1 - SSSV Overview

Diunggah oleh

Seymur AkbarovJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

1 - SSSV Overview

Diunggah oleh

Seymur AkbarovHak Cipta:

Format Tersedia

What is a Subsurface Safety Valve?

• A Subsurface Safety Valve (SSSV)

is a device which automatically

POW! shuts in the well in case of a

major malfunction of the surface

Subsurface

equipment, preventing the

Safety uncontrolled flow of hydrocarbons

Valve to the surface.

• FAIL SAFE – if there is a

failure in the surface

equipment the SSSV will

close

Internal Use Only

Why do we install them?

TO PREVENT A CATASTROPHE!

To Prevent Infrastructure And Production Loss.

To Prevent Environmental Contamination Due To

Uncontrolled Hydrocarbon Flow.

Law Requirements. Many Countries’ Laws Require The

Installation Of SSSVs In Offshore Wells.

Internal Use Only

SSSV Classification

• Tubing Retrievable Safety Valves (TRSV)

– Integral Part of the Tubing String

– Require Tubing to be Removed for Retrieval of the Safety Valve

• Wireline Retrievable Safety Valves (WLRSV)

– Installed Inside the Tubing by Using a Locking Device to Secure

Them Inside a Safety Valve Landing Nipple (SVLN) or a

standard Landing Nipple in the case of a SSCSV

– WLRSVs can be Installed and Retrieved Without Removal of

the Tubing

• Closure Mechanisms

– Flapper

– Ball

– Poppet (Used only in SSCSVs)

Internal Use Only

Surface Controlled Subsurface Safety Valves (SCSSV)

• Uses a Piston Which Hydraulic Pressure Acts to

Open the Closure Mechanism

• Spring Acts in Opposite Direction on Piston to Close

the Closure Mechanism as Hydraulic Pressure is

Lost

• In Most Designs, Well Pressure Acts With the Spring

to Oppose the Hydraulic Pressure and Close the

Valve

Internal Use Only

Surface Controlled Subsurface Safety Valves

• Preferred SSSV In Use

Today

• Can Be Shut-in From The

Surface Using The Control

Manifold, For Testing And

Well Maintenance.

• Can Be Tied Into The

Surface Safety System To

Shut-in The Well In

Response To ESD And

Fire Alarms

Internal Use Only

Hydraulic Control Line

•A ¼” OD Control Line is used to

connect the Control Manifold to

the Safety Valve.

•The Control Line comes on a

spool and has been filled with

control fluid and tested.

Internal Use Only

Hydraulic Control Line

•Control line is attached to

the tubing using either:

•Control line protectors

•Steel banding straps

•Tie wraps

•Combination

Internal Use Only

How Does a SCSSV Work?

Hydraulic Pressure

• Valve is closed Well (Tubing) Pressure is

Hydraulic P contained by the SSSV Flapper

Control Line

Pressure • Apply Hydraulic Pressure to the Control Line

Acts on the piston

Moves the SSSV towards the open position.

Subsurface

Safety Hyd. Press. ≥ Well Press. + Open Press.

Valve

• Pressure is maintained in Hydraulic

the Control Line to

Pressure

OPEN

CLOSED Valve is open. Flow is established

operate thetovalve

surface.

Formation • If pressure is bled off Valve goes to its

Pressure “fail safe” closed position.

Fail Safe Condition

Well Pressure acting

on the back side of

the piston

Internal Use Only

How A Control Manifold Works

•Supply gas (blue) is fed to the manifold.

MANUAL

SHUTDOWN •This gas runs a hydraulic pump and is

FUSIBLE also regulated (yellow) to feed Fusible

PLUG

Plugs, Manual Shutdown Stations, or

other controls used to monitor the

CONTROL Production System.

MANIFOLD

SUPPLY TO

GAS SCSSV •The hydraulic pressure created by the

pump (red) is applied downhole to the

Safety Valve.

•This pressure is used to equalize and

open the safety valve, then hold it open

during normal flowing conditions.

Internal Use Only

How A Control Manifold Works

•If for any reason (e.g. Fire,

CONTROL

Catastrophe, Control Failure, etc.),

PRESSURE the control pressure (yellow) is

RELEASED

released.

CONTROL •The hydraulic pump in the manifold

SUPPLY

MANIFOLD

TO

is by-passed by a control valve.

GAS SCSSV

• Hydraulic pressure is released

back into the reservoir.

