Adv Training For Engineers - 080916

Diunggah oleh

vijay kumar0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

20 tayangan4 halamanf

Judul Asli

Adv Training for Engineers _080916

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPTX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inif

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPTX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

20 tayangan4 halamanAdv Training For Engineers - 080916

Diunggah oleh

vijay kumarf

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPTX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 4

Spline Engineering Consultants,SEC

Consultancy for Engineers

Plot No.623,2nd floor, Vivekananda Nagar Colony, Kukatpally, Hyderabad-

500085,

Phone: 040-65180006, 9059968366 email ID:hr@splineengg.com

Basic & Advanced trainings for Fresh/Experienced Engineers, in

Automotive interiors, Exteriors, Plastics, Sheet metal, Castings,

BIW and Seating systems

Course Content:

Plastic Product development and Tool design

Sheet metal Product Development and Tool design

Casting Design

Automotive Interiors, Exteriors, BIW and Seating systems

Basic Aerospace systems

Product definition, design per ASME standards

Geometrical Dimensioning and Tolerancing, GD&T per ASME Y14.5

2009

Stack-up analysis.

Job/interview assistance:

Interview tips

Sample projects execution

Assistance for arranging interviews

Provides placement assistance to our trainees.

Experienced trainer with hands on software skills and practical

knowledge with live industrial projects and enhance studying

concepts of engineering drawings.

Trainees benefit from personal attention of our experienced staff.

Gives you a choice of training styles to suit your skills and needs.

Provides certificate for the training course.

Course details / requirements:

Duration : 3months

Candidate has to carry his/her own laptop with CAD software

installed

Fee should be paid in two installments. 50% at the beginning

remaining after one month.

Course content

Product definition, PD, Part-1

Angle of Projections, First & Third Angle Projections

Definitions of different Planes

First Angle Projections

Third Angle Projections

Comparison of 1st and 3rd Angle Projections

Orthographic projections

Isometric views / drawings

Auxiliary Views

Sectional Views

Break out Sectional Views

Exploded Views

Bill of materials

Part-2

ASME Y14.100 Engineering Drawing Practices

ASME Y14.2 Line Conventions and Lettering

ASME Y14.24 Types and Applications of Engineering Drawings

ASME Y14.8 -Castings, Forgings, and Molded Parts

ASME Y14.36 Surface TextureSymbols

ASME B46.1, Surface Texture, SurfaceRoughness, Waviness, and

Lay

ASME Y14.6 - Screw Thread Representation

ANSI Y14.13M Mechanical Spring Representation

ASME Y14.1 - Decimal Inch Drawing Sheet Size & Format

ASME Y14.41 Digital Product Definition Data Practices

Fundamental rules- Dimensioning & Tolerancing

Dimension and tolerance

Types of Tolerance

Millimeter and inch Dimensioning.

Dimensioning Scheme for Gaskets / Flanges

Screw Thread designation

Surface finish Requirements

Slot Dimensioning practices

Fillet and edge radii dimensioning

Course content GD&T, per ASME Y14.5

2009

Understanding the need for GD & T, Advantages of GD & T over

conventional limit tolerancing.

Definitions of Terms and Symbols

Definition of Feature Control Frame

Taylor principle or Rule#1

Feature definitions, Size and Surfaces

Material and Datum modifiers

Tolerance concepts, MMC / LMC / RFS, Material modifier

Calculation of bonus tolerance per MMC / LMC

MMB,LMB, RMB and translation concepts

Datum Targets and six degrees of freedom

Training on CAD software:

CAD training will be given by an expert. The course content for

Catia will be as given below. Course content will be similar for

other soft wares.

CATIA V5 Sketcher

1. Reference Elements

2. Basic Sketch Operations

3. Advanced Sketch Operations

CATIA V5 Modeling

1. Basic Solid Geometry

2. Boolean Operations

3. Dress Up Features

4. Transformation Features

CATIA V5 Generative Shape Design

1. Reference Features

2. Basic Wireframe Geometry

3. Advanced Wireframe Geometry 1

CATIA V5 Assemblies

1. Basic Assemblies

2. Assembly Constraints

CATIA V5 Drafting

Drafting Introduction Unit Introduction

Creating Drawings

Automotive interiors, exteriors,

plastics, BIW and seating

1. Vehicle overview

Types of vehicles

Common vehicle components

Automotive manufacturing overview

Assembly plant layout

Vehicles co-ordinate systems

2. Jigs and fixture

How manufacturing systems are built

Types of jigs & fixtures

Design criteria for fixtures

3. BIW overview

BIW systems - components

BIW joining process

4. BIW process planning

Process overview

System layout

Standard components and specifications

Data creation standards

5. BIW fixture design

Types of BIW tools

BIW fixture elements

BIW tool design data

BIW fixture design criteria

Materials for tool design

6. BIW systems integration

Automation welding systems overview

Part handling and mechanical conveyance

Control engineering

Manual assembly operations and b-side tooling

7. BIW Drafting overview

BIW drafting practises

BOM creation

Body shop safety overview

8. BIW assembly project overview

Scope and inputs

Tools and operations

Anda mungkin juga menyukai

- Test Execution Summary Reports 100% Pass RateDokumen3 halamanTest Execution Summary Reports 100% Pass Ratevijay kumarBelum ada peringkat

