Desperdicios en Los Procesos Productivos

Diunggah oleh

jesustorres0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

28 tayangan12 halamanMudas in manufacturing

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPTX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniMudas in manufacturing

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPTX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

28 tayangan12 halamanDesperdicios en Los Procesos Productivos

Diunggah oleh

jesustorresMudas in manufacturing

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPTX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 12

UNIT 1

DESPERDICIOS EN LOS PROCESOS

PRODUCTIVOS

INDUSTRIAL MAINTENANCE

What

• The simplest way to describe waste is as “Something

Exactly that adds no Value.” Our customers would not be

happy to pay for any action that we take that does

is not add value to what they actually want and nor

should we be.

THE SEVEN Waste?

WASTES • Your companies Profit is your selling price less your

costs, no matter how you think about the selling

price it is very much dictated by the market not by

Why yourself. If you charge too much then your

customers will go elsewhere, even if you charge too

Remove little you may lose customers as they will perceive

there may be something wrong with what you are

Waste? offering. Therefore the only way you have to

improve your profits are to reduce your costs; this

means removing all elements of waste from your

processes.

THE WASTE OF TRANSPORT

Transport is the movement of materials from

one location to another, this is a waste as it

adds zero value to the product. Why would

your customer (or you for that matter) want

to pay for an operation that adds no value?

Transport adds no value to the product, you

as a business are paying people to move

material from one location to another, a

process that only costs you money and makes

nothing for you. The waste of Transport can

be a very high cost to your business, you

need people to operate it and equipment

such as trucks or fork trucks to undertake this

expensive movement of materials.

THE WASTE OF INVENTORY

Inventory costs you money, every piece of

product tied up in raw material, work in

progress or finished goods has a cost and

until it is actually sold that cost is yours. In

addition to the pure cost of your inventory

it adds many other costs; inventory feeds

many other wastes.

Inventory has to be stored, it needs space,

it needs packaging and it has to be

transported around. It has the chance of

being damaged during transport and

becoming obsolete. The waste of Inventory

hides many of the other wastes in your

systems.

THE WASTE OF MOTION

Unnecessary motions are those movements

of man or machine which are not as small or

as easy to achieve as possible, by this I mean

bending down to retrieve heavy objects at

floor level when they could be fed at waist

level to reduce stress and time to retrieve.

Excessive travel between work stations,

excessive machine movements from start

point to work start point are all examples of

the waste of Motion.

All of these wasteful motions cost you time

(money) and cause stress on your employees

and machines, after all even robots wear out.

THE WASTE OF WAITING

How often do you spend time waiting

for an answer from another

department in your organization, or

waiting for a delivery from a supplier

or an engineer to come and fix a

machine? We tend to spend an

enormous amount of time waiting for

things in our working lives (and

personal lives too), this is an obvious

waste.

The Waste of Waiting disrupts flow,

one of the main principles of Lean

Manufacturing, as such it is one of the

more serious of the seven wastes or 7

mudas of lean manufacturing.

THE WASTE OF OVERPRODUCTION

The most serious of all of the seven

wastes; the waste of overproduction is

making too much or too early. This is

usually because of working with oversize

batches, long lead times, poor supplier

relations and a host of other reasons.

Overproduction leads to high levels of

inventory which mask many of the

problems within your organization.

The aim should be to make only what is

required when it is required by the

customer, the philosophy of Just in Time

(JIT), however many companies work on

the principle of Just in Case!

THE WASTE OF OVER-PROCESSING

The waste of Over processing is where we

use inappropriate techniques, oversize

equipment, working to tolerances that are

too tight, perform processes that are not

required by the customer and so forth. All of

these things cost us time and money.

One of the biggest examples of over-

processing in most companies is that of the

“mega machine” that can do an operation

faster than any other, but every process flow

has to be routed through it causing

scheduling complications, delays and so

forth. In lean; small is beautiful, use small

appropriate machines where they are

needed in the flow, not break the flow to

route through a highly expensive monstrosity

that the accountants insist is kept

THE WASTE OF DEFECTS

The most obvious of the seven wastes,

although not always the easiest to detect

before they reach your customers. Quality

errors that cause defects invariably cost you

far more than you expect. Every defective

item requires rework or replacement, it

wastes resources and materials, it creates

paperwork, it can lead to lost customers.

