276985

Diunggah oleh

Tibebu Meride0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

10 tayangan26 halamandownload

Judul Asli

1111128618_276985

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPT, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inidownload

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

10 tayangan26 halaman276985

Diunggah oleh

Tibebu Meridedownload

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 26

Bearings, Seals, and Greases

Chapter 60

2012 Delmar, Cengage Learning

Objectives

Understand terms that relate to wheel bearings

Select the correct grease to use for a particular

application

Describe the various wheel and axle bearing

arrangements

Service wheel bearings on front and rear axles

2012 Delmar, Cengage Learning

Introduction

Automobiles contain many types of bearings

This chapter deals with fundamentals of

bearings, seals, and lubricants

Last part of chapter covers bearing service

2012 Delmar, Cengage Learning

Plain Bearings

Example: engine crankshaft bearings

Do not use rolling parts

Provide sliding contact between two mating

surfaces

Also called friction bearings

2012 Delmar, Cengage Learning

Frictionless Bearings

Provide a rolling contact

Ball, roller, or needle bearings

Made of hardened steel alloys

Ground to a precise finish and size

Must be lubricated

Some are sealed

Ball or roller bearings

Balls or rollers ride between an inner race and an

outer race

Bearing cage holds balls or rollers in position

2012 Delmar, Cengage Learning

Bearing Loads

Bearings are made to handle different loads

Radial load: bearing load in up-and-down

direction

Thrust load: load in front-to-rear direction

Also called axial thrust

2012 Delmar, Cengage Learning

Ball Bearings

Ride in machined grooves

At rest: load is distributed equally wherever balls

and races are in contact

Control end thrust and radial movement

Must control thrust: groove in bearing race will be

offset to one side

Single-row bearings

Susceptible to damage when shaft is misaligned

2012 Delmar, Cengage Learning

2012 Delmar, Cengage Learning

Roller Bearings

Used great load-carrying capacity is needed

Provide more surface area of contact with the race

Several types

Do not control end thrust

Most popular is the tapered roller bearing

Used for front-wheel bearings

Can control end thrust when installed with tapers

facing in opposite directions

Needle bearing

Very small roller bearing

2012 Delmar, Cengage Learning

2012 Delmar, Cengage Learning

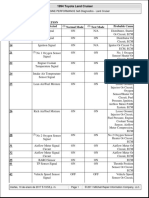

Wheel Bearings

Found on all wheels of a vehicle

Axle bearings are on live axles

Drive axle bearings

Located at ends of rear axle housing on RWD

car or on hub on FWD car

Full-floating axles

Found on ton and larger trucks and vans

FWD bearings

Compact and need to fit in a tight space

2012 Delmar, Cengage Learning

Greases

Greases are used in:

Wheel bearings and chassis joints

Universal joints and gear boxes

Properties and characteristics of grease

Limited by quality of oil it is made of

Greases are fibrous

Different sizes of fibers available

Greases do not have a sharp melting point

Viscosity of oil used in making grease is

important to grease's apparent viscosity

2012 Delmar, Cengage Learning

Greases (cont'd.)

Automotive grease

Classified by NLGI

Grease types

Extreme pressure lubricants

Same as those found in gear lubricants

Chassis grease

Consistency allows application through zerk fitting

Wheel bearing grease

Resistant to heat

2012 Delmar, Cengage Learning

Greases (cont'd.)

Universal joint grease

Made for universal joints

Multipurpose grease

Satisfies requirements of chassis, wheel bearing,

and universal joint lubricants

Solid lubricant grease

Often used to lubricate speedometer cables,

emergency brake cables, splines, and leaf springs

2012 Delmar, Cengage Learning

Wheel Bearing Seals

Automobiles and

equipment use seals

to:

Seal in lubricants

Keep different

lubricants

separated

Keep out dirt

Maintain vacuum or

pressure

2012 Delmar, Cengage Learning

Seal Materials and Design

Most popular seals are made of synthetic

materials

Most lip seals made of nitrile

Silicone seals

Often used in engines and transmissions

Fluoroelastomers

Used with special lubricants and chemicals

Non-synthetic seals

Leather, felt, etc.

