Scuderi Split Cycle

Diunggah oleh

Manish KumarHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Scuderi Split Cycle

Diunggah oleh

Manish KumarHak Cipta:

Format Tersedia

BY

MANISH KUMAR

INTRODUCTION

The Scuderi Engine is a split cycle, internal combustion

engine invented by Carmelo J. Scuderi (1925 - 2002)

Scuderi Group, an engineering and licensing company

based in West Springfield, Massachusetts , is testing a

working prototype of the engine that was officially unveiled

to the public on April 20, 2009.

Scuderi Engine shows gains in efficiency and reduced toxic

emissions over conventional four-stroke Otto cycle designs

It utilizes a unique combustion process referred to as

Firing After Top Dead Center. This produces a highly

efficient and clean-burning combustion process

DESIGN FEATURES

It has two cylinder to split

the cycle

One cylinder is used for

intake and compression

Another is used for power

and exhaust

And a crossover passage is

used to interconnect these

cylinders

One power stroke for each

revolution of crank shaft

Intake/

Compression

Crossover

Passage

Power/Exhaust

Exhaust Intake

Fuel

Injector

WORKING

The engine uses pairs of cylinders operating in parallel

to split the typical 4-stroke cycle into pairs of two

strokes. The first cylinder handles the intake and

compression strokes with only air coming in. the air is

compressed before a crossover valve is opened allowing

the compressed air to pass over to the power side.

A pair of poppet valves manage the flow of compressed

air to flow from the compression to the power cylinder.

However, because of the high pressures being generated,

approximately 50 BAR, Scuderi set the crossover valves

to be outward opening.

direct injection systems sprays fuel into the cross over

passage and the high pressure air causes it to mix more

thoroughly than a conventional engine.

The fuel being ignited after

the power piston passes top

dead center. Firing the spark

plug after TDC prevents any

re-compression of the

expanding gases

The cylinder pressure rises

to about 65 BAR during

ignition but drops as the

piston moves down the

cylinder. The result is that

the combustion temperature

actually drops at the same

time, eliminating about 80

percent of NOx production.

Intake

Intake/

Compression

Crossover

Passage

Power/Exhaust

Exhaust

The Scuderi Air-Hybrid System

Unlike electric hybrids that

use recovered kinetic energy

to charge high-voltage

batteries, Air-Hybrid system

uses kinetic energy to charge

an air storage tank.

The Scuderi Air-Hybrid

Engine takes one-third the

time to store energy than it

does to use all of that energy,

which could potentially

make it the most efficient

hybrid system

Air Tank

Modes of Operation

Normal Operating Mode: The

air tank stores energy, in the form

of compressed air, which is

normally lost during the operation

of the vehicle, and uses it for

combustion.

Regenerative Braking Mode: By

turning off the power cylinder and

diverting the flow of compressed

air to the storage tank, the

momentum of the vehicle

continues turning the engine,

thereby compressing air and

storing it in the tank for later use.

Cruising Mode: Only a portion of the

compression cylinders charge is sent to

the power cylinder during cruising

mode. The remainder of the charge is

sent to the air storage tank for later use.

Whenever the air tank is full, the

compression cylinder shuts off, and the

vehicle operates in high-efficiency

mode.

High-Efficiency Mode: By turning off

the compression cylinder and utilizing

high-pressure air from the storage tank

to supply the power cylinder, losses due

to compression are reduced to nearly

zero when operating in the high-

efficiency mode.

Benefits of Air Hybrid System

Reduces CO2 Emissions by up to 50%

Reduces NOx Emissions by up to 80%

Increases Fuel Efficiency by up to 50%

No High-Voltage System / Batteries

Positive Recharge Time

Minimal Retooling Costs

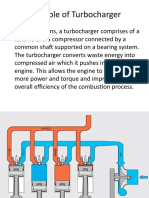

The Scuderi Engine with Turbocharger

As we know that the

compression stroke is negative

work, or energy that the

engine consumes to create

mechanical work.