The Waste of Defects should be prevented

where possible, better to prevent than to

try to detect them, implementation of

poka-yoke systems and autonomation can

help to prevent defects from occurring.

ADDITIONAL WASTES

• WASTE OF TALENT; FAILING TO MAKE USE OF THE PEOPLE WITHIN YOUR ORGANIZATION. THIS IS

AN ISSUE THAT MANY OF OUR COMPANIES IN THE WEST FAIL TO ADDRESS. WE STILL TEND TO

OPERATE WITHIN A COMMAND AND CONTROL ENVIRONMENT AND TAKE LITTLE REAL NOTICE

OF WHAT OUR EMPLOYEES REALLY THINK AND WHAT THEY CAN CONTRIBUTE. YOUR EMPLOYEES

ARE YOUR GREATEST ASSET BY FAR AND CAN HELP YOU TO DRIVE OUT MANY OF THE OTHER

WASTES.

• WASTE OF RESOURCES; FAILURE TO MAKE EFFICIENT USE OF ELECTRICITY, GAS, WATER. NOT

ONLY DOES THIS WASTE COST YOU MONEY IT IS ALSO A BURDEN ON OUR ENVIRONMENT AND

SOCIETY AS A WHOLE.

• WASTED MATERIALS; TOO OFTEN OFF-CUTS AND OTHER BYPRODUCTS ARE JUST SENT TO

LANDFILL RATHER THAN BEING UTILIZED ELSEWHERE.

ELIMINATING THE SEVEN WASTES

• ELIMINATING THE SEVEN WASTES IS SOMETHING THAT CAN BE DONE THROUGH THE

IMPLEMENTATION OF LEAN AND THE VARIOUS LEAN TOOLS, HOWEVER THE FOCUS OF YOUR

IMPLEMENTATION SHOULD NOT BE TO IDENTIFY AND REMOVE WASTE. INSTEAD YOU SHOULD

USE THE PRINCIPLES OF LEAN MANUFACTURING TO IDENTIFY VALUE ACCORDING TO THE

CUSTOMER AND MAKE THOSE VALUE ADDING PROCESSES FLOW THROUGH YOUR

ORGANIZATION AT THE PULL OF THE CUSTOMER. THIS APPROACH HELPS YOU TO MAKE YOUR

VALUE ADDING PROCESSES MORE EFFICIENT AND CAUSES THE WASTE TO LITERALLY “DISSOLVE.”

• APPROACHING LEAN FROM A PERSPECTIVE OF REMOVING THE 7 WASTES RATHER THAN

MAKING VALUE FLOW HOWEVER USUALLY ENDS UP WITH US MAKING NON-VALUE ADDING

PROCESSES MORE EFFICIENT AND WE GET BETTER AND BETTER AT DOING THINGS THAT THE

CUSTOMER DOES NOT WANT. TO ELIMINATE THE 7 WASTES OF LEAN WE HAVE TO FOCUS ON

THE LEAN PRINCIPLES AND VALUE AS PERCEIVED BY OUR CUSTOMERS.

Anda mungkin juga menyukai

- Identifying Mura-Muri-Muda in the Manufacturing Stream: Toyota Production System ConceptsDari EverandIdentifying Mura-Muri-Muda in the Manufacturing Stream: Toyota Production System ConceptsPenilaian: 5 dari 5 bintang5/5 (1)

- 7 WastesDokumen13 halaman7 WastesNicko SarcenBelum ada peringkat

- 7 Wastes of Lean ManufacturingDokumen9 halaman7 Wastes of Lean ManufacturingAnamul Haq Siddiqe Masum0% (1)

- Q 1Dokumen9 halamanQ 1mintesinot denekewBelum ada peringkat

- 8 Wastes of Lean by Praneet SurtiDokumen25 halaman8 Wastes of Lean by Praneet SurtiSanket SavlaBelum ada peringkat

- 7 Wastes 5s LeanDokumen12 halaman7 Wastes 5s LeanJulio Cesar Gonzalez MendezBelum ada peringkat

