MOM2E Chap3a

Diunggah oleh

poom2007Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

MOM2E Chap3a

Diunggah oleh

poom2007Hak Cipta:

Format Tersedia

3.

Mechanical Properties of Materials

CHAPTER OBJECTIVES

Show relationship of stress

and strain using experimental

methods to determine stressstrain diagram of a specific

material

Discuss the behavior

described in the diagram for

commonly used engineering

materials

Discuss the mechanical properties and other test

related to the development of mechanics of

materials

2005 Pearson Education South Asia Pte Ltd

3. Mechanical Properties of Materials

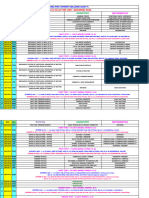

CHAPTER OUTLINE

1. Tension and Compression Test

2. Stress-Strain Diagram

3. Stress-Strain Behavior of Ductile and Brittle

Materials

4. Hookes Law

5. Strain Energy

6. Poissions Ratio

7. Shear Stress-Strain Diagram

8. *Failure of Materials Due to Creep and Fatigue

2005 Pearson Education South Asia Pte Ltd

3. Mechanical Properties of Materials

3.1 TENSION & COMPRESSION TEST

Strength of a material can only be determined by

experiment

One test used by engineers is the tension or

compression test

This test is used primarily to determine the

relationship between the average normal stress

and average normal strain in common

engineering materials, such as metals, ceramics,

polymers and composites

2005 Pearson Education South Asia Pte Ltd

3. Mechanical Properties of Materials

3.1 TENSION & COMPRESSION TEST

Performing the tension or compression test

Specimen of material is made into standard

shape and size

Before testing, 2 small punch marks identified

along specimens length

Measurements are taken of both specimens initial

x-sectional area A0 and gauge-length distance L0;

between the two marks

Seat the specimen into a testing machine shown

below

2005 Pearson Education South Asia Pte Ltd

3. Mechanical Properties of Materials

3.1 TENSION & COMPRESSION TEST

Performing the tension or compression test

Seat the specimen into a testing machine shown

below

The machine will stretch

specimen at slow constant

rate until breaking point

At frequent intervals during

test, data is recorded of the

applied load P.

2005 Pearson Education South Asia Pte Ltd

3. Mechanical Properties of Materials

3.1 TENSION & COMPRESSION TEST

Performing the tension or compression test

Elongation = L L0 is measured using either a

caliper or an extensometer

is used to calculate the normal strain in the

specimen

Sometimes, strain can also be read directly using

an electrical-resistance strain gauge

2005 Pearson Education South Asia Pte Ltd

3. Mechanical Properties of Materials

3.2 STRESS-STRAIN DIAGRAM

A stress-strain diagram is obtained by plotting the

various values of the stress and corresponding

strain in the specimen

Conventional stress-strain diagram

Using recorded data, we can determine nominal

or engineering stress by

P

=

A0

Assumption: Stress is constant over the x-section

and throughout region between gauge points

2005 Pearson Education South Asia Pte Ltd

3. Mechanical Properties of Materials

3.2 STRESS-STRAIN DIAGRAM

Conventional Stress-Strain Diagram

Likewise, nominal or engineering strain is found

directly from strain gauge reading, or by

=

L0

Assumption: Strain is constant throughout region

between gauge points

By plotting (ordinate) against (abscissa), we

get a conventional stress-strain diagram

2005 Pearson Education South Asia Pte Ltd

3. Mechanical Properties of Materials

3.2 STRESS-STRAIN DIAGRAM

Conventional stress-strain diagram

Figure shows the characteristic stress-strain

diagram for steel, a commonly used material for

structural members and mechanical elements

2005 Pearson Education South Asia Pte Ltd

3. Mechanical Properties of Materials

3.2 STRESS-STRAIN DIAGRAM

Conventional stress-strain diagram

Elastic behavior.

A straight line

Stress is proportional to

strain, i.e., linearly elastic

Upper stress limit, or

proportional limit; pl

If load is removed upon

reaching elastic limit,

specimen will return to its

original shape

2005 Pearson Education South Asia Pte Ltd

10

3. Mechanical Properties of Materials

3.2 STRESS-STRAIN DIAGRAM

Conventional stress-strain diagram

Yielding.