- Err System Config FailedDokumen2 halamanErr System Config Failedvijay kumarBelum ada peringkat

- ERR SYSTEM CONFIG FAILED v1Dokumen2 halamanERR SYSTEM CONFIG FAILED v1vijay kumarBelum ada peringkat

- B UCSM GUI Storage Management Guide 3 1 Chapter 010101Dokumen16 halamanB UCSM GUI Storage Management Guide 3 1 Chapter 010101vijay kumarBelum ada peringkat

- ESXI Qualification Test PlanDokumen2 halamanESXI Qualification Test Planvijay kumarBelum ada peringkat

- Upgrade Component Report 10.1.21.26Dokumen1 halamanUpgrade Component Report 10.1.21.26vijay kumarBelum ada peringkat

- Login Logs and Federation DetailsDokumen252 halamanLogin Logs and Federation Detailsvijay kumarBelum ada peringkat

- Rapid TablesDokumen27 halamanRapid Tablesvijay kumarBelum ada peringkat

- Process Engineer Oil & Gas Role Bangalore 3.5-5.5 LPADokumen2 halamanProcess Engineer Oil & Gas Role Bangalore 3.5-5.5 LPAvijay kumarBelum ada peringkat

- New Batches Info: Blueprism ContentDokumen4 halamanNew Batches Info: Blueprism Contentvijay kumarBelum ada peringkat

- VMware Vsphere 6Dokumen1 halamanVMware Vsphere 6vijay kumarBelum ada peringkat

- BP JAY IT Content - Charan - 2Dokumen3 halamanBP JAY IT Content - Charan - 2vijay kumarBelum ada peringkat

- Unix QT - PPSXDokumen52 halamanUnix QT - PPSXswaroop24x7Belum ada peringkat

- ChatLog Quality Thought BI Tools Day4 Class On Dec 22 2018-12-22 20 - 57Dokumen1 halamanChatLog Quality Thought BI Tools Day4 Class On Dec 22 2018-12-22 20 - 57vijay kumarBelum ada peringkat

- Quality Thought Daily Class Notes Manual TestingDokumen12 halamanQuality Thought Daily Class Notes Manual Testingvijay kumarBelum ada peringkat

- Vizag Grinding Unit, Gobburupalem Village, Visakhapatnam Andhra Pradesh (0.95 MTPA) Plant DetailsDokumen35 halamanVizag Grinding Unit, Gobburupalem Village, Visakhapatnam Andhra Pradesh (0.95 MTPA) Plant Detailsvijay kumar100% (1)

- New Batches Info: Core Java ContentDokumen3 halamanNew Batches Info: Core Java Contentvijay kumarBelum ada peringkat

- Mutual Funds in Icici 2017Dokumen92 halamanMutual Funds in Icici 2017vijay kumarBelum ada peringkat

- VVVSGDDNDVHF TTDokumen24 halamanVVVSGDDNDVHF TTvijay kumarBelum ada peringkat

- Babji Cuurriculumvtiae - 2 (1) BajiDokumen2 halamanBabji Cuurriculumvtiae - 2 (1) Bajivijay kumarBelum ada peringkat

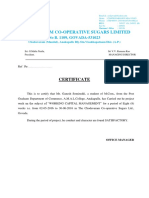

- Company Certificate RammiDokumen1 halamanCompany Certificate Rammivijay kumarBelum ada peringkat

- Leadership: Peyton InvestmentsDokumen2 halamanLeadership: Peyton Investmentsvijay kumarBelum ada peringkat

- VVVSGDDNDVHF TTDokumen24 halamanVVVSGDDNDVHF TTvijay kumarBelum ada peringkat

- Company Certificate RammiDokumen1 halamanCompany Certificate Rammivijay kumarBelum ada peringkat

- Process Engineer Oil & Gas Role Bangalore 3.5-5.5 LPADokumen2 halamanProcess Engineer Oil & Gas Role Bangalore 3.5-5.5 LPAvijay kumarBelum ada peringkat

- VVVSGDDNDVHF TTDokumen24 halamanVVVSGDDNDVHF TTvijay kumarBelum ada peringkat

- VVVSGDDNDVHF TTDokumen24 halamanVVVSGDDNDVHF TTvijay kumarBelum ada peringkat

- Early counting devices and analog computersDokumen2 halamanEarly counting devices and analog computersvijay kumarBelum ada peringkat

