Salah 2

Diunggah oleh

Hani HassanHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Salah 2

Diunggah oleh

Hani HassanHak Cipta:

Format Tersedia

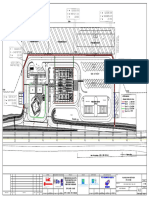

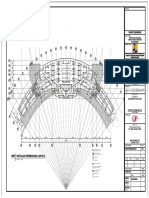

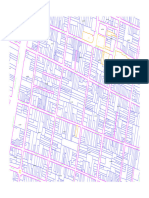

PVC Ø 16

3,00

c.w. c.w.

DRAIN DRAIN 0 DRAIN 5 7

PVC Ø 160

11 07

Ø

07

11

PVC Ø 075 PVC Ø 110 Ø PVC Ø 075 Ø

2,965

2,965

2,965

60 1,565

0

5

5

2,00

5 07

07

4

4 PVC Ø 110

2,00

1,40 Ø c.w.

1,875

1,93

c.w. Ø 40 70 50 PVC Ø 160

1,875

1,00 45 0

Ø

DRAIN RW

11

11

60

c.w.

PVC Ø 110

Ø 160 Ø c.w.

0

G1

3,00

11

c.w. c.w.

12

0

75

64

17

17

c.w.

Ø

185

1,42

405

405

1,05 35

11

1,50

NOTE:

1,96

PVC Ø 160

0

DRAIN RW 1,435

LEGEND 49

2,50

PVC Ø 110

DRAIN

Ø 160

Ø

Ø 110 DRAIN

11

DRAIN

0

THE COLLECTION AND DISTRIBUTION UTILITY LINES SHOWN ON COLD WATER PIPE 2,97 5

59 5

DRAIN PVC Ø 110 PVC Ø 160 c.w.

PVC Ø 160

Ø 110

THIS PLAN ONLY TO THE PERIMETER OF THE BUILDING. PE 80 HD Ø50 x 4,6 mm 60 805 2,495

DRAIN 11

0

DRAIN

11

0 PVC Ø 075

Ø

2,84

sewer ( to septic-tank ) 0 Ø

FOR CONTINUATION SEE SITE UTILITY PLAN Ø 110 Ø

11 DRAIN

52 1,60

sewer ( proces water )

2,06

11

DRAIN

sewer ( rainwater )

Ø

1.3.1 2,965

H

11

2,85

2,85

1.2.9 1.2.10

0

Room number

11

1.2.1. 1.6.4

0

1,815

R.W. Rainwater drain DRAIN DRAIN

935

935

PVC Ø 160

H1

3,05

Drainage for this room to be connected to process line c.w. condensation water drain pipe

