Gas Turbine - AKushari

Diunggah oleh

ImtiyazJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Gas Turbine - AKushari

Diunggah oleh

ImtiyazHak Cipta:

Format Tersedia

IIT, Kanpur

Gas Turbine Combustion

and Power Generation

Dr. A. Kushari

Department of Aerospace Engineering

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Outline

• Introduction

• Advantages and Disadvantages

• Future Requirements

• Gas Turbine Combustors

• Ongoing Research

• Conclusions

• Acknowledgement

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

TURBINES: Machines to extract fluid

power from flowing fluids

Steam Water Wind Gas

Turbine Turbines Turbines Turbines

•High Pressure, High Temperature gas

Aircraft Engines

•Generated inside the engine

Power Generation

•Expands through a specially designed TURBINE

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

GAS TURBINES

• Invented in 1930 by Frank Whittle

• Patented in 1934

• First used for aircraft propulsion in 1942 on Me262 by

Germans during second world war

• Currently most of the aircrafts and ships use GT engines

• Used for power generation

• Manufacturers: General Electric, Pratt &Whitney,

SNECMA, Rolls Royce, Honeywell, Siemens –

Westinghouse, Alstom

• Indian take: Kaveri Engine by GTRE (DRDO)

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

PRINCIPLE OF OPERATION

• Intake

– Slow down incoming air

– Remove distortions

• Compressor

– Dynamically Compress air

• Combustor

– Heat addition through

chemical reaction

• Turbine

– Run the compressor

• Nozzle/ Free Turbine

– Generation of thrust

power/shaft power

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Advantages and Disadvantages

• Great power-to- • Expensive:

weight ratio – high speeds and high operating

temperatures

compared to – designing and manufacturing

reciprocating engines. gas turbines is a tough problem

from both the engineering and

• Smaller than their materials standpoint

reciprocating • Tend to use more fuel when

counterparts of the they are idling

same power. • They prefer a constant rather

• Lower emission than a fluctuating load.

levels

That makes gas turbines great for things like transcontinental jet aircraft and

power plants, but explains why we don't have one under the hood of our car.

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Emission in Gas Turbines

•Lower emission compared to all conventional methods (except nuclear)

•Regulations require further reduction in emission levels

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Needs for Future Gas Turbines

• Power Generation

– Fuel Economy

– Low Emissions

– Alternative fuels

• Military Aircrafts

– High Thrust Half the size and twice the thrust

– Low Weight

• Commercial Aircrafts

– Low emissions Double the size of the Aircraft

– High Thrust and double the distance traveled

– Low Weight with 50% NOx

– Fuel Economy

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Gas Turbine Combustion

F/A – 0.01

Combustion efficiency : 98%

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Ongoing Research

• Effect of inlet disturbances

• Combustion in recirculating flows

• Spray Combustion

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Effect of Inlet Disturbance

Tunable inlet to create weak disturbance of

varying frequency

Bluff body stabilized flame

Unsteady pressure and heat release

measurement

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Pressure Amplitude variation

= 0.2211 L = 20 cm

•Pressure oscillations increases

with decreasing length

•Dominant frequency 27 Hz

•Acoustic frequency 827 Hz

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Pressure and Heat Release

Prms Phase angle

330 160

150

280 140

Phase angle (degree)

130

Prms (pascal)

230 120

110

180 100

90

Less damping with increasing

130 80 length

70

80 60 Causes the rise is pressure

10 15 20 25 30

Length of Inlet (cm )

fluctuations

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Low Frequency Variation with Inlet

Length Frequency Amplitude

45 124

40

122

35

120

30

frequency (Hz)

SPL (Db)

25 118

20 116

15

114

10

112

5

0 110

10 15 20 25 30

Length of Inlet (cm )

ma 3.0 g / s , = 0.3455

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Variation of Dominant Frequency with Inlet Velocity

45 f *D

40 St s

U

35

Frequency (Hz)

30

St = 0.171 (60 deg cone)

25

20 Measured 0.171* U

Calulated (St = 0.171) fs

15 0.02

10

0.8 1 1.2 1.4 1.6 1.8 2

Mean Inlet Velocity (m/s)

