Storage Process of Precast Concrete

Diunggah oleh

esh0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

307 tayangan5 halamanStacking and storage of precast concrete elements requires proper support and bracing to prevent damage. Support points should be within 300mm of lifting points for beams and slabs, and no more than two support points should be used for pre-stressed elements like hollow core slabs. Wall panels must be stored vertically and braced. Incorrect stacking can cause long-term creep and cracking, so storage locations and dunnage supports should be clearly indicated in shop drawings. Dunnage supports the bottom units and prevents concrete-to-concrete contact that could damage elements.

Deskripsi Asli:

s 5

Judul Asli

safety 5

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPTX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniStacking and storage of precast concrete elements requires proper support and bracing to prevent damage. Support points should be within 300mm of lifting points for beams and slabs, and no more than two support points should be used for pre-stressed elements like hollow core slabs. Wall panels must be stored vertically and braced. Incorrect stacking can cause long-term creep and cracking, so storage locations and dunnage supports should be clearly indicated in shop drawings. Dunnage supports the bottom units and prevents concrete-to-concrete contact that could damage elements.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPTX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

307 tayangan5 halamanStorage Process of Precast Concrete

Diunggah oleh

eshStacking and storage of precast concrete elements requires proper support and bracing to prevent damage. Support points should be within 300mm of lifting points for beams and slabs, and no more than two support points should be used for pre-stressed elements like hollow core slabs. Wall panels must be stored vertically and braced. Incorrect stacking can cause long-term creep and cracking, so storage locations and dunnage supports should be clearly indicated in shop drawings. Dunnage supports the bottom units and prevents concrete-to-concrete contact that could damage elements.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPTX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 5

STORAGE PROCESS OF PRECAST CONCRETE

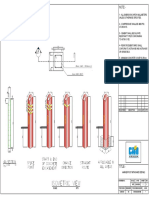

Stacking method and packers

(or support spacers) vary according to the

types of precast elements. Horizontal stacking

of slab/beam or column units can be done with

suitable packers or support spacers. As a guide,

the storage support position for beams and

planks should be within 300mm from the lifting

point.

The packers or support spacers or miss aligned as

shown in picture.

STORAGE PROCESS OF PRECAST CONCRETE

Do not use more than

two support points in particular

for pre-stressed elements such

as precast hollow core slab.

Wall panels should be

stored vertically and braced in

position by A frames or a racking

system.

STORAGE PROCESS OF PRECAST CONCRETE

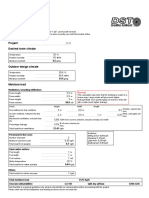

Stacking and Storage:

Incorrect stacking and storage can

damage precast elements. For those units

where support points are critical, for stacking,

transport or long term storage, the locations for

dunnage or support should be noted on the

shop drawings or on the precast layout drawing.

Dunnage:

Dunnage performs the

important function of supporting the bottom

unit of a stack clear of the ground, allowing

access between units to fit lifting forks or

strops, and preventing damage resulting from

concrete-to-concrete contact. The bottom level

of dunnage must be adequate to transfer the

load to the ground without excess settlement.

Settlement of dunnage can result in cracking of

some types of elements. Dunnage must be

arranged to avoid twisting or distorting the

precast elements. Dunnage for the next level in

a stockpile should be directly over the dunnage

below. Materials used for dunnage on surfaces

that will be exposed in the finished structure

should be non-staining. Note: Variations in

concrete curing under dunnage may result in

colour variations that could take some time to

fade

STORAGE PROCESS OF PRECAST CONCRETE

Creep: The storage area at the

job site should be

(Long- preferably be close to

Term Permanent the locations where the

Deformation) precast elements are to

Incorrect stacking can be installed to minimize

cause long-term creep the risk of damage by

that is difficult to handling.

remove from precast

elements. The

younger the age at

which precast

elements deflect or

twist under incorrect

storage, the greater

the creep.

