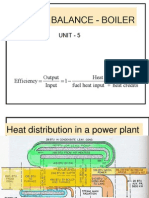

Boiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated Steam

Diunggah oleh

Anonymous 3HTgMDO0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

123 tayangan21 halamanThis document discusses boiler efficiency calculations and losses. It provides details on calculating efficiency using the loss method according to ASME standards. It lists the various losses in a boiler such as dry flue gas loss, unburnt carbon loss, and radiation losses. It also identifies controllable losses and how to reduce them, such as maintaining optimal flue gas temperature and reducing unburnt carbon in ash. Finally, it lists the necessary data required to calculate boiler efficiency including fuel properties, operating parameters, and flue gas composition.

Deskripsi Asli:

Judul Asli

3193-292321-BOILER_EFFICIENCY

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

PPT, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThis document discusses boiler efficiency calculations and losses. It provides details on calculating efficiency using the loss method according to ASME standards. It lists the various losses in a boiler such as dry flue gas loss, unburnt carbon loss, and radiation losses. It also identifies controllable losses and how to reduce them, such as maintaining optimal flue gas temperature and reducing unburnt carbon in ash. Finally, it lists the necessary data required to calculate boiler efficiency including fuel properties, operating parameters, and flue gas composition.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

123 tayangan21 halamanBoiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated Steam

Diunggah oleh

Anonymous 3HTgMDOThis document discusses boiler efficiency calculations and losses. It provides details on calculating efficiency using the loss method according to ASME standards. It lists the various losses in a boiler such as dry flue gas loss, unburnt carbon loss, and radiation losses. It also identifies controllable losses and how to reduce them, such as maintaining optimal flue gas temperature and reducing unburnt carbon in ash. Finally, it lists the necessary data required to calculate boiler efficiency including fuel properties, operating parameters, and flue gas composition.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PPT, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 21

BOILER EFFICIENCY

Steam Output

Radiation Loss

Second

Pass

Heat

ESP

Input

Furnace

Heat Input is Pulverised Coal

Heat Output is Superheated Steam

Efficiency Calculations

Standard Applied :- ASME Standard PTC 4.1

Calculation Method :- Loss Method

Losses calculated as percentage of INPUT as 100%

Losses in Boilers

Second

Pass

Heat Furnace

Input ESP

1) Loss due to dry flue gas = 4.928%

Losses in Boilers Contd.

Second

Pass

Heat

Input Furnace

ESP

2) Loss due to Unburnt Carbon = 0.331%

Losses in Boilers Contd.

Second

Heat Pass

Input ESP

Furnace

3) Due to Sen. Heat of Bottom Ash = 0.071%

4) Due to Sen. Heat of Fly Ash = 0.102%

Losses in Boilers Contd.

