tank Seat Slab DesignMesfin Derbew100% (2)

- List of International and National Professional Bodies - PECDokumen4 halamanList of International and National Professional Bodies - PECerumerBelum ada peringkat

- PQ070XF02SZH: Features Outline DimensionsDokumen4 halamanPQ070XF02SZH: Features Outline DimensionsJulio Cesar CastilloBelum ada peringkat

- AULA 13 - RespondidoDokumen4 halamanAULA 13 - RespondidoRanyelle WanessaBelum ada peringkat

- Tutorial Joint Push Pull - English - V1.1 - 20 Feb 08Dokumen31 halamanTutorial Joint Push Pull - English - V1.1 - 20 Feb 08shadownrunBelum ada peringkat

- DPP Series 1 PDFDokumen1 halamanDPP Series 1 PDFsukainaBelum ada peringkat

- Module 8: Numerical Relaying I: Fundamentals: Fourier AlgorithmsDokumen15 halamanModule 8: Numerical Relaying I: Fundamentals: Fourier Algorithmsjijo123408Belum ada peringkat

- Individual: DR Winnie Louis LeeDokumen27 halamanIndividual: DR Winnie Louis Leeedn_mj1645Belum ada peringkat

- Case Study Analysis of Apex Corporation PDFDokumen2 halamanCase Study Analysis of Apex Corporation PDFAJBelum ada peringkat

- Fi SlingDokumen4 halamanFi SlingSony TogatoropBelum ada peringkat

- Manual Ni Usrp 2920Dokumen56 halamanManual Ni Usrp 2920Anghye Plata100% (1)

- Leaflet US5Ge ProtectedDokumen3 halamanLeaflet US5Ge Protectedquochung0606Belum ada peringkat

- CAM Charges Working For The Month of May 2023Dokumen1 halamanCAM Charges Working For The Month of May 2023adnandani2882Belum ada peringkat

- LPIC-2 Exam PrepDokumen882 halamanLPIC-2 Exam PrepcuthieuBelum ada peringkat