20x47x7 Oil Seal

Diunggah oleh

Seeni VSDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

20x47x7 Oil Seal

Diunggah oleh

Seeni VSHak Cipta:

Format Tersedia

paraolio - oil seal 20*47*7

PARAOLIO - OIL SEAL

Oil sealsor shaftsealsare an integral part in any rotating and moving part

assembly The function of the oil seal is to stop whatever fluid is inside from

leaking out the clearance between the shaft and housing. The seal may also be

used to prevent outside materials, such as dirt, from moving in through the

clearance.

"Dynamic sealing" is the relationship between the rotating shaft and the seal and

is handled by the sealing element. A garter spring may used in the oil seal to

increase the radial interference between the seal lip and contact point on the

shaft. In order to achieve this interference, the oil seal's ID must be slightly

smaller than the diameter of the shaft.

"Static sealing" is the relationship between the housing and the seal. In order to

achieve this interference, the oil seal's OD must be slightly larger than the

diameter of the housing or bore.

An oil seal normally consists of three basic components: the sealing element, the

metal case and the spring. The purpose of the sealing element is to stop the fluid

from leaking between the shaft and housing. The metal case will give rigidity and

strength to the seal while it is being held in the bore or recessed groove. The

spring will help make the sealing element more effective. All materials must be

selected depending on the environment in which the oil seal will function.

.

Oil seal

Oil seal

Constructional Aspects of anOil Seal:

1.Theoil sealconsists of a metal ring as the inner skeleton which provides the structural stability to

theoil seal.

2.The outer skin is made ofnitrilerubber and various othermaterialswhich are used based on the

requirement.

3.The spring on the lip of theoil sealtends to provide support to the lip and prevents the lubricant

from leaking outside and also prevents the entry of contaminants from outside.

Based on theapplicationof theoil seal, the outer skin layer tends to differ. Here are some types of

thematerialsused for the outer skin of theoil seal.

1.Nitrilerubber -The commonly used material foroil seals

2.Silicone Used in specificapplicationswhere only light loads are applied.

3.Poly acrylate

4.Fluroelastomer also popularly known as Viton. The high temperatureresistantmaterial used in

places where temperature is more than 120DegreeCelcius.

5.PolytetraFluroEthylene (PTFE)

The oilssealsrequire certain prerequisites to be maintained for their proper working. They are as

follows:

a)The shaft on which theoil sealis to be mounted should be ground with the surface finish or

surface roughness between 0.2 to 0.8 Microns. It is best for the shaft to be hardened atleast to 40

45 HRc in order to prevent groove formation on the shaft due to the pressure exerted by the spring.

b)The area where theoil sealis seated is to be plunge ground in order to prevent wear grooves that

normally tend to wear out the lip of theoil sealat a faster rate.

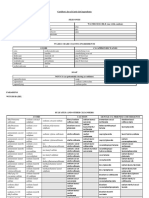

SC=R21 & TC=R23 being the most common R21=Single

Lip R23=Double Lip

20x47x7 oil seal - Double lip nitrile rubber metric rotary

shaft oil seal with garter spring 20mm inside x 47mm

outside x 7mm wide.

To prevent potential damage, circlips are

installed with the smooth side facing the

part and the rough side facing out

Anda mungkin juga menyukai

- How To Choose The Right Oil Filter For Your CarDokumen22 halamanHow To Choose The Right Oil Filter For Your CarMar Christian SilverioBelum ada peringkat

- 17 Oil Seals The BasicsDokumen2 halaman17 Oil Seals The BasicsGajanan NalegaonkarBelum ada peringkat

- Presentasi Oil Seal PolerDokumen13 halamanPresentasi Oil Seal PolerIndi SeptiantiBelum ada peringkat

- Seal Off Centrifugal Pump ProblemsDokumen6 halamanSeal Off Centrifugal Pump ProblemsArturo Valles TerrazasBelum ada peringkat

- Oil Seal DesignDokumen3 halamanOil Seal Designmanoj262400/2100% (1)

- Compressor SealDokumen6 halamanCompressor SealManojkumarBelum ada peringkat

- Paper Valve - Stem - Seals - Materials - and - Designs PDFDokumen8 halamanPaper Valve - Stem - Seals - Materials - and - Designs PDFRidwanUsmanBelum ada peringkat

