Weld Calc PDF

Diunggah oleh

rustamriyadi0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

33 tayangan1 halamanJudul Asli

WELD CALC.pdf

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

33 tayangan1 halamanWeld Calc PDF

Diunggah oleh

rustamriyadiHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 1

458

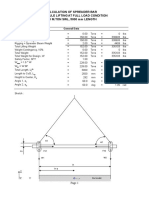

DESIGN OF WELDED JOINTS

FOR STRUCTURAL MEMBERS

GROOVE WELD

Groove welds ar usually a continuation ofthe base metal. For groove welds the same

Strength i aeibed as forthe members that they join.

FILLET WELD.

Se of weld

‘The size ofan equate filet weld isthe le

anes aincasion ofthe hig ight ange trib

inthe cross section of the wel

tee

“The size of an uncqual-lg fillet weld ig the

Shortest datance fom the root to the face of the

filler weld

te

ey

root

‘Throat dimension = 0.707 x leg dimension

‘Minimum Weld size*

“Thickness of the thicker plate, in. | wy % 1% 2M 6 6

Minimum fillet weld size, Yeo he

* Weld size need not to exceed the thickness of the thinner part joined

‘Economy of fillet wel

TGS the enum se of

1 required fr th desired sre

eet eportons he slams ind on) of it

3, Apply filet weld transversely tothe force to achieve greater strength

TRANSVERSE

WELD

ofthe welding procedure and the electrode used,

lowanle static load 9, ips) bs

ets of 600 Ibs on meld

+ example: the llowable load on 20% 1 long lel weld #3600 = 2.

PARALLEL

WELD

Allowable Load

DESIGN OF WELDED JOINTS

FOR STRUCTURAL MEMBERS

DEFINITION OF SYMBOLS

Az, = Length of weld, in

7 = Allowable load’ on ‘we

per

subjeced to bending

v = Vertical shear, ps

ton

5, = Selon Modulus of weld ines

COMPRESSION VERTICAL SHEAR BEND

RESULTANT FORCE: W = VW? + Wi + WE

EXAMPLE #1

Determine the requiced size of filet weld. The length of the weld i all arc

inches and the tensional load 20 kips.

20,000 Ibs.

we

we eg 2.35 kis per lin. in.

(2) we #. 288 - 0.24; vse Y" fillet we!

EXAMPLE #2

acne he eae se filet weld, Te eng of the wel 12 ices

hh

Bending Force, gis = 2.5 kips per

Shear Force W, = X= 3 = 015 kips peri

Resultant force, W VW + WE =

VERB + OTF = 2.37 kips pe:

Anda mungkin juga menyukai

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Hook Pallet Capacity CalculationDokumen2 halamanHook Pallet Capacity CalculationrustamriyadiBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Bentley Limcon v3.63Dokumen4 halamanBentley Limcon v3.63rustamriyadiBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Calculation of Lifting (Horizontal Position) Piperack Module 14A 24tons Total WeightDokumen14 halamanCalculation of Lifting (Horizontal Position) Piperack Module 14A 24tons Total WeightrustamriyadiBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Lifting Calculation Pipe-Pipe Jn680 Turret Access Structure, Bluewater 110 Ton WeightDokumen10 halamanLifting Calculation Pipe-Pipe Jn680 Turret Access Structure, Bluewater 110 Ton WeightrustamriyadiBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Flat Head Calculation (Based On Ug 34)Dokumen2 halamanFlat Head Calculation (Based On Ug 34)rustamriyadiBelum ada peringkat

- Pressure Vessel (Design)Dokumen132 halamanPressure Vessel (Design)Victor Rizal Filosofi50% (2)

- Rectangular Tank Calc - STDDokumen24 halamanRectangular Tank Calc - STDrustamriyadiBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Beam DesignDokumen6 halamanBeam DesignrustamriyadiBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Tutorial Manual Safi PDFDokumen53 halamanTutorial Manual Safi PDFrustamriyadiBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Davit CalcDokumen4 halamanDavit CalcrustamriyadiBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Lifting Lug STD Design 5tDokumen3 halamanLifting Lug STD Design 5trustamriyadi50% (2)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Shape 2000Dokumen217 halamanShape 2000rustamriyadiBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Spreader 150T - PL100 A36Dokumen8 halamanSpreader 150T - PL100 A36rustamriyadiBelum ada peringkat

- Weld KcalculationDokumen1 halamanWeld KcalculationrustamriyadiBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Mech-HT 13.0 L05 SteadyStateDokumen9 halamanMech-HT 13.0 L05 SteadyStaterustamriyadiBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- SPMT BrochureDokumen15 halamanSPMT BrochureAnonymous qT66pyKBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Mech-Intro 13.0 WS07.1 SStherm PDFDokumen14 halamanMech-Intro 13.0 WS07.1 SStherm PDFrustamriyadiBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- AnsysDokumen26 halamanAnsysrustamriyadiBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Spreader 150T - PL100 A36Dokumen8 halamanSpreader 150T - PL100 A36rustamriyadiBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Spreader 150T - PL100 A36Dokumen8 halamanSpreader 150T - PL100 A36rustamriyadiBelum ada peringkat

- Lifting Lug CalculationDokumen2 halamanLifting Lug Calculationrustamriyadi100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)