Material deforms

permanently; yielding;

plastic deformation

Figure 3-4

Yield stress, Y

Once yield point reached, specimen continues to

elongate (strain) without any increase in load

Note figure not drawn to scale, otherwise induced

strains is 10-40 times larger than in elastic limit

Material is referred to as being perfectly plastic

2005 Pearson Education South Asia Pte Ltd

11

3. Mechanical Properties of Materials

3.2 STRESS-STRAIN DIAGRAM

Conventional stress-strain diagram

Strain hardening.

Ultimate stress, u

While specimen is

elongating, its xsectional area will

decrease

Decrease in area is fairly

uniform over entire gauge

length

2005 Pearson Education South Asia Pte Ltd

Figure 3-4

12

3. Mechanical Properties of Materials

3.2 STRESS-STRAIN DIAGRAM

Conventional stress-strain diagram

Necking.

At ultimate stress, xsectional area begins to

decrease in a localized

region

As a result, a constriction

or neck tends to form in

this region as specimen

elongates further

Figure 3-4

Specimen finally breaks at fracture stress, f

2005 Pearson Education South Asia Pte Ltd

13

3. Mechanical Properties of Materials

3.2 STRESS-STRAIN DIAGRAM

Conventional stress-strain diagram

Necking.

Specimen finally breaks

at fracture stress, f

Figure 3-4

2005 Pearson Education South Asia Pte Ltd

14

3. Mechanical Properties of Materials

3.2 STRESS-STRAIN DIAGRAM

True stress-strain diagram

Instead of using original cross-sectional area and

length, we can use the actual cross-sectional area

and length at the instant the load is measured

Values of stress and strain thus calculated are

called true stress and true strain, and a plot of their

values is the true stress-strain diagram

2005 Pearson Education South Asia Pte Ltd

15

3. Mechanical Properties of Materials

3.2 STRESS-STRAIN DIAGRAM

True stress-strain diagram

In strain-hardening range, conventional -

diagram shows specimen supporting decreasing

load

While true - diagram shows material to be

sustaining increasing stress

2005 Pearson Education South Asia Pte Ltd

16

3. Mechanical Properties of Materials

3.2 STRESS-STRAIN DIAGRAM

True stress-strain diagram

Although both diagrams are different, most

engineering design is done within elastic range

provided

1. Material is stiff, like most metals

2. Strain to elastic limit remains small

3. Error in using engineering values of and is

very small (0.1 %) compared to true values

2005 Pearson Education South Asia Pte Ltd

17

3. Mechanical Properties of Materials

3.3 STRESS-STRAIN BEHAVIOR OF DUCTILE & BRITTLE MATERIALS

Ductile materials

Defined as any material that can be subjected to

large strains before it ruptures, e.g., mild steel

Such materials are used because it is capable of

absorbing shock or energy, and if before

becoming overloaded, will exhibit large

deformation before failing

Ductility of material is to report its percent

elongation or percent reduction in area at time of

fracture

2005 Pearson Education South Asia Pte Ltd

18

3. Mechanical Properties of Materials

3.3 STRESS-STRAIN BEHAVIOR OF DUCTILE & BRITTLE MATERIALS

Ductile materials

Percent elongation is the specimens fracture

strain expressed as a percent

Lf L 0

Percent elongation =

(100%)

L0

Percent reduction in area is defined within

necking region as

A0 Af

(100%)

Percent reduction in area =

A0

2005 Pearson Education South Asia Pte Ltd

19

3. Mechanical Properties of Materials

3.3 STRESS-STRAIN BEHAVIOR OF DUCTILE & BRITTLE MATERIALS

Ductile materials

Most metals do not exhibit constant yielding

behavior beyond the elastic range, e.g. aluminum

It does not have well-defined yield point, thus it is

standard practice to define its yield strength using

a graphical procedure called the offset method

2005 Pearson Education South Asia Pte Ltd

20

3. Mechanical Properties of Materials

3.3 STRESS-STRAIN BEHAVIOR OF DUCTILE & BRITTLE MATERIALS

Ductile materials

Offset method to determine yield strength

1. Normally, a 0.2 % strain is

chosen.

2. From this point on the

axis, a line parallel to

initial straight-line portion

of stress-strain diagram is

drawn.

