EB001 CH6 - Aggregates For Concrete

Diunggah oleh

beto pagoada0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

44 tayangan46 halamanAggregates for Concrete presentation

Judul Asli

EB001 CH6 - Aggregates for Concrete

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPTX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniAggregates for Concrete presentation

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPTX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

44 tayangan46 halamanEB001 CH6 - Aggregates For Concrete

Diunggah oleh

beto pagoadaAggregates for Concrete presentation

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPTX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 46

Aggregates for Concrete

Design and Control of Concrete Mixtures – Chapter 6

Overview

Geology

Classification

Characteristics of Aggregates

Potentially Harmful Materials

Alkali-Aggregate Reactivity

Beneficiation

Handling and Storage

Aggregates for Concrete

Aggregate Geology

Aggregate Classification

Normal-weight,

lightweight,

heavyweight

Natural aggregate

Manufactured aggregate

Recycled-concrete

aggregate

Marine-dredged aggregate

Natural Aggregate

Gravel and sand

Mixture of several minerals

Pits, rivers, lakes, seabeds

Quality depends on parent bedrock

Manufactured Aggregate

Crushed rock or air-cooled slag

Fine and coarse aggregate

Rough, angular texture

Cubical or elongated shape

More uniform in size

Less likely to be contaminated

Recycled-Concrete Aggregate

Recycled-Concrete Aggregate

Marine-Dredged Aggregate

Tidal estuaries, seashore

Two concerns: seashells and salt

Avoid uncrushed shells

Avoid using high chloride aggregates in

reinforced concrete

Aggregate

Character-

istics

Grading

Grading

Grading Limits

Fine-Aggregate Grading

Coarse-Aggregate Grading

Coarse-Aggregate

Grading

Maximum Size vs. Nominal Maximum Size

Maximum size – 100% passing

Nominal maximum size – typically 85% to 95%

passing

Nominal Maximum Size

Combined Aggregate Grading

Combined Aggregate Grading

Combined Aggregate Grading

Gap-Graded Aggregates

Certain particle sizes omitted, typically one

coarse aggregate size

Excess coarse aggregate – honeycomb,

segregate

Excess fine aggregate – high water demand,

shrinkage

Properly proportioned mixtures are readily

consolidated with vibration

Fineness Modulus

Particle Shape and Surface Texture

Bulk Density and Voids

Bulk density – mass of aggregate in unit volume

Includes voids

30% - 45% voids in coarse aggregates

40% - 50% voids in fine aggregates

Angularity increases voids

Density and Relative Density

Density = Relative density x density of water

Typically between 2400 and 2900 kg/m3

(150 and 181 lb/ft3)

Relative density typically between 2.4 and 2.9.

Absorption and Surface Moisture

Bulking

Resistance to Freezing and Thawing

D-Cracking

Abrasion and Skid Resistance

Abrasion resistance used as quality index

Los Angeles abrasion test is most common

No correlation between aggregate abrasion and

concrete abrasion

Siliceous content > 25% for good skid

resistance

Strength

Rarely tested

Tensile strength – 2 MPa to 15 MPa (300 psi to

2300 psi)

Compressive strength – 65 MPa to 270 MPa

(10,000 psi to 40,000 psi)

Shrinkage

Resistance to Acid

Acids generally attack calcareous aggregates

Calcareous aggregates neutralize acid

Siliceous aggregates are attacked by sodium

hydroxide

Fire Resistance and Thermal Properties

Dependent on mineral constituents

Lightweight aggregates outperform normal-

weight aggregates

Calcareous aggregates outperform siliceous

aggregates

Coefficient of thermal expansion – 0.55 x 10-6

per °C to 5 x 10-6 per °C (1 x 10-6 per °F to 9 x

10-6 per °F)

Potentially Harmful

Materials

Potentially Harmful Materials

Alkali-Aggregate Reactivity

Alkali-Silica Reaction

Alkali-Carbonate Reaction

Rare due to general unsuitability of reactive

aggregates

Tested through:

