Design of Pressure Vessel Components and Stresses

Diunggah oleh

AMIT SOLANKIJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Design of Pressure Vessel Components and Stresses

Diunggah oleh

AMIT SOLANKIHak Cipta:

Format Tersedia

Design of Pressure Vessel

By A.B.Solanki

INTRODUCTION [1]

Vessels, tanks, and pipelines that carry, store, or receive fluids are

called pressure vessels.

A pressure vessel is defined as a container with a pressure

differential between inside and outside.

The inside pressure is usually higher than the outside, except for

some isolated situations.

Pressure vessels often have a combination of high pressures

together with high temperatures.

Because of such hazards it is imperative that the design be such

that no leakage can occur.

Pressure vessels and tanks are, in fact, essential to the chemical,

petroleum, petrochemical and nuclear industries. It is in this class of

equipment that the reactions, separations, and storage of raw

materials occur.

Pressure vessel

Function

Storage tank

Process vessel

Heat Exchanger

Geometry

Cylindrical

Spherical

Conical

Horizontal/Vertical

Construction

Monowall

Multi Wall

Forged

Service

Cryogenic

Steam

Lethal

Fired/Unfired

CLASSIFICATION OF PRESSURE VESSEL [3]

COMPONENTS OF PRESSURE VESSELS

The main components of pressure vessel are [4]

i. Shell

ii. Heads

iii. Nozzles

iv. Stiffening rings

v. Supports

Photo courtesy: www.theculminates.com

Shell

The shell is the primary component that contains the

pressure.

Pressure vessel shells are welded together to form a

structure that has a common rotational axis.

Most pressure vessel shells are cylindrical, spherical and

conical in shape

Head

All pressure vessel shells must be closed at the ends by

heads (or another shell section).

Heads are typically curved rather than flat.

Curved configurations are stronger and allow the heads to

be thinner, lighter, and less expensive than flat heads.

Heads are usually categorized by their shapes.

Fig: Different types of heads.

(Modified from ASME Boiler and Pressure Vessel Code, ASME, New York.)

Support

The type of support that is used depends primarily on the size

and orientation of the pressure vessel.

the pressure vessel support must be adequate for the applied

weight, wind, and earthquake loads.

Typical kinds of supports are as follow:

a. Skirt

b. Leg

c. Saddle

d. Lug

Photo courtesy: www.pressurevesslesconsulting.com

Saddle

Leg

Skirt

Lug

Figure showing various

pressure vessel supports.

Nozzle

A nozzle is a cylindrical component that penetrates the shell or heads of a

pressure vessel.

The nozzle ends are usually flanged to allow for the necessary connections

and to permit easy disassembly for maintenance or access.

Nozzles are used for attaching piping for flow into or out of the vessel and

attach instrument connections, (e.g., level gauges, thermowells, or

pressure gauges).

Stiffener Rings

Rings made of flat bar or plate or structural shapes welded around the

Circumference of the vessel.

These rings are installed on vessels operating under external pressure to

prevent collapse of the vessel.

Photo courtesy: www.pressurevesslesconsulting.com

Major Failures associated with pressure vessel can usually be classified as 5 types :

1. EXCESSIVE ELASTIC DEFORMATION

It is a type of expansion of vessel till limit of proportionality.

It affects the volume and density of fluid inside the vessel, hence the purpose of

the vessel will fail and effect the process. So excessive elastic deformation is

undesirable.

2. PLASTIC INSTABILITY :

Plastic deformations occur in a pressure vessel if the Internal or external pressure

becomes so high that resultant stresses acting on the pressure vessel exceeds the

yield point.

Elastic instability in vessels is usually associated with the use of thin shells.

Plastic instability

3. BRITTLE RUPTURE :

If the material used for the vessel is brittle than instead of plastic or elastic

deformation, vessel will ruptured instantly after increasing the slight load after yield

point.