- WASTEDokumen5 halamanWASTEJosé MartínezBelum ada peringkat

- Lean SystemDokumen2 halamanLean SystemVENESHNEEBelum ada peringkat

- 7 Wastes LecturesDokumen16 halaman7 Wastes LecturesLauraBelum ada peringkat

- The Waste of InventoryDokumen9 halamanThe Waste of InventoryRioBelum ada peringkat

- Lean IntroDokumen12 halamanLean IntroShirley OmbrogBelum ada peringkat

- LeanDokumen21 halamanLeanlorraine SandyBelum ada peringkat

- What Is LeanDokumen18 halamanWhat Is LeanraunBelum ada peringkat

- 7 Types of Waste PDFDokumen20 halaman7 Types of Waste PDFjogedhayalBelum ada peringkat

- 4 Waste Overview All Types of Wastes and HeijunkaDokumen95 halaman4 Waste Overview All Types of Wastes and Heijunkaالبراء عسيريBelum ada peringkat

- Araf Afsah Haider - 221003106 - Final Assignment - SCMDokumen26 halamanAraf Afsah Haider - 221003106 - Final Assignment - SCMAraf AfsahBelum ada peringkat

- Lean NewsletterDokumen3 halamanLean NewsletterKomal TagraBelum ada peringkat

- Total Quality ManagementDokumen7 halamanTotal Quality ManagementmansoorliveBelum ada peringkat

- PDF 20220316 001604 0000Dokumen11 halamanPDF 20220316 001604 0000Trashy kawaBelum ada peringkat

- Guide Lean ManufacturingDokumen16 halamanGuide Lean ManufacturingSofia MazzaBelum ada peringkat

- Pull Production System 1Dokumen38 halamanPull Production System 1shailesh_tiwari_mechBelum ada peringkat

- EAN Anufacturing: Reported By: Uly Reyes & Mheng BanzonDokumen64 halamanEAN Anufacturing: Reported By: Uly Reyes & Mheng BanzongoldenridgeBelum ada peringkat

- Unit 4 - Notes - Operations Planning and ControlDokumen25 halamanUnit 4 - Notes - Operations Planning and ControlHarshit gargBelum ada peringkat

- Lean ManufacturingDokumen13 halamanLean ManufacturingMohammad Shaniaz IslamBelum ada peringkat

- Lean ManufacturingDokumen1 halamanLean Manufacturingdynaz12Belum ada peringkat

- What Is Lean ManufacturingDokumen5 halamanWhat Is Lean Manufacturingaishwary ranaBelum ada peringkat

- 5S 7W TPM OeeDokumen59 halaman5S 7W TPM OeeKaushik BarmanBelum ada peringkat

- Lean ManufacturingDokumen6 halamanLean ManufacturingGreendotBelum ada peringkat

- 7-Wastes: Value Added (VA)Dokumen3 halaman7-Wastes: Value Added (VA)Venkateswaraa InsulationBelum ada peringkat

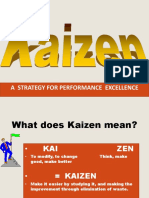

- KaizenDokumen50 halamanKaizenP. Lakshmanakanth100% (2)

- What Is LeanDokumen19 halamanWhat Is LeanRudford GectoBelum ada peringkat

- Waste EliminationDokumen3 halamanWaste EliminationVishnu Rayapeddi100% (3)

- Lean ManufacturingDokumen90 halamanLean ManufacturingSasa TesijaBelum ada peringkat

- Tim WoodDokumen3 halamanTim WoodANUSHREE V 1627035Belum ada peringkat

- Session 5Dokumen120 halamanSession 5Sumi Sam AbrahamBelum ada peringkat

- Lean Management: Business Process Re-EngineeringDokumen4 halamanLean Management: Business Process Re-EngineeringMansi VishnoiBelum ada peringkat

- Unidad IV Supplier Certification and DevelopmentDokumen12 halamanUnidad IV Supplier Certification and DevelopmentCaptian BenettsBelum ada peringkat

- Foro Identificación y Características de Los Tipos de Mudas SENADokumen6 halamanForo Identificación y Características de Los Tipos de Mudas SENAYolima MartinezBelum ada peringkat

- Lesson 1: Introduction - What Are The 7 Wastes and What Are They All About?Dokumen3 halamanLesson 1: Introduction - What Are The 7 Wastes and What Are They All About?Rohit BaggaBelum ada peringkat