Petrographic examination (ASTM C295)

Rock cylinder method (ASTM C586)

Concrete prism test (ASTM C1105)

Aggregate Beneficiation

Improving quality through processing

Heavy media separation

Jigging

Rising-current classification

Crushing

Handling and Storing Aggregates

Handling and Storing Aggregates

Summary

Geology

Classification

Characteristics of Aggregates

Potentially Harmful Materials

Alkali-Aggregate Reactivity

Beneficiation

Handling and Storage

Questions

Anda mungkin juga menyukai

- EB001 CH11 - DurabilityDokumen58 halamanEB001 CH11 - DurabilityJuan MartinezBelum ada peringkat

- EB001 CH19 - High-Performance ConcreteDokumen29 halamanEB001 CH19 - High-Performance ConcretePtp AbyBelum ada peringkat

- RILEM TC 205 Report on Durability of Self-Compacting ConcreteDokumen9 halamanRILEM TC 205 Report on Durability of Self-Compacting ConcretealiBelum ada peringkat

- EB001 CH20 - Special Types of ConcreteDokumen25 halamanEB001 CH20 - Special Types of ConcreteAbdisamed AhmedBelum ada peringkat

- Crack Preparation and Capping for Concrete InjectionDokumen59 halamanCrack Preparation and Capping for Concrete Injectiongonzalez_m_aBelum ada peringkat

- Design and Control of Concrete Mixtures 16th Edition Komatka WilsonDokumen633 halamanDesign and Control of Concrete Mixtures 16th Edition Komatka WilsonGeorgie Macha50% (2)

- CHALMERS (Fibre-Reinforced Concrete For Industrial Construction PDFDokumen162 halamanCHALMERS (Fibre-Reinforced Concrete For Industrial Construction PDFsochiva pramestiBelum ada peringkat

- Hoeg. Kaare-1993Dokumen85 halamanHoeg. Kaare-1993BertrandBelum ada peringkat

- Proceeding of Rasce 2015Dokumen245 halamanProceeding of Rasce 2015Alex ChristopherBelum ada peringkat

- XIII DBMC Proceedings Final DraftDokumen1.166 halamanXIII DBMC Proceedings Final DraftEloy F. Viegas Jr.100% (1)

- 41012008-Masonry Facade EvaluationDokumen48 halaman41012008-Masonry Facade EvaluationPeter GriemBelum ada peringkat

- Mix Design for Durable Concrete Using Fly Ash and SlagDokumen185 halamanMix Design for Durable Concrete Using Fly Ash and SlagMIL RAB100% (1)

- Mechanical Properties of Concrete Incorporating High Volumes of Fly Ash From Sources in The U.S.Dokumen10 halamanMechanical Properties of Concrete Incorporating High Volumes of Fly Ash From Sources in The U.S.Afifah FauziBelum ada peringkat

- R o A D W o R K S: Problems and SolutionsDokumen16 halamanR o A D W o R K S: Problems and SolutionsFITSUM BerheBelum ada peringkat

- Alkali Aggregate Reactions in Concrete (Dissertation)Dokumen202 halamanAlkali Aggregate Reactions in Concrete (Dissertation)Carlos Augusto Sánchez RondónBelum ada peringkat

- Pavement Types: Concrete PavementsDokumen20 halamanPavement Types: Concrete PavementsMohamedBelum ada peringkat

- Guidance notes and model clauses for minimising ASR riskDokumen33 halamanGuidance notes and model clauses for minimising ASR riskRavi7654Belum ada peringkat

- BRE Digest 330 pt4 Alkali-Silica Reaction in ConcreteDokumen4 halamanBRE Digest 330 pt4 Alkali-Silica Reaction in ConcretehemendraengBelum ada peringkat

- Carbonation of ConcreteDokumen51 halamanCarbonation of ConcreteGaurav DhembareBelum ada peringkat