Hence for brittle material stresses should be kept low below the yield point.

MAJOR FAILURES ASSOCIATED WITH PRESSURE

VESSELS

4. CREEP:

Creep is a failure of material due to constant loading and unloading of

material kept at one place for long time.

It arises due to periodic loading and loading. It starts initially from grain

boundary where abnormal grains are there.

It increases to cracks in the material after some time and finally material

fails on load much lower than the yield point stress.

5. CORROSION:

If excessive corrosion occurs than material thickness will decrease

constantly and after a certain limit the material will fail

Due to this the vessels are provided with corrosion allowance thickness.

Generally taken 3mm at inside boundary layer.

At outside some corrosion resistant material are used to prevent the

rusting.

SHELL UNDER INTERNAL

PRESSURE

Calculate internal

design pressure

P = Pi + Pliquid level

HOOP STRESS

Classical Equation

ASME CODE EQUATION

LONGITUDINAL STRESS

Classical Equation

ASME CODE EQUATION

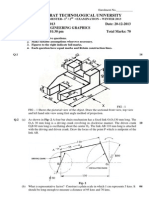

Design of Thin Cylinders

In the design of thin cylinders the following assumptions are

made.

1.The curvature of cylinder wall ignored.

2.The tensile stresses induced at the cross section of the wall are

distributed uniformly.

3.Restraning effect of cylinder head is ignored.

15

Stresses in Pressurized Cylinders

Cylindrical pressure vessels, hydraulic cylinders, shafts with components mounted

on (gears, pulleys, and bearings), gun barrels, pipes carrying fluids at high

pressure,.. develop tangential, longitudinal, and radial stresses.

Wall

thickness

t

A pressurized cylinder is considered a thin-walled vessel if the wall

thickness is less than one-twentieth of the radius.

< 1/20

t

r

Thin-walled pressure vessel

Stress element

Small element

Tangential

stress o

Hoop stress

Longitudinal stress

o

l

(closed ends)

Radial stress

o

r

Stresses in Thin-walled Pressure Vessels (I)

) y 2 ( ) y 2 (

1

d r d t p = o

t

pr

=

1

o

(Hoop Stress)

) r ( ) rt 2 (

2

2

t = t o p

t

pr

2

2

= o

(Longitudinal Stress)

Design of thick wall Cylinder

Thick wall refers to a vessel having an inner-radius-to-wall-thickness ratio less than

10.

Thick wall:

10 <

t

r

i

Example of thick walled applications:

Gun barrel

Very high pressure hydraulic cylinder

For thick wall cylinder, o

R

(radial stress) no longer be neglected.

Introduction

Thick Cylinder wall subject to Internal

Pressure

Consider a thick walled cylinder with internal

pressure P

i

and external pressure P

o

. The

cylinder has inner radius r

i

and outer radius r

o

.

The stress analysis in thick cylinder can be

obtained using Lames Equation.

2

2

r

B

A

and

r

B

A

H

R

+ =

=

o

o

(1)

(2)

where A and B are constant which may

be found using the boundary conditions.

Thick cylinder

Boundary conditions

1. Internal and external pressure

at r = r

i

, o

R

= -p

i

(pressure being negative sign)

and r = r

o

, o

R

= -p

o

subtituting these values to equation (1) and (2), we get:

( )

( )

2 2

2

2 2

2 2

2 2

2 2

2

2 2

2 2

2 2

2 2

2 2

2 2

2 2

) (

) (

) (

i o

o i o i

i o

o o i i

H

i o

o i o i

i o

o o i i

R

i o

o o i i

i o

o i o i

r r r

r r p p

r r

r p r p

r r r

r r p p

r r

r p r p

so

r r

r p r p

A and

r r

r r p p

B

=

o

o

(

(

|

|

.

|

\

|

+

|

|

.

|

\

|

+

=

(

(

|

|

.

|

\

|

|

|

.