2012 Delmar, Cengage Learning

Seal Tolerance

Seals can accommodate shaft that is

undersized up to 1/64 if parts are in perfect

alignment

RMA recommends runout tolerance be held to

0.003 for shafts up to four inches in diameter

Surface finish should be smooth

2012 Delmar, Cengage Learning

Wheel Bearing Diagnosis and

Service

Seal and bearing failure

Lubricant can leak out

Moisture can leak in

Boat trailer bearing failures

Common wheel bearing problem: trailer is towed

for a long distance before launching

Possible solution: Bearing Buddy

2012 Delmar, Cengage Learning

Wheel Bearing Adjustment

Wheel bearings must be adjusted correctly

Designed to operate with very little clearance

Generic method of adjusting a loose bearing can

be done with tire raised off ground

Spindle nuts are kept in place with a cotter pin

Remove to tighten

Washer under spindle nut has a tab that fits into

spindle groove

Prevents bearing from loosening or tightening

Wheel bearing nuts are typically hexagonal

2012 Delmar, Cengage Learning

Wheel Bearing Adjustment

(contd.)

Selecting and installing a

cotter pin

Use largest diameter

cotter pin that will fit into

hole

Pull longer end of cotter

pin to seat fully in its

hole

Cut it off

Cut off remaining end

flush with spindle

2012 Delmar, Cengage Learning

Disc Brake Caliper Removal

Procedure for repacking disc brake wheel

bearings

Same as that followed for drum brakes

Except disc caliper must be removed in order to

gain access to the inside wheel bearing

Caliper must be supported or wired to the steering

knuckle support

2012 Delmar, Cengage Learning

Repacking Wheel Bearings

Major steps and considerations

Remove hub and bearings from spindle

Seals are replaced during a bearing repack

Use a long dowel or drift to remove the seal

Clean out the old bearing

Look for metal flakes

Let the clean bearing air dry

2012 Delmar, Cengage Learning

Bearing Inspection and

Diagnosis

After cleaning inspect for damage

Spalling: pieces break off the bearing metal

Brinelling: bearing or race has indentations

Add grease to bearing

Pack with new grease by hand or pressure

bearing packer

Put small amount of grease in cavity of hub

Inspect the spindle

Clean and lubricate

2012 Delmar, Cengage Learning

Diagnosing Wheel Bearing

Noise

Driving car can help pinpoint problem

Check tires and bearings

Make slow left and right turns

Shifts weight of vehicle from one side to the other

Weight increases on bearing: noise increases

2012 Delmar, Cengage Learning

Replacing Bearing Races

Anti-friction bearings usually have one race that

is pressed fit and the other is push fit

When a damaged wheel bearing is replaced:

pressed-fit race must be removed

Old bearing race: removed by pounding it with a

drift punch or special tool

New race must fit the hub tightly

New race can be chilled in refrigerator to make

easier to install

2012 Delmar, Cengage Learning

Servicing Front-Wheel-Drive

Bearings

Most bearings on FWD vehicles are sealed

Require no service

Remove axle to get to bearing

Puller often required

Front-wheel bearing

Pressed or bolted onto the steering knuckle

Some manufacturers recommend bearing

replacement any time FWD assembly is

removed

Special care required during reassembly

2012 Delmar, Cengage Learning

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Inspection and Adjustment of Pump Ls ControlDokumen10 halamanInspection and Adjustment of Pump Ls ControlHai Van100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Candle MakingDokumen7 halamanCandle MakingnorthsageBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- 50TJDokumen56 halaman50TJHansen Henry D'souza100% (2)

- As ISO 128.23-2005 Technical Drawings - General Principles of Presentation Lines On Construction DrawingsDokumen9 halamanAs ISO 128.23-2005 Technical Drawings - General Principles of Presentation Lines On Construction DrawingsSAI Global - APAC0% (3)

- Lotus 1-2-3 For WindowsDokumen75 halamanLotus 1-2-3 For Windowskennedy_saleh100% (1)

- Civil DEMOLITION OF BUILDINGDokumen12 halamanCivil DEMOLITION OF BUILDINGShaik Abdul RaheemBelum ada peringkat

- Mechanical seal design principlesDokumen6 halamanMechanical seal design principlesTibebu MerideBelum ada peringkat

