Maximizing Shear Strength with Steel Fibers

Diunggah oleh

wtfisf0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

53 tayangan58 halamanthesis presentation

Judul Asli

Ppt Presentation 031512-Final

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPTX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inithesis presentation

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPTX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

53 tayangan58 halamanMaximizing Shear Strength with Steel Fibers

Diunggah oleh

wtfisfthesis presentation

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPTX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 58

UTILIZATION OF STEEL FIBERS AS

REPLACEMENT FOR STIRRUPS IN

REINFORCED CONCRETE BEAM

CHAPTER I:

The Problem and i!

Ba"#$ro%nd

INTRODUCTION

Stirrups are the conventional shear reinforcement for

reinforced concrete beams. Resistance to diagonal

tension and crack propagation are the advantages of

using this conventional shear reinforcement. ut on the

other hand! some disadvantages have been found b"

the researchers. The" think that this conventional

shear reinforcement increases the labor cost and

prolongs the casting of steel reinforcement as #ell as

the forms. ecause of these! the researchers #ould like

to present an alternative shear reinforcement that has

a capabilit" similar to conventional$ the steel %ber.

CONC&'TU() *R(+&,OR-

ST(T&+&NT O* T.& 'RO)&+

The stud" aims to evaluate the

ma/imum load of reinforced concrete

beams utili0ing steel %ber as shear

reinforcement. (t the end of the research

the follo#ing concerns #ill be addressed1

2. ,hat are the e3ects of steel %ber #ith

di3erent volume fraction 45.56! 5.786!

2.56 and 2.986: on reinforced concrete

beam #ithout stirrups;

9. ased on the ma/imum load! #hat

are the advantages of specimens #ith

steel %ber over specimens containing

stirrups;

<. *or all the specimens tested in this

stud"! #hich specimen #ill attain the

highest ma/imum load;

=. ,hat are the similarities bet#een

specimens #ith steel %bers and

specimens #ith stirrups based on the

test result;

8. .o# consistent is the distribution of

steel %bers on concrete mi/ture;

>. ,hich specimens on t#o batches do

not e/ceed the percentage error of 86;

.?'OT.&S&S1

2. Inclusion of steel %ber in the concrete mi/

improves the ma/imum load of reinforced

concrete beams.

9. Change in ma/imum load is directl"

proportional to the change in volume fraction.

<. Change in ma/imum load is directl"

proportional to the change in number of

stirrups.

=. The mode of failure of the specimens is

shear failure.

O@&CTIA& O* T.& STUD?

The main obBective of this stud" is to determine the

possibilit" of utili0ing steel %bers as replacement for

stirrups in reinforced concrete beam.

Speci%call" the researchers #ould like to determine

the follo#ing1

2. The ma/imum load of reinforced concrete

beams #ith di3erent number of stirrups1

a. 5

b. <

c. =

d. 8

e. >

9. The ma/imum load of reinforced concrete

beams #ith di3erent volume fraction1

a.5.786

b.2.56

c.2.986

<. Signi%cant di3erence bet#een the

ma/imum load of reinforced concrete beams

#ith di3erent number of stirrups and ma/imum

load of reinforced concrete beams #ith

di3erent volume fraction.

CHAPTER II:

RE&IE' OF RELATED

STUDIES AND

LITERATURES

R&AI&, O* R&)(T&D )IT&R(TUR& 4*OR&ICN (ND

)OC():

Seel Fiber a! Re(la"emen o) 'eb Rein)or"emen )or RCC

Dee( Beam! in Shear

Shear Sren$h o) Hi$h Sren$h Fiber Rein)or"ed Con"ree

beam!

The e*e" o) +(e and ,ol%me )ra"ion -&F. o) !eel /ber on

he me"hani"al (ro(erie! o) !el)0"om(a"in$ "on"ree.

Sren$henin$ Beam0Col%mn 1oin 2ih Seel Fiber Rein)or"ed

Con"ree D%rin$ Earh3%a#e Loadin$4

Beha,ior o) Seel Fiber Rein)or"ed Con"ree Beam and Plae!

%nder Sai" Load -lo"al.

CHAPTER III:

RESEARCH DESI6N

METHODOLO67

R&S&(RC. +&T.ODO)OC?

This stud" aims to observe and evaluate the

ma/imum load of reinforced concrete beam

utili0ing steel %ber as shear reinforcement. This

chapter illustrates the procedure and test used

to attain the ma/imum load of the test

specimens. Researchers prefer to use concrete

#ith the mi/ture proportion ratio of 212.D81<.97

4b" #eight:. Test specimens #ith di3erent

volume fraction #ill be compared to the

specimens #ith di3erent numbers of

conventional shear reinforcement 4stirrups:

R&S&(RC. D&SICN

The researchers used an e/perimental method of stud"

#herein data gathering process and accurate

interpretation of data is to be e/hibited based on the

outcome of the procedures.

