Cagre 1 - Saad

Diunggah oleh

benlahnecheJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Cagre 1 - Saad

Diunggah oleh

benlahnecheHak Cipta:

Format Tersedia

Algerian Large Electrical Network Conference

To the electrical networks of future

Needs for New Values in the Technical

Specifications of Insulating Power

Transformer Oils

By : Benlahneche Saâd-eddine

Transmission Chief Engineer

DTE/ST- GRTE

Arelec Member

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

Introduction

- Challenges:

Technical:

• New specific using issues

• Presence of corrosive Sulphur

• Level of oil quality needed for transformers of a wide power

rating range

• Extension of service life desired for units in operating conditions

Safety:

• Good Behaviour against fire situations ( fire stability)

Environmental: ( Green oils = Green power transformers)

• Excellent biodegradation behaviour ( Oil free from the formation

of the PAH; Oil produced from renewable resources, ..)

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

Forces of Change

- Traditional mineral oils are unable to provide suitable

security measures especially against fire and the

environment despite their cheap price, availability and

their technical properties correctly accepted.

- The transformer is taking more reduced dimensions

with even lower weight, but in the other hand, it will be

exploited at higher rating.

- The volume of oil used in transformers begins to

decline significantly in active parts putting thus, the

oil at highly thermal and dielectric stresses in

operating conditions.

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

Some Current Changes

- A - In Design Level :

- 12% Decrease in the total weight of the transformer

- 11% Decrease in case weight

- 10% Decrease in oil weight

- 13% Decrease in core and coil weight

- 9% Decrease in no-load losses

- 3.5% Decrease in load losses

- 25% Increase in number of pumps

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

Some Current Changes

- B – Oil Volume in Rating Conditions over

the years :

Manufacturing Liters of oil per Current trend

marked by the

year kVA rating volume oil decrease

1915 7.6

1945 1.9

1960 1.3 The electric

industry

1977 0.5 must adapt

itself to this

In recent years 0.4 trend

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

Sources &Ways to design and to Formulate PT Oils ( Key

element in the competitiveness for new requirements in

use):

- From :

Pure substances :

• Mineral : Paraffinic or naphtenic

• Synthetic : Like synthetic organic esters

• Vegetal : Vegetable esters coming from seeds, crops, palms,

soya, …,ect.

• Polymers : Like silicone and polybutadiene oils, …..

Mixture and blending of different oils:

• In all or partial proportions according to the miscibility criteria

Formulated Packaging by adding some additives:

• For improvements some specific properties

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

PROPERTIES AND SPECIFICATIONS

A - Mineral Oil: Naphthenic / Paraffinic

Proportions

Cp = Paraffinic Carbon Type

Cp below 50% Naphthenic oil

Cp 50 – 60% Intermediate oil

Cp 60%< Paraffinic oil

Cn = Naphthenic Carbon Type

Cn Above 40% Naphthenic oil

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

What have been changed in

Mineral oil ?

- Today, the major tendency is the use of the naphtenic oil rather the

paraffinic one (Properties at low temperatures, Gassing behaviour,

Impulse breakdown, Solvency power,Solubility,Wax formation,….).

- Modern oils must meet these following specific properties such a

good heat dissipation and stability against degradation to ensure a

long life for power transformers

- Mineral oils are now standardized according to IEC 60296

document- edition 2012 which had replaced the one of 2003.

- It takes into account some of the more recent problems such :

New interpretation of inhibited and uninhibited oil

Metals passivators / deactivators (IEC 60666).

Presence of dibenzyl disulfide (IEC 60535).