•Allows the downhole safety valve to

close.

Internal Use Only

Halliburton Surface and Subsurface Safety

System for a Producing Well

TO

SALES

LINE

PNEUMATIC

ACTUATOR INSTRUMENT AIR

SUPPLY

SAFETY

PNEUMATIC CONTROL

PRESSURE PANEL LEVEL SWITCH

TO SSV

LO AND HI SEPARATOR

MONITOR PILOT FUSIBLE LO AND HI

QUICK PLUG MONITOR PILOT

EXHAUST

HEATER LEVEL

SWITCH

FUSIBLE SAND

PLUG EROSION

PILOT

HYDRAULIC PRESSURE TO DHSV TO SALES STORAGE

Legend

Pneumatic Line

Hydraulic Line

Internal Use Only

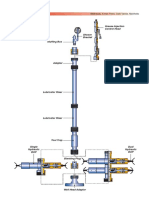

Tubing Retrievable Safety Valve

Tubing Pressure

Hydraulic Control Line Pressure, Used To Open Valve

Hydraulic Control Line, Typically 1/4” OD

Nipple Profile For Secondary Insert Lock

Mandrel / WLRSV Assembly

Piston / Flow Tube

Spring (Used to close valve by offsetting hydrostatic

head of C/L fluid and moving flowtube up to allow

flapper to close)

Self-Equalizing Feature (TRSV’s are also available

in Non-Equalizing Designs)

Flapper Closure Mechanism

Lower Honed Bore For Insert Lock Mandrel /

WLRSV Assembly

Open Closed

Internal Use Only

TRSV

TRSV vs WLRSV

WRSV

•TRSVs are the primary SSSV used in new

well completions today due to:

• ID nearly equivalent to tubing

• No restriction to flow or tool access

below valve

• Improved reliability

• Provision secondary WLRSV in the

event the TRSV fails

•WLRSVs are mostly used today in:

•Secondary insert valve in TRSV

•Casing restriction allowing only SVLN to

be installed

•Existing fields with SVLN

Internal Use Only

Wireline Retrievable Safety Valve

Lock Mandrel

• X, R Nipple

Profile

• Single

Control Line

• Same Size

Packing

Bores

Safety Valve

Landing Nipple

Internal Use Only

Sliding Side Door Safety Valve L/N

Features

• Sleeve Opens when valve is

inserted

• Sleeve Closes when valve is

removed

• Control Line Fluid

Protected from

Contamination

Internal Use Only

Regulatory Requirements

• Subsurface Safety Valves are manufactured and tested to

API Specification 14A / ISO 10432

• Subsurface Safety Valve Systems are designed, installed,

repaired, and operated in accordance with API

Recommended Practice 14B / ISO 10417.

Internal Use Only

Anda mungkin juga menyukai

- 89 Sub Surface Safety Valves SSSV InstallationDokumen16 halaman89 Sub Surface Safety Valves SSSV InstallationManuel Coxe100% (1)

- SSSV & SCP ManualDokumen77 halamanSSSV & SCP Manualyasirism0% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Dari EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Penilaian: 5 dari 5 bintang5/5 (2)

- SubsurfacesafetyvalvesDokumen17 halamanSubsurfacesafetyvalveslmar1567100% (1)

- GRAVEL Packer Tool OperationDokumen7 halamanGRAVEL Packer Tool OperationCerón Niño Santiago100% (2)

- Cactus Wellhead PresentationDokumen40 halamanCactus Wellhead Presentationchamaljs90% (10)

- WellheadDokumen2 halamanWellheadRicardo Paz SoldanBelum ada peringkat

- Ch04 WELL HEAD EQUIPMENTS AND FLOW CONTROL DEVICESDokumen16 halamanCh04 WELL HEAD EQUIPMENTS AND FLOW CONTROL DEVICESWhiskey /Belum ada peringkat

- Christmas TreeDokumen11 halamanChristmas TreezaideidBelum ada peringkat

- Esp Running ProceduresDokumen12 halamanEsp Running ProceduresAhmedMohsenBelum ada peringkat

- Diverter SystemDokumen46 halamanDiverter Systemjairaso2950100% (1)

- Wellhead Equipment and Flow Control DevicesDokumen40 halamanWellhead Equipment and Flow Control DevicesFranklyn Frank0% (1)

- Slick LineDokumen10 halamanSlick LineChoochart Thongnark100% (1)