|

\

|

=

2

2

2

2

2

2

2

2

2

2

2

2

1 1

1

1

1 1

1

1

r

r

k p

r

r

p

k

r

r

k p

r

r

p

k

i

o

o

i H

i

o

o

i R

o

o

Let the radius ratio r

o

/r

i

=k

then

Thick cylinder

2. Internal pressure only

If the external pressure is atmospheric only, p

o

= 0

|

|

.

|

\

|

+

=

|

|

.

|

\

|

+

=

|

|

.

|

\

|

=

|

|

.

|

\

|

=

2

2

2 2

2

2 2

2

2

2

2 2

2

2 2

2

1

1

1

1

1

1

r

r

k

p

r

r

r r

r p

r

r

k

p

r

r

r r

r p

o i o

i o

i i

H

o i o

i o

i i

R

o

o

At the inner surface (where r=ri),

o

R

and o

H

each have their maximum magnitude.

o

R

=-p

i

(radial compressive stress)

At the outer surface (where r=r

o

)

1

2

0

2

= =

k

p

and

i

H R

o o

i

i o

i

i o

i o

H

p

r r

k

p

r r

r r

2 2

2

2 2

2 2

1

+

=

+

= o

Thick cylinder

Stress distribution for o

H

and o

R

internal

pressure

=p

i

1 2

3

-p

i

-1.5p

i

-p

i

-1.5p

i

o

H

o

R

Stress

Thick cylinder

Maximum shear stress in the cylinder

Maximum shear stress in the plane of the cross section is

given by,

2

2

max

1

2

|

.

|

\

|

=

r

r

k

p

o i

R H

o o

t

Thick cylinder

Example:

Given that:

P

i

= 20 MPa

P

o

= 10 MPa

R

i

= 100 mm

R

o

= 200 mm

Determine the hoop and radial stress at

radius 150 mm.

Thick cylinder

Solution:

2

2

r

B

A

and

r

B

A

H

R

+ =

=

o

o

2

) 1 . 0 (

20

B

A =

Boundary condition:

At r = 0.1, o

R

= -20 MPa

At r = 0.2, o

R

= -10 MPa

Therefore,

2

) 2 . 0 (

10

B

A =

(1)

(2)

Solve the equation (1) and (2) simultaneously, we get: :

A = - 6.7

B = 0.133

Thick cylinder

Substitute all the value A, B and r into the equation, then:

2

r

B

A

R

= o

2

r

B

A

H

+ = o

2

) 15 . 0 (

133 . 0

7 . 6 =

2

) 15 . 0 (

133 . 0

7 . 6 + =

= -12.6 MPa

= -0.79 MPa

Thick cylinder

Design of thick wall Cylinder

Thick Cylinder Subject to External

Pressure

Design of thick cylinder

Compound cylinder made from two

cylinders of different size and could be also

from different materials.

They are used to increased the pressure

that can be obtained in cylinders.

Method of fabrication:

Shrinkage

Force fit

Compound Cylinder

Compound Cylinder

The assembly (shrink fit)

Compound Cylinder

In a compound cylindrical shell, as shown in Fig. the outer

cylinder (having inside diameter smaller than the outside

diameter of the inner cylinder) is shrunk fit over the inner cylinder

by heating and cooling. On cooling, the contact pressure is

developed at the junction of the two cylinders, which induces

compressive tangential stress in the material of the inner cylinder

and tensile tangential stress in the material of the outer cylinder.

When the cylinder is loaded, the compressive stresses are first

relieved and then tensile stresses are induced. Thus, a compound

cylinder is effective in resisting higher internal pressure than a

single cylinder with the same overall dimensions. The principle of

compound cylinder is used in the design of gun tubes.

Compound Cylinder

The method of solution for compound cylinder constructed form similar

material is break the problem down into three separate effects:

(a) shrinkage pressure only on the outside cylinder

(b) shrinkage pressure only on the inside cylinder

(c) internal pressure only on the complete cylinder

Lames equation can be for both inner and outer cylinder.