3. The point where this line

intersects the curve

defines the yield strength.

2005 Pearson Education South Asia Pte Ltd

21

3. Mechanical Properties of Materials

3.3 STRESS-STRAIN BEHAVIOR OF DUCTILE & BRITTLE MATERIALS

Brittle Materials

Material that exhibit little or no yielding before

failure are referred to as brittle materials, e.g.,

gray cast iron

Brittle materials do not have a well-defined

tensile fracture stress, since appearance of

initial cracks in a specimen is quite random

2005 Pearson Education South Asia Pte Ltd

22

3. Mechanical Properties of Materials

3.3 STRESS-STRAIN BEHAVIOR OF DUCTILE & BRITTLE MATERIALS

Brittle Materials

Instead, the average fracture stress from a set of

observed tests is generally reported

2005 Pearson Education South Asia Pte Ltd

23

3. Mechanical Properties of Materials

3.4 HOOKES LAW

Most engineering materials exhibit a linear

relationship between stress and strain with the

elastic region

Discovered by Robert Hooke in 1676 using

springs, known as Hookes law

= E

E represents the constant of proportionality, also

called the modulus of elasticity or Youngs

modulus

E has units of stress, i.e., pascals, MPa or GPa.

2005 Pearson Education South Asia Pte Ltd

24

3. Mechanical Properties of Materials

3.4 HOOKES LAW

As shown above, most grades

of steel have same modulus of

elasticity, Est = 200 GPa

Modulus of elasticity is a

mechanical property that

indicates the stiffness of a

material

Materials that are still have

large E values, while spongy

materials (vulcanized rubber)

have low values

2005 Pearson Education South Asia Pte Ltd

25

3. Mechanical Properties of Materials

3.4 HOOKES LAW

IMPORTANT

Modulus of elasticity E, can be used only if a

material has linear-elastic behavior.

Also, if stress in material is greater than the

proportional limit, the stress-strain diagram ceases

to be a straight line and the equation is not valid

2005 Pearson Education South Asia Pte Ltd

26

3. Mechanical Properties of Materials

3.4 HOOKES LAW

Strain hardening

If a specimen of ductile material (steel) is loaded

into the plastic region and then unloaded, elastic

strain is recovered as material returns to its

equilibrium state

However, plastic strain remains, thus material is

subjected to a permanent set

2005 Pearson Education South Asia Pte Ltd

27

3. Mechanical Properties of Materials

3.4 HOOKES LAW

Strain hardening

Specimen loaded beyond yield point A to A

Inter-atomic forces have to be overcome to

elongate specimen elastically, these same

forces pull atoms back together when load is

removed

Since E is the same,

slope of line OA is the

same as line OA

2005 Pearson Education South Asia Pte Ltd

28

3. Mechanical Properties of Materials

3.4 HOOKES LAW

Strain hardening

Load reapplied, atoms will be displaced until

yielding occurs at or near A, and stress-strain

diagram continues along same path as before

New stress-strain

diagram has higher

yield point (A), a result

of strain-hardening

Specimen has a

greater elastic region

and less ductility

2005 Pearson Education South Asia Pte Ltd

29

3. Mechanical Properties of Materials

3.4 HOOKES LAW

Strain hardening

As specimen is unloaded and loaded, heat or

energy may be lost

Colored area between the curves represents lost

energy and is called mechanical hysteresis

Its an important

consideration when

selecting materials to

serve as dampers for

vibrating structures and

equipment

2005 Pearson Education South Asia Pte Ltd

30

Anda mungkin juga menyukai

- DeflectionDokumen63 halamanDeflectionsteven6967Belum ada peringkat

- Chapter Objectives: 2005 Pearson Education South Asia Pte LTDDokumen27 halamanChapter Objectives: 2005 Pearson Education South Asia Pte LTDpoom2007Belum ada peringkat

- Distributed Across The Thickness of The Tube: 5.7 Thin-Walled Tubes Having Closed Cross SectionsDokumen38 halamanDistributed Across The Thickness of The Tube: 5.7 Thin-Walled Tubes Having Closed Cross Sectionspoom2007Belum ada peringkat

- Hibbeler, Mechanics of Materials-Stress Transformation 2Dokumen69 halamanHibbeler, Mechanics of Materials-Stress Transformation 2poom2007Belum ada peringkat