The e/perimental method renders a logical and s"stematic

#a" to kno# the possibilit" of steel %ber to replace

conventional steel reinforcement 4stirrups:. To provide a

precise ans#er to this! the researchers manipulated

certain inEuences and observe ho# the condition or the

behavior of the subBect is a3ected or change. The

researchers had to isolate these inEuences in. such #a"

that the" are sure that the e3ects that observe can be

attributed and relevant.

+(T&RI() US&D (ND T&ST S'&CI+&N D&T(I)

The steel %ber that #ill be used in this stud" has a

diameter of 5.78mm and length of =5mm! and

having an aspect ratio 4lFd: of >7. +i/ture proportion

ratio of 212.D81<.97 4b" #eight: #ill be used. ( total

of eleven specimens #ill be tested in this stud".

Researchers used a > inches b" > inches b" 92

inches rectangular reinforced concrete beam #ith <

bars of 29mm diameter as longitudinal

reinforcement. Di3erent volume fraction of steel %ber

45.56! 5.786! 5.786! 2.56! 2.56! 2.986 and 2.986:

#ill be prepared for specimens (! 2! 9! C2! C9! D2!

and D9 respectivel".

These specimens do not contain

stirrups. Specimens 9! C9! and D9!

#ere provided to perceive the

consistenc" of the steel %ber

distribution into the concrete mi/ture.

Specimens &! *! C and . have di3erent

number of >mm diameter stirrups to

sho# the change in ma/imum load.

T&ST S'&CI+&NS

GU()IT? T&ST O* +(T&RI()S

S(e"i/" 6ra,i+ o) "emen

-ASTM 8990:9 Den!i+ o) H+dra%li" Cemen.

Uni 'ei$h o) A$$re$ae!

-ASTM ;<0:9 Te! Mehod )or Uni and &oid!

in A$$re$ae!.

S(e"i/" 6ra,i+ o) he Coar!e A$$re$ae

-ASTM C 8;:098 S(e"i/" 6ra,i+ and

Ab!or(ion o) Coar!e A$$re$ae!.

S(e"i/" 6ra,i+ o) Fine A$$re$ae

-ASTM C 8;90:< S(e"i/" 6ra,i+ and

Ab!or(ion o) Fine A$$re$ae!.

Uni 'ei$h o) A$$re$ae!

-ASTM C ;<0:9 Te! Mehod! )or Uni and

&oid! in A$$re$ae!.

Sie,e Anal+!i! o) A$$re$ae!

-ASTM C 8=>09= Sie,e Anal+!i! o) Fine and

Coar!e A$$re$ae!.

(CI 922 CONCR&T& +IH D&SICN 'ROC&DUR&

Sl%m( Te!:

Te! )or Sl%m( o) Fre!h Con"ree

-ASTM ;=809; Air Conen o) Fre!hl+

Mi?ed Con"ree b+ he Pre!!%re

Mehod.

Choi"e o) Ma?im%m Si@e o) A$$re$ae

E!imaion o) Mi?in$ 'aer and Air

Conen

Sele"ion o) 'aer0Cemen or 'aer0

Cemeniio%! maerial raio

Cal"%laion o) Cemen Conen

E!imaion o) Fine A$$re$ae Conen

AdA%!men )or A$$re$ae Moi!%re

Trial Ba"h AdA%!men

T&ST 'ROC&DUR&

Specimens are to be designed in >inches b" >inches b"

92 inches rectangular beam mold.

'repare design mi/! #hich #ill be used all throughout

the stud".

Trial mi/es are to be conducted to achieve the desired

compressive strength of concrete.

(fter the trial mi/ has been establish! series of standard

mi/ #ill produce #ith a standard 9D curing da"s.

Then! prepare all specimens for third point loading

tests.

Record all data needed and assess the di3erences

in their strengths.

Data that #ill be presented on this stud" are to be

recorded b" the researches in an accurate detailed

manner based outcome of the test has been done.

CURINC (ND C(STINC

During mi/ing of the steel %ber to the mi/ed

concrete! balling$up of steel %bers can be avoided b"

feeding the %bers into the mi/ in small Juantities at

a time. ,hen the %bers are uniforml" spread over

the mi/! the mi/ture #ill be poured and compacted

into the beam molds. Used oil is used as lubricant to

cover the molds for the ease of releasing the

specimens out of each mold. The specimens are

hardened %rst for about 9= hours. (fter the

hardening! the specimens are released out of the

molds and placed at room temperature. (ll the

specimens #ill undergo curing range of 9D da"s

*)O, C.(RT 'ROC&DUR&

CHAPTER I&:

PRESENTATIONB

ANAL7SIS AND

INTERPRETATION OF

DATA

'R&S&NT(TION (ND (N()?SIS O*

D(T(

Specimen

Volume Fraction Number of Stirrups

Beam A 0.0%

Beam B1 0.75% -

Beam B2 0.75% -

Beam C1 1.0% -

Beam C2 1.0% -

Beam D1 1.25% -

Beam D2 1.25% -

Beam E - 3

Beam F - 4

Beam G - 5

Beam H - 6

The table above sho#s the di3erent

number of stirrups and di3erent volume

fraction of the specimens. The

researchers used four di3erent volume

fractions ranging from 56 to 2.986 to

establish the right amount of steel

%bers to be added to the concrete mi/

to attain the most durable sample after

several tests #ere conducted.