D

A

M

A

G

E

S

Anda mungkin juga menyukai

- Wet and Dry Installation of Natural Stone CladdingDokumen12 halamanWet and Dry Installation of Natural Stone CladdinglakshmiBelum ada peringkat

- Climbing FormworkDokumen5 halamanClimbing Formworksanjeev2812Belum ada peringkat

- Types of Precast Construction PDFDokumen6 halamanTypes of Precast Construction PDFJignesh PingulBelum ada peringkat

- Aci Mix DesignDokumen14 halamanAci Mix DesignAzam KhanBelum ada peringkat

- Guide Specification For Architectural Precast Concrete: This DocumentDokumen37 halamanGuide Specification For Architectural Precast Concrete: This DocumentOmar Mokhtar100% (1)

- Method Statement and SpecificationDokumen17 halamanMethod Statement and SpecificationApai MfarBelum ada peringkat

- GFRC (Glass Fiber Reinforced Concrete) - : Cast in Place Concrete StructureDokumen2 halamanGFRC (Glass Fiber Reinforced Concrete) - : Cast in Place Concrete StructureElanur MayaBelum ada peringkat

- Drainage SanitationDokumen16 halamanDrainage Sanitation2011kumarBelum ada peringkat

- Method Statement For Precast Post Tensioned I-Beams atDokumen8 halamanMethod Statement For Precast Post Tensioned I-Beams atMAYMODERN STEELBelum ada peringkat

- WaterproofingDokumen2 halamanWaterproofinghoney4747Belum ada peringkat

- Pre-Fabrication by Kanika JainDokumen42 halamanPre-Fabrication by Kanika Jainkanika jainBelum ada peringkat

- Proposed Method StatementDokumen3 halamanProposed Method StatementkrmchariBelum ada peringkat

- FlowCon Project Tornado Tower QatarDokumen5 halamanFlowCon Project Tornado Tower QatarJupremae MacadangdangBelum ada peringkat

- Shoring and UnderpinningDokumen14 halamanShoring and UnderpinningShraddha KaushikBelum ada peringkat

- Checklist by Girish MishraDokumen30 halamanChecklist by Girish MishraDeepak Kaushik100% (1)

- Doka System ComponentsDokumen24 halamanDoka System ComponentsAditya ManeBelum ada peringkat

- RC Retaining Wall: Method Statement For Concreting Vertical Elements Setting OutDokumen3 halamanRC Retaining Wall: Method Statement For Concreting Vertical Elements Setting OutAnonymous ze9ag1Belum ada peringkat

- MS-CVL-009 Erection of Hollowcore Slabs 1Dokumen12 halamanMS-CVL-009 Erection of Hollowcore Slabs 1Suju RajanBelum ada peringkat

- Form WorkDokumen25 halamanForm Workhina khanBelum ada peringkat

- FST Crack Report PDFDokumen16 halamanFST Crack Report PDFEkky CecilBelum ada peringkat

- MMBC - Sem 7 B.archDokumen8 halamanMMBC - Sem 7 B.archARTFOLIO .49Belum ada peringkat

- Precast Construction SeminarDokumen30 halamanPrecast Construction SeminarNzar HamaBelum ada peringkat

- Sikagrout 214 - 11: High Strength Non-Shrink Cementitious GroutDokumen2 halamanSikagrout 214 - 11: High Strength Non-Shrink Cementitious GroutDani LerviBelum ada peringkat

- Slipform Construction TechniqueDokumen6 halamanSlipform Construction TechniqueDivyansh NandwaniBelum ada peringkat

- DESIGN Method Statement For Concrete RepairDokumen14 halamanDESIGN Method Statement For Concrete RepairBleep NewsBelum ada peringkat

- Wall Cladding: Ar. Subhra P NayakDokumen44 halamanWall Cladding: Ar. Subhra P NayakArsh ChaudharyBelum ada peringkat

- Method Statement of Overwatervilla and WalkwayDokumen10 halamanMethod Statement of Overwatervilla and WalkwayMuhammad Uwais100% (1)

- Portland Cement Plaster - SpecDokumen7 halamanPortland Cement Plaster - Speclinga2014Belum ada peringkat