- Hibbeler, Mechanics of Materials-Strain TransformationDokumen62 halamanHibbeler, Mechanics of Materials-Strain Transformationpoom2007Belum ada peringkat

- Hibbeler, Mechanics of Materials-Prismatic Beam DesignDokumen50 halamanHibbeler, Mechanics of Materials-Prismatic Beam Designpoom2007Belum ada peringkat

- Hibbeler, Mechanics of Materials-Deflections 1Dokumen57 halamanHibbeler, Mechanics of Materials-Deflections 1poom2007Belum ada peringkat

- Hibbeler, Mechanics of Materials-Transverse Shear 1Dokumen29 halamanHibbeler, Mechanics of Materials-Transverse Shear 1poom2007Belum ada peringkat

- Hibbeler, Mechanics of Materials-Strain Transformation 2Dokumen62 halamanHibbeler, Mechanics of Materials-Strain Transformation 2poom2007Belum ada peringkat

- Hibbeler, Mechanics of Materials-Transverse Shear 2Dokumen39 halamanHibbeler, Mechanics of Materials-Transverse Shear 2poom2007Belum ada peringkat

- Hibbeler, Mechanics of Materials-BendingDokumen63 halamanHibbeler, Mechanics of Materials-Bendingpoom2007Belum ada peringkat

- Hibbeler, Mechanics of Materials-Transverse Shear 2Dokumen39 halamanHibbeler, Mechanics of Materials-Transverse Shear 2poom2007Belum ada peringkat

- Hibbeler, Mechanics of Materials-Stress TransformationDokumen47 halamanHibbeler, Mechanics of Materials-Stress Transformationpoom2007Belum ada peringkat

- Hibbeler, Mechanics of Materials-Bending 2Dokumen68 halamanHibbeler, Mechanics of Materials-Bending 2poom2007Belum ada peringkat

- Hot-Dip CoatingDokumen19 halamanHot-Dip Coatingpoom2007Belum ada peringkat

- MOM2E Chap1bDokumen33 halamanMOM2E Chap1bpoom2007Belum ada peringkat

- MOM2 Echap 1 ADokumen45 halamanMOM2 Echap 1 AJules NanaBelum ada peringkat

- MOM2E Chap3bDokumen33 halamanMOM2E Chap3bpoom2007Belum ada peringkat

- Hot RollingDokumen10 halamanHot Rollingpoom2007Belum ada peringkat

- MOM2E Chap2aDokumen16 halamanMOM2E Chap2apoom2007Belum ada peringkat

- Chapter 6 Mechanical PropertiesDokumen31 halamanChapter 6 Mechanical Propertiespoom2007Belum ada peringkat

- Cold RollingDokumen8 halamanCold Rollingpoom2007Belum ada peringkat

- Chapter 4 Phase DiagramDokumen24 halamanChapter 4 Phase Diagrampoom2007Belum ada peringkat

- Chapter 7 Recovery, Recrystallization, Grain GrowthDokumen19 halamanChapter 7 Recovery, Recrystallization, Grain Growthpoom2007Belum ada peringkat

- Chapter 9 Solid State Phase TransformationDokumen18 halamanChapter 9 Solid State Phase Transformationpoom2007Belum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- ASU PHY 131 Homework 2 Fall 2020Dokumen2 halamanASU PHY 131 Homework 2 Fall 2020Vyomika TewaryBelum ada peringkat

- HW1Dokumen5 halamanHW1Nathan YangBelum ada peringkat

- Plane Stress - MSE 305-1Dokumen149 halamanPlane Stress - MSE 305-1Oloyede RidwanBelum ada peringkat

- ANSI ESD SP15.1-2005 Standard Practice For In-Use Resistance Tetsing of Gloves and Finger CotsDokumen16 halamanANSI ESD SP15.1-2005 Standard Practice For In-Use Resistance Tetsing of Gloves and Finger Cotssmalnif0% (1)

- Me 201 Engineering Mechanics Statics3121Dokumen19 halamanMe 201 Engineering Mechanics Statics3121tugskulBelum ada peringkat