Dominant Frequency governed by vortex

dynamics

Feed back locking of flow instability and

combustion process

Phase relationship leads to

enhancement of combustion oscillations

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Ongoing Research

• Effect of inlet disturbances

• Combustion in recirculating flows

• Spray Combustion

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Recirculating Flow Dynamics

• Primary zone

• Fuel air mixing

Understanding recirculating flow dynamics

• Intense combustion Time scales

• Short combustion length Pressure transients

• High turbulence Energy cascading

• Fuel rich combustion Combustion in recirculating flows

Droplet Flow interaction

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Image Processing

Filtered out image from the noises Grayscale image

Intensity image Simulation results

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Vortex Dynamics

0.01

total area of the cold

Ratio of the second

inlet of the combustor

vortex aera to the

second vortex to the

0.008

distance(L2/L) of

Non-dimentional

0.6 flowfield

0.55 0.006

0.5 0.004

0.45 0.002

0.4

0

0.35

2.33 3.33 4.33 5.33 6.33

2.33 3.33 4.33 5.33 6.33

Non-dimensional time

Non-dimensional time

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Transient Analysis

•Identification of signatures of re-circulation, turbulence and acoustics

through frequency domain analysis of pressure transients

•Turbulence energy cascading due to re-circulation

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Combustion in Recirculating Flow

Temperature in degree

0.6 450

Non -dimensional

400

centigrate

flame area

0.4 350

300

0.2

250

0 200

0 8 16 24 32 40 48 56 0 0.2 0.4 0.6 0.8 1

Non-dimensional time Non-dimensional distance along the combustor diameter

Time scale reduces, complete combustion, Good pattern factor

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Ongoing Research

• Effect of inlet disturbances

• Combustion in recirculating flows

• Spray Combustion

–Needs and Challenges

–Controlled atomization

–Emissions in spray combustion

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Spray Combustion: Issues

• Non-symmetrical spray flames and hot

streaks

– Serious damage to combustor liner

– Combustor exit temperature (pattern factor)

• Flame location, shape and pattern

• Emission Levels

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Need for controlled atomization

– Big Drops => Longer Evaporation Time => Incomplete

Combustion => Unburned Hydrocarbons & Soot,

Reduced Efficiency

– Small Drops => Faster Evaporation and Mixing =>

Elongated Combustion Zone => More NOx

– Uniform size distribution for favorable pattern factor

• Reduced thermal loading on liner and turbine

– Reduced feedline coupling

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Ongoing Research

• Effect of inlet disturbances

• Combustion in recirculating flows

• Spray Combustion

–Needs and Challenges

–Controlled atomization

–Emissions in spray combustion

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

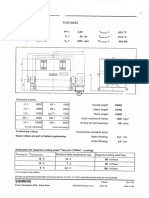

Internally Mixed Swirl Atomizer

Good atomization with small

pressure drop

Both hollow-cone and solid cone

spray from same atomizer

(wide range of applications)

Possible to atomize very viscous

liquid

Self cleaning

Finer atomization at low flow rates Atomization of engine oil

Less sensitive to manufacturing

defects

The liquid flow rate and atomization

quality can be controlled

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Performance

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Multi-head internally mixed atomizer

• Build to provide a throughput rate in excess to 0.5 LPM with a droplet

size in the range of 20-30 mm

2.5

LIQUID SUPPLY PRESSURE

y = 0.149x-0.9698

2 5 psi

10 psi

Liquid Flow Rate (LPM)

15 psi

20 psi

1.5

25 psi

1

90

80 LIQUID SUPPLY PRESSURE

0.5

70 5 psi

60 10 psi

0 15 psi

D32 (mm)

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 50 20 psi

ALR 25 psi

40

30

Flow rate independent of pressure 20

difference 10

0

Reduced feedline coupling 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

ALR

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Ongoing Research

• Effect of inlet disturbances

• Combustion in recirculating flows

• Spray Combustion

–Needs and Challenges

–Controlled atomization

–Emissions in spray combustion

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Emissions in spray flames

100 4500

90 4000

80 Exp 3500

NOX (Theory)