- Precasting and PrefabricationDokumen51 halamanPrecasting and PrefabricationSadia HusainBelum ada peringkat

- Hollow Core Slab PDFDokumen4 halamanHollow Core Slab PDFStraus WaseemBelum ada peringkat

- SRG Slipform Construction 2016 04 e PDFDokumen8 halamanSRG Slipform Construction 2016 04 e PDF94738183Belum ada peringkat

- Method Statement For Loose Furniture Fixing: Sandvik PVT LTD, Dapodi, PuneDokumen2 halamanMethod Statement For Loose Furniture Fixing: Sandvik PVT LTD, Dapodi, PuneParasBelum ada peringkat

- The Shards LondonDokumen24 halamanThe Shards LondonRuxandra Maria Popescu100% (1)

- Sto Skim Coat 82216 Guide Specifications B26371Dokumen4 halamanSto Skim Coat 82216 Guide Specifications B26371Anthony Al Lakiss100% (1)

- Pre StressingDokumen5 halamanPre StressingAakriti VermaBelum ada peringkat

- Fencing, Compound Wall and Gate (Pranoti) - 1Dokumen36 halamanFencing, Compound Wall and Gate (Pranoti) - 1MG100% (1)

- Standard and Specifications FOR Riprap Slope ProtectionDokumen9 halamanStandard and Specifications FOR Riprap Slope ProtectionBabu SundararamanBelum ada peringkat

- HOLLOW-CORE SLAB SYSTEMS Information ManDokumen36 halamanHOLLOW-CORE SLAB SYSTEMS Information ManEng.wissam Safaa100% (1)

- Roadway General Notes: LegendDokumen1 halamanRoadway General Notes: LegendAlzhammer ManupacBelum ada peringkat

- Precast Concrete ReportDokumen28 halamanPrecast Concrete ReportAchyutam Khajuria50% (2)

- Honeycomb in Concrete - Causes, Prevention & RemediesDokumen1 halamanHoneycomb in Concrete - Causes, Prevention & RemediesAjeya AcharyaBelum ada peringkat

- Wms - Concrete Repairing Works (Pedestals)Dokumen4 halamanWms - Concrete Repairing Works (Pedestals)krmchari100% (1)

- Sliding Door Installation InstructionsDokumen2 halamanSliding Door Installation InstructionsJaseSG1Belum ada peringkat

- Chemical PrestressingDokumen5 halamanChemical PrestressingDarryl LaynoBelum ada peringkat

- Steel Fibre Method StatementDokumen3 halamanSteel Fibre Method StatementDadfdklgjfhgdusuiuewekjhkjhasf Ancheta100% (1)

- Technical Note TN 105 Asphalt Surfacing of Concrete Bridge DecksDokumen3 halamanTechnical Note TN 105 Asphalt Surfacing of Concrete Bridge DecksSpiros LicoudisBelum ada peringkat

- Standard Specs - Masonry WorkDokumen7 halamanStandard Specs - Masonry Worknirmal sutharBelum ada peringkat

- Methodology For Convreting WorksDokumen7 halamanMethodology For Convreting WorksLokesh SaranBelum ada peringkat

- Method Statement For Installation of Pre-Cast MH.: Prepared byDokumen8 halamanMethod Statement For Installation of Pre-Cast MH.: Prepared byBara'a ManciBelum ada peringkat

- Pretensioning SystemsDokumen13 halamanPretensioning SystemsAbdul Azeem100% (1)

- Damp Proof Course (DPC) - Methods of DPC InstallationDokumen5 halamanDamp Proof Course (DPC) - Methods of DPC Installationvenkateswara rao PothinaBelum ada peringkat

- Hollow Core HandlingDokumen4 halamanHollow Core HandlingSulaiman Mohsin AbdulAzizBelum ada peringkat

- Spider Glass Curtain Walls-Glass OptionsDokumen3 halamanSpider Glass Curtain Walls-Glass OptionsHAN HANBelum ada peringkat