27

Since it is emergency slaughter area

475

stainless floor drain DRAIN RW 1,50

1,435

Ø 160

sewerage control 1 2 3 4 5 6 7 8 9 10 DRAIN

Ø

11

DRAIN

PVC Ø 110

0

5

15

Ø

6,00

PVC Ø 110

2,84

11

-7 -6 -5 -5A -4 -3 -2 -1 -1A 0 1A 2A

0

PVC Ø 160

0 To be connected

DRAIN RW

Ø

11

to trench 24,00

Jx 24,535 35,47 I

34

Ø 110

135 DRAIN RW

Ø 160

J2 11

0

J2

26

Ø

21

DRAIN RW PVC Ø 160

Ø 110

2,37

Ø

DRAIN

11

11

3,365

11

0

0

1,515 1,50

2,30 20 1,00 20 2,30 RW lines to be checked

20

6,00

3,03

and confirmed

Is it required if surface

20

Short drainage recomended

20

trenche 95 1,00 20 3,65 J

s was 155

515

DRAIN RW

deleted DRAIN RW

Ø 110

Ø 160

J1 J1

11 11.1 12

245

1,87

21

DRAIN RW

20

1,59 1,00 20 3,01

Ø

11

0

4,84

20

6,00

20

1,27 1,00 20 3,33

Size revised to be of less

PVC Ø 160

depth and width to suit the

requirement with slope of

20

1to1

K1 K1

25

155

collector channel

collector channel

collector channel

collector channel

DRAIN RW

Ø 160

21,695

7,23

6,00

155

DRAIN RW

27

Ø 160

L1 L1

245

37

21

PVC Ø 160

DRAIN RW

DRAIN RW

1,50

24

Ø

11

0

0

11

Dung

Ø

1,00

1,00

4,00

6,00

24

1,50

1.2.1. SLAUGHTERHOUSE DIRTY SIDE

24

24

1,24 24 6,94 24 15 5 1.2.2. STAIRCASE

DRAIN RW 1.2.3. WC

Ø 160

1.2.4. HYGIENE SLUICE

25

M1 M1 1.2.5. FIRST AID

33

DRAIN RW 1.2.6. SLAUGHTERHOUSE CLEAN SIDE

4,86

1.2.7. ACCEPTANCE AREA

1.2.8. CONDEMNED CARCASSES & ORGANS

0

1.2.9. HEADS & LEGS TREATMENT

11

Ø

Dung

4,00

1.2.10. DISPATCH HEADS & LEGS

1.2.11. HYGIENE SLUICE

6,00

1.2.12. WC

1.2.13. STAIRCASE

1,29 9,42 1,29 1.2.14. VETERINARY

1.2.15. LAB. VETERINARY

1.2.16. FIRST AID

9,10

24

1,24 24 6,085 24 1.3.1. CRIPPLE

DRAIN RW DRAIN RW 1.3.2. HYGIENE SLUICE

1.3.3. PRAYER ROOM

-7 -6 N1 N1 1.3.4. BLOOD

21

21

21

DRAIN RW 1.3.5. ELECTRICAL ROOM I.