For each of resulting load, there are two value knows of the radial stress.

Stress Calculation

BC1: shrinkage internal cylinder

At r = r

i

, o

R

= 0

At r = r

c

, o

R

= -p

c

Compound Cylinder

BC2: shrinkage external cylinder

At r = r

c

o

R

= -p

c

At r = r

o

, o

R

= 0

BC3: internal pressure complete cylinder

At r = r

i

o

R

= -p

i

At r = r

o

, o

R

= 0

For each condition, the hoop and radial stress at any radius can be

evaluated.

The various stresses are the combined algebraically to produce the stress in

compound cylinder subjected to both shrinkage and internal pressure.

Compound Cylinder

PRESTRESSTING OF THICK CYLINDER

PRESTRESSTING OF THICK CYLINDER

Method of Increasing Pressure

Capacity

COMPOUND CYLINDER

Autofrettage

In order to use the material effectively and achieve the

uniform stress distribution across the cylinder wall

thickness, the pre stressing is done to the cylinder

In pre stressing residual compressive stresses are

induced at the inner surface and tensile stresses at

outer surface.

When the cylinder is loaded in service the residual

compressive stresses at the inner surface begin to

decrease, become zero and finally become tensile as

the pressure is further increased.

Increase the pressure capacity.

Autofrettage

Overloading Portion of cylinder near the inner

diameter is subjected to stresses in plastic

range while outer portion still in elastic range.

When the pressure is released the outer

portion contracts exerting pressure on the

inner portion which has undergone

permanent deformation. This induces the

residua compressive stresses at the inner

surface and tensile stresses at outer surface.

COMPOUND CYLINDER

In a compound cylindrical shell, as shown in Fig. the outer

cylinder (having inside diameter smaller than the outside

diameter of the inner cylinder) is shrunk fit over the inner

cylinder by heating and cooling. On cooling, the contact

pressure is developed at the junction of the two cylinders,

which induces compressive tangential stress in the material of

the inner cylinder and tensile tangential stress in the material of

the outer cylinder. When the cylinder is loaded, the compressive

stresses are first relieved and then tensile stresses are induced.

Thus, a compound cylinder is effective in resisting higher

internal pressure than a single cylinder with the same overall

dimensions. The principle of compound cylinder is used in the

design of gun tubes.

Anda mungkin juga menyukai

- Dynamic Systems Mathematical Topics 031906 DYNSYSDokumen80 halamanDynamic Systems Mathematical Topics 031906 DYNSYSjohn_max03Belum ada peringkat

- PLANT DAILY MAINTENANCE SCHEDULEDokumen1 halamanPLANT DAILY MAINTENANCE SCHEDULERavi ShankarBelum ada peringkat

- Overview of PV EliteDokumen35 halamanOverview of PV EliteVishaka ThekkedathBelum ada peringkat

- PART 1GasProcessHandbook - 2006 (PDF - Io)Dokumen30 halamanPART 1GasProcessHandbook - 2006 (PDF - Io)ganimedesBelum ada peringkat

- Electrical and Instrumentation Engineering For Oil and Gas FacilitiesDokumen19 halamanElectrical and Instrumentation Engineering For Oil and Gas FacilitiesSyafRizalBelum ada peringkat

- Effectively Managing Multiple Projects: Pdhonline Course P206 (2 PDH)Dokumen23 halamanEffectively Managing Multiple Projects: Pdhonline Course P206 (2 PDH)hadrienBelum ada peringkat

- Absorption of GasesDokumen25 halamanAbsorption of GaseswetcoBelum ada peringkat

- Distillation Column-3Dokumen36 halamanDistillation Column-3Sana BashirBelum ada peringkat

- Prabhu - CV - Structural DesignerDokumen4 halamanPrabhu - CV - Structural DesignerprabhutmuBelum ada peringkat