- Lecture 13 & 14Dokumen26 halamanLecture 13 & 14farah nazBelum ada peringkat

- Housing Designs & Seal Options PDFDokumen27 halamanHousing Designs & Seal Options PDFmimi_chan_17100% (1)

- ENB 04 0555 Rev B Bearing Lubrication PDFDokumen5 halamanENB 04 0555 Rev B Bearing Lubrication PDFIrwan SyahBelum ada peringkat

- BTEC Assignment - Unit 12Dokumen16 halamanBTEC Assignment - Unit 12Muthu RajanBelum ada peringkat

- Hydraulic and PneumaticDokumen15 halamanHydraulic and PneumaticDhvanirBelum ada peringkat

- 06Dokumen12 halaman06JJBelum ada peringkat

- EGT001 Roller Bearings Lubrication TrainingDokumen10 halamanEGT001 Roller Bearings Lubrication TrainingJom BonhayagBelum ada peringkat

- Compressor Piston SealingDokumen7 halamanCompressor Piston SealingVarada Radjou CBelum ada peringkat

- Seals and GasketsDokumen53 halamanSeals and GasketsMadan YadavBelum ada peringkat

- Lubrication GuideDokumen22 halamanLubrication GuideRizalBelum ada peringkat

- Preventive maintenance tips for thermoset molds and pressesDokumen6 halamanPreventive maintenance tips for thermoset molds and pressesAnurag SrivastavaBelum ada peringkat

- U3l2s Seals - HosesDokumen18 halamanU3l2s Seals - HosespmcisissengueBelum ada peringkat

- RTV Is800 SeriesDokumen4 halamanRTV Is800 SeriesFaraan KhanBelum ada peringkat

- Sect 29 Preventive MaintenanceDokumen6 halamanSect 29 Preventive MaintenancezfiyldvmBelum ada peringkat

- Lubricants - Always Important-Sometimes EssentialDokumen2 halamanLubricants - Always Important-Sometimes EssentialGordinhorsBelum ada peringkat

- Constant Level Oiler - Vented or NonventedDokumen7 halamanConstant Level Oiler - Vented or Nonventedpeach5Belum ada peringkat

- Cylinder Liner NotesDokumen15 halamanCylinder Liner NotesHrishikesh MoreBelum ada peringkat

- Atlas Copco 14013 Manual PDFDokumen164 halamanAtlas Copco 14013 Manual PDFtadeoo22100% (1)

- SAP PARTS: Installation Guidelines For Installation Guidelines For Duo-Cone SealsDokumen5 halamanSAP PARTS: Installation Guidelines For Installation Guidelines For Duo-Cone SealsRavi MirzaBelum ada peringkat

- Valve SealantsDokumen10 halamanValve Sealantsrondulf goBelum ada peringkat

- Chapter 1 Oil Seal IntroductionDokumen6 halamanChapter 1 Oil Seal IntroductionNCvetarskyBelum ada peringkat

- Mansete de RotatieDokumen20 halamanMansete de RotatieLavinia LupulescuBelum ada peringkat

- Gaskets, Seals, and Packings Guide for Machinery ComponentsDokumen10 halamanGaskets, Seals, and Packings Guide for Machinery ComponentsKrishna MohanBelum ada peringkat

- Technical Discussion - Cutless BearingsDokumen7 halamanTechnical Discussion - Cutless BearingsSoodyod Yodyod0% (1)

- Maintain Hydraulic Systems EfficientlyDokumen39 halamanMaintain Hydraulic Systems Efficientlyavinash babu100% (1)

- What Are Labyrinth Seals For BearingsDokumen18 halamanWhat Are Labyrinth Seals For BearingsAthiphap SrisupareerathBelum ada peringkat

- 2005 Seal and Its FunctionDokumen1 halaman2005 Seal and Its FunctionHaseeb BokhariBelum ada peringkat

- Understand Ing Bearing Housing Protection and Reliable Lubricant ApplicationDokumen13 halamanUnderstand Ing Bearing Housing Protection and Reliable Lubricant ApplicationRuchi Ragvendra BistBelum ada peringkat

- Dodge Type E BearingsDokumen2 halamanDodge Type E BearingsGilberto Diaz CastilloBelum ada peringkat