4,86

1.3.6. HIDE PROCESSING AREA

Ø

11

0

1.3.7. DISPATCH

11

0

Ø

Ø

11

1.3.8. CONFISCATE

56,70

0

1.3.9. NOSE | EAR | FEET

1.3.10. WASHING TROLEYS

1.3.11. CORRIDOR

6,00

1.3.12. COOLING ROOM CASINGS

1.3.13. TRIPERY

52,20

1A 2A 1.3.14. CORRIDOR DISPATCH

0 1.3.15. DISPATCH

1.3.16. DRIVER

1,825 8,35 1,825 1.3.17. OFFICE DISPATCH

DRAIN RW

1.3.18. CORRIDOR

O1 O1 1.3.19. RED ORGANS AND HEAD TREATMENT

21

1.3.20. COOLING ROOM RED ORGANS

215

DRAIN RW

1.3.21. BONES AND FAT

1.3.22. PACKING ROOM RED & WHITE ORGANS

0

11

Ø

1.4.1. CORRIDOR

0

11

Ø

1.4.2. COOLING ROOM I.

1.4.3. COOLING ROOM II.

1.4.4. COOLING ROOM III.

6,00

1.4.5. COOLING ROOM IV.

1.4.6. QUATERING

1.4.7. COOLING ROOM FRESH MEAT

1.4.8. DISPATCH I.

1.4.9. OFFICE DISPATCH

1.4.10. CORRIDOR

DRAIN RW 1.4.11. DRIVER

P1 P1 1.4.12. COOL STORAGE

21

1.4.13. SHOP

21

DRAIN RW

1.5.1. DEBONING

Ø

1.5.2. PACKAGING

11

0

Ø

1,5.3. PACKED MEAT STORAGE

11

0

1.5.4. PREPARATION FREEZING

1.5.5. BLAST FREEZER I.

1.5.6. BLAST FREEZER II.

6,00

1.5.7. FREEZER STORAGE I.

1.5.8. FREEZER STORAGE II.

1.5.9. PREPARATION DISPATCH

1.5.10. DISPATCH II.

1.5.11. STORAGE PACKING MATERIAL

1.5.12. CORRIDOR

DRAIN RW 1.5.13. KNIFE SHARPENING

1.5.14. OFFICE

Q1 Q1 1.5.15. WASHING TROLLEYS

21

215

DRAIN RW 1.5.16. HYGIENE SLUICE

1.5.17. WC LADIES

0

11

1.5.18. WC MAN

Ø

0

11

1.5.19. STAIRCASE

Ø

1.5.20. STORAGE TROLLEYS RED & WHITE OFFAL

1.5.21. SECONDARY PROCESSING

6,00

1.6.1. REFRIGERATION STATION

1.6.2. CLEANNING EQUIPMENT

1.6.3. STAIRCASE

1.6.4. STAIRCASE

1.6.5. ELECTRICAL ROOM III.

1.5.6. ELECTRICAL ROOM II.

Plans for Construction

DRAIN RW

R1 R1

21

21

DRAIN RW

Ø

This drawing constitutes intellectual property rights of the involved planers and companies and may not be

11

0

Ø

copied or made available for whatever purpose to any third party without our prior written consent.

11

0

PROJECT | DESCRIPTION:

New Slaughterhouse & Meat processing Plant

6,00

Cattle slaughterline: 30 - 35 per hour

Sheep slaughterline : 100 - 150 per hour

Cutting & Deboning : 96 quaters per hour

BUILDER OWNER

Algunade For Multiactivities CO.Ltd.

Khartoum | Sudan

PROJECT MANAGEMENT | ARCHITECT:

S1 S1

365

215

27

DRAIN RW 13

DRAIN RW

2,00

2,00

0

11

0

11

24

-5 -5A -4 -3 -2 -1 -1A 3 4 5 6 7 8

Ø

NAME:

SJ

Dung Dung

1,00

1,00

5,00

1,00

5,00

DATE:

Gerster Joschika Architecture

24

26.03.2020

2,00

2,00

Marel Red Meat Slaughtering B.V.

P.O.Box 160 Goetheplatz 2

88214 Ravensburg SCALE:

7130 AD Lichtenvoorde

The Netherlands Germany

Fon: +49 751 3525965

M 1: 100

marel.com/meat stefan@gersterjoschika.de

24

24

24

DRAWING NR.:

1,00 PHASE :

24 1,00 24 10,00 24 2,26

24 24 7,00 24

CONSTRUCTION DOCUMENTS 2017-185-101.10.A

3,93 2,07 6,00 6,00 6,00 2,07 6,00 6,00 6,00 6,00 6,00

DRAWING :

SLAUGHTERHOUSE MAIN BUILDING | LAIRAGE REVISION:

- FLOOR COORDINATIONS PLAN - DRAINAGE - B. | 30.07.2021

GSPublisherVersion 0.0.100.98

Anda mungkin juga menyukai

- Denah Tangki BBC - BPN - ISO - A0rev.Dokumen1 halamanDenah Tangki BBC - BPN - ISO - A0rev.fazril SaputroBelum ada peringkat

- Koordinat Saluran Keliling Rest AreaDokumen1 halamanKoordinat Saluran Keliling Rest AreaUlul Azmi AIBelum ada peringkat

- Peta Induk A3Dokumen1 halamanPeta Induk A3Tomy DewantaraBelum ada peringkat

- Tahap Pembangunan-1Dokumen1 halamanTahap Pembangunan-1Muhammad Mufid Widi ArsandoBelum ada peringkat

- Peta Kabupaten Kebumen Peta Kabupaten Kebumen: Peta Lokasi Peta LokasiDokumen1 halamanPeta Kabupaten Kebumen Peta Kabupaten Kebumen: Peta Lokasi Peta LokasiAkhmad KhoeroniBelum ada peringkat

- Jembatan 1,2dan3-ModelDokumen1 halamanJembatan 1,2dan3-ModelMuslichBelum ada peringkat

- Layout Galangan-Model - PDF KeseluruhanDokumen1 halamanLayout Galangan-Model - PDF KeseluruhannurgiantoBelum ada peringkat

- DD Dadap Timur 1Dokumen8 halamanDD Dadap Timur 1Okdi FranciscoBelum ada peringkat

- Denah Titik Siram Keran Taman r.2Dokumen1 halamanDenah Titik Siram Keran Taman r.2AdhemazBelum ada peringkat