By incorporating turbocharger

into engine, the size of the

compression cylinder can be

reduced to eliminate some

negative compression work

Less Work Here More Work Here

Air Tank

Turbocharger

STATICS

CONCLUSION

The Most Significant Advancement in internal

combustion engine after invention of Otto cycle

Dramatic Reduction in fuel consumption and

CO2 emissions

Lowers NOx Up to 80%

Delivers more power and torque

Anda mungkin juga menyukai

- 03 Principle of TurbochargerDokumen19 halaman03 Principle of TurbochargerSky RBelum ada peringkat

- Compressed Air Engines SynopsisDokumen6 halamanCompressed Air Engines Synopsisalfambar902100% (1)

- Truwater - TCM SeriesDokumen12 halamanTruwater - TCM SeriesnkhhhBelum ada peringkat

- M2-Cert 22 Prof Dev Plus Exam ST Gd-1Dokumen20 halamanM2-Cert 22 Prof Dev Plus Exam ST Gd-1Khôi Lê100% (1)

- Period Based Accounting Versus Cost of Sales AccountingDokumen13 halamanPeriod Based Accounting Versus Cost of Sales AccountingAnil Kumar100% (1)

- American Woodworker 163 2012-2013 PDFDokumen76 halamanAmerican Woodworker 163 2012-2013 PDFkaskdos100% (1)

- Split Engine ReportDokumen14 halamanSplit Engine ReportSameer Patil0% (1)

- Two Stroke NXT Generation EngineDokumen10 halamanTwo Stroke NXT Generation EnginesaswatmahantyBelum ada peringkat

- Six Stroke EngineDokumen36 halamanSix Stroke EngineAmandeep Tanwar100% (2)

- 4 Stroke Petrol EngineDokumen11 halaman4 Stroke Petrol EngineAnkit Joshi50% (4)

- Scuderi Split Cycle EngineDokumen8 halamanScuderi Split Cycle EnginefalconnBelum ada peringkat

- Ic Engines: Four Stroke Cycle Diesel EnginesDokumen11 halamanIc Engines: Four Stroke Cycle Diesel Enginesmechjobs4meBelum ada peringkat

- Six Stroke EngineDokumen25 halamanSix Stroke EngineDeepak JindalBelum ada peringkat

- Seminar Report 2ND PartDokumen19 halamanSeminar Report 2ND PartAshutosh RautBelum ada peringkat

- Split Cycle EnginesDokumen28 halamanSplit Cycle Enginesthy7rexBelum ada peringkat

- Development of High Efficiency Engine by Combining I. C. Engine and E C EngineDokumen4 halamanDevelopment of High Efficiency Engine by Combining I. C. Engine and E C EngineMuhammad Rifqi PinandhitoBelum ada peringkat

- Ic Engines: Four Stroke Cycle Diesel EnginesDokumen10 halamanIc Engines: Four Stroke Cycle Diesel Enginesmechjobs4meBelum ada peringkat

- Seminar Powerpoint Presentation On 6 Stroke EnginesDokumen31 halamanSeminar Powerpoint Presentation On 6 Stroke EnginesVijay ChauhanBelum ada peringkat

- GDI Stratified Charge Engine 1Dokumen9 halamanGDI Stratified Charge Engine 1Jasdeep SandhuBelum ada peringkat

- Ijaret 11 11 202Dokumen7 halamanIjaret 11 11 202Abhisekh PattanaikBelum ada peringkat

- Sumeet Sharma, MED Email: Ssharma: Presented byDokumen13 halamanSumeet Sharma, MED Email: Ssharma: Presented bysumeetsharma27Belum ada peringkat

- What Is Stratified Charge Engine?Dokumen18 halamanWhat Is Stratified Charge Engine?ÅBin PÅulBelum ada peringkat

- Four-Stroke, Four Cylinder Diesel Engine: BY Shubham Kulshrestha Atul Yadav Irfan KhanDokumen27 halamanFour-Stroke, Four Cylinder Diesel Engine: BY Shubham Kulshrestha Atul Yadav Irfan KhanShubham Kulshrestha100% (1)

- Prepared By: Muhammad Hilmi Bin ZaidDokumen44 halamanPrepared By: Muhammad Hilmi Bin ZaidTimothy Del Valle100% (1)

- Chapter 3Dokumen29 halamanChapter 3Hasif EnazBelum ada peringkat

- Diesel EngineDokumen14 halamanDiesel EngineAyşenur ÇetinBelum ada peringkat

- Super ChargingDokumen23 halamanSuper Charginghirenbabaji100% (2)

- Unit 1 B Ic EnginesDokumen47 halamanUnit 1 B Ic Enginesoliyad teferiBelum ada peringkat

- IC AssignmentDokumen43 halamanIC AssignmentBoppudBelum ada peringkat

- Ic Engine: Assignment#02Dokumen9 halamanIc Engine: Assignment#02Jawad ZafarBelum ada peringkat