- BTS Training Fiber Optic Advanced SplicingDokumen5 halamanBTS Training Fiber Optic Advanced Splicingjama99Belum ada peringkat

- Composites Part B: Mehdi Kalantari, Chensong Dong, Ian J. DaviesDokumen12 halamanComposites Part B: Mehdi Kalantari, Chensong Dong, Ian J. DaviesTibebu MerideBelum ada peringkat

- Vibrations of Cantilever BeamsDokumen11 halamanVibrations of Cantilever Beamsrahim UllahBelum ada peringkat

- Evaluation of Ballistic Armor Behavior2017 - 2Dokumen9 halamanEvaluation of Ballistic Armor Behavior2017 - 2Tibebu MerideBelum ada peringkat

- Step 5Dokumen2 halamanStep 5Tibebu MerideBelum ada peringkat

- Low Velocity Impact Properties of Foam SDokumen13 halamanLow Velocity Impact Properties of Foam STibebu MerideBelum ada peringkat

- Robust DesignDokumen11 halamanRobust DesignTibebu MerideBelum ada peringkat

- Microsoft Word 19 Bennett, Alyssa - Final Paper - Docx Modeling of Shear Thickening Fluids For Analysis of Energy Absorption Under Impulse LoadingDokumen9 halamanMicrosoft Word 19 Bennett, Alyssa - Final Paper - Docx Modeling of Shear Thickening Fluids For Analysis of Energy Absorption Under Impulse LoadingTibebu MerideBelum ada peringkat

- Susi96022fu 2 PDFDokumen11 halamanSusi96022fu 2 PDFTibebu MerideBelum ada peringkat

- Engineering Fracture Mechanics: I. Jandejsek, L. Gajdoš, M. Šperl, D. Vavr ÍkDokumen14 halamanEngineering Fracture Mechanics: I. Jandejsek, L. Gajdoš, M. Šperl, D. Vavr ÍkTibebu MerideBelum ada peringkat

- Effect of Graphene Oxide Coating On Natural Fiber 2019Dokumen18 halamanEffect of Graphene Oxide Coating On Natural Fiber 2019Tibebu MerideBelum ada peringkat

- Evaluation of The Absorbed EnergyDokumen8 halamanEvaluation of The Absorbed EnergyTibebu MerideBelum ada peringkat

- Analysis On Failure Mechanisms of An Interlock Woven FabricDokumen9 halamanAnalysis On Failure Mechanisms of An Interlock Woven FabricTibebu MerideBelum ada peringkat

- 1 s2.0 S0263822318343435 MainDokumen9 halaman1 s2.0 S0263822318343435 MainTibebu MerideBelum ada peringkat

- Advanced Body Armor Utilizing Shear Thickening FluDokumen19 halamanAdvanced Body Armor Utilizing Shear Thickening FluTibebu MerideBelum ada peringkat

- Composite Lightweight Bullet Proof Panel for Marine Vessel ProtectionDokumen8 halamanComposite Lightweight Bullet Proof Panel for Marine Vessel ProtectionTibebu MerideBelum ada peringkat

- Symmetric LaminatesDokumen1 halamanSymmetric LaminatesTibebu MerideBelum ada peringkat

- Targeted Group 1:-Year 2018:summer StudentsDokumen3 halamanTargeted Group 1:-Year 2018:summer StudentsTibebu MerideBelum ada peringkat

- 1 s2.0 S0734743X15002201 Main PDFDokumen13 halaman1 s2.0 S0734743X15002201 Main PDFTibebu MerideBelum ada peringkat

- Main Components of Pressure VesselDokumen5 halamanMain Components of Pressure VesselTibebu MerideBelum ada peringkat

- AAU SponsorshipLetterFormDokumen1 halamanAAU SponsorshipLetterFormTibebu MerideBelum ada peringkat

- Types of Composite MaterialsDokumen4 halamanTypes of Composite MaterialsTibebu MerideBelum ada peringkat

- MultiDokumen5 halamanMultiTibebu MerideBelum ada peringkat

- Application of Optimization Techniques To Weight Reduction of Automobile BodiesDokumen6 halamanApplication of Optimization Techniques To Weight Reduction of Automobile BodiesTibebu MerideBelum ada peringkat