- BLOKPLAN CUR 2 FIX (New)Dokumen1 halamanBLOKPLAN CUR 2 FIX (New)Rizky Dwi PriyandokoBelum ada peringkat

- 11a.akses Quarry Satelit Perumahan Lagon NuansaDokumen1 halaman11a.akses Quarry Satelit Perumahan Lagon Nuansasilmi saelyBelum ada peringkat

- Plan Hydroseeding Seksi 5-64+800-65+175Dokumen1 halamanPlan Hydroseeding Seksi 5-64+800-65+175MHD. FADLIANSYAHBelum ada peringkat

- Utara: Jalan Arteri Surabaya - MalangDokumen1 halamanUtara: Jalan Arteri Surabaya - MalangorganisasiBelum ada peringkat

- Tes LT.1Dokumen1 halamanTes LT.1alif mapajayaBelum ada peringkat

- Map Cluster 3Dokumen1 halamanMap Cluster 3Fathurrizqi RahmanBelum ada peringkat

- Marwati SE - Rumah - Mangga I - Lamper Kidul-Model-3Dokumen1 halamanMarwati SE - Rumah - Mangga I - Lamper Kidul-Model-3lialutfiatur16Belum ada peringkat

- 1 Peta Daerah IrigasiDokumen17 halaman1 Peta Daerah IrigasiUbay Dillah100% (2)

- Leger Metro 1-Imam Bonjol 1Dokumen1 halamanLeger Metro 1-Imam Bonjol 1yudi prastowo (GEODETIC LAMPUNG)Belum ada peringkat

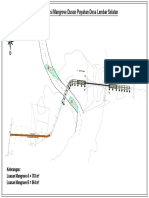

- Layout Pelanggan-Penerima Manfaat Air Desa Lae ItamDokumen1 halamanLayout Pelanggan-Penerima Manfaat Air Desa Lae ItamDaniel TobingBelum ada peringkat

- Contoh Gambar KerjaDokumen1 halamanContoh Gambar KerjaFadli Ahmad ErnasBelum ada peringkat

- Aresta KRNE 0516Dokumen1 halamanAresta KRNE 0516Roni RohadianBelum ada peringkat

- Ar.00.011 Block Plan-Ar.00.011Dokumen1 halamanAr.00.011 Block Plan-Ar.00.011udantoBelum ada peringkat

- 4217 Imb A 0101 Ra Denah TapakDokumen1 halaman4217 Imb A 0101 Ra Denah TapakAdi PriyapurnatamaBelum ada peringkat

- Tes LT.2Dokumen1 halamanTes LT.2alif mapajayaBelum ada peringkat

- Lokasi 2 2010 R2-LayoutDokumen1 halamanLokasi 2 2010 R2-LayoutdhimozaBelum ada peringkat

- Lokasi 1 (STA 0 - STA 40)Dokumen1 halamanLokasi 1 (STA 0 - STA 40)dhimozaBelum ada peringkat

- Mep 008 Instalasi Penerangan Lantai 2 DimensionDokumen1 halamanMep 008 Instalasi Penerangan Lantai 2 DimensionKevin Strife GenesisNamikazeBelum ada peringkat

- X TBSM GenapDokumen29 halamanX TBSM GenapViktor TornandoBelum ada peringkat

- GABUNGANDokumen171 halamanGABUNGANMuhammad Raditya Adjie PratamaBelum ada peringkat

- Detail Pintu 1: Catatan: Posisi Handle & Bukaan Pintu Lihat LayoutDokumen1 halamanDetail Pintu 1: Catatan: Posisi Handle & Bukaan Pintu Lihat LayoutzaynfianBelum ada peringkat

- Update Peta Gabungan 240X120 CM - Revisi Terakhir PDFDokumen1 halamanUpdate Peta Gabungan 240X120 CM - Revisi Terakhir PDFMANGGALA PRINTBelum ada peringkat

- Site Plan PerumahanDokumen1 halamanSite Plan PerumahanherdianBelum ada peringkat