Second

Heat Pass

Input ESP

Furnace

5) Radiation Losses = 0.200%

Losses Related to Coal &

Ambient Air Quality

6) Loss due to moisture in Fuel = 1.263%

7) Loss due to Hydrogen in Fuel = 5.537%

8) Loss due to Moisture in Air = 0.074%

9) Unaccounted Losses = 1.327%

Total Losses = 13.83%

Data required for Boiler

Efficiency Calculations

Unit load MW

FW Flow at Econ inlet T/hr

Wet bulb Temp 0

C

Dry bulb Temp 0

C

Barometric Pressure mmHg

Total Coal Flow T/hr

Unburnt C in BA %

Unburnt C in FA %

Radiation & Unaccounted Losses %

% Fly ash to Total Ash %

% Bottom ash to Total ash %

Data required……….2

Proximate Analysis of Coal Air Dry As fired

Moisture % %

Ash % %

Volatile Matter % %

Fixed Carbon % %

Gross Cal. Value Kcal/kg Kcal/kg

Ave FG O2 APH in Ave FG O2 APH Out

Ave FG CO2 APH in Ave FG CO2 APH Out

Ave FG CO APH in Ave FG CO APH Out

Ave. FG Temp APH in Ave. FG Temp APH Out

Air to APH in Air APH out Total Primary Flow

Total Air Flow L Total Air Flow R

Design Ambient / Ref air Temp

Calculations

Ultimate Analysis As fired Basis

1. Carbon = (Fixed Carbon AD+0.9(Vol Matter AD-14))

*GCV AF/GCV AD

2. Sulphur = 0.4 * GCV AF/GCV AD

3. Hydrogen = Vol.Matter AD*(7.35/(Vol Matter AD+10)-

0.013)* GCV AF/GCV AD

4. Moisture = Moisture AF

5. Nitrogen = (2.1-0.012 * Vol.Matter AD)* GCV AF/GCV AD

6. Oxygen = 100-(Carbon+Hydrogen+Nitrogen+Ash

AD+Moisture AD)* GCV AF/GCV AD

7. Ash = Ash AF and 8. Gross Cal. Value=GCV AF

Calculations ….. Losses

Dry Gas Loss = Sensible heat of dry gas*100/(GCV

AF*4.186) %

Carbon in fuel

%

Sulfur in fuel

%

Carbon in ash / kg of fuel

kg/kg coal

Specific Heat of Gas

kg/kg C

Avg. Flue gas temp - APH Out

CONTROLLABLE LOSSES 1

FOLLOWING LOSSES CAN BE CONTROLLED

1. LOSS DUE TO DRY FLUE GAS

THE DESIGNER GIVES THIS LOSS AT THE FLUE GAS

0

APH OUTLET TEMP OF 140 C

0

ANY INCREASE IN THE FGT MORE THAN 140 C WILL

BE RESULTING IN MORE LOSSES. THIS TEMP HAS TO

BE CONTROLLED BY PROPER CLEANING OF THE

FURNACE

CONTROLLABLE LOSSES 2a

LOSSES DUE TO THE UNBURNT COAL IN BOTTOM

AND FLY ASH.

LOSS DUE TO UNBURNT IN BOTTOM ASH

THE DESIGNER GIVES THIS %AGE AS MAX 4.8 %

ANY INCREASE IN THIS PERCENTAGE BEYOND

THIS WILL RESULT IN MORE LOSSES

IF UNBURNT IN BOTTOM ASH IS MORE, THE

CULPRIT IS THE COAL MILL, CHECK THE

FINENESS OF PULVERISED COAL. CHECK THE

% RETENTION ON 50 MESH. IT SHALL NOT

EXCEED 1%.

CONTROLLABLE LOSSES 2b

CHECK THE UNBURNT IN FLY ASH SAMPLE TAKEN

FROM THE FIRST HOPPER OF ESP/BF

AS PER THE DESIGNER IT SHALL NOT EXCEED 0.8%.

IF UNBURNT IN FLY ASH EXCEEDS 0.8% IT

INDICATES INCOMPLETE COMBUSTION DUE TO

LESS AMOUNT OF AIR

CHECK FOR O2 % AT THE APH FG INLET FOR 2.8%,

INCREASE IF NECESSORY TO 3.2%. AGAIN CHECK

FOR UNBURNTS IN FLY ASH. SIMULTANIOUSLY

CHECK FOR AIR LEAKAGES/INGRESS IN THE

SECOND PASS

Losses Calculations

Assumptions:-

1. Fly Ash is 80% of Total Ash.

2. Bottom Ash is 20% of Total Ash

3. Sulphur is 0.4% in Coal

DATA REQUIRED

Fuel Properties

Proximate Analysis of Coal

Air Dry Basis As Fired basis

Moisture % Moisture %

Ash % Ash %

Volatile Matter % Volatile Matter %

Fixed Carbon % Fixed Carbon %

Gross Cal. Value % Gross Cal. Value %

Data Required contd.

Unit load MW

FW Flow at Econ inlet T/hr

Wet bulb Temp 0

C

Dry BulbTemp 0

C

Barometric Pressure

Total Coal Flow T/hr

Unburnt Carbon in BA %

Unburnt Carbon in FA %

Data Required Contd.