- Sikagard - 550 W ElasticDokumen4 halamanSikagard - 550 W ElasticAndrei GheoBelum ada peringkat

- Cib1808 PDFDokumen3.076 halamanCib1808 PDFf_dbdominguesBelum ada peringkat

- Concrete Jul 09 BRE Digest 330 Alkali Silica Reaction in Concrete The Case For Revision Part IDokumen3 halamanConcrete Jul 09 BRE Digest 330 Alkali Silica Reaction in Concrete The Case For Revision Part IHAFEEL100% (1)

- Steyr Marine Engines: MO256H45 I MO256K43Dokumen2 halamanSteyr Marine Engines: MO256H45 I MO256K43Ayegba AchimuguBelum ada peringkat

- Report of The Joint Review Panel: Site C Clean Energy ProjectDokumen471 halamanReport of The Joint Review Panel: Site C Clean Energy ProjectThe Globe and Mail100% (1)

- TVBM 3104Dokumen257 halamanTVBM 3104Bianca CalderónBelum ada peringkat

- Roller Compacted Concrete (RCC) in PavementsDokumen15 halamanRoller Compacted Concrete (RCC) in PavementsAlhilali ZiyadBelum ada peringkat

- Water Retaining Conc RepairDokumen48 halamanWater Retaining Conc Repairanele_amisBelum ada peringkat

- Aci sp-222-2004Dokumen252 halamanAci sp-222-2004Abigael Valles RamirezBelum ada peringkat

- Latex Agents For Bonding Fresh To Hardened ConcreteDokumen2 halamanLatex Agents For Bonding Fresh To Hardened ConcretemickyfelixBelum ada peringkat

- Concrete Institute of Australia - Recomended Practice - Z40 Super Workable ConcreteDokumen30 halamanConcrete Institute of Australia - Recomended Practice - Z40 Super Workable Concretetim100% (1)

- Shrinkage Compensating Admixtures by Sunanda CoatingsDokumen2 halamanShrinkage Compensating Admixtures by Sunanda Coatingss.skumar10% (1)

- Nanotechnology in Concrete - A ReviewDokumen12 halamanNanotechnology in Concrete - A ReviewYongliang Liu100% (1)

- NEVILLE, AITCIN (1998) - High Performance Concrete - An OverviewDokumen7 halamanNEVILLE, AITCIN (1998) - High Performance Concrete - An OverviewKimberley HollandBelum ada peringkat

- Shrinkage (CEB FIP)Dokumen4 halamanShrinkage (CEB FIP)Sabbir SiddiqueBelum ada peringkat

- Maintenance Methods For Concrete BridgesDokumen52 halamanMaintenance Methods For Concrete Bridgesကိုနေဝင်းBelum ada peringkat

- Chryso Fluid Premia 150: DescriptionDokumen2 halamanChryso Fluid Premia 150: DescriptionNidDouBelum ada peringkat

- Rockfall BarrierDokumen12 halamanRockfall BarrierĐorđe RadisavljevićBelum ada peringkat

- Self Compacting ConcreteDokumen9 halamanSelf Compacting ConcreteSiva KrishnaBelum ada peringkat

- As 3583.1-1998 Methods of Test For Supplementary Cementitious Materials For Use With Portland and Blended CemDokumen2 halamanAs 3583.1-1998 Methods of Test For Supplementary Cementitious Materials For Use With Portland and Blended CemSAI Global - APACBelum ada peringkat

- EB001 CH5 - Mixing Water For ConcreteDokumen26 halamanEB001 CH5 - Mixing Water For ConcreteJuan MartinezBelum ada peringkat

- Construction Materials and TestingDokumen61 halamanConstruction Materials and TestingAliñabo RoqueBelum ada peringkat

- Comparing Concrete Durability TestsDokumen3 halamanComparing Concrete Durability TestsHoang An TranBelum ada peringkat