- MultiDokumen5 halamanMultiTibebu MerideBelum ada peringkat

- ClutshesDokumen15 halamanClutshesAmr Abd ElrahmanBelum ada peringkat

- Problem of StatementDokumen1 halamanProblem of StatementTibebu MerideBelum ada peringkat

- MultiDokumen5 halamanMultiTibebu MerideBelum ada peringkat

- Significant AdvantagesDokumen1 halamanSignificant AdvantagesTibebu MerideBelum ada peringkat

- Assessment Clo1 Clo2 Clo3 Clo4 Clo5 Plo1 Plo2 Plo2 Plo1Dokumen12 halamanAssessment Clo1 Clo2 Clo3 Clo4 Clo5 Plo1 Plo2 Plo2 Plo1Ma Liu Hun VuiBelum ada peringkat

- Master Opp GaveDokumen84 halamanMaster Opp GaveRizki Al AyyubiBelum ada peringkat

- ARRIMAX New Service Manual ENDokumen20 halamanARRIMAX New Service Manual ENMohammed IsmailBelum ada peringkat

- Structural Systems Engineering GuideDokumen67 halamanStructural Systems Engineering Guidejucar fernandezBelum ada peringkat

- Parts List 8198417 RevCDokumen12 halamanParts List 8198417 RevCSonaina KhanBelum ada peringkat

- Simucube 2 Quick Release GuideDokumen7 halamanSimucube 2 Quick Release Guideemyrs12Belum ada peringkat

- 2014 Solder Joint ReliabilityDokumen18 halaman2014 Solder Joint ReliabilitychoprahariBelum ada peringkat

- AASHTO T283-22 Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced DamageDokumen11 halamanAASHTO T283-22 Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced DamageErnesto Oscar VidelaBelum ada peringkat

- ITU ISUP Release Cause CodesDokumen5 halamanITU ISUP Release Cause Codesdelgado08Belum ada peringkat

- Dimensions of Physical Quantities DensityDokumen100 halamanDimensions of Physical Quantities DensityGerman Rincon UrregoBelum ada peringkat

- Tabla 1 Engine ControlDokumen2 halamanTabla 1 Engine Controljulio montenegroBelum ada peringkat

- Mobiltech (Textile Used in Transportation, Automotive & Aerospace)Dokumen12 halamanMobiltech (Textile Used in Transportation, Automotive & Aerospace)cario galleryBelum ada peringkat

- An Algorithm For Minimax Solution of Overdetennined Systems of Non-Linear EquationsDokumen8 halamanAn Algorithm For Minimax Solution of Overdetennined Systems of Non-Linear EquationsDewi FitriyaniBelum ada peringkat

- DC DC DC DC Iiii 6 6 6 6: Spec Spec Spec SpecDokumen12 halamanDC DC DC DC Iiii 6 6 6 6: Spec Spec Spec SpecarsolBelum ada peringkat

- Java Topics To Cover in InterviewsDokumen5 halamanJava Topics To Cover in InterviewsHemanth KumarBelum ada peringkat

- Artificial LiftDokumen18 halamanArtificial LiftRasya RefanBelum ada peringkat

- Demographically Similar EntriesDokumen1 halamanDemographically Similar EntriesTahsildar MydukurBelum ada peringkat

- Inventory Management PreetDokumen28 halamanInventory Management PreetKawalpreet Singh MakkarBelum ada peringkat

- 06 HVAC Plumbing PDFDokumen727 halaman06 HVAC Plumbing PDFTamBelum ada peringkat

- Siemens-Relee de Timp PDFDokumen2 halamanSiemens-Relee de Timp PDFChioibasNicolaeBelum ada peringkat

- CUCM Intracluster Port Usage GuideDokumen3 halamanCUCM Intracluster Port Usage GuideAbhinayMylavarapuBelum ada peringkat

- DMD Documentation Error - Freetronics ForumDokumen3 halamanDMD Documentation Error - Freetronics ForumapofviewBelum ada peringkat

- Micron Ezeprox Access Control KeypadDokumen4 halamanMicron Ezeprox Access Control KeypadThuy VuBelum ada peringkat

- WPD Flotationdrying PDFDokumen19 halamanWPD Flotationdrying PDFVvbjBelum ada peringkat