T&ST R&SU)T S 'RO@&CTION O* S'R&CI+&N ,IT.

STIRRU'S

5 < = 8 >

95

=5

>5

D5

255

295

2=5

2>5

Fi$%re C48 Te! Re!%l! ProAe"ion o) he S(e"imen! 2ih Sirr%(!

*igure =.2 Test Results

'roBection of the

Specimens #ith

Stirrups

*igure =.2 sho#s the ma/imum load

proBection of reinforced concrete beams

#ith stirrups as shear reinforcement.

*rom this proBection! the ma/imum load

increases #ith the increasing number

of stirrups. (s e/pected! stirrups have

an abilit" to resist shear in reinforced

concrete beam.

T&ST R&SU)T S 'RO@&CTION O* S'R&CI+&N ,IT.

ST&&) *I&RS 42

ST

(TC.:

95

=5

>5

D5

255

295

2=5

2>5

Fi$%re C4; Te! Re!%l! ProAe"ion o) he S(e"imen! 2ih Seel Fiber! -8! ba"h.

*igure =.9 sho#s the ma/imum load

proBection of the 2

st

batch of reinforced

concrete beams #ith steel %bers as

shear reinforcement. *rom this %gure!

the di3erent volume fraction a3ects the

ma/imum load of reinforced concrete

beams. (s the volume fraction

increases! the ma/imum load increases

as #ell.

T&ST R&SU)T S 'RO@&CTION O* S'R&CI+&N ,IT.

ST&&) *I&R& 49

ND

(TC.:

95

=5

>5

D5

255

295

2=5

2>5

/$%re C4= e! re!%l! (roAe"ion o) he !(e"imen! 2ih !eel /ber! -;nd Ba"h.

9nd batch

*igure =.< sho#s the ma/imum load

proBection of the 9

nd

batch of reinforced

concrete beams #ith steel %bers as

shear reinforcement. ased on the %gure

sho#n! it sho#s that the ma/imum load

increases #ith increasing volume

fraction. Therefore! #e can sa" that

steel %bers have the abilit" to resist

shear in reinforced concrete beam.

CO+'(RISON &T,&&N T,O (TC.&S O* S'&CI+&N

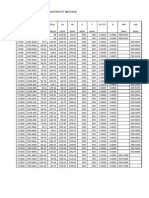

,IT. ST&&) *I&RS

Specimen Vo!me

F"ac#ion

1

$#

Ba#c%

&'()

2

n*

Ba#c%

&'()

A+e"a,e

&'()

-e"cen#a,

e E""o"

&%)

A 0.0% 5..047 5..047 5..047 0

B 0.75% 111.474 120.30/ 115./.1 3./1

C 1.0% 141.334 143.74 142.537 0./4

D 1.25% 147.74. 147.30/ 147.53 0.15

The table sho#s the comparison bet#een t#o

batches of concrete mi/ed #ith steel %ber. These

t#o batches of concrete mi/ture #ere made to

perceive the consistenc" of the steel %ber

distribution on the mi/ture. ased on the

percentage error sho#n in the table! Specimen ! C

and D have a percentage error of <.D26! 5.D=6!

and 5.286 respectivel". Since the percentage error

of t#o batches of concrete mi/ture #ith steel %bers

is belo# the allo#able percentage error of 86! the

distribution of steel %bers in each batch is

considered consistent and #idel" spread.

CO+'(RISON &T,&&N T,O (TC.&S O* S'&CI+&N

,IT. ST&&) *I&R

95

=5

>5

D5

255

295

2=5

2>5

2st atch

9nd atch

(verage

Figure 4.4 Com(ari!on be2een T2o

Ba"he! o) S(e"imen! 2ih Seel

Fiber!

*igure =.= sho#s the ma/imum load proBection

of t#o batches of reinforced concrete beams

#ith steel %bers. (lso! their average is

proBected. (s #e can see from the %gure! the

ma/imum load of the 2

st

batch and 9

nd

batch

are almost eJual and their percentage errors

do not e/ceed the allo#able error. ased on

these results! #e can sa" that the distribution

of steel %bers into t#o batches is consistent.