- AGR 318 Lec 3 - Engine Cons & CompDokumen42 halamanAGR 318 Lec 3 - Engine Cons & CompHaikal SapurataBelum ada peringkat

- Project Title Proposed Research Research Domain Field of ResearchDokumen11 halamanProject Title Proposed Research Research Domain Field of ResearchAffan ChoudhryBelum ada peringkat

- Lecture Notes On Advanced I.C. Engine Part-IDokumen0 halamanLecture Notes On Advanced I.C. Engine Part-IJaiguru Narayanasamy0% (1)

- Review Six Stroke EngineDokumen7 halamanReview Six Stroke EngineSuhas G FADNISBelum ada peringkat

- 4 Stroke EngineDokumen5 halaman4 Stroke Enginehim1234567890Belum ada peringkat

- Chapter 12 Supercharging TurbochargingDokumen33 halamanChapter 12 Supercharging Turbochargingdesie yalewBelum ada peringkat

- Diesel Power PlantDokumen47 halamanDiesel Power PlantRajput Divyapratap Singh Chauhan0% (1)

- Four-Stroke Engine: From Wikipedia, The Free EncyclopediaDokumen4 halamanFour-Stroke Engine: From Wikipedia, The Free EncyclopediaSam B. SucalitBelum ada peringkat

- Scavenging in 2 Stroke Engine FinalDokumen35 halamanScavenging in 2 Stroke Engine Finalnitin_parwaniBelum ada peringkat

- Two Stroke EngineDokumen5 halamanTwo Stroke Enginedwarika2006Belum ada peringkat

- Two-Stroke EngineDokumen15 halamanTwo-Stroke EngineRevanKumarBattuBelum ada peringkat

- R.Vijay Kumar Pes ItDokumen37 halamanR.Vijay Kumar Pes ItVenkatesh VenkyBelum ada peringkat

- Bme Module 4Dokumen32 halamanBme Module 4eldhosekjnitBelum ada peringkat

- Engine: An Engine Is Motor Which Converts Chemical Energy of A Fuel Into The Mechanical EnergyDokumen61 halamanEngine: An Engine Is Motor Which Converts Chemical Energy of A Fuel Into The Mechanical EnergyMuhammad BilalBelum ada peringkat

- Comparision of Two Stroke, Four Stroke & Six Stroke Engine According To P-V & Valve Timing DiagramDokumen3 halamanComparision of Two Stroke, Four Stroke & Six Stroke Engine According To P-V & Valve Timing DiagramBSAScitiBelum ada peringkat

- Air EngineDokumen5 halamanAir EngineVinay MohanBelum ada peringkat

- Asi Unit 3Dokumen21 halamanAsi Unit 3Raja RamBelum ada peringkat

- 10-Piston-Engine Based Power PlantsDokumen27 halaman10-Piston-Engine Based Power PlantsSaif YounusBelum ada peringkat

- Recent Trends: 5.1 Homogeneous Charge Compression Ignition EngineDokumen14 halamanRecent Trends: 5.1 Homogeneous Charge Compression Ignition EnginesuriyaBelum ada peringkat

- Diesel CycleDokumen10 halamanDiesel CycleSri Ram VikasBelum ada peringkat

- How Diesel Engines WorkDokumen23 halamanHow Diesel Engines WorkBabu Stunner100% (1)

- Scuderi Split Engine CycleDokumen10 halamanScuderi Split Engine CycleBaranidharan GopiBelum ada peringkat

- Supercharging and TurbochargingDokumen8 halamanSupercharging and TurbochargingMudassir Hussain100% (1)

- Internal Combustion EnginesDokumen32 halamanInternal Combustion Enginespramodkb_cusatBelum ada peringkat

- Greater Noida Institute of Technology: 2-Stroke Petrol EngineDokumen13 halamanGreater Noida Institute of Technology: 2-Stroke Petrol EngineEr Raghvendra SinghBelum ada peringkat

- Diesel Engine TechnologyDokumen59 halamanDiesel Engine TechnologyAnonymous f2zDTm7kmBelum ada peringkat

- Artifact 4 Parts Small Engines PowerpointDokumen56 halamanArtifact 4 Parts Small Engines Powerpointapi-240922530Belum ada peringkat

- Supercharger VS TurbochargerDokumen25 halamanSupercharger VS TurbochargerAllen CastorBelum ada peringkat