- The 7 Wastes Of: Improve QualityDokumen12 halamanThe 7 Wastes Of: Improve QualitykrishnanBelum ada peringkat

- Chapter 10-Lean ManufacturingDokumen6 halamanChapter 10-Lean ManufacturingMovie 6890Belum ada peringkat

- Lean Project 1Dokumen14 halamanLean Project 1Siddharth SinghBelum ada peringkat

- 7 WastesDokumen15 halaman7 WastesPaul HansenBelum ada peringkat

- 5 Wastes of LeanDokumen4 halaman5 Wastes of LeanBalkirat SinghBelum ada peringkat

- 2 Value & Waste OverviewDokumen21 halaman2 Value & Waste Overviewالبراء عسيريBelum ada peringkat

- 8 WasteDokumen1 halaman8 WasteNaresh YadavBelum ada peringkat

- LEAN MANUFACTURING ClasspptDokumen24 halamanLEAN MANUFACTURING ClasspptSmruti ChoudhuryBelum ada peringkat

- 00the 7 MFG WasteDokumen15 halaman00the 7 MFG WasteRohit PrakashBelum ada peringkat

- Eight (8) Areas of Waste by CzaDokumen15 halamanEight (8) Areas of Waste by CzaCyrishBelum ada peringkat

- Lean Manufacturing, or Lean Production DefinitionDokumen8 halamanLean Manufacturing, or Lean Production DefinitionAnjan KumarBelum ada peringkat

- Lean Supply Chain Management & It Enabled Operations ManagementDokumen13 halamanLean Supply Chain Management & It Enabled Operations Managementchristy bijuBelum ada peringkat

- BMFP 3423 Lean P1 - Dec2022Dokumen31 halamanBMFP 3423 Lean P1 - Dec2022Idham NasrulBelum ada peringkat

- Cut To Box Module FinalDokumen26 halamanCut To Box Module FinalMukund NarayanBelum ada peringkat

- Categories of Goods: Inventory Management Component of InventoryDokumen17 halamanCategories of Goods: Inventory Management Component of InventoryEva Zunaida KurniawantiBelum ada peringkat

- Importance of Inventory ControlDokumen1 halamanImportance of Inventory ControlSelvaraj BalasundramBelum ada peringkat

- Chapter 5 Lean Enterprise Sakichi ToyodaDokumen10 halamanChapter 5 Lean Enterprise Sakichi ToyodaAMIEL TACULAOBelum ada peringkat

- Lean OperationsDokumen14 halamanLean OperationsMojtabaBelum ada peringkat

- Ten Kaizen PrinciplesDokumen4 halamanTen Kaizen PrinciplesDamien CosgroveBelum ada peringkat

- Lean NewsletterDokumen3 halamanLean NewsletterKomal TagraBelum ada peringkat

- 7 Waste and Quality ManagementDokumen2 halaman7 Waste and Quality ManagementupasanapanBelum ada peringkat

- MakerBot Educators Guidebook PDFDokumen198 halamanMakerBot Educators Guidebook PDFcakirah100% (4)

- Six Sigma Methods and Formulas For Successful Quality ManagementDokumen4 halamanSix Sigma Methods and Formulas For Successful Quality ManagementjesustorresBelum ada peringkat

- Drawings As A Contract Develop3D Ebook 61049 - tcm27 2694 PDFDokumen4 halamanDrawings As A Contract Develop3D Ebook 61049 - tcm27 2694 PDFSANJOYBelum ada peringkat

- Value Stream MappingDokumen35 halamanValue Stream MappingNevets NonnacBelum ada peringkat

- Solid Works Tutorial 12 Clamp English 08 LRDokumen53 halamanSolid Works Tutorial 12 Clamp English 08 LRAmilcar BVBelum ada peringkat

- EDU Detailed DWG Exercises 2010 ENGDokumen51 halamanEDU Detailed DWG Exercises 2010 ENGHG GabyBelum ada peringkat

- 11 Cswa VorbereitungDokumen43 halaman11 Cswa VorbereitungSohail Aslam100% (3)

- Asset Valuation: Basic Bond Andstock Valuation ModelsDokumen23 halamanAsset Valuation: Basic Bond Andstock Valuation ModelsMa Via Bordon SalemBelum ada peringkat