70

3000

NOx Theory (ppm)

60

Nox (ppm)

2500

50

2000

40

1500

30

1000

20

10 500

0 0

0.6 0.7 0.8 0.9 1 1.1 1.2 1.3

160

Distance from Flame Holder

z=5mm z=10mm

140

z=20mm z=35mm

•Measured values quite less

Sauter Mean Diameter (mm)

120

100

compared to the theoretical

predictions

80

•Inherent fuel staging reduces the

60 NOx

40

•Longer flame => less NOx

-1 0 1 2 3 4 5

Radial Distance from Center Line (cm)

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Conclusions

• Disturbances can lead to combustion

oscillations

• Recirculating flow helps in reducing

disturbances

• Controlled Atomization can be achieved

through air-assisting

• Spray combustion reduces NOx emissions

through fuel staging

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

Acknowledgements

• M. S. Rawat • Dr. K. Ramamurthi

• S. K. Gupta • LPSC (ISRO)

• S. Pandey • CFEES (DRDO)

• P. Berman

• J. Karnawat

• S. Karmakar

• N. P. Yadav

• S. Nigam

• R. Sailaja

• M. Madanmohan

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

IIT, Kanpur

THANK YOU

PROPULSION LAB, DEPARTMENT OF AEROSPACE ENGG.

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- ATA 25 - 737 NG B1 B2 Equip and FurnishingDokumen53 halamanATA 25 - 737 NG B1 B2 Equip and FurnishingTharrmaselan manimaran100% (4)

- Beauty Therapy-L1 (Cur) PDFDokumen154 halamanBeauty Therapy-L1 (Cur) PDFImtiyaz67% (3)

- ReportDokumen19 halamanReportRitvik Dobriyal100% (1)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- GypsumPlasterDataSheet1 2 PDFDokumen1 halamanGypsumPlasterDataSheet1 2 PDFImtiyazBelum ada peringkat

- GypsumPlasterDataSheet1 2 PDFDokumen1 halamanGypsumPlasterDataSheet1 2 PDFImtiyazBelum ada peringkat

- Our Courses Schools FAQ's Prices Blog Contact Us: EnglishDokumen15 halamanOur Courses Schools FAQ's Prices Blog Contact Us: EnglishImtiyazBelum ada peringkat

- Our Courses Schools FAQ's Prices Blog Contact Us: EnglishDokumen15 halamanOur Courses Schools FAQ's Prices Blog Contact Us: EnglishImtiyazBelum ada peringkat

- Notice: State Bank of IndiaDokumen1 halamanNotice: State Bank of IndiaImtiyazBelum ada peringkat

- Plaster GuideDokumen1 halamanPlaster GuideImtiyazBelum ada peringkat

- Gypsum Plaster: Product Description Physical PropertiesDokumen1 halamanGypsum Plaster: Product Description Physical PropertiesImtiyazBelum ada peringkat

- 53 Megawatt GeneratorDokumen9 halaman53 Megawatt GeneratorImtiyaz0% (1)

- Fitnatul WahhabiyaDokumen20 halamanFitnatul WahhabiyaImtiyazBelum ada peringkat

- Home Control in A Consumer's Perspective: /smartobjects/papers/brandt PDFDokumen10 halamanHome Control in A Consumer's Perspective: /smartobjects/papers/brandt PDFImtiyazBelum ada peringkat

- FlooringDokumen20 halamanFlooringImtiyazBelum ada peringkat

- Electronics Books GoodDokumen32 halamanElectronics Books GoodImtiyaz50% (2)

- How The Media Misconstrue Jihad and The Crusades: by Timothy FurnishDokumen6 halamanHow The Media Misconstrue Jihad and The Crusades: by Timothy FurnishImtiyazBelum ada peringkat

- 400scale - b747-8 - Korean AirDokumen1 halaman400scale - b747-8 - Korean Airbellanascimento2603Belum ada peringkat