Therefore! #e can use the ma/imum load of

an" of the t#o batches.

FI6URE C4D COMPARISONS BET'EEN TEST RESULTS OF

SPECIMENS 'ITH STIRRUPS AND 'ITH STEEL FIBERS

( & * C C . D

specimens #ith

stirrups

specimens #ith steel

%ber

*igure =.8 presents the comparison bet#een the test

results of specimens #ith stirrups and specimens

#ith steel %bers as shear reinforcement. Smaller

value bet#een2

st

batch and 9

nd

batch #ere used to

allo# the possibilit" of error in distribution of steel

%ber in the concrete mi/ture. ased on the %gure! it

is clearl" evident that steel %bers and stirrups can

increase ma/imum load in reinforced concrete

beams. +a/imum load in specimens #ith stirrups

increases #ith increasing number of stirrups. (lso!

ma/imum load in specimens #ith steel %bers

increases #ith increasing volume fraction.

ased also from the result! it is visibl" seen that

specimens #ith steel %bers have an advantage over

specimens #ith stirrups. The increase in ma/imum

load of specimens #ith steel %bers is more than for

the specimens containing stirrups. (lso! for the

entire specimens tested! utmost ma/imum load is

attained in specimen #ith steel %bers #hich is

S'&CI+&N D2! #ith the ma/imum load of 2=7.7=K

-N. These results support the use of steel %ber as

replacement to conventional shear reinforcement

4stirrups: in reinforced concrete beams.

GU()IT? T&ST R&SU)T

Sample

Quality Test Specification

(ACI)

Test esult emar!s

Fine

Grading Fineness

Modulus 2.3-3.1 2.4 Passed

Specific Gravity 2.3-2.9 2.55 Passed

Moisture ontent 11.!2 Passed

"#sorption $-1$% 5.$3% Passed

&nit 'eig(t

)oose

*odded

12+$- 192$

12+$- 192$

14!+.2!

1,23.$2

Passed

Passed

Coarse

Grading- "#rasion 5$% 23.+!% Passed

Specific Gravity 2.5-3.$ 2.+3 Passed

Moisture ontent $.544% Passed

"#sorption $-2% $.!4,% Passed

&nit 'eig(t

)oose

*odded

145$-1!5$

145$-1!5$

15,5.25,

1!4+.43+

Passed

Passed

Cement Specific Gravity 2.94-3.15 3.$2 Passed

D&SICN +IHTUR&

"ater (to be a##e#) $%& !g

e-ent '&( .g

oarse "ggregate /0et1 $$%% .g

Fine "ggregate /0et1 &&% .g

T)TA* +',( .g

The E!imaed Ma!!e! (er Re"an$%lar Beam

CONCRETE MIETURE PROPORTION RATIO

8:849D:=4;:

,&IC.T O* AO)U+& *R(CTION

Specimen -e"cen#

Vo!me

F"ac#ion

&%)

Vo!me o0

S#ee 0i1e"

&mm

3

)

2ei,%# o0

S#ee

Fi1e"

&3,)

A 0 0 0

B 0.75 .2.14.65 0.75

C 1.0 123//6.20 1.00

D 1.25 154/57.75 1.25

The Table sho#n above presents the

#eight of steel %ber that #ill be added

to the concrete mi/ture of specimen (!

! C! and D. The steel %bers #ill serve

as the shear reinforcement of the

specimen.

CHAPTER &:

SUMMAR7 OF FINDIN6S

AND OBSER&ATIONSB

CONCLUSIONSB

AND RECOMMENDATIONS

SU++(R? O* *INDINCS (ND OS&RA(TION

(fter anal"0ing the data gathered and

conducting series of tests! the researchers

arrived to these %ndings and observations1

2. *or all the specimens tested in this stud"!

highest ma/imum load #as attained in

specimen #ith steel %bers #hich is

S'&CI+&N D2 #ith a volume fraction of

2.986. This result supports the use of steel

%ber as a replacement to conventional shear

reinforcement 4stirrups:.

9. The ma/imum load of specimens #ith steel %bers

increases #hen the volume fraction or steel %ber

content also increases. *rom the result of the

e/periment made! steel %ber #ith volume fraction of

56! 5.786! 2.556! and 2.986 had a ma/imum load

of 8K.5=7-N! 222.=7=-N! 2=2.<<=-N! and

2=7.<5D-N respectivel".

<. The ma/imum load of specimens #ith stirrups

increases #ith increasing number of stirrups. *rom

the result of the e/periment! specimens #ith

di3erent number of stirrups of 5! <! =! 8! and > had

a ma/imum load of 8K.5=7-N! D<.=K8-N! K7.=52-N!

KK.227-N! and 25=.7>>-N respectivel".