- Research Project ReportDokumen21 halamanResearch Project ReportinternationalbankBelum ada peringkat

- Pump CalcDokumen5 halamanPump CalcpavanBelum ada peringkat

- Process Simulation in Refineries SamplerDokumen30 halamanProcess Simulation in Refineries SamplerNagendra HBelum ada peringkat

- Engineering Services Related To Process Study: SRU RevampDokumen16 halamanEngineering Services Related To Process Study: SRU RevampSiddiqui Muhammad AshfaqueBelum ada peringkat

- FALLSEM2020-21 CHE1014 TH VL2020210101682 Reference Material I 19-Aug-2020 Catalytic Cracking Different Types PDFDokumen77 halamanFALLSEM2020-21 CHE1014 TH VL2020210101682 Reference Material I 19-Aug-2020 Catalytic Cracking Different Types PDFJateni GedaBelum ada peringkat

- ES Petroleum Energy GuideDokumen122 halamanES Petroleum Energy GuideRizkina Ika AryanaBelum ada peringkat

- Destilation Column InfoDokumen33 halamanDestilation Column InfokumarBelum ada peringkat

- DB-SP2021-ON-PR-103-P312-5000-Rev1-OPERATING MANUAL UNIT 103Dokumen108 halamanDB-SP2021-ON-PR-103-P312-5000-Rev1-OPERATING MANUAL UNIT 103mohsen ranjbarBelum ada peringkat

- Bisep Hot Tapping Plugging 1Dokumen7 halamanBisep Hot Tapping Plugging 1mospt100% (1)

- Progg 01. Pt. DekadeDokumen7 halamanProgg 01. Pt. DekadeAzazel LuciferBelum ada peringkat

- Equipment DesignDokumen146 halamanEquipment DesignhuyBelum ada peringkat

- SAECS Company ProfileDokumen8 halamanSAECS Company ProfileBec EnggBelum ada peringkat

- Inst Vortex PDFDokumen54 halamanInst Vortex PDFambeshBelum ada peringkat

- 08 How To Select TemaDokumen29 halaman08 How To Select TemaJoan CordovaBelum ada peringkat

- HYSYS-Simu Con Preheat Exch THC Grayson Streed. 38API.@1300 Bls DiaDokumen200 halamanHYSYS-Simu Con Preheat Exch THC Grayson Streed. 38API.@1300 Bls DiaLuis Gabriel Gomez AmorteguiBelum ada peringkat

- 10 Beach Well Intakes For Small Seawater Reverse Osmosis PlantsDokumen239 halaman10 Beach Well Intakes For Small Seawater Reverse Osmosis PlantsAnonymous tqG0TJSAap100% (1)

- National Oil Corporation: Rev Date Description Checked ApprovedDokumen36 halamanNational Oil Corporation: Rev Date Description Checked ApprovednizardsouissiBelum ada peringkat

- SOW For Heat Exchanger RFQ 29868 UZB1005 Revised 2017-06-01 PDFDokumen19 halamanSOW For Heat Exchanger RFQ 29868 UZB1005 Revised 2017-06-01 PDFMallu BroBelum ada peringkat

- Ario Damar - Sriwijaya Oil & Gas Development: Document No. CT-F17795-TE2-31-E-002-001Dokumen5 halamanArio Damar - Sriwijaya Oil & Gas Development: Document No. CT-F17795-TE2-31-E-002-001idilfitriBelum ada peringkat

- 02 - Reactor DesignDokumen13 halaman02 - Reactor DesignnadBelum ada peringkat

- Overview of Small Bore PipingDokumen7 halamanOverview of Small Bore PipingCelestine OzokechiBelum ada peringkat

- Gas-Liquid Operations Equipment: Mr. Chintan K. Modi Asst. Professor Chemical Engineering Department SrictDokumen76 halamanGas-Liquid Operations Equipment: Mr. Chintan K. Modi Asst. Professor Chemical Engineering Department SrictSoma BerwariBelum ada peringkat

