What Good Warping Should Have

Diunggah oleh

Mansoor Khanali0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

7 tayangan3 halamanjjj

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPTX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inijjj

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPTX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

7 tayangan3 halamanWhat Good Warping Should Have

Diunggah oleh

Mansoor Khanalijjj

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPTX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 3

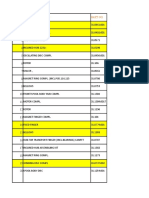

Head Stock

1. MACHINE SHPULD BE UNIVERSAL TYPE For ALL STAPLE Fiber TYPE

2. HIGH PRODUCTION ITS MECHNICAL SPEED ABOVE 1200 Meter PER MIN

3. ALL DEVICES SHOULD ELECTRONICALLY MONITOR ANS CONTROLLED

4. ITS PRESS ROLL SYSTEM SHOULD PROVIDE PRECISE TENSION TROUGHT OUT ITS

PREPARATION

5. ITS YARN ARRANGEMENT SHOULD BE SO PARALLEL SHOULD NOT OVERLAP AS Shown IN Fig

A

6. SHOULD HAVE KICK BACK FUNCTION

7. PRECISE AND ACCURATE WARPING LENGTH FOR ALL BEAM

8. INDIRECT PRESSURE WITH HYDRAULICALY DRIVEN WHICH SWING UT BRAKE IMMEDIATELY

ENSURE less FRICTION WITH YARN AND PRESS ROLL.

9. Maintenance cost for 5 Years

Warping Creel

1. Tensionless creel Semi V TYPE

2. To Reduced machine downtime always choose with stand-by option.

3. Creel should have option with adoptability with all count range Flexible options for every

application

4. Creel Should incl. reserve loading on swivel-frames, enables creel loading even during

operation

5. Swivel-frame creel for different applications such as spun yarns,

6. Compensating yarn tensioner for a large number of different applications and yarn tension

ranges

7. Yarn tensioner should be with integrated end-break sensor for the direct warping process of

spun yarn

8. Warp tensioner must be Easy handling

9. Automatic compensation of the yarn tension

10. Air-damping system

11. Completely wear-free due to ceramic elements

12. Designed for high speeds

13. Adjustment by rows or central adjustment

14. Motor-driven pretension discs

Advantages for adopting :-

Compensating yarn tensioners always keep the same yarn tension, regardless of whether the

draw-off speed is slow or fast, and regardless of whether the bobbin is full or almost empty

Option Should be to avoid :-

Yarn break detector

Disc lifting system

Central yarn tension readjustment

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Guideline For Production and Quality ControlDokumen22 halamanGuideline For Production and Quality Controlalmutazim97% (34)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Denim Quality ControlDokumen10 halamanDenim Quality ControlEhsan HameedBelum ada peringkat

- Homeopathy in Intensive Care and Emergency Medicine Michael Frass Martin Buendner.14188 1Dokumen10 halamanHomeopathy in Intensive Care and Emergency Medicine Michael Frass Martin Buendner.14188 1Mansoor Khanali100% (2)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Cover Letter DescriptionDokumen1 halamanCover Letter DescriptionMansoor KhanaliBelum ada peringkat

- Dail Visit Report: Discussion About ProporsalDokumen3 halamanDail Visit Report: Discussion About ProporsalMansoor KhanaliBelum ada peringkat

- We Are The Leaders in Knitted Fabrics of All Kinds in The Sub ContinentDokumen6 halamanWe Are The Leaders in Knitted Fabrics of All Kinds in The Sub ContinentMansoor KhanaliBelum ada peringkat

- 1 No of Looms A.New Summum B.Omni Plus 585 90 465 89 3 2 Type 3 No Frames 4 Assign No of Looms To WeaverDokumen3 halaman1 No of Looms A.New Summum B.Omni Plus 585 90 465 89 3 2 Type 3 No Frames 4 Assign No of Looms To WeaverMansoor KhanaliBelum ada peringkat

- Illumination Conditions and Visual Comfort in Production Spaces of Ready-Made Garments Factories in DhakaDokumen6 halamanIllumination Conditions and Visual Comfort in Production Spaces of Ready-Made Garments Factories in DhakaMansoor KhanaliBelum ada peringkat

- Cover Letter DescriptionQualityDokumen1 halamanCover Letter DescriptionQualityMansoor KhanaliBelum ada peringkat

- Quality Policy: Weinu Curtain Trading PLCDokumen1 halamanQuality Policy: Weinu Curtain Trading PLCMansoor KhanaliBelum ada peringkat

- Prod CalculationDokumen2 halamanProd CalculationMansoor KhanaliBelum ada peringkat

- Commonwealth of Independent States )Dokumen3 halamanCommonwealth of Independent States )Mansoor KhanaliBelum ada peringkat

- Count, Construction and Width of Common Cotton FabricsDokumen3 halamanCount, Construction and Width of Common Cotton FabricsMansoor KhanaliBelum ada peringkat

- Sample Resume - Executive CVDokumen4 halamanSample Resume - Executive CVMansoor KhanaliBelum ada peringkat

- Sample Resume - Executive CVDokumen4 halamanSample Resume - Executive CVMansoor KhanaliBelum ada peringkat

- Mansoor Ali Khan: Summary of QualificationsDokumen6 halamanMansoor Ali Khan: Summary of QualificationsMansoor Khanali100% (1)

- Economizer 01 No. S. # Description SizeDokumen1 halamanEconomizer 01 No. S. # Description SizeMansoor KhanaliBelum ada peringkat

- Parts RequestDokumen4 halamanParts RequestMansoor KhanaliBelum ada peringkat

- 11 - Chapter 6 PDFDokumen14 halaman11 - Chapter 6 PDFMansoor KhanaliBelum ada peringkat

- Pcs 45000 8203 36797 26th March 12000 Pcs 14400 6852 7548 7th MarchDokumen2 halamanPcs 45000 8203 36797 26th March 12000 Pcs 14400 6852 7548 7th MarchMansoor KhanaliBelum ada peringkat

- Developing An Incentive Scheme For A ProjectDokumen14 halamanDeveloping An Incentive Scheme For A ProjectMansoor KhanaliBelum ada peringkat

- Hall Exb 4Dokumen2 halamanHall Exb 4Mansoor KhanaliBelum ada peringkat

- AESA Air Engineering ProjectsDokumen2 halamanAESA Air Engineering ProjectsMansoor KhanaliBelum ada peringkat

- Warp MasterDokumen2 halamanWarp MasterIbrahim GezginBelum ada peringkat

- Writing To CollaboratorsDokumen30 halamanWriting To CollaboratorsdialauchennaBelum ada peringkat

- Detailed Revenue Plan1Dokumen6 halamanDetailed Revenue Plan1Mansoor KhanaliBelum ada peringkat

- Pin MasterDokumen2 halamanPin MasterMansoor KhanaliBelum ada peringkat

- Stenter Exhaust Heat Recovery For Combustion Air PreheatingDokumen17 halamanStenter Exhaust Heat Recovery For Combustion Air PreheatingMansoor Khanali100% (1)