=. The ma/imum load of %rst batch and second

batch of specimens #ith steel %bers are almost

eJual. The percentage error for specimen ! C!

and D are <.D26! 5.D=6! and 5.286 respectivel".

These errors do not e/ceed the allo#able

percentage error #hich is 86.

8. The increase in ma/imum load for specimens

#ith steel %bers is more than the increase in

ma/imum load for specimens #ith stirrups based

on the test result.

>. Shear failure is the mode of failure in all

specimens tested in this stud".

CONC)USIONS

(fter the e/perimentation! the researchers

arrived to these follo#ing conclusions1

2. Steel %bers can be used as a replacement to

conventional shear reinforcement in reinforced

concrete beams.

9. (ppl"ing steel %bers to the concrete mi/ture

gives a good result in increasing the ma/imum

load of reinforced concrete beams #ithout

stirrups. (s the volume fraction increases! the

ma/imum load increases as #ell.

<. Test specimen #ith the highest volume fraction

has the utmost ma/imum load.

=. +ore signi%cant increase in ma/imum load #as

found for the specimens #ith steel %bers because

of their increased resistance to propagation of

cracks.

8. The steel %bers and stirrups have the same

function! as to resist shearing stress.

>. The steel %bers can be consistentl" distributed

in the reinforced concrete beams #ithout stirrups.

R&CO+&ND(TIONS

Researchers recommend future

pursuers of this stud" to use other

concrete mi/ture to kno# if the

compressive strength of concrete

a3ects the result of the test.

Researchers recommend using higher

volume fraction. Through this! #e #ill

kno# the ma/imum volume fraction

the beam could obtain.

Researchers recommend tr"ing three or

more batches of reinforced concrete beam

#ith steel %bers to observe more of the

consistenc" of the steel %ber distribution

on concrete mi/.

Researchers recommend using di3erent

dimensions of beam to determine the

e3ect of the si0e in the reinforced concrete

beam #ith steel %bers.

ased on the results! the researchers

recommend to use steel %bers as shear

reinforcement in reinforced concrete beam.

Anda mungkin juga menyukai

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Pipelines Welding HandbookDokumen64 halamanPipelines Welding HandbookSixto GerardoBelum ada peringkat

- Unani Pharmacopoeia of India Part II Vol 3Dokumen248 halamanUnani Pharmacopoeia of India Part II Vol 3azeem dilawar100% (6)

- 3.2.P.2.3 Manufacturing Process Development (92 Págs) PDFDokumen92 halaman3.2.P.2.3 Manufacturing Process Development (92 Págs) PDFaldoBelum ada peringkat

- CWP Cert PDFDokumen4 halamanCWP Cert PDFmurtazagulzar3Belum ada peringkat

- Scope of WorkDokumen4 halamanScope of WorkwtfisfBelum ada peringkat

- APPENDIX B Filler Metal Comparison Chart ABS-AWSDokumen3 halamanAPPENDIX B Filler Metal Comparison Chart ABS-AWSplkv100% (1)

- Lecture Notes - Chem 16 LE3Dokumen8 halamanLecture Notes - Chem 16 LE3Alexander Gordon InesBelum ada peringkat

- VacuumDokumen7 halamanVacuumMassimilianø Erricø100% (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyDari EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyBelum ada peringkat

- Mechanical Characteristics of Fused Cast Basalt Tube Encased in Steel Pipe For Protecting Steel SurfaceDokumen6 halamanMechanical Characteristics of Fused Cast Basalt Tube Encased in Steel Pipe For Protecting Steel SurfacebelloxBelum ada peringkat

- Bryan : England. Printed in Great BritainDokumen24 halamanBryan : England. Printed in Great BritainSohini MishraBelum ada peringkat

- Behavior of Concrete Beams Reinforced With Astm A1035 Grade 100 Stirrups Under ShearDokumen25 halamanBehavior of Concrete Beams Reinforced With Astm A1035 Grade 100 Stirrups Under ShearJiabin LiBelum ada peringkat

- 1 s2.0 S0020740306001846 MainDokumen15 halaman1 s2.0 S0020740306001846 Mainisraaahmed12Belum ada peringkat

- Design and Analysis of Connecting Rod For Reduction of Weight and Cost ReportDokumen52 halamanDesign and Analysis of Connecting Rod For Reduction of Weight and Cost Reporthemtheboss100% (1)

- Shear Strength of Steel Fiber-Reinforced Lightweight Concrete BeamsDokumen7 halamanShear Strength of Steel Fiber-Reinforced Lightweight Concrete Beamsmoraru_gabriel_2Belum ada peringkat

- Experimental Behaviour and Strength of Concrete-Encased Composite Beam-Columns With T-Shaped Steel Section Under Cyclic LoadingDokumen19 halamanExperimental Behaviour and Strength of Concrete-Encased Composite Beam-Columns With T-Shaped Steel Section Under Cyclic LoadingMarimuthu KaliyamoorthyBelum ada peringkat