Other additives

Test of corrosive sulfur (IEC 60535)

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

The difference between inhibited and

uninhibited oil? The antioxidant use

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

Oxidation and Degradation of Mineral Oils

Induction period Induction period

for uninhibited oil for inhibited oil

Oil Type Acid number in Tan delta at

Sludge in %

m g KOH / g 90 °C in%

IEC limit for

1.2 0.8 0.5

uninhibited oil

IEC limit for

0.3 0.05 0.05

inhibited oil

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

Mineral Oil as a weak point in impregnated

insulation system

- Channels and oil ducts inside the coil level are the

ultimate concentration point where the action of

dielectric stresses is generally destructive

- The dielectric stress in the oil is 1.8 to 1.9 higher than

the one in the insulating paper [(εo is between 2 and

2.2); (εp =4.0 )]

- The dielectric strength of the pressboard is about 3 to

4 times higher than that of oil

- The mineral oil in this impregnated system is the

most sensitive point of partial discharge occurrence

- This problem can increase drastically by the

existence of high concentration of moisture or

decomposition products and conductive particles

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

How to tackle the difference in the dielectric

permittivity values

E1/ E2= ε2/ ε1

- It can be overcome by using an alternative oil,

mixed with mineral oil, having a dielectric

permittivity close to that of the paper and capable

of dissolving the maximum of humidity under the

operating conditions without affecting its

dielectric strength

- The conditions of this mixture are imperative to

meet the criteria of miscibility and material

compatibility, and should interfere positively with

the internal design of the transformer.

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

PROPERTIES AND SPECIFICATIONS

B – Vegetable Based Ester Oil

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

B – Vegetable Based Ester Oil

Their key features include :

- Good fire resistance behaviour

- High water solubility

- Excellent toxicity/ biodegradability behaviour

Certain properties are completely

adverse :

- High viscosity and flow point

- The dissipation factor and its oxidation

stability

- High pour point temperature

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

B – Vegetable Based Ester Oil

Some other properties are also

adverse :

- Gelled oil skin thin film forming by some

polymerisation reactions

- The dielectric withstand for long distance

gap of ester oil is significantly different from

that of mineral one with a rating tension for

power transformers higher than 150 kV

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

Some practical used solutions to

overcome these adverse features

- We can lower the pour point with 10 ° C by adding the

dimethyl - acrylate at a concentration of about 1% with

practically no effect registered on its electrical

conductivity.

- Flushing the service equipment with mineral oil or

synthetic esters is recommanded if the vegetable oil thin

film in the equipment is exposed to air and high ambiant

temperatue over an extended period of time

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

Paradoxically to what is always happening with

Mineral oil

-The dissolved water reacts with ester-type oil to form long chains fatty

acids

- Hydrolysis increases then the acid value, but these fatty acids are less

aggressive than Mineral oil derived ones.

- Fatty acids can react with Hydroxyl groups of the cellulose via the

transesterification reaction to reduce the formation of new moisture

- Sludge formation during Naturel ester is negligible compared to

Mineral oil derived sludge

Sludge in Vegetable ester Sludge in Mineral oil

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

Dielectric Breakdown comparison between

Mineral oil and Naturel Ester as fonction of

moisture content

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

Aging comparison between Mineral oil

and Naturel Ester impregnated systems

- The cellulose insulation impregnated with vegetal based oil

displays a much reduced rate of aging compared to that

impregnated with mineral oil.

- This corresponds to an overload capacity for a temperature

increase of nearly 20 ° C

- This feature combined with the good thermal conductivity of

vegetal ester; greatly outweigh the effect of viscosity

Mineral oil (68 °C) Vegetal ester (80°C)

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

Aging comparison between Mineral oil

and Naturel Ester impregnated systems

Overload capacity of about 20°C

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

PROPERTIES AND SPECIFICATIONS

C – Synthetic Based Ester Oil

- It is synthesized from alcohols and organic acids. During

operation, it generates no dioxin or toxic products in the

presence of fire as the case of PCBs and has at the same time a

good biodegradability behavior.

- These esters have been developed primarily to resist against

oxidation and to absorb considerably higher quantities of

humidity without any deterioration of the dielectric system.

- Its high solubility is certainly the highlight of this type of oil where

the water saturation is reached at about 2600 PPM.