- Kokori Flowstation Surge Vessel Calculations VerifiedDokumen6 halamanKokori Flowstation Surge Vessel Calculations VerifiedToniBelum ada peringkat

- Skikda Training CDU (Goal Content)Dokumen26 halamanSkikda Training CDU (Goal Content)Mohamed OuichaouiBelum ada peringkat

- Heat Exchanger Sizing E-7010 #1Dokumen2 halamanHeat Exchanger Sizing E-7010 #1Luis Enrique Leyva OvalleBelum ada peringkat

- PWR Is The Abbreviation For The Pressurized Water ReactorDokumen18 halamanPWR Is The Abbreviation For The Pressurized Water Reactorshrishmapaik2070Belum ada peringkat

- Safe Chemical Reaction Scale Up: by Dennis C. Hendershot, Aaron SarafinasDokumen7 halamanSafe Chemical Reaction Scale Up: by Dennis C. Hendershot, Aaron Sarafinasnitin_kheseBelum ada peringkat

- 32 Samss 007Dokumen84 halaman32 Samss 007Inamullah KhanBelum ada peringkat

- Algiers Refinery Instrument Tie-In Engineering DossierDokumen8 halamanAlgiers Refinery Instrument Tie-In Engineering Dossiermissoum mohamedBelum ada peringkat

- KIL3012 - WEEK 1 - 10.9.19 (Student Copy)Dokumen61 halamanKIL3012 - WEEK 1 - 10.9.19 (Student Copy)Ed100% (1)

- McCabe Thiele method: graphical solution for binary distillationDokumen104 halamanMcCabe Thiele method: graphical solution for binary distillationKhin Oo100% (1)

- Proposal Work Flow GuidelineDokumen2 halamanProposal Work Flow Guidelineirshad sondeBelum ada peringkat

- Design Calculations For Pressure VesselsDokumen51 halamanDesign Calculations For Pressure VesselsFuehrerBelum ada peringkat

- Vessel Internals OptimizationDokumen20 halamanVessel Internals Optimizationjannick86100% (1)

- 'Field Instrument List For Wagon Tippler PackagDokumen5 halaman'Field Instrument List For Wagon Tippler PackagAnandharaj .K0% (1)

- Princeton Petroleum RefiningDokumen30 halamanPrinceton Petroleum RefiningDaniel RedondoBelum ada peringkat

- 5000LPH Ro PlantDokumen5 halaman5000LPH Ro PlantYash HariaBelum ada peringkat

- Hazard Evaluation Techniques HAZOP GuideDokumen25 halamanHazard Evaluation Techniques HAZOP Guidemarius_brkt6284Belum ada peringkat

- Vessels & Column Tower PipingDokumen47 halamanVessels & Column Tower Pipingامین کاظمیBelum ada peringkat

- Column & Vessel - NSDokumen144 halamanColumn & Vessel - NSmujeebtalibBelum ada peringkat

- Aais - PMCDokumen9 halamanAais - PMCneel78Belum ada peringkat

- Ponchon Savarit MethodDokumen17 halamanPonchon Savarit MethodRose Dane Escobedo DiestaBelum ada peringkat

- Equipment Design BasisDokumen4 halamanEquipment Design BasisAnjani GantiBelum ada peringkat

- Design Criteria DUDPDokumen419 halamanDesign Criteria DUDPsridar rBelum ada peringkat

- 411 E10AB AdequacyDokumen7 halaman411 E10AB AdequacyMuhammadUsmanSaeed100% (1)

- Unit 4 NotesDokumen60 halamanUnit 4 NotesVikas RathodBelum ada peringkat

- Chapter One: Pressure Vessel Design Models For CylindersDokumen60 halamanChapter One: Pressure Vessel Design Models For Cylindersabiy balkewBelum ada peringkat