- Coiled Tubing Cleanout, Diagnosis, and Remediation of Sand Control FailuresDokumen43 halamanCoiled Tubing Cleanout, Diagnosis, and Remediation of Sand Control FailuresDavide Boreaneze100% (1)

- Surface Systems Wellhead Training File (10 Puntos)Dokumen68 halamanSurface Systems Wellhead Training File (10 Puntos)Claudio Aguirre100% (13)

- Diverter Drilling System For Well Control Full GuideDokumen19 halamanDiverter Drilling System For Well Control Full GuiderahulBelum ada peringkat

- IWCF WI Completion-Geo B&WDokumen92 halamanIWCF WI Completion-Geo B&WTuesou MachereBelum ada peringkat

- Completion Equipment1Dokumen32 halamanCompletion Equipment1MUHAMMAD AKRAMBelum ada peringkat

- Sand ControlDokumen35 halamanSand ControlMukul Goyal100% (1)

- Completion Fluid SelectionDokumen31 halamanCompletion Fluid Selectionandrew_yeap_2100% (3)

- Surface Well Testing Presentation - NewDokumen32 halamanSurface Well Testing Presentation - NewHammad_Asif_5099Belum ada peringkat

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsDari EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsBelum ada peringkat

- Part 1 Introduction New PDFDokumen12 halamanPart 1 Introduction New PDFRanim HishamBelum ada peringkat

- Wellhead AssemblyDokumen39 halamanWellhead AssemblyAmit VermaBelum ada peringkat

- Exploration and Appraisal Well Testing Delivering The Complete PackageDokumen16 halamanExploration and Appraisal Well Testing Delivering The Complete Packagerahul84803Belum ada peringkat

- Well EquipmentsDokumen51 halamanWell EquipmentsUPES SPE Student ChapterBelum ada peringkat

- FC WellheadDokumen32 halamanFC WellheadEfe Alexander Orieka100% (2)

- Wireline NotesDokumen46 halamanWireline NotesDavide Boreaneze100% (15)

- WOM Wellhead and X-Mas ReferenceDokumen22 halamanWOM Wellhead and X-Mas ReferenceAli Manshur100% (5)

- Perforating BasicsDokumen64 halamanPerforating BasicsLawrence Mbah100% (1)

- Choke PDFDokumen32 halamanChoke PDFobumuyaemesi100% (1)

- Inflow TestDokumen2 halamanInflow TestR.G100% (1)

- Grease Injection Control Head: ParveenDokumen46 halamanGrease Injection Control Head: ParveenKedai KopiBelum ada peringkat

- Wellhead For Oil and Gas PDFDokumen49 halamanWellhead For Oil and Gas PDFAmine MimoBelum ada peringkat

- Chapter 4-GDokumen18 halamanChapter 4-GMahrouz MadoBelum ada peringkat

- Use of Coiled Tubing As A Velocity StringDokumen3 halamanUse of Coiled Tubing As A Velocity StringMark Johnson100% (1)

- 2 - Completion Pressure Control Equipment - Well Control For Well Intervention - 6619932 - 01Dokumen94 halaman2 - Completion Pressure Control Equipment - Well Control For Well Intervention - 6619932 - 01Carlos A.Belum ada peringkat

- Completion TheoryDokumen74 halamanCompletion TheoryHKHKBOOKSBelum ada peringkat

- Introduction To Coiled Tubing Well InterventionDokumen86 halamanIntroduction To Coiled Tubing Well InterventionMaleja Perpiñan Barrios100% (6)

- Brines and Other Workover FluidsDokumen90 halamanBrines and Other Workover Fluidsqazim786100% (4)

- Tree Saver Product SheetDokumen2 halamanTree Saver Product SheettxcrudeBelum ada peringkat

- Barrier QuestionDokumen9 halamanBarrier QuestionShoaib KhalilBelum ada peringkat

- Coiled Tubing OverviewDokumen120 halamanCoiled Tubing Overviewyazid100% (3)

- Packer Technology: Joshua BeierDokumen75 halamanPacker Technology: Joshua BeierOctopus100% (1)

- Tubing SelectionDokumen51 halamanTubing SelectionImam Zulkifli SBelum ada peringkat

- Introduction Well Integrity 2013Dokumen21 halamanIntroduction Well Integrity 2013ClOudyo VirgílioBelum ada peringkat

