Engineers Guide CFRP Monocoque Design

Diunggah oleh

Shivam Wankhede100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

192 tayangan24 halamanThe document discusses the design of a carbon fiber reinforced polymer (CFRP) monocoque for a Formula Student race car. It describes the motivation for using a monocoque design, which includes benefits like lightweight construction and integrated functions. Various concepts and geometry variations are analyzed using finite element modeling to evaluate characteristics like torsional stiffness. The preliminary design undergoes crash testing simulations. Detailed design considerations include load transmission paths, bonded joints, and cockpit reinforcement. The manufacturing process is also outlined, from cutting plies on a CNC machine to curing the completed monocoque in an autoclave. Tips are provided for teams new to CFRP monocoque design.

Deskripsi Asli:

Presentation of monocoque chassis in EuroMold

Judul Asli

Monocoque Darmstadt FSG-Workshop EuroMold

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPT, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThe document discusses the design of a carbon fiber reinforced polymer (CFRP) monocoque for a Formula Student race car. It describes the motivation for using a monocoque design, which includes benefits like lightweight construction and integrated functions. Various concepts and geometry variations are analyzed using finite element modeling to evaluate characteristics like torsional stiffness. The preliminary design undergoes crash testing simulations. Detailed design considerations include load transmission paths, bonded joints, and cockpit reinforcement. The manufacturing process is also outlined, from cutting plies on a CNC machine to curing the completed monocoque in an autoclave. Tips are provided for teams new to CFRP monocoque design.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

192 tayangan24 halamanEngineers Guide CFRP Monocoque Design

Diunggah oleh

Shivam WankhedeThe document discusses the design of a carbon fiber reinforced polymer (CFRP) monocoque for a Formula Student race car. It describes the motivation for using a monocoque design, which includes benefits like lightweight construction and integrated functions. Various concepts and geometry variations are analyzed using finite element modeling to evaluate characteristics like torsional stiffness. The preliminary design undergoes crash testing simulations. Detailed design considerations include load transmission paths, bonded joints, and cockpit reinforcement. The manufacturing process is also outlined, from cutting plies on a CNC machine to curing the completed monocoque in an autoclave. Tips are provided for teams new to CFRP monocoque design.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 24

Creating a Future for Engineers

Formula Student Germany

FSAE-CFRP monocoque

Creating a Future for Engineers

Contents

Motivation

Concept

Dimensioning

Design

Cuts

Manufacturing

Creating a Future for Engineers

+ mass-specific mechanical properties

+ safety

+ lightweight design possibilities

+ integration of functions

+ (new challenge)

Motivation

- time and cost (depends)

- design complexity

- maintenance and repair

Why a Monocoque?

Has to be answered during design event!

Creating a Future for Engineers

axle to axle front-only

more interaction

no additional load transmissions

one-piece multi-part

manufacturability

no joint

push- pullrod

considerable influence on MC-design

Concepts Basic Options

manufacturing method

wide influence on MC-design

influence on cost

joint integrated

manufacturability

no joint

ergonomy und package

tool mock-up

shouldnt change too often

Creating a Future for Engineers

Concepts Geometry Variation

simplified FE-model qualitative analysis

of concepts

initially: isotropic material

presumed weaknesses:

upper wishbones

cockpit

Creating a Future for Engineers

Influence on Torsional Stiffness

0.00

1.00

2.00

3.00

4.00

massenspezifische Torsionssteifigkeit (normiert)