- Torsional Behavior of Reinforced Concrete Beams Strengthened With FRP CompositesDokumen13 halamanTorsional Behavior of Reinforced Concrete Beams Strengthened With FRP CompositesJiabinBelum ada peringkat

- The Impact of Strain Rate On The Material Mechanical Properties - Abdallah Refate Ahmed - Bn.19Dokumen7 halamanThe Impact of Strain Rate On The Material Mechanical Properties - Abdallah Refate Ahmed - Bn.19Abdalla RefateBelum ada peringkat

- Tensile Test, Pre-Fracture Tensile Test, Post-Fracture: FatigueDokumen9 halamanTensile Test, Pre-Fracture Tensile Test, Post-Fracture: FatigueGowsh VeeraBelum ada peringkat

- Ultimate Load Behaviour of Tapered Plate GirdersDokumen33 halamanUltimate Load Behaviour of Tapered Plate GirdersPablo RicoBelum ada peringkat

- Fatigue in Welded BeamsDokumen18 halamanFatigue in Welded BeamsMohamed GamalBelum ada peringkat

- Non-Tensioned Steel in Prestressed Concrete BeamsDokumen23 halamanNon-Tensioned Steel in Prestressed Concrete Beamsunix0123100% (1)

- 86-S60confinement of Reinforced Concrete Columns With Welded Wire FabricDokumen9 halaman86-S60confinement of Reinforced Concrete Columns With Welded Wire Fabricshuangyaksa100% (1)

- Ground Anchor Tendons in Carbon Fibre Reinforced Polymers A D Barley John Hartley For Presentation Atice London 2007Dokumen10 halamanGround Anchor Tendons in Carbon Fibre Reinforced Polymers A D Barley John Hartley For Presentation Atice London 2007Kenny CasillaBelum ada peringkat

- Pengaruh Bentuk Takikan (Notched) Pada Poros Baja Karbon St. 60 Akibat Beban TarikDokumen5 halamanPengaruh Bentuk Takikan (Notched) Pada Poros Baja Karbon St. 60 Akibat Beban TarikDelioPradanaBelum ada peringkat

- Behavior of Concrete Beams Reinforced With ASTM A1035 Grade 100 Stirrups Under ShearDokumen8 halamanBehavior of Concrete Beams Reinforced With ASTM A1035 Grade 100 Stirrups Under ShearTrong Tuan TranBelum ada peringkat

- Experimental Study of The Strength and Behaviour of Reinforced Coped BeamsDokumen11 halamanExperimental Study of The Strength and Behaviour of Reinforced Coped BeamsAnderson TrindadeBelum ada peringkat

- Compressive Strength of Cold-Formed Steel C-Shape Columns With Slotted Web HolesDokumen15 halamanCompressive Strength of Cold-Formed Steel C-Shape Columns With Slotted Web HolesDinesh lakshmananBelum ada peringkat

- Behaviour and Design of Structural Steel PinsDokumen28 halamanBehaviour and Design of Structural Steel PinsJoão BarrigóBelum ada peringkat

- HSS Columns Filled with SCCDokumen15 halamanHSS Columns Filled with SCCGunaBelum ada peringkat

- SD Article 46Dokumen8 halamanSD Article 46Mustafa MoussaouiBelum ada peringkat

- 1990 Tied Concrete Columns Under Axial Load and FlexureDokumen21 halaman1990 Tied Concrete Columns Under Axial Load and FlexureHHTBelum ada peringkat

- Mechanical testing - Tensile testing overviewDokumen45 halamanMechanical testing - Tensile testing overviewshrikantajitBelum ada peringkat

- REINFORCING STEEL FOR CONCRETEDokumen8 halamanREINFORCING STEEL FOR CONCRETEPrittam Kumar JenaBelum ada peringkat

- Lecture 2 - Test For SteelDokumen55 halamanLecture 2 - Test For SteelKier Lorenz FernandezBelum ada peringkat

- A Study On Structural Performance of End-Reinforced Steelbeam SystemDokumen8 halamanA Study On Structural Performance of End-Reinforced Steelbeam SystemMarimuthu KaliyamoorthyBelum ada peringkat

- Fatigue Analysis of Aluminum Drill PipesDokumen7 halamanFatigue Analysis of Aluminum Drill Pipesdf_campos3353Belum ada peringkat

- Paper 7Dokumen9 halamanPaper 7RakeshconclaveBelum ada peringkat

- ASTM-Designation G109 99aDokumen5 halamanASTM-Designation G109 99aJorge LeconaBelum ada peringkat

- Self Piercing RivetDokumen11 halamanSelf Piercing RivetyomansahajBelum ada peringkat