- Alkali Reaction in ConcreteDokumen348 halamanAlkali Reaction in ConcreteLAM COBelum ada peringkat

- Thermal Control of Thermal Control of C T C T Concrete ConcreteDokumen83 halamanThermal Control of Thermal Control of C T C T Concrete ConcreteDivakant ChoudharyBelum ada peringkat

- Factors Affecting Durability of Concrete PDFDokumen2 halamanFactors Affecting Durability of Concrete PDFMary50% (2)

- Aci SP-153 Vol1,2 Book - 1995Dokumen1.195 halamanAci SP-153 Vol1,2 Book - 1995ananthBelum ada peringkat

- Route To Zero Carbon LCCG - Publication - FINAL - REVISED PDFDokumen41 halamanRoute To Zero Carbon LCCG - Publication - FINAL - REVISED PDFSebastianBelum ada peringkat

- Chloride Resistance of Concrete: Factors and TestsDokumen37 halamanChloride Resistance of Concrete: Factors and TestsCarlos Augusto Sánchez Rondón100% (1)

- Guideline For Inorganic Repair Material Data Sheet ProtocolDokumen10 halamanGuideline For Inorganic Repair Material Data Sheet ProtocolMauricio Javier León TejadaBelum ada peringkat

- Qatar Conference CIC 2023Dokumen37 halamanQatar Conference CIC 2023ravi 127Belum ada peringkat

- Ib 39Dokumen19 halamanIb 39Rup JoshiBelum ada peringkat

- Eurocode 2 GUIDE (How To Design With EC2 - 2007)Dokumen248 halamanEurocode 2 GUIDE (How To Design With EC2 - 2007)itai100% (1)

- Projectmodified Mix Design For ConcreteDokumen32 halamanProjectmodified Mix Design For ConcreteSagarBelum ada peringkat

- Aci sp-228-2005Dokumen1.562 halamanAci sp-228-2005Abigael Valles RamirezBelum ada peringkat

- Abrams LawDokumen2 halamanAbrams LawShazwanShahBelum ada peringkat

- Concrete Testing The Structural Engineer 87Dokumen3 halamanConcrete Testing The Structural Engineer 87istructeBelum ada peringkat

- Ycet Jammu: Seminar OnDokumen19 halamanYcet Jammu: Seminar OnSherry SherBelum ada peringkat

- Concrete from Grey to Green: Gammon's Sustainable SolutionsDokumen12 halamanConcrete from Grey to Green: Gammon's Sustainable SolutionsOmar Marghani SalmaBelum ada peringkat

- Dissert Domingues PauloCDokumen292 halamanDissert Domingues PauloCIgor BarcelosBelum ada peringkat

- Probabilistic service life model of RC structures subjected to the combined effect of chloride-induced corrosion and cyclic loadingDari EverandProbabilistic service life model of RC structures subjected to the combined effect of chloride-induced corrosion and cyclic loadingBelum ada peringkat

- Lect16 PDFDokumen11 halamanLect16 PDFbeto pagoadaBelum ada peringkat

- SUPER-SPAN Guide To Specifiers (2013)Dokumen5 halamanSUPER-SPAN Guide To Specifiers (2013)Nathan JonatBelum ada peringkat

- High-performance shotcrete acceleratorDokumen1 halamanHigh-performance shotcrete acceleratorbeto pagoadaBelum ada peringkat

- ADMIX Epoflex SRDokumen2 halamanADMIX Epoflex SRbeto pagoadaBelum ada peringkat

- MINE 292 Lecture 12 - Terminal Velocity of Settling ParticleDokumen56 halamanMINE 292 Lecture 12 - Terminal Velocity of Settling ParticleMinh CaoBelum ada peringkat

- Concrete Admixture Retains SlumpDokumen1 halamanConcrete Admixture Retains Slumpbeto pagoadaBelum ada peringkat