Geschlossen, mit Spant

Offen, mit Spant

Unverstrkt, mit Spant

Geschlossen, ohne Spant

Offen, ohne

Creating a Future for Engineers

300 mm

F = 177 kN

Preliminary Design: Frontal Crash

Creating a Future for Engineers

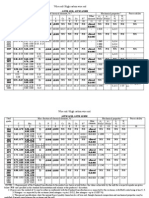

no. material E

||

E

^

G

^||

n

^||

r

Corres

ponding j

1 E-Glas / EP 44480 13219 5562 0,25 2 0,6

2 HTA/MTM49-3 125650 9800 4580 0,335 1,55 0,6

3 T700S/MTM49-3 125300 9105 3830 0,33 1,55 0,6

no. material R

||

t

R

||

c

R

^

t

R

^

c

R

^||

Corres

ponding j

1 E-Glas / EP 1100 1000 54 150 75 0,6

2 HTA/MTM49-3 1810 1455 35,3 232 89,3 0,6

3 T700S/MTM49-3 2662 1386 28,3 180,2 56,8 0,6

loads

n

x

[N/mm] -147,5

laminate lay-up

lamina t

k

[mm] a j material

1

0,116 0 0,49 8

2

0,116 90 0,49 8

3

0,116 45 0,49 8

4

0,116 -45 0,49 8

5

0,462 0 0,49 8

6

0,116 -45 0,49 8

7

0,116 45 0,49 8

8

0,116 90 0,49 8

9

0,116 0 0,49 8

lamina angle [a] e

1

[%] e

2

[%] g

21

[%] s

1

[N/mm

2

] s

2

[N/mm

2

] t

21

[N/mm

2

] f

E,FF

f

E,IFF

Fracture

mode

Fracture

angle

weakening

1 0,00 -0,17 0,05 0 -179,6 0,5 0 0,15 0,01 A 0 3

2 90,00 0,05 -0,17 0 51,6 -12,9 0 0,03 0,06 C 51,22 2

3 45,07 -0,06 -0,06 0,23 -63,8 -6,2 8,6 0,05 0,08 B 0 2

4 -45,07 -0,06 -0,06 -0,23 -63,8 -6,2 -8,6 0,05 0,08 B 0 2

5 0,00 -0,17 0,05 0 -179,6 0,5 0 0,15 0,01 A 0 3

6 -45,07 -0,06 -0,06 -0,23 -63,7 -6,2 -8,6 0,05 0,08 B 0 2

7 45,07 -0,06 -0,06 0,23 -63,7 -6,2 8,6 0,05 0,08 B 0 2

8 90,00 0,05 -0,17 0 51,6 -12,9 0 0,03 0,06 C 51,2 2

9 0,00 -0,17 0,05 0 -179,2 0,5 0 0,15 0,01 A 0 3

http://www.klub.tu-darmstadt.de/forschung/download.php

reserve factor

laminate fracture

6,6

reserve factor first

inter-fibre fracture

6,6

CLT

Creating a Future for Engineers

FE-Model

anisotropic material

align element coordinate system!

shell elements

Ansys: SHELL99, SHELL91

Input of single plies enables CLT

and Puck to be used in Ansys

reasonable results without tests?

Creating a Future for Engineers

1. Load Transmission

2. Bonded Joint

3. Cockpit Reinforcement

Design in Detail

1

2

3

Creating a Future for Engineers

Load Transmission

critical

safety seat belt

suspension

complex detailed calculations

tests are more reasonable

integration of functions

roll hoops

Creating a Future for Engineers

Bonded Joint

Creating a Future for Engineers

Cockpit Reinforcement

Creating a Future for Engineers

Machine-Cut Plies

(Vistagy Fibersim, CATIA Composite Design, NX Laminate Composites)

+ less wasted material

+ faster manufacturing

+ higher quality

each cut CAD surface model

3d surface 2d contour *.dxf

N

X

4

splines lines and circular arcs

reduce number of segments

nesting

A

u

t

o

c

a

d

Creating a Future for Engineers

Ply Book

ply book pages for overview and for each cut

in sequence of actual manufacturing steps

if necessary: exact position and alignment

Creating a Future for Engineers

Manufacturing

Epoxy blocks cut

and bonded

5 axis mill

Creating a Future for Engineers

fine-grained abrasive paper

mould release agent

alignment pins

CFK tooling prepregs

(2x200gr | 3x650gr | 1x200gr)s

Creating a Future for Engineers

autoclave curing of negative moulds defrosting of prepregs

CNC cut plies

Creating a Future for Engineers

labeling and arranging first face

positioning via pins

Creating a Future for Engineers

inserts are also nested

CFK panel jet cutting

honeycomb core machine cut

insert positioning via pins

Creating a Future for Engineers

vacuum parts to be cured in autoclave

2 or 3 shots

Creating a Future for Engineers

removing alignment pins

demoulding

bonding

tension belts

Creating a Future for Engineers

Tips for a Start

Concept

examine concepts and solutions of

other teams

define manufacturing method early

(depends on your options and those

provided by partners)

Design

define package early

lightweight construction!