- VVVSGDDNDVHF TTDokumen24 halamanVVVSGDDNDVHF TTvijay kumarBelum ada peringkat

- GrgreerhDokumen1 halamanGrgreerhvijay kumarBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Bernoulli Lab ReportDokumen18 halamanBernoulli Lab ReportRam Krishna Singh80% (15)

- Amc 20-28Dokumen31 halamanAmc 20-28Vivian TellerBelum ada peringkat

- Nikola Tesla PaperDokumen6 halamanNikola Tesla Paperapi-302403539Belum ada peringkat

- Thyristor Controlled Reactor: Circuit DiagramDokumen4 halamanThyristor Controlled Reactor: Circuit DiagramSpk SudhinBelum ada peringkat

- PP43C10-10.25-VS 43c10varDokumen2 halamanPP43C10-10.25-VS 43c10varJonas RachidBelum ada peringkat

- CoreLine LED Brochure 2013Dokumen20 halamanCoreLine LED Brochure 2013Dragan VuckovicBelum ada peringkat

- Programa Congreso CIDUPDokumen2 halamanPrograma Congreso CIDUPGigi GallardoBelum ada peringkat

- Revision Sex Death and EpicsDokumen77 halamanRevision Sex Death and EpicsAshli KingfisherBelum ada peringkat

- Self PublishingDokumen84 halamanSelf PublishingFrancesco CusumanoBelum ada peringkat

- PVC Pipe Longevity ReportDokumen24 halamanPVC Pipe Longevity ReportUnibellBelum ada peringkat

- IalDokumen24 halamanIalWMONTOYA4897Belum ada peringkat

- Po Ex en 170413 WebDokumen1 halamanPo Ex en 170413 Webswordleee swordBelum ada peringkat

- Basic Principles of Counseling ProcessDokumen2 halamanBasic Principles of Counseling ProcessBhavna SinghalBelum ada peringkat

- C ProgramsDokumen54 halamanC Programskodali_madhav100% (3)

- 1.4404 enDokumen5 halaman1.4404 enyraju88Belum ada peringkat

- Fluid Mechanics & Machines IES2009 GATE2009Dokumen451 halamanFluid Mechanics & Machines IES2009 GATE2009paragmishra1986Belum ada peringkat

- Raft Slab DesignDokumen5 halamanRaft Slab DesignLekins Sefiu Yekini100% (2)

- Resume: Advanced Diploma in Power System Engineering Advanced Diploma in EEEDokumen2 halamanResume: Advanced Diploma in Power System Engineering Advanced Diploma in EEEMozahidul IslamBelum ada peringkat

- Devops Training in Bangalore - Devops Training in Bangalore MarathahalliDokumen8 halamanDevops Training in Bangalore - Devops Training in Bangalore MarathahalliitrainBelum ada peringkat

- Scientific American - February 2019Dokumen112 halamanScientific American - February 2019Frankling AguilarBelum ada peringkat

- Ekspanzioni VentilDokumen6 halamanEkspanzioni VentilNevena AksićBelum ada peringkat

- Comprehensive Solid Waste Management OrdinanceDokumen19 halamanComprehensive Solid Waste Management OrdinanceAnob EhijBelum ada peringkat

- VingDokumen8 halamanVingNguyễnĐắcĐạt100% (1)

- Copper Wire and Cable: From Wikipedia, The Free EncyclopediaDokumen16 halamanCopper Wire and Cable: From Wikipedia, The Free Encyclopediatanwar_anuj1990Belum ada peringkat

- Keac 212Dokumen17 halamanKeac 212Ias Aspirant AbhiBelum ada peringkat

- CamlabDokumen22 halamanCamlabviswamanojBelum ada peringkat

- Position: Chapter-9 Flow Past Through BodyDokumen3 halamanPosition: Chapter-9 Flow Past Through BodyAbishek AdhikariBelum ada peringkat

- Cv-Sreenath (T&i)Dokumen5 halamanCv-Sreenath (T&i)sreenaths100% (1)

- Assignment # La 01 Name: Muhammad Ghufran Siddiqui F.Name: Abdul Sami Class: BSSE (Ii) Section: A Roll No: 32Dokumen5 halamanAssignment # La 01 Name: Muhammad Ghufran Siddiqui F.Name: Abdul Sami Class: BSSE (Ii) Section: A Roll No: 32Mehak AnsariBelum ada peringkat

- Thermodynamic properties of R740 (ammonia) in SI unitsDokumen1 halamanThermodynamic properties of R740 (ammonia) in SI unitsJose LuisBelum ada peringkat