- Work Methodology For Clearing and Grubbing of Trees and ShrubsDokumen2 halamanWork Methodology For Clearing and Grubbing of Trees and ShrubsNasser Issa Abu HalimehBelum ada peringkat

- RMC Batching PlantDokumen28 halamanRMC Batching PlantPradip ParidaBelum ada peringkat

- Construction TechniqueDokumen3 halamanConstruction TechniqueatifaBelum ada peringkat

- Paroc PS Sandwich Panels Installation Guide 22032022 INTDokumen8 halamanParoc PS Sandwich Panels Installation Guide 22032022 INTandyBelum ada peringkat

- Terrazzo Vertical Installation GuideDokumen11 halamanTerrazzo Vertical Installation Guide안윤모Belum ada peringkat

- Safety 1Dokumen6 halamanSafety 1eshBelum ada peringkat

- After Sales Best Practice & Preventive MaintenanceDokumen15 halamanAfter Sales Best Practice & Preventive Maintenancem.ramadanBelum ada peringkat

- Faa 9Dokumen2 halamanFaa 9eshBelum ada peringkat

- What Happens When A V/PD Occurs. Construction Personnel Committing A V/PD, or As A Minimum, Be Required To Be RetrainedDokumen1 halamanWhat Happens When A V/PD Occurs. Construction Personnel Committing A V/PD, or As A Minimum, Be Required To Be RetrainedeshBelum ada peringkat

- Driving or Walking On An Active Runway or Runway Safety Area, Without ATC Clearance, Is A V/PD Runway IncursionDokumen2 halamanDriving or Walking On An Active Runway or Runway Safety Area, Without ATC Clearance, Is A V/PD Runway IncursioneshBelum ada peringkat

- Holding Position Marking Holding Position Sign Runway 13-31Dokumen2 halamanHolding Position Marking Holding Position Sign Runway 13-31eshBelum ada peringkat

- Enhanced Taxiway Centerline MarkingDokumen2 halamanEnhanced Taxiway Centerline MarkingeshBelum ada peringkat

- Fire 13Dokumen2 halamanFire 13eshBelum ada peringkat

- Typical Runway Used by AirlinesDokumen2 halamanTypical Runway Used by AirlineseshBelum ada peringkat

- Runway 7Dokumen2 halamanRunway 7eshBelum ada peringkat

- The Air Operations Area (AOA) Is The Portion of The Airfield Inside The Security Fence Where Airport Safety and Security Regulations ApplyDokumen2 halamanThe Air Operations Area (AOA) Is The Portion of The Airfield Inside The Security Fence Where Airport Safety and Security Regulations ApplyeshBelum ada peringkat

- Runway 6Dokumen2 halamanRunway 6eshBelum ada peringkat

- FAA Safety Requirements For Airfield ConstructionDokumen2 halamanFAA Safety Requirements For Airfield ConstructioneshBelum ada peringkat

- Factor Affecting Basic Runway LengthDokumen2 halamanFactor Affecting Basic Runway LengtheshBelum ada peringkat

- Landing & Take-Off Gross Weights of The AircraftDokumen2 halamanLanding & Take-Off Gross Weights of The AircrafteshBelum ada peringkat

- Kansai International Airport: by Renzo PianoDokumen2 halamanKansai International Airport: by Renzo PianoeshBelum ada peringkat

- Use of Rubber As Aggregate in Concrete: A Review: April 2015Dokumen6 halamanUse of Rubber As Aggregate in Concrete: A Review: April 2015Suno AliBelum ada peringkat

- Acg080 PDFDokumen1 halamanAcg080 PDFSonia Liset Mamani HuamaniBelum ada peringkat

- Subject: Structural Design III Introduction of Subject: Examination SchemeDokumen63 halamanSubject: Structural Design III Introduction of Subject: Examination SchemeKiran BandeBelum ada peringkat

- RCC11 Element DesignDokumen6 halamanRCC11 Element DesignMuhammad IshaqBelum ada peringkat