Ave FG O2 APH in Ave FG CO2 APH in

Ave FG CO APH in Ave FG O2 APH Out

Ave FG CO2 APH Out Ave FG CO APH Out

Air to APH in Temp Air APH out Temp

Total Air Flow L Total Air Flow R

Ave. FG Temp APH in

Ave. FG Temp APH Out

Total Primary Air Flow

GCV Calculations for Coal

Calculations of GCV

As fired Basis

Coal sample is taken as received basis, heated for

calculation of

A) Total Moisture content = TM%

Air Dry Basis

The sample is air dried for removal of surface

moisture and burned completely for

A) Inherent moisture content = M%

B) Ash percentage = A%

GCV Calculations for Coal Contd.

1) Useful Heat Value = 8900 – 138(A%+M%) kcal/kg

2) Gross Calorific Value = (UHV + 3645 – 75.4 M%)/1.466

(Air Dry Basis) Kcal/kg

3) Ash % (As fired basis) = [A %] (100 - TM%)/(100 – M%) %

4) Gross Calorific Value = [GCVAD] (100 - TM%)/(100 – M%)

(As fired Basis) Kcal/kg

5) Net Calorific Value = [GCV] – 10.02M% Kcal/kg

Calculations

Weight of Dry Gas = (Ca+S/2.67-100*U)/(12*CO2out)

Ca = % Carbon in fuel (Ultimate Analysis as Fired)

S = % Sulfur in fuel (Ultimate Analysis as Fired)

A = % of Ash in fuel (Ultimate Analysis as Fired)

Unburned C in Ash = Pfa/100*Cfa + Pba/100*Cba

U = Carbon in ash / kg of fuel=A/100*Cash/(100-Cash)

CO2 Out = Avg. CO2 Flue Gas -APH Out

Sensible Heat Dry Gas = Wd*30.6(Tgo-Trai)

Anda mungkin juga menyukai

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsDari EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerBelum ada peringkat

- Boiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated SteamDokumen21 halamanBoiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated SteamZakirUllahBelum ada peringkat

- Unit Heat RateDokumen7 halamanUnit Heat RateSelvaBelum ada peringkat

- Kuliah 2 Perancangan Tungku 2018Dokumen21 halamanKuliah 2 Perancangan Tungku 2018BakrifanBelum ada peringkat

- Plant EfficiencyDokumen51 halamanPlant EfficiencyknsaravanaBelum ada peringkat

- HR Deviation U#2 06.03.2016 (Day Avg)Dokumen32 halamanHR Deviation U#2 06.03.2016 (Day Avg)golden430Belum ada peringkat

- Energy Performance Assessment of BoilersDokumen17 halamanEnergy Performance Assessment of BoilersLohith KumarBelum ada peringkat

- Boiler Performance Calculation1Dokumen41 halamanBoiler Performance Calculation1chinmay sundar dashBelum ada peringkat

- Dry Wet Unburnt Daily Dev CalculationDokumen11 halamanDry Wet Unburnt Daily Dev CalculationVenkateswara Rao DoodalaBelum ada peringkat

- Mod 6Dokumen49 halamanMod 6mkpq100% (1)

- 07 - Combustion - Optimisation PDFDokumen90 halaman07 - Combustion - Optimisation PDFLakshmi NarayanBelum ada peringkat

- Power Plant Boiler EfficiencyDokumen15 halamanPower Plant Boiler EfficiencyMarcJexsonDeGuzmanBelum ada peringkat

- 02 - Combustion - OptimisationDokumen88 halaman02 - Combustion - OptimisationDSGBelum ada peringkat

- Boiler PerformanceDokumen20 halamanBoiler Performancesameer betalBelum ada peringkat

- Heat Rate & Its EffectDokumen48 halamanHeat Rate & Its Effectइंजी. महेन्द्र प्रताप सिंहBelum ada peringkat

- Boiler DesignDokumen10 halamanBoiler DesignbobBelum ada peringkat

- EFFICIENCY by BEE FormulaDokumen8 halamanEFFICIENCY by BEE FormulaVenkateswara Rao DoodalaBelum ada peringkat