- Chapter One: Pressure Vessel Design M Odels For CylindersDokumen36 halamanChapter One: Pressure Vessel Design M Odels For Cylindersabiy balkewBelum ada peringkat

- Presser Vessel DesignDokumen30 halamanPresser Vessel DesignAsila Ahmed100% (1)

- Pressure VesselDokumen40 halamanPressure VesselPrt00789% (18)

- Chapter-Five 5.: Pressure VesselDokumen13 halamanChapter-Five 5.: Pressure Vesselkibromgidey12Belum ada peringkat

- Anmol1 140125064020 Phpapp02Dokumen21 halamanAnmol1 140125064020 Phpapp02AMIT SOLANKIBelum ada peringkat

- Robotics 130224122655 Phpapp02Dokumen23 halamanRobotics 130224122655 Phpapp02AMIT SOLANKIBelum ada peringkat

- Pdve Paper Soultion 2011Dokumen19 halamanPdve Paper Soultion 2011AMIT SOLANKIBelum ada peringkat

- Guidelines For The OpenDokumen4 halamanGuidelines For The Openjijo123408Belum ada peringkat

- DOM Question BankDokumen4 halamanDOM Question BankAMIT SOLANKIBelum ada peringkat

- Whit Worth QuickReturn Mechanism Robotpark - 6 PDFDokumen95 halamanWhit Worth QuickReturn Mechanism Robotpark - 6 PDFAnonymous 2xjDjAcZBelum ada peringkat

- Pdve Paper Solution 2012Dokumen19 halamanPdve Paper Solution 2012AMIT SOLANKIBelum ada peringkat

- Question Bank AOTDokumen4 halamanQuestion Bank AOTAMIT SOLANKIBelum ada peringkat

- Design of SpindleDokumen36 halamanDesign of SpindleAMIT SOLANKI0% (1)

- Design of SpindleDokumen36 halamanDesign of SpindleAMIT SOLANKI0% (1)

- Thick Thin Cylinders Pressure Vessel. PPT in PDFDokumen5 halamanThick Thin Cylinders Pressure Vessel. PPT in PDFlram70Belum ada peringkat

- Theory of Elasticity - TIMOSHENKO PDFDokumen263 halamanTheory of Elasticity - TIMOSHENKO PDFShaik BademiyaBelum ada peringkat

- GearDokumen30 halamanGearsai babuBelum ada peringkat

- 110013Dokumen2 halaman110013AMIT SOLANKIBelum ada peringkat

- 5 Product SpecifiactionDokumen43 halaman5 Product SpecifiactionAMIT SOLANKIBelum ada peringkat

- Factories Act, 1948Dokumen60 halamanFactories Act, 1948mrnishu2011Belum ada peringkat

- Bearing 2007-08Dokumen60 halamanBearing 2007-08Mahmoud NaelBelum ada peringkat

- 9 Value Engineering ProjectsDokumen5 halaman9 Value Engineering ProjectsAMIT SOLANKIBelum ada peringkat

- MDID IntroductionDokumen36 halamanMDID IntroductionAMIT SOLANKIBelum ada peringkat

- Value EngineeringDokumen52 halamanValue EngineeringAMIT SOLANKIBelum ada peringkat

- Web SpreadingDokumen21 halamanWeb SpreadingKamalam CloudsoftBelum ada peringkat

- THM 700 R4 4L60 1982 1986 - ATSG Automatic Transmission Service Group PDFDokumen96 halamanTHM 700 R4 4L60 1982 1986 - ATSG Automatic Transmission Service Group PDFAntonio Perez100% (4)

- R070T Parts ManualDokumen43 halamanR070T Parts ManualDieselkBelum ada peringkat

- Tpi 31 - VVKN - enDokumen13 halamanTpi 31 - VVKN - enKundzoBelum ada peringkat

- Api Bottom Load ValveDokumen2 halamanApi Bottom Load ValveMạnh Ngô ĐứcBelum ada peringkat