- GarnierDokumen60 halamanGarnierAamna AnwarBelum ada peringkat

- Fac1502 Exam Pack Exam Pack With AnswersDokumen175 halamanFac1502 Exam Pack Exam Pack With AnswersPortia MokoenaBelum ada peringkat

- Branch Banking-Interview PreparationDokumen4 halamanBranch Banking-Interview PreparationDuma DumaiBelum ada peringkat

- Case Study 1Dokumen4 halamanCase Study 1Ambily SaliBelum ada peringkat

- Complete List of Published Papers Papers and PresentationsDokumen15 halamanComplete List of Published Papers Papers and PresentationsWayne H WagnerBelum ada peringkat

- Chapter 1-Marketing Channel Concepts: Multiple ChoiceDokumen12 halamanChapter 1-Marketing Channel Concepts: Multiple ChoiceGorgina FrizBelum ada peringkat

- Repatriation of Human ResourcesDokumen4 halamanRepatriation of Human ResourcesCesare BorgiaBelum ada peringkat

- Final CPM & PertDokumen66 halamanFinal CPM & Pertsafoun peyalBelum ada peringkat

- Resume Eugenio Caldararo 01-06-16Dokumen2 halamanResume Eugenio Caldararo 01-06-16api-320990940Belum ada peringkat

- Resolution 2021 - 53 Re Privatization - Calapan DPPDokumen6 halamanResolution 2021 - 53 Re Privatization - Calapan DPPPatrick MabbaguBelum ada peringkat

- Delhi University - BMS Syllabus PDFDokumen72 halamanDelhi University - BMS Syllabus PDFthakkar030Belum ada peringkat

- D31PS-Unit 6 - Tutorial - VisionDokumen1 halamanD31PS-Unit 6 - Tutorial - VisionAmir_Jamal_QureshiBelum ada peringkat

- Exide Batteries AnalysysDokumen16 halamanExide Batteries AnalysysRasool Bux TalpurBelum ada peringkat

- Navy ERP For SailorsDokumen4 halamanNavy ERP For SailorsUday.mahindrakarBelum ada peringkat

- Module I: Assessment of Inherent RiskDokumen8 halamanModule I: Assessment of Inherent RiskbtstanBelum ada peringkat

- Statement of Changes in Comprehensive IncomeDokumen33 halamanStatement of Changes in Comprehensive Incomeellyzamae quiraoBelum ada peringkat

- Gurarsh's Final AssignmentDokumen15 halamanGurarsh's Final AssignmentGuntaaj Kaur SranBelum ada peringkat

- About Apics Cpim PresentationDokumen32 halamanAbout Apics Cpim PresentationdeushomoBelum ada peringkat

- Model Grant Proposal Format Overseas 2010Dokumen8 halamanModel Grant Proposal Format Overseas 2010dpledger2Belum ada peringkat

- Garment Industry 1Dokumen28 halamanGarment Industry 1Mega MegalaBelum ada peringkat

- Session 2Dokumen132 halamanSession 2marcchamiehBelum ada peringkat

- Vanguard InvestingDokumen40 halamanVanguard InvestingrasmussenmachineBelum ada peringkat

- Sample Exams-Bainbridge EssaysDokumen52 halamanSample Exams-Bainbridge Essayslogan doop100% (1)

- 3i's Paper ExampleDokumen74 halaman3i's Paper ExampleVenj CreagBelum ada peringkat

- Cash and Cash EqDokumen18 halamanCash and Cash EqElaine YapBelum ada peringkat

- 15 Procedure For Corrective Action Integrated Preview enDokumen3 halaman15 Procedure For Corrective Action Integrated Preview enBogdan CorneaBelum ada peringkat

- LIC Annual Report 2017 2018 WEB PDFDokumen268 halamanLIC Annual Report 2017 2018 WEB PDFLeander D'souzaBelum ada peringkat

- International Commercial Terms (INCOTERMS)Dokumen9 halamanInternational Commercial Terms (INCOTERMS)albertBelum ada peringkat

- Dominos in US Aus MalaysiaDokumen9 halamanDominos in US Aus MalaysiaPrithvi BarodiaBelum ada peringkat