- 8900 FAA Operational Control RequirementsDokumen17 halaman8900 FAA Operational Control RequirementsHavva SahınBelum ada peringkat

- Coast Artillery Journal - Jun 1944Dokumen100 halamanCoast Artillery Journal - Jun 1944CAP History Library100% (1)

- Cirrus SR2X Flight Operations Manual - PerspectiveDokumen218 halamanCirrus SR2X Flight Operations Manual - Perspectivecash flowBelum ada peringkat

- Aeros Combat 2 Combat LDokumen77 halamanAeros Combat 2 Combat LsebastiaanBelum ada peringkat

- 20x102mm Fact SheetDokumen2 halaman20x102mm Fact SheetHossam AliBelum ada peringkat

- Vehicle Aerodynamics 02Dokumen41 halamanVehicle Aerodynamics 02Dinku Seyoum ZelekeBelum ada peringkat

- Coatings Non-ITAR Product and Specification GuideDokumen16 halamanCoatings Non-ITAR Product and Specification GuideCarlos Alberto Rozo R.Belum ada peringkat

- Helicopter Flight Safety Enhancement: A Eurocopter Continuing ActionDokumen9 halamanHelicopter Flight Safety Enhancement: A Eurocopter Continuing ActionKarad KaradiasBelum ada peringkat

- Application of Fdi To A Nonlinear Boeing 747 AircraftDokumen7 halamanApplication of Fdi To A Nonlinear Boeing 747 AircraftjfnegretiBelum ada peringkat

- III. Solid Propellant Rocket MotorsDokumen18 halamanIII. Solid Propellant Rocket MotorsdBelum ada peringkat

- G3X BrochureDokumen8 halamanG3X BrochureSaeid MirBelum ada peringkat

- Routefinder: Online Flight PlannerDokumen2 halamanRoutefinder: Online Flight PlannerRAdE0nEXEBelum ada peringkat

- Plane Power Reference GuideDokumen1 halamanPlane Power Reference GuideSkySupplyUSABelum ada peringkat

- Thai Airways Polar Operations MeetingDokumen85 halamanThai Airways Polar Operations Meetingchhetribharat08100% (1)

- Procedural Leg TypesDokumen30 halamanProcedural Leg Typesinterword222Belum ada peringkat

- Suzlon S88 2.1MW Product BrochureDokumen4 halamanSuzlon S88 2.1MW Product BrochureVitor Nunes BragaBelum ada peringkat

- Wing LoadingDokumen17 halamanWing LoadingMouni's SreeBelum ada peringkat

- Airline Allied Services Limited: (A Wholly Owned Subsidiary of AIL)Dokumen5 halamanAirline Allied Services Limited: (A Wholly Owned Subsidiary of AIL)ВѻѕѕBelum ada peringkat

- Black BoxDokumen25 halamanBlack BoxMohan Rama SwamyBelum ada peringkat

- Ometric Design of Highway PDFDokumen48 halamanOmetric Design of Highway PDFTadi Fresco Royce75% (4)

- Research and Design of A Centrifugal Compressor For Fuel Cell TurbochargerDokumen5 halamanResearch and Design of A Centrifugal Compressor For Fuel Cell TurbochargerjswxieBelum ada peringkat

- Gpma1153 ManualDokumen20 halamanGpma1153 Manualapi-3778653Belum ada peringkat

- UFO: Antigravity or Coandă Effect Man Made Saucers or Aircrafts?Dokumen41 halamanUFO: Antigravity or Coandă Effect Man Made Saucers or Aircrafts?brotherthebig100% (9)

- Tutorial Sheet (ME324) 2018-19Dokumen1 halamanTutorial Sheet (ME324) 2018-19Asif SadarBelum ada peringkat

- NASA JAXA ISS HTV Resupply Vehicle Press KitDokumen86 halamanNASA JAXA ISS HTV Resupply Vehicle Press KitOrion2015Belum ada peringkat

- Fuel PlanningDokumen3 halamanFuel PlanningDefril ArcanggiBelum ada peringkat

- SA02636SEDokumen21 halamanSA02636SElouisBelum ada peringkat