- Aluminium Using AFSDDokumen12 halamanAluminium Using AFSDKinesys TechsolutionsBelum ada peringkat

- PSXX OMR0002 PDFDokumen64 halamanPSXX OMR0002 PDFLupeBelum ada peringkat

- pc200 7 Main Pump Test MethodDokumen26 halamanpc200 7 Main Pump Test Methodalfred100% (1)

- Corporate Brochure Part No. TitleDokumen15 halamanCorporate Brochure Part No. TitleAnonymous V9fdC6Belum ada peringkat

- Basics of Pumps Training ModuleDokumen54 halamanBasics of Pumps Training ModulesuprateemBelum ada peringkat

- Wiring Diagram V7Dokumen1 halamanWiring Diagram V7NadeeshBelum ada peringkat

- Bagatelle Showroom Structural AnalysisDokumen15 halamanBagatelle Showroom Structural AnalysisDhiraj BeechooBelum ada peringkat

- Hazard and Operability Analysis (HAZOP) of A Plastic Manufacturing Plant at Karachi, PakistanDokumen7 halamanHazard and Operability Analysis (HAZOP) of A Plastic Manufacturing Plant at Karachi, PakistanFaisal AkhterBelum ada peringkat

- Analysis of Arch Dams Using Coupled Trial LoadDokumen10 halamanAnalysis of Arch Dams Using Coupled Trial LoadUzair Maqbool KhanBelum ada peringkat

- Owners manual for Maveric GK-32A go kartDokumen18 halamanOwners manual for Maveric GK-32A go kartedgar santanaBelum ada peringkat

- Toyota Celica Wiring Diagram 1993Dokumen18 halamanToyota Celica Wiring Diagram 1993Gary Reynolds100% (2)

- BS en 12334-2001Dokumen14 halamanBS en 12334-2001Udit Kumar SarkarBelum ada peringkat

- Exercises Marine Engineer + Internal Combustion EnginesDokumen3 halamanExercises Marine Engineer + Internal Combustion EnginesGeorge GaneaBelum ada peringkat

- McCormick X60 Series (2011-2014) - RP67 - X60.50 Tractor Service Repair Manual PDFDokumen25 halamanMcCormick X60 Series (2011-2014) - RP67 - X60.50 Tractor Service Repair Manual PDFfjkkekmdmBelum ada peringkat

- Goulds 3171 / CV3171: Vertical Sump and Process PumpsDokumen16 halamanGoulds 3171 / CV3171: Vertical Sump and Process PumpsJavier Fernando Agudelo GómezBelum ada peringkat

- Manual Motor Crrcpro26iDokumen8 halamanManual Motor Crrcpro26ieduardo_albornoz_5Belum ada peringkat

- Elektrisk (Katalog - Ermax)Dokumen267 halamanElektrisk (Katalog - Ermax)ionel1987Belum ada peringkat

- Mechanical Sensors 25augustDokumen74 halamanMechanical Sensors 25augustSasikumar SukumaranBelum ada peringkat

- Mechanical Engineering: Department ofDokumen50 halamanMechanical Engineering: Department ofUsman SarwarBelum ada peringkat

- Curvilinear Motion and ProjectilesDokumen15 halamanCurvilinear Motion and ProjectilesAltammar1367% (3)

- PPM High-Strength Anchor Bolt Peikko Group 05-2015Dokumen36 halamanPPM High-Strength Anchor Bolt Peikko Group 05-2015Jody Inggil PambudiBelum ada peringkat

- Parts Manual Parts Manual Service Manual: Reach TrucksDokumen22 halamanParts Manual Parts Manual Service Manual: Reach TrucksChristian Bedoya10% (10)

- Fluid Mechanics Test and Exam DetailsDokumen8 halamanFluid Mechanics Test and Exam DetailsDiego FungBelum ada peringkat