- Engineering Structures: Cheng Shi, Hossein Karagah, Mina Dawood, Abdeldjelil BelarbiDokumen11 halamanEngineering Structures: Cheng Shi, Hossein Karagah, Mina Dawood, Abdeldjelil BelarbiIliuta FloreaBelum ada peringkat

- Tensil Headed Anchors With Large Diameter and Deep Embedment in ConcreteDokumen7 halamanTensil Headed Anchors With Large Diameter and Deep Embedment in ConcreteJack SmithBelum ada peringkat

- CivilBay Steel Connection Brace ConnectionDokumen12 halamanCivilBay Steel Connection Brace ConnectionMichenerparkBelum ada peringkat

- B769Dokumen4 halamanB769wpwmhatBelum ada peringkat

- Shear Behavior of Ultra-High-Strength Steel Fiber-Reinforced Self-Compacting Concrete BeamsDokumen8 halamanShear Behavior of Ultra-High-Strength Steel Fiber-Reinforced Self-Compacting Concrete BeamsRawash OmarBelum ada peringkat

- Eddy Current MeasurementsDokumen4 halamanEddy Current MeasurementsBassam AbdelazeemBelum ada peringkat

- Tensile and Creep Behaviour of Modified 9Cr 1mo Steel Cladding Tube For Fast Reactor Using Metallic Fuel 2014 Procedia EngineeringDokumen9 halamanTensile and Creep Behaviour of Modified 9Cr 1mo Steel Cladding Tube For Fast Reactor Using Metallic Fuel 2014 Procedia EngineeringalkhiatBelum ada peringkat

- 8630 Cast SteelDokumen17 halaman8630 Cast SteelCatweazle999Belum ada peringkat

- Asset Doc Loc 2814975 Apc RawDokumen7 halamanAsset Doc Loc 2814975 Apc RawmurdicksBelum ada peringkat

- Paper Uji TarikDokumen23 halamanPaper Uji TarikEdo DestradaBelum ada peringkat

- Robotic Stud Welding Process Optimization With Designed ExperimentDokumen8 halamanRobotic Stud Welding Process Optimization With Designed ExperimentSam KashBelum ada peringkat

- Genesis of Spalling in Tandem Mill Work-RollsDokumen9 halamanGenesis of Spalling in Tandem Mill Work-Rolls54321qazBelum ada peringkat

- Shear Behaviour of Steel Fibre Reinforced Self-Compacting ConcreteDokumen8 halamanShear Behaviour of Steel Fibre Reinforced Self-Compacting Concretejack21abBelum ada peringkat

- 2004 Int Ansys Conf 201Dokumen9 halaman2004 Int Ansys Conf 201Vigneshwar ManokaranBelum ada peringkat

- 1994-High Strength Concrete Columnes Confined by Rectrangular TiesDokumen22 halaman1994-High Strength Concrete Columnes Confined by Rectrangular Tiesnedim.halebic1Belum ada peringkat

- 87 s10Dokumen12 halaman87 s10carlosestayBelum ada peringkat

- Metal2014 Turczyn MetalDokumen6 halamanMetal2014 Turczyn MetalAhmed KassemBelum ada peringkat

- Short ColumnsDokumen15 halamanShort ColumnssrividyaBelum ada peringkat

- Lecture 10.3: Single Span Beams: Objective/ScopeDokumen21 halamanLecture 10.3: Single Span Beams: Objective/ScopeDenis DimićBelum ada peringkat

- 1992 - 07 Slotted Bolted Connection Energy DissipatersDokumen26 halaman1992 - 07 Slotted Bolted Connection Energy DissipatersHenry HoyosBelum ada peringkat

- Hollow Circular Steel Tube in Filled With Epoxy Blended Concerte PDFDokumen6 halamanHollow Circular Steel Tube in Filled With Epoxy Blended Concerte PDFRkkodiBelum ada peringkat

- Experimentally Enhancing Performance of Circular Hollow Section T-JointsDokumen15 halamanExperimentally Enhancing Performance of Circular Hollow Section T-Jointssherif IbrahimBelum ada peringkat

- Multistoreyed BLDGDokumen89 halamanMultistoreyed BLDGsohanpmeharwadeBelum ada peringkat

- Riser Sleeve Properties and Effect on Casting YieldDokumen18 halamanRiser Sleeve Properties and Effect on Casting YieldDavindRa Soni100% (1)

- Experimental Study on the Ultimate Capacity of Cementitious Slabs Reinforced with Wired MeshDokumen9 halamanExperimental Study on the Ultimate Capacity of Cementitious Slabs Reinforced with Wired MeshSulaiman Mohsin AbdulAzizBelum ada peringkat

- Abu Altemen Et Al., 2017, Punching Shear Behavior of Small SFRC Flat PlateDokumen11 halamanAbu Altemen Et Al., 2017, Punching Shear Behavior of Small SFRC Flat PlatefaridBelum ada peringkat