- Basic Surface Wellhead SchoolDokumen47 halamanBasic Surface Wellhead SchoolIWCF IADC100% (2)

- Lubricate and BleedDokumen18 halamanLubricate and BleedRoby Rido100% (1)

- Wellheads 01Dokumen12 halamanWellheads 01arianaseriBelum ada peringkat

- DST Slip Joint PDFDokumen8 halamanDST Slip Joint PDFcrni rokoBelum ada peringkat

- Well Surface Equipment: Presented By: Submitted ToDokumen17 halamanWell Surface Equipment: Presented By: Submitted ToShaykh AlthamasBelum ada peringkat

- Safety ValvesDokumen12 halamanSafety ValvesMuhammad Ahmed KhanBelum ada peringkat

- Wellhead and Producton Systems T3 Energy ServicesDokumen49 halamanWellhead and Producton Systems T3 Energy Servicesramonaco100% (3)

- Gas Lift School MaterialDokumen220 halamanGas Lift School MaterialMohanad Hussien100% (5)

- Advanced Water Injection for Low Permeability Reservoirs: Theory and PracticeDari EverandAdvanced Water Injection for Low Permeability Reservoirs: Theory and PracticePenilaian: 4 dari 5 bintang4/5 (2)

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldDari EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldPenilaian: 3 dari 5 bintang3/5 (2)

- Pressure Relief DeviceDokumen17 halamanPressure Relief DeviceShweta PadteBelum ada peringkat

- Rank PDFDokumen1 halamanRank PDFSeymur AkbarovBelum ada peringkat

- Be StreamDokumen2 halamanBe StreamSeymur AkbarovBelum ada peringkat

- Tank CoGDokumen38 halamanTank CoGSeymur AkbarovBelum ada peringkat

- Abaqus TutorialDokumen1 halamanAbaqus TutorialSeymur AkbarovBelum ada peringkat

- SUSTADokumen2 halamanSUSTASeymur AkbarovBelum ada peringkat

- Portable LaddersDokumen48 halamanPortable LaddersSeymur AkbarovBelum ada peringkat

- DataDokumen2.631 halamanDataSeymur AkbarovBelum ada peringkat

- PML Basics Part 1Dokumen29 halamanPML Basics Part 1Tushar Börse75% (4)

- Cast Steel Cylindrical Body Gate Valves Outside Screw and Yoke, PN 100Dokumen2 halamanCast Steel Cylindrical Body Gate Valves Outside Screw and Yoke, PN 100Seymur AkbarovBelum ada peringkat

- Pipe Deck North BearingDokumen2 halamanPipe Deck North BearingSeymur AkbarovBelum ada peringkat

- Truss 2Dokumen1 halamanTruss 2Seymur AkbarovBelum ada peringkat

- Astm A36 Material: Physical Properties Metric English CommentsDokumen1 halamanAstm A36 Material: Physical Properties Metric English CommentsSeymur AkbarovBelum ada peringkat

- E3d Command ListDokumen2 halamanE3d Command ListSeymur Akbarov86% (7)

- Vessel ImpactDokumen15 halamanVessel ImpactSeymur AkbarovBelum ada peringkat

- Subsea Actuation: Valves and ActuatorsDokumen20 halamanSubsea Actuation: Valves and ActuatorsSeymur AkbarovBelum ada peringkat

- Parameters Study of Deep Water Subsea Pipeline Selection: Jurnal Teknologi July 2014Dokumen6 halamanParameters Study of Deep Water Subsea Pipeline Selection: Jurnal Teknologi July 2014Seymur AkbarovBelum ada peringkat

- γ = du dx: Strain due to shear stressDokumen17 halamanγ = du dx: Strain due to shear stressSeymur AkbarovBelum ada peringkat

- Absheron Cdfw-Feb06-2017Dokumen13 halamanAbsheron Cdfw-Feb06-2017Seymur AkbarovBelum ada peringkat

- Propulsion I Unit V: CompressorsDokumen39 halamanPropulsion I Unit V: CompressorsPottigari Venkata Sreegeeth VarshaBelum ada peringkat

- DB 01.01.03.02 Pump M189 2Dokumen2 halamanDB 01.01.03.02 Pump M189 2PRAMOD KUMARBelum ada peringkat

- Restriction Orifice Sizing For A Minimum Recirculation LineDokumen5 halamanRestriction Orifice Sizing For A Minimum Recirculation LineChemical.AliBelum ada peringkat