symmetrical ply layout

complete CAD model

avoid unnecessary joints

Material

high-tension fibres arent beneficial

for axial compression

high modulus fibres: brittle, low

ultimate elongation!

fabric: fine, compact, not wavy

twill or sateen (e. g. 3k-yarn: 200g/m

for instance)

local UD reinforcements (e. g. for

distinct, not varying state of stress)

core: e. g. fine aluminum

honeycombs of low density

Creating a Future for Engineers

05. 09. August 2009

See you at Hockenheim

Anda mungkin juga menyukai

- MEL311Dokumen281 halamanMEL311Shiri ShaBelum ada peringkat

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDokumen11 halamanIjesrt: International Journal of Engineering Sciences & Research TechnologySanthosh LingappaBelum ada peringkat

- Machine Elements DesignDokumen281 halamanMachine Elements DesignsgmdoBelum ada peringkat

- An Integrated Design and CAPP System For Cold or Hot Forging ProductsDokumen8 halamanAn Integrated Design and CAPP System For Cold or Hot Forging ProductsAmir JoonBelum ada peringkat

- Sheet Metal Forming Simulation in IndustryDokumen8 halamanSheet Metal Forming Simulation in IndustrysscamdBelum ada peringkat

- Coupling DesignDokumen3 halamanCoupling DesignMochammad Syaiful BakriBelum ada peringkat

- Die Casting DesignDokumen20 halamanDie Casting Designtiep_design100% (1)

- Tokyo SympDokumen13 halamanTokyo Sympkirt wirk skythomasBelum ada peringkat

- Simufact BR Sheet Metal enDokumen8 halamanSimufact BR Sheet Metal enBobby MartaBelum ada peringkat

- Production Technology of ROPS Cab: Technical PaperDokumen8 halamanProduction Technology of ROPS Cab: Technical Paperjose rosasBelum ada peringkat

- PagoluSreenivasaRao HariSankarVanka 48 PDFDokumen8 halamanPagoluSreenivasaRao HariSankarVanka 48 PDFRavinder ReddyBelum ada peringkat

- A Runner-Gate Design System For Die CastingDokumen4 halamanA Runner-Gate Design System For Die CastingDiazBelum ada peringkat

- Design of Experiments in Production EngineeringDokumen201 halamanDesign of Experiments in Production Engineeringmipuldd100% (2)

- Taguchi Method Calculation & AnalysisDokumen96 halamanTaguchi Method Calculation & Analysischoksi himanshu100% (1)

- Talk 5-3-1 CST Euc 2012Dokumen175 halamanTalk 5-3-1 CST Euc 2012Anonymous 3GE9cFCBelum ada peringkat

- A RUNNER-GATE DESIGN SYSTEM FOR DIE CASTING DIESDokumen9 halamanA RUNNER-GATE DESIGN SYSTEM FOR DIE CASTING DIESKetan ChhedaBelum ada peringkat

- Pro CastDokumen16 halamanPro CastMuhammad BilalBelum ada peringkat

- Lázaro Plata 2020 J. Phys. Conf. Ser. 1587 012034Dokumen8 halamanLázaro Plata 2020 J. Phys. Conf. Ser. 1587 012034fernandoBelum ada peringkat

- Esi ProCAST PDFDokumen16 halamanEsi ProCAST PDFanwarsitangangBelum ada peringkat

- Simulation of A Rectangular Object With Shinkage DefectDokumen8 halamanSimulation of A Rectangular Object With Shinkage DefectHumberto Suarez LiscaBelum ada peringkat

- Sl. No. Title Page No.: B. M. S. College of EngineeringDokumen26 halamanSl. No. Title Page No.: B. M. S. College of EngineeringBn SharathBelum ada peringkat

- Modeling and Analysis of Cotter Joint REPORT R20ER055Dokumen21 halamanModeling and Analysis of Cotter Joint REPORT R20ER055Akash AkashBelum ada peringkat

- Comparative Study of Casting Simulation Packages Used in FoundriesDokumen4 halamanComparative Study of Casting Simulation Packages Used in FoundriesPrasad AnandBelum ada peringkat

- NuCast SlidesDokumen35 halamanNuCast SlidesAbdel DaaBelum ada peringkat

- 304 DesignDokumen39 halaman304 DesignPramod KulkarniBelum ada peringkat

- Ansys Project WorkDokumen24 halamanAnsys Project Workvicky120950% (2)