- 8.performance Evaluation of BoilersDokumen9 halaman8.performance Evaluation of Boilerskcp1986Belum ada peringkat

- Boiler Efficiency CalculationDokumen5 halamanBoiler Efficiency CalculationSuparna Bhose100% (3)

- Boiler Efficiency Calculation:-: 2. Indirect MethodDokumen8 halamanBoiler Efficiency Calculation:-: 2. Indirect MethodVISHAL GANGWARBelum ada peringkat

- BOILER Losses: Loss Due To Unburnt CarbonDokumen5 halamanBOILER Losses: Loss Due To Unburnt CarbonVenkateswara Rao DoodalaBelum ada peringkat

- Steam Generator: Safety: Critical ConcernDokumen59 halamanSteam Generator: Safety: Critical ConcernpatlninadBelum ada peringkat

- Heat BalanceDokumen18 halamanHeat Balancehafidhrahadiyan2Belum ada peringkat

- Boiler Efficiency MeasurementDokumen7 halamanBoiler Efficiency MeasurementManoj MishraBelum ada peringkat

- Boiler Eff SolutionsDokumen11 halamanBoiler Eff SolutionsnpBelum ada peringkat

- Boiler & Turbine Efficiency: Rohit Verma Dy - Director NPTI, FaridabadDokumen77 halamanBoiler & Turbine Efficiency: Rohit Verma Dy - Director NPTI, FaridabadLakshya Soni100% (3)

- Boiler Efficiency by As Hwan I KumarDokumen17 halamanBoiler Efficiency by As Hwan I KumarJoshi DhvanitBelum ada peringkat

- ChE132 Case Study WriteupDokumen20 halamanChE132 Case Study WriteuphuyBelum ada peringkat

- Boiler EfficiencyDokumen4 halamanBoiler EfficiencyComputer Maintainance Hardware and softwareBelum ada peringkat

- Boiler Efficiency by Indirect Method Coal Fired BoilerDokumen4 halamanBoiler Efficiency by Indirect Method Coal Fired BoilerM Ziaul ArifBelum ada peringkat

- Combustión: Section 3Dokumen9 halamanCombustión: Section 3Luciana RequejoBelum ada peringkat

- KKP Boiler Training Material - Vol 1Dokumen92 halamanKKP Boiler Training Material - Vol 1parthi20065768Belum ada peringkat

- Boiler Efficiency Test: Manual InputsDokumen7 halamanBoiler Efficiency Test: Manual InputsSHIVAJI CHOUDHURYBelum ada peringkat

- Clearstone II Appendix IIIDokumen233 halamanClearstone II Appendix IIIrezaBelum ada peringkat

- 4.10.4 Performance Evaluation of BoilersDokumen7 halaman4.10.4 Performance Evaluation of BoilersGanti AsegarBelum ada peringkat

- Boiler EfficiencyDokumen32 halamanBoiler Efficiencyइंजी. महेन्द्र प्रताप सिंह100% (2)

- Power Plat EfficiencyDokumen11 halamanPower Plat EfficiencyrezaBelum ada peringkat

- Energy Audits in Thermal Power StationDokumen62 halamanEnergy Audits in Thermal Power Stationfiroj_khan995% (22)

- Previous NextDokumen7 halamanPrevious NextWajid HussainBelum ada peringkat

- Determining Boiler EfficiencyDokumen7 halamanDetermining Boiler EfficiencySuprio KamalBelum ada peringkat

- TC3 - Day 2 (Aug. 29)Dokumen98 halamanTC3 - Day 2 (Aug. 29)weam nourBelum ada peringkat

- Ultimate AnalysisDokumen3 halamanUltimate AnalysisComputer Maintainance Hardware and softwareBelum ada peringkat

- Iftah Fahmi Waladi - UTS Etika Profesi Sem6Dokumen17 halamanIftah Fahmi Waladi - UTS Etika Profesi Sem6Aldi WaladiBelum ada peringkat

