Presentation 1

Diunggah oleh

Mohd Syed0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

10 tayangan1 halamanChart of gears

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPTX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniChart of gears

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPTX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

10 tayangan1 halamanPresentation 1

Diunggah oleh

Mohd SyedChart of gears

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPTX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 1

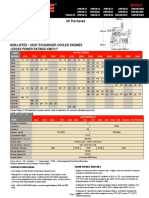

NED UNIVERSITY OF ENGINEERING AND TECHNOLOGY

GEAR AND IT’s TYPES

A gear is a rotating machine part having teeth which mesh with another toothed part to transmit torque.

TYPES OF GEAR

SPUR GEAR SCREW GEAR

Spur gears belong to the parallel shaft gear group.

Screw gears are a pair of same hand helical gears with

They are cylindrical gears with a tooth line which is

the twist angle of 45° on non-parallel, non-intersecting

straight and parallel to the shaft. Spur gears are

shafts. Because the tooth contact is a point, their load

the most widely used gears that can achieve high

carrying capacity is low and they are not suitable for

accuracy with relatively easy production

large power transmission.

processes.

HELICAL GEAR WORM GEAR

Helical gears are used with parallel shafts similar

A screw shape cut on a shaft is the worm, the mating

to spur gears and are cylindrical gears with

gear is the worm wheel, and together on non-

winding tooth lines. They have better teeth

intersecting shafts is called a worm gear. Worms and

meshing than spur gears and have superior

worm wheels are not limited to cylindrical shapes.

quietness and can transmit higher loads, making

There is the hour-glass type which can increase the

them suitable for high speed applications

contact ratio, but production becomes more difficult.

Due to the sliding contact of the gear surfaces, it is

BEVEL GEAR necessary to reduce friction. For this reason, generally

Bevel gears have a cone shaped appearance and a hard material is used for the worm, and a soft

are used to transmit force between two shafts material is used for worm wheel. Even though the

which intersect at one point (intersecting shafts). A efficiency is low due to the sliding contact, the rotation

bevel gear has a cone as its pitch surface and its is smooth and quiet. When the lead angle of the worm

teeth are cut along the cone is small, it creates a self-locking feature.

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- 42rle Automatic TransmissionDokumen128 halaman42rle Automatic Transmissionapi-2614064490% (48)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Kubota BX 2200 Operators ManualDokumen64 halamanKubota BX 2200 Operators ManualMark Dubravec63% (16)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Packard-Merlin Engine - Rcaf 01Dokumen40 halamanPackard-Merlin Engine - Rcaf 01Armando Hernández100% (1)

- Vec002068-9 Installation Manual PDFDokumen455 halamanVec002068-9 Installation Manual PDFumair100% (2)

- 9852 2024 01a Operator's Instructions ROC F9CR PDFDokumen142 halaman9852 2024 01a Operator's Instructions ROC F9CR PDFAhmad100% (2)

- Spare Part Philosophy - XX PDFDokumen27 halamanSpare Part Philosophy - XX PDFharmlesdragon50% (2)

- JU6H-NL34 143.5 KWDokumen8 halamanJU6H-NL34 143.5 KWReza Tamba67% (3)

- MACHINING Helical Gear Production Lab ReportDokumen1 halamanMACHINING Helical Gear Production Lab ReportZafar Alam0% (1)

- Camless EngineDokumen17 halamanCamless EngineSarvesh Mhatre100% (1)

- Sir Rizwan After MidDokumen28 halamanSir Rizwan After MidMohd SyedBelum ada peringkat

- 5th Semester Past PapersDokumen13 halaman5th Semester Past PapersMohd SyedBelum ada peringkat

- Crash CourseDokumen1 halamanCrash CourseMohd SyedBelum ada peringkat

- Combustion Pass PDFDokumen2 halamanCombustion Pass PDFMohd SyedBelum ada peringkat

- Combustion Pass PDFDokumen2 halamanCombustion Pass PDFMohd SyedBelum ada peringkat

- Advantages ofDokumen1 halamanAdvantages ofMohd SyedBelum ada peringkat

- W - 8 - Mce 3513 - Lo3Dokumen12 halamanW - 8 - Mce 3513 - Lo3Muhammed RazaBelum ada peringkat

- New TCM Forklift QuotationDokumen2 halamanNew TCM Forklift QuotationWai Yan HtetBelum ada peringkat

- Auto-17002 Electronic Ignition SystemDokumen97 halamanAuto-17002 Electronic Ignition SystemNatty NuggetBelum ada peringkat

- Tutorial 2 PDFDokumen4 halamanTutorial 2 PDFMohamedBelum ada peringkat

- Comparison Between VR, PM and Hybrid Stepper MotorsDokumen2 halamanComparison Between VR, PM and Hybrid Stepper MotorsMuhammed IfkazBelum ada peringkat

- Collage Plano Electrico YyzDokumen54 halamanCollage Plano Electrico YyzAlex Consuegra MedinaBelum ada peringkat

- Mercruiser Repower GuideDokumen204 halamanMercruiser Repower GuideansimicBelum ada peringkat

- Force Outboard Gearcase & Drive PartsDokumen7 halamanForce Outboard Gearcase & Drive PartsMarine Parts ChinaBelum ada peringkat

- Pollution-Free Stirling Engine: A Step Towards Sustainable FutureDokumen19 halamanPollution-Free Stirling Engine: A Step Towards Sustainable Futureshailu347Belum ada peringkat

- ME 3671 Homework Set 6 Solutions PDFDokumen5 halamanME 3671 Homework Set 6 Solutions PDFHammad ShaukatBelum ada peringkat

- EMG ELHY EN Rev00 06-2018Dokumen12 halamanEMG ELHY EN Rev00 06-2018Luis Pinto RojasBelum ada peringkat

- Design and Fabrication of Treadmill Bicycle: e-ISSN: 2456-3463Dokumen5 halamanDesign and Fabrication of Treadmill Bicycle: e-ISSN: 2456-3463Rakesh jayamaniBelum ada peringkat

- 3.abus - Electric - Wire - Rope - Hoists CatalogDokumen13 halaman3.abus - Electric - Wire - Rope - Hoists CatalogDinh Nguyen VanBelum ada peringkat

- PPD Week 5.1 LectureDokumen28 halamanPPD Week 5.1 LectureMaster CalculusBelum ada peringkat

- Sk-429ec-800 Rev C 4-18-19Dokumen6 halamanSk-429ec-800 Rev C 4-18-19DadangBelum ada peringkat

- Hi Perf 4t Sport10w40 Pds PDFDokumen1 halamanHi Perf 4t Sport10w40 Pds PDFhoussem houssemBelum ada peringkat

- WheelHorse Lawn Sweeper Manual 7-2513Dokumen6 halamanWheelHorse Lawn Sweeper Manual 7-2513Kevins Small Engine and Tractor Service100% (1)

- 212-412J MicrovacDokumen9 halaman212-412J MicrovacJose QuincosBelum ada peringkat

- Right Hand Group Assembly Installation PrintDokumen3 halamanRight Hand Group Assembly Installation PrintReyes VargasBelum ada peringkat

- CT Series & Service ManualDokumen4 halamanCT Series & Service ManualboyBelum ada peringkat

- Disk Brakes 2001-2003Dokumen65 halamanDisk Brakes 2001-2003dickenszzBelum ada peringkat