- Additive ManufacturingDokumen20 halamanAdditive Manufacturingjoeborderline100% (1)

- Computer-Aided Design of Tooling For Casting Process: August 1999Dokumen11 halamanComputer-Aided Design of Tooling For Casting Process: August 1999didoBelum ada peringkat

- E 08Dokumen16 halamanE 08João PauloBelum ada peringkat

- Design & Fabrication of Metal Scrap Bailing PressDokumen4 halamanDesign & Fabrication of Metal Scrap Bailing PressReyazul HaqueBelum ada peringkat

- Sand Casting Using RP and Conventional MethodsDokumen5 halamanSand Casting Using RP and Conventional MethodsjlplazaolaBelum ada peringkat

- Assignment 2 MPMDokumen2 halamanAssignment 2 MPMShivalik NaikBelum ada peringkat

- Presentation EBM NewDokumen70 halamanPresentation EBM NewpenhameedBelum ada peringkat

- Design and Mechanical Properties June2015 1039HOGinteractiveDokumen130 halamanDesign and Mechanical Properties June2015 1039HOGinteractivePestisan IustinianBelum ada peringkat

- Mathematical Modelling and Shape Optimisation of Front Damper Mount of Ashok Leyland 1612 Truck Using 3d Finite Element MethodDokumen7 halamanMathematical Modelling and Shape Optimisation of Front Damper Mount of Ashok Leyland 1612 Truck Using 3d Finite Element MethodtheijesBelum ada peringkat

- Design of Lattice Structure For Additive ManufacturingDokumen8 halamanDesign of Lattice Structure For Additive ManufacturingGunaseelanMurugesanBelum ada peringkat

- PlasticProductdesign 2 PDFDokumen115 halamanPlasticProductdesign 2 PDFAmolPagdalBelum ada peringkat

- FULLTEXT01Dokumen79 halamanFULLTEXT01Azeb TeklemariamBelum ada peringkat

- شبیه سازی 3Dokumen6 halamanشبیه سازی 3muhammadaliBelum ada peringkat

- Lampa Ijcim Dalsanto 2014Dokumen11 halamanLampa Ijcim Dalsanto 2014Sk.Abdul NaveedBelum ada peringkat

- Fulltext01 PDFDokumen72 halamanFulltext01 PDFSanthiBelum ada peringkat

- Research On The Influence of Moulding-Casting TechDokumen10 halamanResearch On The Influence of Moulding-Casting TechmallikahotBelum ada peringkat

- Stampack: Technology For Cost Reduction, Quality Improvement and Productivity GainsDokumen2 halamanStampack: Technology For Cost Reduction, Quality Improvement and Productivity GainsBG2012Belum ada peringkat

- Masters Thesis-Additive ManufacturingDokumen123 halamanMasters Thesis-Additive ManufacturingSameer SonuBelum ada peringkat

- Design and Analysis of Chain Sprocket Using ReversDokumen9 halamanDesign and Analysis of Chain Sprocket Using ReversAhmed MohamedBelum ada peringkat

- analsis of casting processDokumen113 halamananalsis of casting processNaveen KumarBelum ada peringkat

- Machine Design Lec - 1Dokumen22 halamanMachine Design Lec - 1Sasthi HensBelum ada peringkat

- CAD and Cae in Biomedical Field Seminar ReportDokumen20 halamanCAD and Cae in Biomedical Field Seminar ReportAshish RajBelum ada peringkat

- Vessel Design CalculationsDokumen15 halamanVessel Design CalculationsmadhurBelum ada peringkat

- Accepted Manuscript: Additive ManufacturingDokumen53 halamanAccepted Manuscript: Additive ManufacturingAnkushBelum ada peringkat

- Springback Behavior of AA6082T6 Tubes in Three-Point Bending OperationDokumen7 halamanSpringback Behavior of AA6082T6 Tubes in Three-Point Bending OperationYasser BouktirBelum ada peringkat

- MCS 06 UK (Jun-09) PDFDokumen68 halamanMCS 06 UK (Jun-09) PDFhepcomotionBelum ada peringkat

