Rahat Electrician

Diunggah oleh

Ubed Shaikh0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

19 tayangan12 halamanansoff matrix

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPT, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Iniansoff matrix

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

19 tayangan12 halamanRahat Electrician

Diunggah oleh

Ubed Shaikhansoff matrix

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 12

An electrician is a tradesman specialising in

electrical wiring of buildings, stationary machines

and related equipment.

electricians are sometimes referred to as a

electrical wire men as opposed to Electrical

linemen, who work on electric utility company

distribution systems at higher voltages.

Electrical contracting is divided into four areas:

commercial, residential, light industrial, and

industrial wiring.

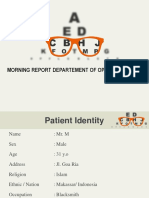

Within the workplace, vision screenings or

examinations are often conducted to ensure the

minimum level of functioning needed to

accomplish specific visual tasks. These procedures

can be conducted

. upon employment (placement)

and periodically throughout a workers career.

Identifying and correcting even a small refractive

error can greatly increase a workers visual

efficiency and productivity.

Results from the tests can help with proper

employee placement and aid in documenting

entering visual functioning.

Basic visual requirement:

Visual aquity

Near vision

Intermediate &

Distance vision

Additional visual requirement

Colour vision

Binocularity (stereopsis)

Visual field

10 foot candle

For distance 2 ft 2.1 5 kilovolt

Near vision should be very accurate N6

For distance minimum 6/6O

Electric shock - burn

Foreign particles or projectiles

Fumes , dusts, flashes

Fuel , battery acid splashes

Due to the nature of their overhead work,

electrical workers are at increased risk for eye

injuries from flying particles such as nails, small

pieces of metal and cut wire ends, as well as falling

objects or sparks striking the eye. Electricians also

face a higher threat of burns, which can lead to

blindness.

Vision - night blindness

Lid - necrosis, blepharospasm

EOMs - paralysis

Cornea- perforation

A.C - hyphema, alt. in IOP

Lens - ant. And post. Cataract

Retina - oedema, hemorrage, holes, venous

dilatation

Optic head- neuritis, atrophy

Field defects

Create a safe work environment

Minimize hazards from falling or unstable

debris.

Make sure that tools work and safety features

(machine guards) are in place.

Make sure that workers (particularly

volunteers) know how to use tools properly.

Evaluate safety hazards.

Identify the primary hazards at the site.

Identify hazards posed by nearby workers, large

machinery, and falling/shifting debris.

Wear the proper eye and face protection

Select the appropriate Z87 eye protection for the

hazard.

Make sure the eye protection is in good condition.

Make sure the eye protection fits properly and will

stay in place.

Use good work practices.

CautionBrush, shake, or vacuum dust and debris

from hardhats, hair, forehead, or the top of the eye

protection before removing the protection.

Do not rub eyes with dirty hands or clothing.

Clean eyewear regularly.

Non-prescription (plano) and prescription (non

plano) safety glasses

Goggles

Face shields

Full-face respirators

Safety glasses with side shields for impact

protection.

Arc rated face shield to protect against arc flash.

Protective goggles

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Falit Jyotish Mai Kal-Chakra-O.KDokumen32 halamanFalit Jyotish Mai Kal-Chakra-O.KKALSHUBH67% (6)

- Forensic PhotographyDokumen11 halamanForensic Photographyfilibertpatrick_tad-awanBelum ada peringkat

- Accounting Standard IcaiDokumen867 halamanAccounting Standard IcaiKrishna Kanojia100% (2)

- Photographing in The DarkDokumen6 halamanPhotographing in The DarkScribme_too100% (1)

- 10Dokumen19 halaman10Bruno100% (3)

- Yashica 35 MEDokumen13 halamanYashica 35 MEΓιάννης ΚουμποτήςBelum ada peringkat

- Digital SLR Photography 2013-12Dokumen164 halamanDigital SLR Photography 2013-12WillimSmith100% (2)

- Corporate Social Responsibility: Media Research Users CouncilDokumen6 halamanCorporate Social Responsibility: Media Research Users CouncilUbed ShaikhBelum ada peringkat

- Circles Template 0001Dokumen5 halamanCircles Template 0001Ubed ShaikhBelum ada peringkat

- Business Template 0001Dokumen5 halamanBusiness Template 0001Ubed ShaikhBelum ada peringkat

- Presentation Title SEO OptimizedDokumen2 halamanPresentation Title SEO OptimizedUbed ShaikhBelum ada peringkat

- Click To Edit Master Subtitle StyleDokumen4 halamanClick To Edit Master Subtitle StyleUbed ShaikhBelum ada peringkat

- MowbrayDokumen28 halamanMowbrayUbed ShaikhBelum ada peringkat

- 3074Dokumen4 halaman3074Ubed ShaikhBelum ada peringkat

- SalerioDokumen28 halamanSalerioRizqaFebrilianyBelum ada peringkat

- Executive Summary Social Media Market 2012 2016Dokumen4 halamanExecutive Summary Social Media Market 2012 2016saaaruuuBelum ada peringkat

- MowbrayDokumen28 halamanMowbrayUbed ShaikhBelum ada peringkat

- Presentation Title: Your Company InformationDokumen3 halamanPresentation Title: Your Company InformationUbed ShaikhBelum ada peringkat