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

Comparison of physical properties of the

several oils

Mineral Synthetic ester Natural ester

Properties

uninhibited oil Midel 7131 Biotemp

Viscosity at 40 ° C / 2 mm / s 9 30 42

Viscosity at 100 ° C / 2 mm / s 2.5 5.25 9

Density at 25 ° C / kg / m 3 0.88 0.97 0.91

Pour Point ° C -25 / - 50 - 50 - 20

Specific heat at 20 ° C / J / kgK 1860 1880 1963

Thermal conductivity at 25 ° C / W / mK 0.126 0.144 0.17

Coefficient of thermal expansion / 1 / ° C 0.00075 0.00075 0.00068

Dielectric strength IEC 60156 / kv > 70 > 75 > 75

Relative permittivity according to IEC 60247 2.2 3.2 3.2

Tan delta at 90 ° C according to IEC 60247 <0.001 <0006 <0.02

Acidity / mg KOH / g 0.01 0.03 0.022

Aging RBOT / min (ASTM 2112) 300 420 197

Biodegradation after 28 days /% 25 89 95

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

INSULATING OIL : AS A TOOL OF ASSET

MANAGEMENT AND IMPROVEMENT OF

TRANSFORMER SPECIFICATIONS

- The evaluation of different electrical, thermal , dielectric and

magnetic withstands is often done by informations acquired via

the insulating oil where all statutes expressing the health of the

transformer are well illustrated .

- This correlation provided by the oil as a vector of information

between these withstands and deterioration processes, linked to

defect and failure states of the transformer, are the main source

of feeding of the asset manager and manufacturers with

analytical tools, focused on the management of transformer life

and the improvement of specifications and standards.

- This feedback guaranteed by this ongoing dynamic, will continue

in the future to make the necessary changes to requirements

because, simply, the transformer will remain for a long time, a key

equipment in the main electricity transmission systems of any

energy sources used

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

FUTUR AND PERSPECTIVES

- The intrinsic properties of the mineral oil have been

already in use well over a century of existence and will

continue to do so for future decades.

- Environmental pressures, continuously in growing

issues , allow to the alternative oils mixed with suitable

additives to be well positioned in the future.

- The arrival of insulating oils, loaded with

nanoparticles can significantly improve the properties

of heat transfer and dielectric strength, which will be

favorable for compact designs of modern units

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

CONCLUSIONS

- In the case of power transformers, IEC 62535 standard – edition

2008 imposed significant changes in the production of mineral oils.

- The inhibited oils, containing the anti-oxidant additive, were little

affected by this standard ; unlike in the case of uninhibited ones

where important changes have been seen because of their market

share, providing thus satisfactory performances for transformers

with high rating power under very stressed loads.

- The retrofilling of power transformers with natural ester fluid drew

already its future, especially when is blended with appropriate

additives.

- The experience with power transformers will certainly be positive,

since it will be supported by modified designs made on the active

parts.

- Intensive normalization that followed this type of oil will further

accelerate its implementation in the coming years

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

THANK YOU FOR YOUR ATTENTION

CAGRE’15 - ALGER, HOTEL HILTON - du 24 au 26 Mars 2015

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Research of The Loss of Power Transformer StructurDokumen8 halamanResearch of The Loss of Power Transformer StructurbenlahnecheBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Matecconf Amme2023 01041Dokumen9 halamanMatecconf Amme2023 01041benlahnecheBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Matecconf Icmmr2016 01002Dokumen6 halamanMatecconf Icmmr2016 01002benlahnecheBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Energies 17 00296Dokumen18 halamanEnergies 17 00296benlahnecheBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- p123 Icste2018Dokumen6 halamanp123 Icste2018benlahnecheBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Instruction Book GSU Spanish RevisionDokumen32 halamanInstruction Book GSU Spanish RevisionJohnBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Poster ICDL 2019 2 Light VerDokumen1 halamanPoster ICDL 2019 2 Light VerbenlahnecheBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- 583-Article Text-2511-2-10-20230222-1Dokumen8 halaman583-Article Text-2511-2-10-20230222-1benlahnecheBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- 2018 - Neuhold - Return of Experience CIGREDokumen13 halaman2018 - Neuhold - Return of Experience CIGREbenlahnecheBelum ada peringkat