- Design of Slab (Moment)Dokumen21 halamanDesign of Slab (Moment)wtfisfBelum ada peringkat

- Design of FoundationDokumen3 halamanDesign of FoundationwtfisfBelum ada peringkat

- Design columns using equivalent eccentricity methodDokumen10 halamanDesign columns using equivalent eccentricity methodwtfisfBelum ada peringkat

- Beam Flexure (Table)Dokumen20 halamanBeam Flexure (Table)wtfisfBelum ada peringkat

- Earthbag HousingDokumen12 halamanEarthbag HousingwtfisfBelum ada peringkat

- 1sty 1CL 7x9m StandardDokumen6 halaman1sty 1CL 7x9m StandardKen ChiaBelum ada peringkat

- Law SubjectsDokumen9 halamanLaw SubjectswtfisfBelum ada peringkat

- Hough - The Crystallography, Metallography and Composition of Gold PDFDokumen6 halamanHough - The Crystallography, Metallography and Composition of Gold PDFSantiaGoAlejandRoBelum ada peringkat

- CONSTRUCTION CHEMISTRY ROOF WATERPROOFINGDokumen2 halamanCONSTRUCTION CHEMISTRY ROOF WATERPROOFINGAmar WadoodBelum ada peringkat

- Safety Data Sheet: Product Name: MOBIL SHC RARUS 68Dokumen10 halamanSafety Data Sheet: Product Name: MOBIL SHC RARUS 68Daniel Rodriguez GutierrezBelum ada peringkat

- 01-02. The Chemical Context of LifeDokumen4 halaman01-02. The Chemical Context of LifeDaniel Angelo MiradorBelum ada peringkat

- 12.co Ordination CompoundsExerciseDokumen34 halaman12.co Ordination CompoundsExerciseMaster Of HakingBelum ada peringkat

- Ch. 13 Carbonyl (1) Answers: Organic Chem II-1Dokumen38 halamanCh. 13 Carbonyl (1) Answers: Organic Chem II-1Nguyễn A.ThưBelum ada peringkat

- I-V Characterization of Tunnel Diodes and Multojunction Solar CellsDokumen7 halamanI-V Characterization of Tunnel Diodes and Multojunction Solar CellsMaura MusioBelum ada peringkat

- Methods For Waste Waters Treatment in Textile IndustryDokumen5 halamanMethods For Waste Waters Treatment in Textile Industryjpsingh75Belum ada peringkat

- MSDS 853021 Dry Charge BatteryDokumen3 halamanMSDS 853021 Dry Charge Batteryjian0889Belum ada peringkat

- Panduan Troli EmergencyDokumen3 halamanPanduan Troli EmergencyTukiyemBelum ada peringkat

- Biostimulation Treatments of Hydrocarbon-Contaminated SoilDokumen6 halamanBiostimulation Treatments of Hydrocarbon-Contaminated SoilGeorgian-Răzvan CheșcaBelum ada peringkat

- Be 14112017Dokumen73 halamanBe 14112017Nikhil GobhilBelum ada peringkat

- Failure Analysis of Metal Alloy Propeller Shafts: SciencedirectDokumen4 halamanFailure Analysis of Metal Alloy Propeller Shafts: SciencedirectAfiq IkhwanBelum ada peringkat

- A 826 - A826m - 95 Qtgyni05nqDokumen5 halamanA 826 - A826m - 95 Qtgyni05nqsachinguptachdBelum ada peringkat

- Waste Water Treatment PlantDokumen10 halamanWaste Water Treatment PlantBoiler ScrubberBelum ada peringkat

- GilbertDokumen24 halamanGilbertVibhuti BhargavaBelum ada peringkat

- Formula Ergun Manto LodosDokumen22 halamanFormula Ergun Manto LodosReinaldoBelum ada peringkat

- Voltaic Cells and Potential Energy PresentationDokumen10 halamanVoltaic Cells and Potential Energy PresentationAnnisa IcaBelum ada peringkat

- CT TPDokumen5 halamanCT TPcesarchiletBelum ada peringkat

- Bio Process Problem 1Dokumen1 halamanBio Process Problem 1AshenafiBelum ada peringkat

- Dorken PDFDokumen3 halamanDorken PDFparamatmuni_prasanthBelum ada peringkat

- SSIP GR 11 Acids N BasesDokumen10 halamanSSIP GR 11 Acids N BasesMangwane Sello100% (1)

- Tds-Duraplate UhsDokumen4 halamanTds-Duraplate UhsAlberto Acosta GongoraBelum ada peringkat

- MasterSeal P 698 MSDS - EN-23.11.2022-Rev1.2Dokumen11 halamanMasterSeal P 698 MSDS - EN-23.11.2022-Rev1.2recep kablanBelum ada peringkat