- Untitled 1Dokumen1 halamanUntitled 1Ubed ShaikhBelum ada peringkat

- SalerioDokumen28 halamanSalerioRizqaFebrilianyBelum ada peringkat

- SalerioDokumen28 halamanSalerioRizqaFebrilianyBelum ada peringkat

- SalerioDokumen28 halamanSalerioRizqaFebrilianyBelum ada peringkat

- Introduction To Media IndustryDokumen5 halamanIntroduction To Media IndustryUbed ShaikhBelum ada peringkat

- Untitled 1Dokumen1 halamanUntitled 1Ubed ShaikhBelum ada peringkat

- My New SipDokumen40 halamanMy New SipUbed ShaikhBelum ada peringkat

- An Assignment On Ias &icai For Accounting For Managers: Introduction of Indian Accounting StandardsDokumen83 halamanAn Assignment On Ias &icai For Accounting For Managers: Introduction of Indian Accounting StandardsUbed ShaikhBelum ada peringkat

- Research Topic 1Dokumen21 halamanResearch Topic 1Ubed ShaikhBelum ada peringkat

- 2836Dokumen3 halaman2836Ubed ShaikhBelum ada peringkat

- Furry Booster Enrgy DrinkDokumen3 halamanFurry Booster Enrgy DrinkUbed ShaikhBelum ada peringkat

- InstruccionesDokumen1 halamanInstruccionesUbed ShaikhBelum ada peringkat

- About Dhirubhai AmbaniDokumen5 halamanAbout Dhirubhai AmbaniUbed ShaikhBelum ada peringkat

- DeathDokumen6 halamanDeathUbed ShaikhBelum ada peringkat

- Survey QuestionsDokumen2 halamanSurvey QuestionsUbed ShaikhBelum ada peringkat

- Hanjin Shipping bankruptcy disrupts global supply chainsDokumen10 halamanHanjin Shipping bankruptcy disrupts global supply chainsUbed ShaikhBelum ada peringkat

- Accounting Standards-Introduction and List For MBA StudentsDokumen7 halamanAccounting Standards-Introduction and List For MBA StudentsSantosh Parashar0% (1)

- Chromatic Energy of Architectural DesignDokumen34 halamanChromatic Energy of Architectural DesignRamzeez PajaritoBelum ada peringkat

- RS Sayang Rakyat - CORPALDokumen11 halamanRS Sayang Rakyat - CORPALNurbaitil Atiq TamiiBelum ada peringkat

- Mediums Visual of Art: MOSAIC - A Mosaic Is A Piece of Art or ImageDokumen4 halamanMediums Visual of Art: MOSAIC - A Mosaic Is A Piece of Art or ImageRuri ChanBelum ada peringkat

- MR - Color-Gunze-Humbrolt-Tamiya and Revells Equivalents Color ChartsDokumen8 halamanMR - Color-Gunze-Humbrolt-Tamiya and Revells Equivalents Color ChartssarrpaBelum ada peringkat

- Elements and Principles of ArtDokumen5 halamanElements and Principles of ArtTheresa MillionBelum ada peringkat

- Eos m6 ManualDokumen221 halamanEos m6 ManualBianca Nicoleta SsnBelum ada peringkat

- FCB Ex985eDokumen8 halamanFCB Ex985ekakaBelum ada peringkat

- Octane Render Functions Comparison (V5)Dokumen50 halamanOctane Render Functions Comparison (V5)Luis CurryBelum ada peringkat

- ERG GuidelinesDokumen15 halamanERG GuidelinesImtiaz AhmedBelum ada peringkat

- Fuho Ir775+775hDokumen1 halamanFuho Ir775+775hTas DtBelum ada peringkat

- LB XG PJB15 EvDokumen362 halamanLB XG PJB15 Evmoneer1994Belum ada peringkat

- Anatomi Dan Fisiologi Mata 1Dokumen61 halamanAnatomi Dan Fisiologi Mata 1MAWANBelum ada peringkat

- Week 1 LAD VocabularyDokumen13 halamanWeek 1 LAD VocabularyJinyoung KimBelum ada peringkat

- Photography - December 2023Dokumen16 halamanPhotography - December 2023ArtdataBelum ada peringkat

- AniseikoniaDokumen40 halamanAniseikoniahenok biruk100% (1)

- Week 1: Contemporary Philippine Arts From The RegionsDokumen27 halamanWeek 1: Contemporary Philippine Arts From The RegionsClarabel LanuevoBelum ada peringkat

- Automatic White Balance Algorithm 1Dokumen10 halamanAutomatic White Balance Algorithm 1pi194043Belum ada peringkat

- Graphic Design Elements & Principles ExplainedDokumen18 halamanGraphic Design Elements & Principles ExplainedTahir UsmanBelum ada peringkat

- Manual Flash 580EX IIDokumen61 halamanManual Flash 580EX IIdarkyuftiwBelum ada peringkat

- An Experimental Training Support Framework For Eye Fundus Examination Skill DevelopmentDokumen13 halamanAn Experimental Training Support Framework For Eye Fundus Examination Skill DevelopmentWalisson BarbosaBelum ada peringkat

- Minicute Imager: Small, Light, and EasyDokumen2 halamanMinicute Imager: Small, Light, and Easyromario1313Belum ada peringkat

- Lens and Cataract - Dr. Angbue-Te (2023)Dokumen4 halamanLens and Cataract - Dr. Angbue-Te (2023)Patricia ManaliliBelum ada peringkat

- Technical Specifications: DTX Af DTX Fa DTX IcgDokumen4 halamanTechnical Specifications: DTX Af DTX Fa DTX IcgFaridBelum ada peringkat

- Anatomy of The EyesDokumen35 halamanAnatomy of The EyesKiela Nicole Gatpandan AguilarBelum ada peringkat