Drop Off Bentang Panjang

Drop Off Bentang Panjang

Diunggah oleh

Ach RofiiHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Drop Off Bentang Panjang

Drop Off Bentang Panjang

Diunggah oleh

Ach RofiiHak Cipta:

Format Tersedia

PERHITUNGAN ATAP KANOPI DROP OFF grid G/J~24/25

I. DATA PERENCANAAN

Referensi

Peraturan Perencanaan bagunan baja indonesia (PPBBI)

PPI untuk gedung 1983

Metode AISC ASD

Shop drawing ST 03 03 W0

Shop drawing ST 03 01 W0

Data material ST 37

1. Tegangan ijin dasar

2. Tegangan geser ijin

3. Tegangan tarik ijin

Bentang

4.jarak bentang

5.Jarak gording

6.Sudut atap

II. BEBAN RENCANA

a. Beban mati (DL)

Beban merata

Beban atap kaca =

Berat hollow 50.50.2.3 =

Berat rangka kaca =

Beban asesoris =

1600 kg/cm

2

960 kg/cm

2

1120 kg/cm

=

t=

tr =

=

=

=

25.8 kg/m2

3.34 kg/m

1 kg/m

10 % berat total

14 m

1.4 m

5

= 25.8 kg/m2x1.4 / cos

3.34 kg/mx1.4 / cos

=

1 kg/mx1.4

/ cos

= 36.25797 kg/m

=

4.676 kg/m

= 1.405348 kg/m

= 4.093397 kg/m

total

46.43 kg/m

Beban sendiri rangka dihitung secara otomatis pada Staad pro

b.

c.

d.

e.

Beban air hujan (H)

Tebal air hujan 0.5 cm

=

=

x1.4

Beban hidup (LL)

beban Pekerja 100 kg

Beban angin (WL)

W=

40

kg/m2

Koefisien angin tekan

C tekan = -1.2

W tekan = C x 40 kg/m2

Combinasi pembebanan

1.4 DL

1.2 DL + 1.6 LL

1.2 DL + 1.6 LL + 0.5 H

1.2 DL + 1 LL+ 0.8 WL

1.2 DL + 0.5 LL+1.3 WL

=

=

5 kg/m2

7 kg/m

100 kg

=

=

-1.2

-48 kg/m

(daerah dekat pantai)

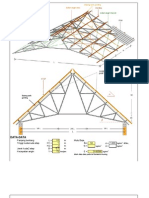

IV. PEMODELAN STRUKTUR

Gbr.1 Dimensi struktur

Gbr.2 penomoran beam

Gbr.3 penomoran nodal

IV. HASIL ANALISA

Dari analisa menggunakan alat bantu program Staad pro,diperoleh gaya dalam yang terjadi dan

perhitungan dimensi yang diperlukan menggunakan metode AISC ASD dengan ratio tegangan ijin

kurang dari 0.95

Summary gaya dalam yang terjadi

Beam

L/C

19

19

19

19

41

41

40

1

8

8

1

8

1

41

1

8

40

41

40

40

53

54

53

54

54

53

54

53

54

53

53

54

54

53

54

53

1

8

8

1

8

1

1

8

41

41

40

41

40

41

40

40

19

19

19

19

Node

(kg)

8

7

5

6

8

7

8

8

8

6

6

5

5

5

7

7

7

6

5

6

8

8

7

7

5

5

6

6

6

6

5

5

7

7

8

8

5

5

6

6

7

7

8

8

6

5

6

7

5

8

7

8

6

5

7

8

Axial

Force (kg)

16

16

16

16

26

26

21

35

37

37

35

37

35

26

35

37

21

26

21

21

40

41

40

41

41

40

41

40

39

39

39

39

39

39

39

39

20

30

30

20

30

20

20

30

31

31

26

31

26

31

26

26

25

25

25

25

6193.519

5581.877

4472.257

3925.538

37.702

33.586

37.702

5193.384

5193.384

3590.312

3590.312

3939.438

3939.438

25.521

4689.129

4689.129

33.586

22.554

25.521

22.554

-6325.494

-6325.494

-5703.076

-5703.076

-4570.472

-4570.472

-4004.722

-4004.722

4004.722

4004.722

4570.472

4570.472

5703.076

5703.076

6325.494

6325.494

-3925.511

-3925.511

-3578.374

-3578.374

-4677.192

-4677.192

-5181.447

-5181.447

-22.554

-25.521

-22.554

-33.586

-25.521

-37.702

-33.586

-37.702

-3913.601

-4458.33

-5569.94

-6181.582

Shear-Y

(kg)