- Mixed OilsDokumen8 halamanMixed OilsbenlahnecheBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Design and Testing of An Arc Resistant Power TransDokumen16 halamanDesign and Testing of An Arc Resistant Power TransbenlahnecheBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- 13 13 Paper - Parameters For Power Generation Fleets To Adverse M ViljoenDokumen11 halaman13 13 Paper - Parameters For Power Generation Fleets To Adverse M ViljoenbenlahnecheBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- 20Dokumen14 halaman20王阳Belum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Titramax Tan TBN EnglDokumen2 halamanTitramax Tan TBN EnglbenlahnecheBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Hydrogène TransportDokumen35 halamanHydrogène TransportbenlahnecheBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- CSE - 30 Power System Resilience Definition Features and PropertiesDokumen40 halamanCSE - 30 Power System Resilience Definition Features and PropertiesbenlahnecheBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Partial Discharge in Gas Insulated Substations GIS Effects Mitigation AnalysisDokumen6 halamanPartial Discharge in Gas Insulated Substations GIS Effects Mitigation AnalysisIndah PermataBelum ada peringkat

- Accelerating Power Grid Monitoring With Flying Robots and Artificial IntelligenceDokumen7 halamanAccelerating Power Grid Monitoring With Flying Robots and Artificial IntelligencebenlahnecheBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- JOAPE21361678566600Dokumen9 halamanJOAPE21361678566600benlahnecheBelum ada peringkat

- Thesis NASSEREDDINEDokumen234 halamanThesis NASSEREDDINEbenlahnecheBelum ada peringkat

- Workshop EOS PraesentationsloopDokumen5 halamanWorkshop EOS PraesentationsloopbenlahnecheBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Mixed OilsDokumen8 halamanMixed OilsbenlahnecheBelum ada peringkat

- CIGRE US National Committee 2019 Grid of The Future SymposiumDokumen9 halamanCIGRE US National Committee 2019 Grid of The Future SymposiumbenlahnecheBelum ada peringkat

- Cagre 1 - SaadDokumen26 halamanCagre 1 - SaadbenlahnecheBelum ada peringkat

- Transformer Transportation Damage, A Case Presentation of A Low Impact EventDokumen12 halamanTransformer Transportation Damage, A Case Presentation of A Low Impact EventbenlahnecheBelum ada peringkat

- Transmission Planning and Unexpected Events: An Economic FrameworkDokumen6 halamanTransmission Planning and Unexpected Events: An Economic FrameworkbenlahnecheBelum ada peringkat

- Safe and Environmentally Friendly Large Power Transformers With EsterDokumen4 halamanSafe and Environmentally Friendly Large Power Transformers With EsterbenlahnecheBelum ada peringkat

- PotM 2018 01 Diagnostic Measurem On ITs ENUDokumen19 halamanPotM 2018 01 Diagnostic Measurem On ITs ENURencziVera100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Cagre 1 - SaadDokumen26 halamanCagre 1 - SaadbenlahnecheBelum ada peringkat

- Transformer Transportation Damage, A Case Presentation of A Low Impact EventDokumen12 halamanTransformer Transportation Damage, A Case Presentation of A Low Impact EventbenlahnecheBelum ada peringkat

- Textile Auxiliaries: Zschimmer & SchwarzDokumen54 halamanTextile Auxiliaries: Zschimmer & SchwarzRezoanul HaqueBelum ada peringkat

- BIORANSFORMATIONDokumen79 halamanBIORANSFORMATIONBandameedi RamuBelum ada peringkat

- Burtoloso Group Meeting: Ketene ChemistryDokumen34 halamanBurtoloso Group Meeting: Ketene ChemistryEvandro AzevedoBelum ada peringkat

- Glycerine PurificationDokumen90 halamanGlycerine PurificationDayat Nak PiliangBelum ada peringkat

- Organic Chemistry Structured Questions (Topical)Dokumen28 halamanOrganic Chemistry Structured Questions (Topical)Lee Jun Hui100% (1)

- Natural DetergentDokumen4 halamanNatural Detergenthri234Belum ada peringkat

- Natural Surfactants (Krister Holmberg) PDFDokumen12 halamanNatural Surfactants (Krister Holmberg) PDFJohnyBelum ada peringkat

- New Organic ChemistryDokumen11 halamanNew Organic Chemistrywama ojha100% (1)