- Robot Arm Without Using Robot Language and Its Application To Machining ProcessDokumen5 halamanRobot Arm Without Using Robot Language and Its Application To Machining ProcessJulio Vega AngelesBelum ada peringkat

- Machine Design Elements and AssembliesDari EverandMachine Design Elements and AssembliesPenilaian: 3.5 dari 5 bintang3.5/5 (2)

- The Art of Timing Closure: Advanced ASIC Design ImplementationDari EverandThe Art of Timing Closure: Advanced ASIC Design ImplementationBelum ada peringkat

- Engineering Applications: A Project Resource BookDari EverandEngineering Applications: A Project Resource BookPenilaian: 2.5 dari 5 bintang2.5/5 (1)

- 2015-16 FSAE Rules Revision in Progress KZ 83114Dokumen176 halaman2015-16 FSAE Rules Revision in Progress KZ 83114Harry BikasBelum ada peringkat

- Minda Industries Interim ReportDokumen10 halamanMinda Industries Interim ReportShivam WankhedeBelum ada peringkat

- Freeman AGP 21 1979Dokumen57 halamanFreeman AGP 21 1979Shivam WankhedeBelum ada peringkat

- Converging Diverging NozzleDokumen6 halamanConverging Diverging NozzleShivam WankhedeBelum ada peringkat

- DifferetialsDokumen1 halamanDifferetialsShivam WankhedeBelum ada peringkat

- Fibre Volume Fraction - SummaryDokumen9 halamanFibre Volume Fraction - SummaryjhtangBelum ada peringkat

- Ansys Training Book.Dokumen15 halamanAnsys Training Book.Sarath Babu SBelum ada peringkat

- Chain Sprocket Design and SpecificationsDokumen1 halamanChain Sprocket Design and SpecificationsShivam WankhedeBelum ada peringkat

- Intake Exhaust Basics 1Dokumen53 halamanIntake Exhaust Basics 1Shivam WankhedeBelum ada peringkat

- Installation ProcedureDokumen7 halamanInstallation ProcedureShivam WankhedeBelum ada peringkat

- Control of EvDokumen5 halamanControl of EvShivam WankhedeBelum ada peringkat

- BrakesDokumen7 halamanBrakesShivam WankhedeBelum ada peringkat

- Various Inputs That Can Be Controlled To Impact MixingDokumen15 halamanVarious Inputs That Can Be Controlled To Impact MixingShivam WankhedeBelum ada peringkat

- Monocoque Zuerich FSG-Workshop EuroMoldDokumen32 halamanMonocoque Zuerich FSG-Workshop EuroMoldShivam WankhedeBelum ada peringkat

- Wheelhub Integration of Electric Motor in FSEDokumen35 halamanWheelhub Integration of Electric Motor in FSEShivam WankhedeBelum ada peringkat

- Matlab 13 Install GuideDokumen161 halamanMatlab 13 Install GuideBen Umobi JnrBelum ada peringkat

- Matlab 13 Install GuideDokumen161 halamanMatlab 13 Install GuideBen Umobi JnrBelum ada peringkat

- LatexDokumen35 halamanLatexapi-3720088Belum ada peringkat

- Matlab Finite Element Modeling For Materials Engineers Using MATLABDokumen74 halamanMatlab Finite Element Modeling For Materials Engineers Using MATLABPujara ManishBelum ada peringkat

- Differential and Drive AxlesDokumen38 halamanDifferential and Drive AxlesShivam Wankhede100% (2)

- Differntial - QDF7ZRDokumen1 halamanDifferntial - QDF7ZRShivam WankhedeBelum ada peringkat

- Fe Exam Review BookDokumen1.229 halamanFe Exam Review BookDeneme Dedeoğlu98% (50)

- Certificate of Analysis: Reference Material - Primary StandardDokumen8 halamanCertificate of Analysis: Reference Material - Primary StandardWidya Dwi AriniBelum ada peringkat

- Temperature Recovery FactorsDokumen64 halamanTemperature Recovery FactorsGokul NathBelum ada peringkat

- Lab Rules Q and ADokumen18 halamanLab Rules Q and Ana-chanBelum ada peringkat

- Device Fabrication Technology: Modern Semiconductor Devices For Integrated Circuits (C. Hu) Slide 3-1Dokumen40 halamanDevice Fabrication Technology: Modern Semiconductor Devices For Integrated Circuits (C. Hu) Slide 3-1EASACOLLEGEBelum ada peringkat