- Neral Notes On Engineering Hardware - Seals, Gaskets, ValvesDokumen37 halamanNeral Notes On Engineering Hardware - Seals, Gaskets, ValvesbrotaccristianBelum ada peringkat

- Hydraulics WhitepaperDokumen4 halamanHydraulics WhitepaperHUERTANESTORBelum ada peringkat

- Hidráulica Sello Cilíndrico de Análisis de FallasDokumen22 halamanHidráulica Sello Cilíndrico de Análisis de FallasPedro Cerna DiazBelum ada peringkat

- ElectricMotorGreasing PDFDokumen6 halamanElectricMotorGreasing PDFHemraj Singh RautelaBelum ada peringkat

- Chapter 1 Oil Seal IntroductionDokumen0 halamanChapter 1 Oil Seal IntroductionZMCONTROLBelum ada peringkat

- Ball Bearing Lubrication in Centrifugal PumpsDokumen4 halamanBall Bearing Lubrication in Centrifugal Pumpsyousafsappal795Belum ada peringkat

- Select the Right Industrial Lubricant for MachineryDokumen14 halamanSelect the Right Industrial Lubricant for MachineryBijendra PrajapatiBelum ada peringkat

- Ball Bearing Lubrication in Centrifugal Pumps: Mcnally InstituteDokumen4 halamanBall Bearing Lubrication in Centrifugal Pumps: Mcnally Instituteagrocel_bhv5591Belum ada peringkat

- Hydrodynamics Journal BearingDokumen14 halamanHydrodynamics Journal BearingAhmad Shayuty75% (4)

- Understanding proper lubrication from a bearing's perspectiveDokumen22 halamanUnderstanding proper lubrication from a bearing's perspectiveengrsurifBelum ada peringkat

- Mechanical Seal Principles Manual - Chapter 1Dokumen28 halamanMechanical Seal Principles Manual - Chapter 1avciayBelum ada peringkat

- 111 Protecting BearingsDokumen3 halaman111 Protecting BearingsIvo Herid LesmanaBelum ada peringkat

- Porosity Sealing - WikipediaDokumen2 halamanPorosity Sealing - WikipediaSiddhant VermaBelum ada peringkat

- Catalogo RHPDokumen83 halamanCatalogo RHPLuisNovoaRivera100% (1)

- Applying Appropriate SealantDokumen64 halamanApplying Appropriate SealantShina AbieraBelum ada peringkat

- Mod 7 Book 3 Engineering PracticesDokumen44 halamanMod 7 Book 3 Engineering Practicesranjit prasadBelum ada peringkat

- Laporan Praktikum Sealing-BearingDokumen26 halamanLaporan Praktikum Sealing-Bearinga2sn_elizBelum ada peringkat

- Mechanical SealDokumen127 halamanMechanical SealVivek Rathod83% (18)

- "Lubed For Life" Bearings - Fact or FrictionDokumen7 halaman"Lubed For Life" Bearings - Fact or Frictionmechmaster4uBelum ada peringkat

- How to Seal Bearings for Maximum ProtectionDokumen6 halamanHow to Seal Bearings for Maximum ProtectionReyes SanchezBelum ada peringkat

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityDari EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityPenilaian: 3 dari 5 bintang3/5 (4)

- Detailers Dictionary Volume 2: The Industry StandardDari EverandDetailers Dictionary Volume 2: The Industry StandardBelum ada peringkat

- Product Specification of Terry TowelsDokumen2 halamanProduct Specification of Terry TowelsAbhishek SrivastavaBelum ada peringkat

- Organic Chemistry ReagentsDokumen7 halamanOrganic Chemistry ReagentsRishabhBelum ada peringkat

- Solvoya TH4603-W TDSDokumen1 halamanSolvoya TH4603-W TDSI Love MusicBelum ada peringkat

- Fa00 PDFDokumen102 halamanFa00 PDFUlma HudinBelum ada peringkat

- Understanding Boat Design 102 PDFDokumen1 halamanUnderstanding Boat Design 102 PDFŁukasz ZygielBelum ada peringkat

- Processing of Green CompositesDokumen142 halamanProcessing of Green CompositesNagarajanBelum ada peringkat

- Electrical Cable Types, Sizes, and Installation: Electric Cables Voltage Índice de ContenidosDokumen8 halamanElectrical Cable Types, Sizes, and Installation: Electric Cables Voltage Índice de ContenidosEmre DalgicBelum ada peringkat