- Comparison of Diesel and Petrol EnginesDari EverandComparison of Diesel and Petrol EnginesPenilaian: 2.5 dari 5 bintang2.5/5 (3)

- Vroom! How Does A Car Engine Work for KidsDari EverandVroom! How Does A Car Engine Work for KidsPenilaian: 5 dari 5 bintang5/5 (1)

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsDari EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsBelum ada peringkat

- SAP MM Module OverviewDokumen15 halamanSAP MM Module OverviewAmit Kumar100% (1)

- Deped SipagDokumen23 halamanDeped Sipagwilliam felisilda100% (1)

- Deodorization-Solutions by Alfa LavalDokumen12 halamanDeodorization-Solutions by Alfa Lavalercanefeoglu100% (1)

- Value Creation Through Project Risk ManagementDokumen19 halamanValue Creation Through Project Risk ManagementMatt SlowikowskiBelum ada peringkat

- Internship Report (EWSD)Dokumen23 halamanInternship Report (EWSD)Spartacus GladBelum ada peringkat

- QR 390 Manual Partes Quincy 390Dokumen31 halamanQR 390 Manual Partes Quincy 390ramiro alvarezBelum ada peringkat

- TCE BE EEE RulesandRegulationsDokumen509 halamanTCE BE EEE RulesandRegulationsAplieBelum ada peringkat

- PDF CatalogEngDokumen24 halamanPDF CatalogEngReal Gee MBelum ada peringkat

- Colphenebswh 1816Dokumen2 halamanColphenebswh 1816vinoth kumar SanthanamBelum ada peringkat

- Soliphant T FTM20, FTM21: Technical Information VibronicDokumen16 halamanSoliphant T FTM20, FTM21: Technical Information VibronicmichaelBelum ada peringkat

- Washing MachinesDokumen6 halamanWashing MachinesAnonymous wK36hLBelum ada peringkat

- TechTrax 09 2003 ScreenReaderVersionDokumen84 halamanTechTrax 09 2003 ScreenReaderVersionMCKINNONBBelum ada peringkat

- CS300.1 CS60.4 CS60.2: The Official Brand of Live MusicDokumen8 halamanCS300.1 CS60.4 CS60.2: The Official Brand of Live MusicLuis RodriguezBelum ada peringkat

- Petronas Technical Standards: Symbols and Identification System - MechanicalDokumen16 halamanPetronas Technical Standards: Symbols and Identification System - MechanicalUdaya Zorro100% (1)

- Lexmark-E 321 Service ManualDokumen184 halamanLexmark-E 321 Service ManualRemysBelum ada peringkat

- LogDokumen2 halamanLogFerdian SumbaBelum ada peringkat

- Compacted Graphite Iron Was First Patented at About The Same Time As Ductile Iron in The Late 1940Dokumen4 halamanCompacted Graphite Iron Was First Patented at About The Same Time As Ductile Iron in The Late 1940Agustin GerardoBelum ada peringkat

- Edtpa 2nd Lesson PlanDokumen5 halamanEdtpa 2nd Lesson Planapi-297045693Belum ada peringkat

- Tds Cross 0325Dokumen1 halamanTds Cross 0325manox007Belum ada peringkat

- ' ' Shail Ahmad: Privet of India Acres N Inches List of ClientDokumen3 halaman' ' Shail Ahmad: Privet of India Acres N Inches List of Clientapi-243316402Belum ada peringkat

- ASME B16.47 Series A FlangeDokumen5 halamanASME B16.47 Series A FlangePhạm Trung HiếuBelum ada peringkat

- Shailendra - Yadav - R.F Design and Optimization Engineer - 5.10 - Yrs ExpDokumen7 halamanShailendra - Yadav - R.F Design and Optimization Engineer - 5.10 - Yrs ExpGaurav TiwariBelum ada peringkat

- Melt ManualDokumen32 halamanMelt ManualSaikat ChakrabortyBelum ada peringkat

- Rigmaster 304 Stainless Steel Fluorescent LuminairesDokumen2 halamanRigmaster 304 Stainless Steel Fluorescent LuminairesErikaGaitanGonzalezBelum ada peringkat

- Presentation 1Dokumen12 halamanPresentation 1Varun MaheshwariBelum ada peringkat

- G 342 Engine Part 1 PDFDokumen26 halamanG 342 Engine Part 1 PDFharley florezBelum ada peringkat