- Ombustion AND AFE Urnace Perations: C S F ODokumen79 halamanOmbustion AND AFE Urnace Perations: C S F OTruth Seeker100% (1)

- Boiler Total Air OptimizationDokumen24 halamanBoiler Total Air OptimizationSam100% (7)

- Tower HMBDokumen26 halamanTower HMBAnkur KoulBelum ada peringkat

- Boiler and Steam SystemDokumen33 halamanBoiler and Steam SystemDr. Akepati Sivarami Reddy100% (4)

- Example Calculations: Time: Run Number: DateDokumen4 halamanExample Calculations: Time: Run Number: DateLong Nguyễn HoàngBelum ada peringkat

- Energy Assesment of BoilerDokumen22 halamanEnergy Assesment of BoilerBrijesh SrivastavBelum ada peringkat

- Boiler Efficiency Improvement Through Analysis of Losses PDFDokumen5 halamanBoiler Efficiency Improvement Through Analysis of Losses PDFTambun BerdikariBelum ada peringkat

- Ijaerd 14-0139Dokumen6 halamanIjaerd 14-0139Saurabh KumarBelum ada peringkat

- CombustionDokumen78 halamanCombustionhansley100% (1)

- Boiler EffDokumen46 halamanBoiler EffIrawan Sutiono100% (1)

- Indirect MethodDokumen6 halamanIndirect MethodFarurrodin Syah AlfahrobiBelum ada peringkat

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersDari EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersBelum ada peringkat

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentDari EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentBelum ada peringkat

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Dari EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Belum ada peringkat

- Corruption Ecological: Rio-Empty-SeatsDokumen5 halamanCorruption Ecological: Rio-Empty-SeatsAnonymous 3HTgMDOBelum ada peringkat

- Keda's SAP ImplementationDokumen1 halamanKeda's SAP ImplementationAnonymous 3HTgMDOBelum ada peringkat

- Ecof 1Dokumen27 halamanEcof 1Anonymous 3HTgMDOBelum ada peringkat

- Keda's SAP ImplementationDokumen1 halamanKeda's SAP ImplementationAnonymous 3HTgMDOBelum ada peringkat

- RiskFactorsERPSumner PDFDokumen12 halamanRiskFactorsERPSumner PDFAnonymous 3HTgMDOBelum ada peringkat

- Alpha For Directional Test (1-Tailed) Alpha For Non-Directional Test (2-Tailed)Dokumen1 halamanAlpha For Directional Test (1-Tailed) Alpha For Non-Directional Test (2-Tailed)Anonymous 3HTgMDOBelum ada peringkat

- RiskFactorsERPSumner PDFDokumen12 halamanRiskFactorsERPSumner PDFAnonymous 3HTgMDOBelum ada peringkat

- Planetary Gear Ratio CalculationsDokumen5 halamanPlanetary Gear Ratio CalculationsAnonymous 3HTgMDO100% (1)

- Hydrazine DosingDokumen2 halamanHydrazine DosingAnonymous 3HTgMDO100% (1)

- Organic Nitrogen CompoundsDokumen9 halamanOrganic Nitrogen CompoundsSaranga BuwanekaBelum ada peringkat

- Chem 16 Sample Problems 1Dokumen1 halamanChem 16 Sample Problems 1HeyowJeiBelum ada peringkat

- Chemicals Zetag MSDS Inverse Emulsion Zetag 8848 FS - 0710Dokumen6 halamanChemicals Zetag MSDS Inverse Emulsion Zetag 8848 FS - 0710PromagEnviro.comBelum ada peringkat

- Evaluation of Red Mud Reinforced Al-2024 MMC Fabricated Using Stir Casting TechniqueDokumen5 halamanEvaluation of Red Mud Reinforced Al-2024 MMC Fabricated Using Stir Casting Techniqueamiter84Belum ada peringkat

- Edexcel Biology IGCSE: 2.9: Food TestsDokumen38 halamanEdexcel Biology IGCSE: 2.9: Food TestsMinhajul Islam MahinBelum ada peringkat