- Preparation #: Paracetamol Tablets I. Objectives:: Pharmaceutical Dosage Forms Laboratory ManualDokumen2 halamanPreparation #: Paracetamol Tablets I. Objectives:: Pharmaceutical Dosage Forms Laboratory Manuallalag yanBelum ada peringkat

- Merv Rating Chart PDFDokumen1 halamanMerv Rating Chart PDFLapecillaBelum ada peringkat

- 16 Toxic Chemicals To Avoid in Cosmetics and Skincare - SkinKraftDokumen7 halaman16 Toxic Chemicals To Avoid in Cosmetics and Skincare - SkinKraftPriya Patel100% (1)

- Chemical CompatibilityDokumen29 halamanChemical CompatibilityH VBelum ada peringkat

- Biomordants As Alternatives To Metal Mordants For Sustainable Textile DyeingDokumen11 halamanBiomordants As Alternatives To Metal Mordants For Sustainable Textile DyeingRahul MandalBelum ada peringkat

- B.Pharm 5 Semester BP501T. Medicinal Chemistry-IIDokumen20 halamanB.Pharm 5 Semester BP501T. Medicinal Chemistry-IIShekh SameenBelum ada peringkat

- Curlsbot's List of Curly Girl IngredientsDokumen3 halamanCurlsbot's List of Curly Girl Ingredientsraphaela_zadielBelum ada peringkat

- Wire DrawingDokumen4 halamanWire DrawingSolomon NgussieBelum ada peringkat

- IUPAC Naming of Organic Compounds and Their Functional GroupsDokumen5 halamanIUPAC Naming of Organic Compounds and Their Functional Groupsoh okBelum ada peringkat

- Dyeing machines overviewDokumen6 halamanDyeing machines overviewChaarvi SaranyaBelum ada peringkat

- A Review On Brake Pad Materials and Methods of ProductionDokumen7 halamanA Review On Brake Pad Materials and Methods of ProductionhiteshBelum ada peringkat

- Commodity ThermoplasticsDokumen55 halamanCommodity ThermoplasticsBernard GanzwaBelum ada peringkat

- Antibiotics: April 2016Dokumen25 halamanAntibiotics: April 2016Santiago LopezBelum ada peringkat

- Composite Materials GuideDokumen23 halamanComposite Materials Guidenasuha batrishahBelum ada peringkat

- Invasive Alien Species (IAS) : Concerns and Status in The PhilippinesDokumen11 halamanInvasive Alien Species (IAS) : Concerns and Status in The PhilippinesZairah TalomaBelum ada peringkat

- Maintenance Manual 95XF PDFDokumen188 halamanMaintenance Manual 95XF PDFAlberjose Sanchez RuizBelum ada peringkat

- What Is Nelcote E-761 PCBDokumen5 halamanWhat Is Nelcote E-761 PCBjackBelum ada peringkat

- PhenolsDokumen34 halamanPhenolsLoran Prelya TengayBelum ada peringkat

- Editable Periodic Table MS WORDDokumen8 halamanEditable Periodic Table MS WORDYasir50% (2)

- A Review On Cell Wall Synthesis InhibitorsDokumen18 halamanA Review On Cell Wall Synthesis InhibitorsAhraxazel Galicia ReynaBelum ada peringkat

- Soil Stabilization: Bituminous vs Resin EmulsionsDokumen15 halamanSoil Stabilization: Bituminous vs Resin EmulsionsYasruddin MtBelum ada peringkat

- Synthetic Fibre-Reinforced Concrete: Zhihong Zheng and Dorel FeldmanDokumen26 halamanSynthetic Fibre-Reinforced Concrete: Zhihong Zheng and Dorel Feldmanhasna adillaBelum ada peringkat

- Isolation of Solasodine From The Unripe Fruits of Solanum Xanthocarpum Schrad and Wendl. (Solanaceae) and It's Anti Cancer Activity Against HeLa and U937 Cell Lines PDFDokumen15 halamanIsolation of Solasodine From The Unripe Fruits of Solanum Xanthocarpum Schrad and Wendl. (Solanaceae) and It's Anti Cancer Activity Against HeLa and U937 Cell Lines PDFwinayusBelum ada peringkat