- 312D Hyd PDFDokumen2 halaman312D Hyd PDFMbahdiro Kolenx100% (3)

- Bill No Gate Valves, & OtherDokumen6 halamanBill No Gate Valves, & OtheryotconstructionplcBelum ada peringkat

- Acetone PFDDokumen1 halamanAcetone PFDAshokBelum ada peringkat

- Losses in Pipe SystemDokumen5 halamanLosses in Pipe SystemMUHAMMAD AKRAMBelum ada peringkat

- Gas Turbine Engine: - Fuel SystemDokumen45 halamanGas Turbine Engine: - Fuel SystemMoin KhanBelum ada peringkat

- Commissioning Procedure - LPG Liquid ReceivingDokumen5 halamanCommissioning Procedure - LPG Liquid ReceivingAba ShahrilBelum ada peringkat

- Bill of MaterialDokumen3 halamanBill of MaterialBhupatiBelum ada peringkat

- Ebara GS Ibb April 2022 - 220404 - 200628Dokumen4 halamanEbara GS Ibb April 2022 - 220404 - 200628chandra atmaBelum ada peringkat

- Control Station and Control Valve in The Process Piping - Make Piping EasyDokumen15 halamanControl Station and Control Valve in The Process Piping - Make Piping EasyEjaz Ahmed RanaBelum ada peringkat

- 416E, 422E and 428E Backhoe Loader Hydraulic System: Fluid Power SymbolsDokumen2 halaman416E, 422E and 428E Backhoe Loader Hydraulic System: Fluid Power SymbolsJorge Mendoza100% (2)

- STERLINGDokumen8 halamanSTERLINGHummac MagañaBelum ada peringkat

- HS-II Single Tank Controls Operation ManualDokumen16 halamanHS-II Single Tank Controls Operation ManualErick Portela cruzBelum ada peringkat

- Curves Are Approximate, Pump Is Guaranteed For One Set of Conditions Capacity, Head, and PowerDokumen4 halamanCurves Are Approximate, Pump Is Guaranteed For One Set of Conditions Capacity, Head, and PowerMohsin RazaBelum ada peringkat

- Nioec SP Field Pressure TestingDokumen47 halamanNioec SP Field Pressure TestingMohammad BadakhshanBelum ada peringkat

- 07-Sequence of Events in A Reciprocating Compressor CylinderDokumen30 halaman07-Sequence of Events in A Reciprocating Compressor CylinderVikram JitBelum ada peringkat

- BobTail Fastener Pressure Chart - InchDokumen8 halamanBobTail Fastener Pressure Chart - Incherick montesBelum ada peringkat

- Well Killing OperationDokumen3 halamanWell Killing OperationmohanadBelum ada peringkat

- Fluid Flow and Mechanical Operations: Practice ProblemsDokumen3 halamanFluid Flow and Mechanical Operations: Practice ProblemsAK KumarBelum ada peringkat

- Air Compressor Piping DiagramDokumen2 halamanAir Compressor Piping DiagramOrueta ClaudioBelum ada peringkat

- Hydraulic On Aircraft CN 235Dokumen14 halamanHydraulic On Aircraft CN 235Della Adlina Nurjihan50% (2)

- 216 Hidraulico PDFDokumen4 halaman216 Hidraulico PDFGarcia Jihoo ReneBelum ada peringkat

- Posicionador 3570Dokumen24 halamanPosicionador 3570Capacitacion TodocatBelum ada peringkat

- Experiment 12 - The Venturi Meter, The Determination of Discharge From A PipeDokumen8 halamanExperiment 12 - The Venturi Meter, The Determination of Discharge From A Pipechanjunshen_rmcBelum ada peringkat

- Technical Data For The Bhel 500 MW Steam Turbine PDFDokumen2 halamanTechnical Data For The Bhel 500 MW Steam Turbine PDFsai ramanaBelum ada peringkat

- Experiment No. 01: Demonstration of Various Parts of Hydraulic Bench Hydraulic BenchDokumen30 halamanExperiment No. 01: Demonstration of Various Parts of Hydraulic Bench Hydraulic BenchZain wazirBelum ada peringkat

- 5 Cabin Conditioning & PressurisationDokumen91 halaman5 Cabin Conditioning & PressurisationIvan Milosevic100% (2)

- ZX200-3 Signal Control ValveDokumen20 halamanZX200-3 Signal Control ValveKevine Khaled100% (2)