- Admix FXLDokumen2 halamanAdmix FXLbeto pagoadaBelum ada peringkat

- KURADDokumen1 halamanKURADbeto pagoadaBelum ada peringkat

- ADICEMDokumen2 halamanADICEMbeto pagoadaBelum ada peringkat

- ADMIX Epoxy BondDokumen3 halamanADMIX Epoxy Bondbeto pagoadaBelum ada peringkat

- Hydraulics & Hydrology PDFDokumen197 halamanHydraulics & Hydrology PDFska51100% (3)

- Description: LLCMS119 Rev01Dokumen3 halamanDescription: LLCMS119 Rev01beto pagoadaBelum ada peringkat

- 1989 - Jones, Berdusco - Practical Sediment Pond DesignDokumen19 halaman1989 - Jones, Berdusco - Practical Sediment Pond Designbeto pagoadaBelum ada peringkat

- Hydrograph Analysis PDFDokumen160 halamanHydrograph Analysis PDFbeto pagoadaBelum ada peringkat

- Load Rating Training Session 4ADokumen45 halamanLoad Rating Training Session 4Atofa01Belum ada peringkat

- Em 1110-2-2300 2Dokumen130 halamanEm 1110-2-2300 2Soenarto SoendjajaBelum ada peringkat

- FormworkDokumen24 halamanFormworkSreedhar Reddy SajjalaBelum ada peringkat

- IDB: Study On The Development of The Renewable Energy Market in Latin America and The Caribbean (2014)Dokumen79 halamanIDB: Study On The Development of The Renewable Energy Market in Latin America and The Caribbean (2014)Detlef LoyBelum ada peringkat

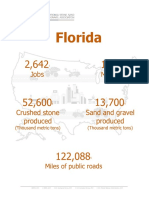

- FloridaDokumen1 halamanFloridabeto pagoadaBelum ada peringkat

- Flood Risk Assessment and ResilienceDokumen2 halamanFlood Risk Assessment and Resiliencebeto pagoadaBelum ada peringkat

- Terex Washing SystemDokumen56 halamanTerex Washing Systembeto pagoadaBelum ada peringkat

- Hydrology Handbook PDFDokumen7 halamanHydrology Handbook PDFbeto pagoadaBelum ada peringkat

- Texas mining industry overviewDokumen1 halamanTexas mining industry overviewbeto pagoadaBelum ada peringkat

- CBL P Elp 01 00Dokumen1 halamanCBL P Elp 01 00beto pagoadaBelum ada peringkat

- Manitoba Infrastructure TendersDokumen5 halamanManitoba Infrastructure Tendersbeto pagoadaBelum ada peringkat

- D6913 04Dokumen36 halamanD6913 04Eduardo Hernández80% (10)

- Moisture MeterDokumen21 halamanMoisture Meterbeto pagoadaBelum ada peringkat

- C I 1301 MuellerDokumen3 halamanC I 1301 Muellerbeto pagoadaBelum ada peringkat

- 2010 Ocean Conservancy ICC ReportDokumen60 halaman2010 Ocean Conservancy ICC Reportbeto pagoadaBelum ada peringkat

- EM I Unit 1Dokumen18 halamanEM I Unit 1Srimathi tjBelum ada peringkat

- Physical Computing NotesDokumen2 halamanPhysical Computing NotesAnonymous W9MgRBVtYCBelum ada peringkat

- Channel Tut v1Dokumen11 halamanChannel Tut v1Umair IsmailBelum ada peringkat

- Science Sample Papers 2Dokumen7 halamanScience Sample Papers 2api-281429068Belum ada peringkat

- Thermocouple Temperature Sensors ExplainedDokumen2 halamanThermocouple Temperature Sensors ExplainedRaymond Yonathan HutapeaBelum ada peringkat

- Parameter Adaptation of Reduced Order Models For Three-Dimensional Flutter AnalysisDokumen9 halamanParameter Adaptation of Reduced Order Models For Three-Dimensional Flutter AnalysisAtsis PapadopoulosBelum ada peringkat