- Ficha Tecnica Fan Coil Tipo Ducto18000 BtuDokumen5 halamanFicha Tecnica Fan Coil Tipo Ducto18000 BtuGiancarlo Reategui GuerraBelum ada peringkat

- Sample ProjectsDokumen21 halamanSample ProjectsVisweswara L MBelum ada peringkat

- Sci P167 PDFDokumen28 halamanSci P167 PDFBorisVelickovBelum ada peringkat

- MARKER POST-ISOMATRIC ModelDokumen1 halamanMARKER POST-ISOMATRIC Modelmostafa ibrahimBelum ada peringkat

- LS Electric Wire&cable EN 06Dokumen56 halamanLS Electric Wire&cable EN 06ahmadkurniawan35Belum ada peringkat

- Intake - Out Chamber Rev.01 SDR CombinedPDFDokumen9 halamanIntake - Out Chamber Rev.01 SDR CombinedPDFJhonnel PunzalanBelum ada peringkat

- Concrete Ballast Deck Span Analysis - 3 PDFDokumen18 halamanConcrete Ballast Deck Span Analysis - 3 PDFJohn VillanuevaBelum ada peringkat

- Special ConcreteDokumen2 halamanSpecial ConcreteRamprasad KadaliBelum ada peringkat

- Schedule of Rates 2011 (Rev1)Dokumen144 halamanSchedule of Rates 2011 (Rev1)Awang AR33% (3)

- Moisture Load CalculationDokumen2 halamanMoisture Load CalculationNguyễn Anh TuấnBelum ada peringkat

- YCM Series - Catalog PUBL-8441 (0418)Dokumen36 halamanYCM Series - Catalog PUBL-8441 (0418)jotace469Belum ada peringkat

- Presented To The Civil Engineering Department de La Salle University - Manila First Term, A.Y. 2020 - 2021Dokumen8 halamanPresented To The Civil Engineering Department de La Salle University - Manila First Term, A.Y. 2020 - 2021Ritik NihalaniBelum ada peringkat

- Case Study ppt11Dokumen25 halamanCase Study ppt11WHATS APP STATUSBelum ada peringkat

- Chimney Journal 1Dokumen6 halamanChimney Journal 1Kaundy BondBelum ada peringkat

- High Performance Concrete by TC HollandDokumen3 halamanHigh Performance Concrete by TC HollandWahyuBudiPrakosoBelum ada peringkat

- Refrigeration and Air ConditioningDokumen2 halamanRefrigeration and Air ConditioningMohd Kashif Abdul RehmanBelum ada peringkat

- Futera XLF IOM (XLF-IOM-9)Dokumen44 halamanFutera XLF IOM (XLF-IOM-9)Mihailo Filipovič JelicBelum ada peringkat

- Architectural Report - Climate Technology Park, GazipurDokumen7 halamanArchitectural Report - Climate Technology Park, GazipurMuhtadin IqbalBelum ada peringkat

- Fiber Composites6Dokumen61 halamanFiber Composites6NounaBelum ada peringkat

- Team 3 - Means of EgressDokumen25 halamanTeam 3 - Means of EgressRhey LuceroBelum ada peringkat

- APK (Code) - ProjectName - Cost Plan EstDokumen91 halamanAPK (Code) - ProjectName - Cost Plan EstMinh TanBelum ada peringkat

- Lab Concrete Mix Design C25aDokumen17 halamanLab Concrete Mix Design C25aSoundar PachiappanBelum ada peringkat

- Ferrocement ReferencesDokumen2 halamanFerrocement ReferencesMuhammad TausifBelum ada peringkat

- Box Culvert Design CalculationDokumen8 halamanBox Culvert Design CalculationDaniel OkereBelum ada peringkat

- Ferro CementDokumen31 halamanFerro CementAbhinav KalathiparambilBelum ada peringkat

- 6.hot Working and Cold Working Processes. Tube Manufacturing ProcessDokumen27 halaman6.hot Working and Cold Working Processes. Tube Manufacturing ProcessHarshit KumarBelum ada peringkat