- K3 Skema Cemerlang Set 1Dokumen4 halamanK3 Skema Cemerlang Set 1annurshah05Belum ada peringkat

- Solomons Frsolomons-Fryhlesyhles Organic Chemistry For Iit JeeDokumen2 halamanSolomons Frsolomons-Fryhlesyhles Organic Chemistry For Iit JeeFazle Rahman Ejazi50% (4)

- FIITJEE ALL INDIA TEST SERIES FULL TEST – XI PHYSICS ANSWERS AND SOLUTIONSDokumen19 halamanFIITJEE ALL INDIA TEST SERIES FULL TEST – XI PHYSICS ANSWERS AND SOLUTIONSVoxBelum ada peringkat

- Chemistry 9 Chap 1 Long QADokumen17 halamanChemistry 9 Chap 1 Long QAAkbar Ali AhmedBelum ada peringkat

- Ceng204P Separation Processes I Coursework 1: 1. Problem DescriptionDokumen3 halamanCeng204P Separation Processes I Coursework 1: 1. Problem DescriptionKaren Chong Yap100% (1)

- Vickers General Hydraulic BookDokumen29 halamanVickers General Hydraulic BookKarthik Sarang100% (15)

- NEET-2021 (Paper Analysis) FinalDokumen32 halamanNEET-2021 (Paper Analysis) FinalMahasina BegumBelum ada peringkat

- 0808231109005091Dokumen2 halaman0808231109005091tinitnthesaiyanBelum ada peringkat

- Comsol Simulation of A 2.45 GHZ Electron Cyclotron Resonance Argon PlasmaDokumen4 halamanComsol Simulation of A 2.45 GHZ Electron Cyclotron Resonance Argon PlasmaArjav VashiBelum ada peringkat

- ME 331 Thermodynamics II Lecture 3cDokumen31 halamanME 331 Thermodynamics II Lecture 3cJosell CaipangBelum ada peringkat

- Bridge Course - First Year SyllabusDokumen25 halamanBridge Course - First Year Syllabusrevanth kumar100% (1)

- Pva 2019Dokumen7 halamanPva 2019kashyap8291100% (1)

- Topic 1.2 Analytical ProcessDokumen52 halamanTopic 1.2 Analytical ProcessEyzah75% (8)

- Measuring errors and their classificationDokumen6 halamanMeasuring errors and their classificationNarendra Reddy0% (1)

- High Carbon Wire RodDokumen9 halamanHigh Carbon Wire Rodninganray6316100% (1)

- Processing and Fish PreservationDokumen13 halamanProcessing and Fish PreservationAbdiqadir JibrilBelum ada peringkat

- Recovery and Purification of Lactic Acid From Fermentation BrothDokumen185 halamanRecovery and Purification of Lactic Acid From Fermentation BrothBilli CostanBelum ada peringkat

- 150 CDokumen13 halaman150 Crobert carbungcoBelum ada peringkat

- Geology Geophysics in Oil ExplorationDokumen70 halamanGeology Geophysics in Oil Explorationberbere68100% (1)

- 13NO03 GN 60 001 Deliverable ListDokumen4 halaman13NO03 GN 60 001 Deliverable Listbagus handokoBelum ada peringkat

- Lecture Planner - Chemistry PDF OnlyDokumen1 halamanLecture Planner - Chemistry PDF OnlyJai ChandBelum ada peringkat

- ELITE™ AT 6900: The Dow Chemical Company - Enhanced Polyethylene ResinDokumen2 halamanELITE™ AT 6900: The Dow Chemical Company - Enhanced Polyethylene ResinLeductoan LeBelum ada peringkat

- Ans No. 4-Conservation of Mass Equation-: + Known As Continuity EquationDokumen4 halamanAns No. 4-Conservation of Mass Equation-: + Known As Continuity EquationHimanshu TrivediBelum ada peringkat

- 1 02 Coco PDFDokumen13 halaman1 02 Coco PDFsandeep lalBelum ada peringkat

- Monsal Enzymic Hydrolysis New Developments and Lessons LearntDokumen23 halamanMonsal Enzymic Hydrolysis New Developments and Lessons LearntAnonymous MVHQ97KEoPBelum ada peringkat