- 14 Three Moment EquationDokumen15 halaman14 Three Moment EquationSaeed AyeenBelum ada peringkat

- Ch-27.2 Crystalline Materials - Detects in Crystalline MaterialsDokumen102 halamanCh-27.2 Crystalline Materials - Detects in Crystalline MaterialsasjfgauojfgfBelum ada peringkat

- 100 Years Werner HeisenbergDokumen308 halaman100 Years Werner Heisenbergmvmbapple100% (3)

- Linear equations worksheet solutionsDokumen4 halamanLinear equations worksheet solutionsHari Kiran M PBelum ada peringkat

- Literature ReviewDokumen17 halamanLiterature ReviewSyafiq ShaffiaiBelum ada peringkat

- M.A.M College of Engineering: Department of Electrical and Electronics EnggDokumen16 halamanM.A.M College of Engineering: Department of Electrical and Electronics EnggKrishna ChaitanyaBelum ada peringkat

- Operation Stages HDI SIEMENSDokumen9 halamanOperation Stages HDI SIEMENSSergio SambuelliBelum ada peringkat

- 4.7.5 Walls: CK Yk CKDokumen2 halaman4.7.5 Walls: CK Yk CKBertin BakariBelum ada peringkat

- Magnetism and Electromagnetism - Electrical Multiple Choice Questions and AnswersDokumen10 halamanMagnetism and Electromagnetism - Electrical Multiple Choice Questions and AnswersNagesh GillBelum ada peringkat

- II Assignment MMDokumen3 halamanII Assignment MMshantan02Belum ada peringkat

- Photo ResistorDokumen3 halamanPhoto ResistorHarish PrakashBelum ada peringkat

- William Liller - Space AstrophysicsDokumen290 halamanWilliam Liller - Space Astrophysicsmuhamad dimas arifin a.k.a Ahmd El ArfBelum ada peringkat

- Cooling PDFDokumen656 halamanCooling PDFTrầnNgọcCườngBelum ada peringkat

- DC30-010 - ODYSSEY Operator Manual - Rev PDokumen92 halamanDC30-010 - ODYSSEY Operator Manual - Rev PYolanda Peña100% (1)

- II PUC Mock Paper 2 MathematicsDokumen4 halamanII PUC Mock Paper 2 MathematicsPandit Katti NarahariBelum ada peringkat

- Chapter 11Dokumen2 halamanChapter 11naniac raniBelum ada peringkat

- ParadoxesDokumen528 halamanParadoxesMihaela CovrigBelum ada peringkat

- Electrical Charges and Fields Chapter - 1 PhysicsDokumen61 halamanElectrical Charges and Fields Chapter - 1 PhysicsPrasad PallaBelum ada peringkat

- Case D Westover Electrical, Inc.Dokumen3 halamanCase D Westover Electrical, Inc.AndresBelum ada peringkat

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 14VSTSP6QKXWAC6Dokumen2 halamanETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 14VSTSP6QKXWAC6Luis Miguel GaviñoBelum ada peringkat

- Power Transmission: Components Used To Transmit Power: Gears, Belt, Clutch and BrakesDokumen17 halamanPower Transmission: Components Used To Transmit Power: Gears, Belt, Clutch and Brakesrip111176Belum ada peringkat

- Internship Report On Railway Coach FactoryDokumen39 halamanInternship Report On Railway Coach FactoryJyotiraj ThakuriaBelum ada peringkat

- Introduction to Solid Modeling Using SolidWorks 2012 SolidWorks Simulation TutorialDokumen8 halamanIntroduction to Solid Modeling Using SolidWorks 2012 SolidWorks Simulation TutorialAYAUWU LOVEDAYBelum ada peringkat

- Air Conditioning: Basic Refrigeration Principles: Unit-1Dokumen16 halamanAir Conditioning: Basic Refrigeration Principles: Unit-1Prabha Karen PalanisamyBelum ada peringkat