- Hanson 2008Dokumen11 halamanHanson 2008Mohamed MOUMOUBelum ada peringkat

- 4A Dough Rheology (2021)Dokumen24 halaman4A Dough Rheology (2021)ArinaAdilaBelum ada peringkat

- Ac S P InstructorDokumen95 halamanAc S P Instructorvschauhan.indiaBelum ada peringkat

- Assignment-1 Problems On ELD and Hydro-Thermal CoordinationDokumen5 halamanAssignment-1 Problems On ELD and Hydro-Thermal CoordinationAli PatelBelum ada peringkat

- NasaDokumen108 halamanNasaVelibor MinićBelum ada peringkat

- CLTD Method PaperDokumen10 halamanCLTD Method Paperวรศิษฐ์ อ๋อง100% (1)

- Global Sliding Mode ControlDokumen9 halamanGlobal Sliding Mode ControlYazdan RastegarBelum ada peringkat

- Aqua Ammonia TablesDokumen11 halamanAqua Ammonia TablesDoug LambBelum ada peringkat

- Aperture Antennas: Chapter 12 - BalanisDokumen18 halamanAperture Antennas: Chapter 12 - BalanisHoraira Zulfiqar AbbasiBelum ada peringkat

- Lecture 3 BSE2201 PsychrometryDokumen63 halamanLecture 3 BSE2201 PsychrometryBrian LiBelum ada peringkat

- Extra Solved Questions Class Ix Term II ChemistryDokumen3 halamanExtra Solved Questions Class Ix Term II Chemistrychhabra navdeep100% (1)

- Chem Lec ReviewerDokumen16 halamanChem Lec ReviewerSophia EspirituBelum ada peringkat

- Irc Gov in SP 064 2005 PDFDokumen20 halamanIrc Gov in SP 064 2005 PDFSiva Prasad Mamillapalli100% (1)

- MSC - Nastran 2007 Implicit Nonlinear (SOL 600) User's GuideDokumen532 halamanMSC - Nastran 2007 Implicit Nonlinear (SOL 600) User's GuideDonBelum ada peringkat

- (Ronald A. Knief) - Nuclear Reactor Theory (Booklet)Dokumen19 halaman(Ronald A. Knief) - Nuclear Reactor Theory (Booklet)sina sanatiBelum ada peringkat

- Ulrike Lohmann, Felix Lüönd, Fabian Mahrt-An Introduction To Clouds - From The Microscale To Climate-Cambridge University Press (2016)Dokumen380 halamanUlrike Lohmann, Felix Lüönd, Fabian Mahrt-An Introduction To Clouds - From The Microscale To Climate-Cambridge University Press (2016)Octavia Hopper100% (3)

- The Optimum Coolant Temperature For Maruti 800 Engine Is Around 92 DegreesDokumen3 halamanThe Optimum Coolant Temperature For Maruti 800 Engine Is Around 92 DegreesMohseen KarcheBelum ada peringkat

- The Operational Mechanism of Continuous Four-Roll Plate Bending ProcessDokumen4 halamanThe Operational Mechanism of Continuous Four-Roll Plate Bending ProcessBenjamin Neciosup PaucarBelum ada peringkat

- JEE ADVANCED Track Sheet (2024)Dokumen3 halamanJEE ADVANCED Track Sheet (2024)MAHESWARA RAO ThotaBelum ada peringkat

- Hsslive-XI-Chemistry-Simplified Notes For 1 Improvement ExamDokumen35 halamanHsslive-XI-Chemistry-Simplified Notes For 1 Improvement ExamLingesh Waran100% (3)

- Modeling and Simulation of A Stepping Motor, 1969.Dokumen3 halamanModeling and Simulation of A Stepping Motor, 1969.Ali H. NumanBelum ada peringkat

- WITRICITYDokumen17 halamanWITRICITYSai VikramBelum ada peringkat

- Answer Sheet: 1 1 Loga X 1 1 Loga yDokumen1 halamanAnswer Sheet: 1 1 Loga X 1 1 Loga ySatyam YadavBelum ada peringkat

- Bob Long Part 2Dokumen296 halamanBob Long Part 2padalakirankumar100% (4)

- Fluent 6.3: Population Balance Module ManualDokumen55 halamanFluent 6.3: Population Balance Module ManualHarshit KapadiaBelum ada peringkat