- PCT MCQ With AnswerDokumen22 halamanPCT MCQ With AnswerswapnilBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- CAPE Chemistry Syllabus Unit 2 Page 1 of 12: Structure and Formulae (Module 1)Dokumen12 halamanCAPE Chemistry Syllabus Unit 2 Page 1 of 12: Structure and Formulae (Module 1)Fabian SealeyBelum ada peringkat

- Bachelor of Engineering Project Report OnDokumen41 halamanBachelor of Engineering Project Report OnanantBelum ada peringkat

- Catalogo NUCHECKDokumen85 halamanCatalogo NUCHECKMayra AyaujaBelum ada peringkat

- United States Patent (19) : Quednau Mar. 21, 1995Dokumen7 halamanUnited States Patent (19) : Quednau Mar. 21, 1995هیمن مBelum ada peringkat

- CIR Carbomer PDFDokumen42 halamanCIR Carbomer PDFangelyna warabaBelum ada peringkat

- Gen Chem 1 Q2 Module 3Dokumen24 halamanGen Chem 1 Q2 Module 3Joshua RaninBelum ada peringkat

- Aromatic Nucleophilic Substitution ReactionsDokumen140 halamanAromatic Nucleophilic Substitution ReactionsAbhishek YadavBelum ada peringkat

- Capturing Volatile Natural Products by Mass SpectrometryDokumen24 halamanCapturing Volatile Natural Products by Mass Spectrometrymartinhoqmc7966Belum ada peringkat

- Karmaveer Bhaurao Patil College Vashi, Navi Mumbai Autonomous CollegeDokumen21 halamanKarmaveer Bhaurao Patil College Vashi, Navi Mumbai Autonomous Collegemathers maddyBelum ada peringkat

- United States Patent Office: Patented Apr. 30, 1963Dokumen8 halamanUnited States Patent Office: Patented Apr. 30, 1963Manoj Lalita GoswamiBelum ada peringkat

- SipDokumen11 halamanSipapi-317607667Belum ada peringkat

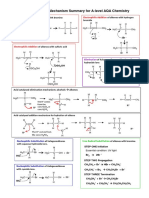

- Aqa Mechanisms A Level SummaryDokumen5 halamanAqa Mechanisms A Level SummaryRS JBelum ada peringkat

- Chemistry Notes For Class 12 Chapter 11 Alcohols, Phenols and EthersDokumen25 halamanChemistry Notes For Class 12 Chapter 11 Alcohols, Phenols and EthersMedicah Simon Peligrino100% (5)

- Fractionation of Medium Chain Fatty Acid Ethyl Esters From Virgin Coconut Oil Via Transesterification and Distillation Under Reduced PressureDokumen5 halamanFractionation of Medium Chain Fatty Acid Ethyl Esters From Virgin Coconut Oil Via Transesterification and Distillation Under Reduced Pressurei love chubzBelum ada peringkat

- B.Sc. I Semester To VI Semester: Approved Draft Syllabus ForDokumen42 halamanB.Sc. I Semester To VI Semester: Approved Draft Syllabus ForgirishBelum ada peringkat

- Propanols ULLMANNDokumen12 halamanPropanols ULLMANNJuan David Céspedes0% (1)

- Exercise 1 (6 Points) Study of A Slow ReactionDokumen4 halamanExercise 1 (6 Points) Study of A Slow ReactionImad RahimBelum ada peringkat

- 12.8 Aldehydes and Ketones Solution - PremiumDokumen24 halaman12.8 Aldehydes and Ketones Solution - PremiumJonathan ParkerBelum ada peringkat

- Organic Chemistry I: The Unofficial Reaction SheetDokumen11 halamanOrganic Chemistry I: The Unofficial Reaction SheetKarl WilsonBelum ada peringkat

- Ecofriendly Finishing of Textile: by Dr. Pintu Pandit Asst. Professor, NIFT PatnaDokumen22 halamanEcofriendly Finishing of Textile: by Dr. Pintu Pandit Asst. Professor, NIFT PatnaARYAN RATHOREBelum ada peringkat

- Journal Pre-Proofs: Tetrahedron LettersDokumen10 halamanJournal Pre-Proofs: Tetrahedron LettersMuhammad Syahrir PratamaBelum ada peringkat