- Oxidation of Tetrahydrofuran and 1,4-Butanediol With Nitric AcidDokumen3 halamanOxidation of Tetrahydrofuran and 1,4-Butanediol With Nitric Acidkanak parmarBelum ada peringkat

- STD - 537 APIDokumen27 halamanSTD - 537 APIAdhi ErlanggaBelum ada peringkat

- Mohamad Alief Ramdhan - Tugas 2 Jurnal ReviewDokumen59 halamanMohamad Alief Ramdhan - Tugas 2 Jurnal Reviewalief ramdhanBelum ada peringkat

- Naming and Structures of HalogenoalkanesDokumen4 halamanNaming and Structures of HalogenoalkanesshahdBelum ada peringkat

- ITW Product Catalog21 PDFDokumen1 halamanITW Product Catalog21 PDFjohnBelum ada peringkat

- Crystal Field TheoryDokumen6 halamanCrystal Field TheoryMAGU_MWENYEWEBelum ada peringkat

- Aldol Condensation Web PDFDokumen12 halamanAldol Condensation Web PDFDaniel Elias Diaz MerinoBelum ada peringkat

- Materials For Energy Efficiency: Thermoelectrics, Thin Films, and Phosphors - Material Matters v6n4Dokumen32 halamanMaterials For Energy Efficiency: Thermoelectrics, Thin Films, and Phosphors - Material Matters v6n4Sigma-AldrichBelum ada peringkat

- Board of Intermediate Education: Senior Inter Model Paper ChemistryDokumen2 halamanBoard of Intermediate Education: Senior Inter Model Paper Chemistryrathod adithBelum ada peringkat

- ColaFax CPE-KDokumen4 halamanColaFax CPE-KmndmattBelum ada peringkat

- Latest Date For Receipt of Comments: 14 October 2019: Form 36Dokumen32 halamanLatest Date For Receipt of Comments: 14 October 2019: Form 36Abdullah DanishBelum ada peringkat

- (Worksheet 2.1) - (Acids Bases and Salts)Dokumen10 halaman(Worksheet 2.1) - (Acids Bases and Salts)AnilBelum ada peringkat

- Catalogue WILO B3 60Hz en ScreenDokumen141 halamanCatalogue WILO B3 60Hz en ScreenRadu ElenaBelum ada peringkat

- Tutorial 1 Answers Q6-Q11Dokumen6 halamanTutorial 1 Answers Q6-Q11A/P SUPAYA SHALINIBelum ada peringkat

- Importance of BuffersDokumen7 halamanImportance of BuffersAsad AzizBelum ada peringkat

- Aral Industrial LubricantsDokumen55 halamanAral Industrial LubricantsAnonymous oAbjbl4H100% (1)

- Exe 3Dokumen29 halamanExe 3AkashGauravBelum ada peringkat

- Class10 Chapter - 2 Acids, Bases and Salts (Notes)Dokumen9 halamanClass10 Chapter - 2 Acids, Bases and Salts (Notes)SBelum ada peringkat

- Salttext SingleDokumen201 halamanSalttext SingleJiHyun ParkBelum ada peringkat

- Full Plate Patterns or Custom Flame Cut Shapes and Parts.: Characteristics/specificationsDokumen7 halamanFull Plate Patterns or Custom Flame Cut Shapes and Parts.: Characteristics/specificationsrcaletaBelum ada peringkat

- Bs Medical Technology: First Year - First Semester Module - IiiDokumen10 halamanBs Medical Technology: First Year - First Semester Module - IiiArjune PantallanoBelum ada peringkat

- April 11 - Gas Sweetening ProcessDokumen95 halamanApril 11 - Gas Sweetening Processhoangduy7696Belum ada peringkat

- BFO Milling TimeDokumen8 halamanBFO Milling TimetweellyBelum ada peringkat

- UTL200 WaterDokumen83 halamanUTL200 Watermika cabelloBelum ada peringkat

- Reading A Solubility CurveDokumen4 halamanReading A Solubility CurveMar GomezBelum ada peringkat