- 4217-Pbg-A-0102-Rb Denah - SituasiDokumen1 halaman4217-Pbg-A-0102-Rb Denah - SituasiAdi Priyapurnatama100% (1)

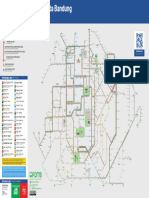

- Angkot BandungDokumen1 halamanAngkot BandungArman YassarBelum ada peringkat

- SILSILAH RB ABDUL MADJID (Mantan Bupati Mojokerto) - BangkalanDokumen1 halamanSILSILAH RB ABDUL MADJID (Mantan Bupati Mojokerto) - BangkalanAbdul Rasjid CakraAdiningrat100% (1)

- Bandung City's "Angkot" Map: LegendaDokumen1 halamanBandung City's "Angkot" Map: LegendaVIRA yaBelum ada peringkat

- Cascading Dinas Perikanan Kutai BaratDokumen1 halamanCascading Dinas Perikanan Kutai BaratArliana Yulianti0% (1)

- DED Irigasi UPTD NgadirejoDokumen9 halamanDED Irigasi UPTD NgadirejoRahmad SulistyawanBelum ada peringkat

- Peta Loteng 3Dokumen1 halamanPeta Loteng 3wendy agustiawanBelum ada peringkat

- 1Dokumen1 halaman1kapm MuaralaweBelum ada peringkat

- Rekod Jadual Ganti 2020Dokumen1 halamanRekod Jadual Ganti 2020LUKMAN BIN MOHAMAD GHAZALI MoeBelum ada peringkat

- NURSE CALL-01-aDokumen1 halamanNURSE CALL-01-aAziz FaizinBelum ada peringkat

- Hard Standing - Smsat .JakbarDokumen1 halamanHard Standing - Smsat .Jakbarpejuang 56Belum ada peringkat

- GasibuuuDokumen1 halamanGasibuuuseftiyandiBelum ada peringkat

- Singgle Line Kota 2019Dokumen1 halamanSinggle Line Kota 2019Wido Okky YanuarBelum ada peringkat

- Kedaulatan Rakjat No 129 Tahun 09 1953 06 09 001Dokumen4 halamanKedaulatan Rakjat No 129 Tahun 09 1953 06 09 001KuniBelum ada peringkat

- PETA TerbaruDokumen1 halamanPETA TerbaruBermudaBelum ada peringkat

- Jalur Pipa Air Baku Mh.01-Mh.30Dokumen1 halamanJalur Pipa Air Baku Mh.01-Mh.30rf140789_20264585Belum ada peringkat

- Formulir Tanpa Judul (Jawaban) PDFDokumen1 halamanFormulir Tanpa Judul (Jawaban) PDFGuru Gahol GarageBelum ada peringkat

- Site Plan RevisiDokumen1 halamanSite Plan RevisidayanaBelum ada peringkat

- FORMAT Catatan Konseling RemajaDokumen2 halamanFORMAT Catatan Konseling RemajaIin MuthmainnahBelum ada peringkat

- DrawingDokumen2 halamanDrawingDani Zoldyck MorahamaBelum ada peringkat

- Petunjuk Arah Rest AreaDokumen1 halamanPetunjuk Arah Rest AreaAfrianda PutraBelum ada peringkat

- Tonala 01Dokumen1 halamanTonala 01Anonymous qlLQozR9Belum ada peringkat

- Luwuk Banggai Topo Map PDFDokumen1 halamanLuwuk Banggai Topo Map PDFAwal Oeddink100% (1)

- Partitura de HavannaDokumen18 halamanPartitura de HavannaPedro LopezBelum ada peringkat

- Layout TubaraoDokumen1 halamanLayout TubaraoFabio Souza BastosBelum ada peringkat

- Relokasi Mangrove (Alur Sungai Puyahan)Dokumen1 halamanRelokasi Mangrove (Alur Sungai Puyahan)CV.PRIMA DESAIN KONSULTANBelum ada peringkat

- Data Lahan: UtaraDokumen1 halamanData Lahan: Utaradendy ridhoBelum ada peringkat