1687.142

1506.096

1225.801

1144.263

559.543

501.244

508.996

216.497

216.497

241.462

241.462

250.166

250.166

379.693

209.644

209.644

458.096

324.497

357.336

307.242

2.187

2.187

2.045

2.045

2.026

2.026

1.863

1.863

-1.863

-1.863

-2.026

-2.026

-2.045

-2.045

-2.187

-2.187

-91.291

-91.291

-105.283

-105.283

-73.465

-73.465

-80.318

-80.318

307.242

357.336

324.497

458.096

379.693

508.996

501.244

559.543

-1008.085

-1066.926

-1369.917

-1550.963

Shear-Z

(kg)

0

0

0

0

-61.331

-55.346

61.331

-873.461

873.461

573.756

-573.756

656.148

-656.148

-44.407

-793.04

793.04

55.346

-38.78

44.407

38.78

-1.443

1.443

-1.282

1.282

0.903

-0.903

0.749

-0.749

-0.749

0.749

0.903

-0.903

-1.282

1.282

-1.443

1.443

656.148

-656.148

-573.756

573.756

-793.04

793.04

873.461

-873.461

38.78

44.407

-38.78

55.346

-44.407

61.331

-55.346

-61.331

0

0

0

0

Torsion Moment-Z

(knM)

(knM)

0

0

0

0

0.906

0.806

-0.91

20.26

-20.3

-12.2

12.24

-14.2

14.19

0.598

18.22

-18.2

-0.81

0.517

-0.6

-0.52

-0.11

0.11

-0.1

0.099

0.075

-0.08

0.064

-0.06

-0.06

0.064

0.075

-0.08

-0.1

0.099

-0.11

0.11

-14.2

14.19

12.24

-12.2

18.22

-18.2

-20.3

20.26

-0.52

-0.6

0.517

-0.81

0.598

-0.91

0.806

0.906

0

0

0

0

38.265

33.999

26.298

23.972

5.703

5.078

3.968

3.954

3.954

3.792

3.792

3.717

3.717

3.697

3.62

3.62

3.597

3.131

2.929

2.539

0.192

0.192

0.176

0.176

0.154

0.154

0.138

0.138

0.022

0.022

0.02

0.02

-0.001

-0.001

-0.005

-0.005

-1.373

-1.373

-1.412

-1.412

-1.676

-1.676

-1.916

-1.916

-2.539

-2.929

-3.131

-3.597

-3.697

-3.968

-5.078

-5.703

-9.197

-10.56

-14.256

-16.037

V.

CEK LENDUTAN

Lendutan yang terjadi akibat beban kombinasi permanen

a.

Batang utama kantilever (dia.nominal 250 std.60)

f ijin = 2x L/240

=

2x8100/240

67.5 mm

f terjadi =

12 mm

....OK

Batang gording (dia.nominal 150 std.40)

f ijin = L/240

=

7000/240

29.17 mm

f terjadi =

25.69 mm

Batang tarik (dia.nominal 90 .10S)

f ijin = L/240

=

36.46 mm

b.

c.

f terjadi =

17 mm

....OK

8750/240

....OK

Hasil analisa Staad pro Ratio tegangan ijin Terlampir

Anda mungkin juga menyukai

- Struktur Baja LanjutDokumen89 halamanStruktur Baja Lanjutherdi_84Belum ada peringkat

- Modul 5 Sesi 4 Balok TerlenturDokumen13 halamanModul 5 Sesi 4 Balok TerlenturTaufiq HJBelum ada peringkat

- Gelagar IndukDokumen22 halamanGelagar IndukSeptiawan ArifinBelum ada peringkat

- Dimensi Ring Balok 12 MeterDokumen54 halamanDimensi Ring Balok 12 MeterAnonymous zL5Rstx6mBelum ada peringkat

- UTS Baja NewDokumen27 halamanUTS Baja NewBurhanudin KomalaBelum ada peringkat

- Tugas Perencanaan Rangka Atap BajaDokumen16 halamanTugas Perencanaan Rangka Atap BajaRosario JeniasBelum ada peringkat

- Merencana BajaDokumen49 halamanMerencana BajaPrastika Wahid Santoso100% (1)

- JembatanDokumen9 halamanJembatanbudianduk5094Belum ada peringkat

- Perhitungan Base Plate AngkurDokumen49 halamanPerhitungan Base Plate Angkurharisnurjamanridwan86% (7)

- Laporan Perhitungan Struktur RukoDokumen92 halamanLaporan Perhitungan Struktur RukoJefta 'Pato' Patola100% (5)

- 01-Perenc Gording PDFDokumen12 halaman01-Perenc Gording PDFZizil Luph PapiBelum ada peringkat

- Baja Am Prin.Dokumen59 halamanBaja Am Prin.iammonata100% (1)

- PERENCANAAN Gudang BajaDokumen66 halamanPERENCANAAN Gudang BajaArdhy Civilians100% (8)

- Formula Balok Precast (Masif)Dokumen6 halamanFormula Balok Precast (Masif)YusufBelum ada peringkat

- Hitung Gudang Jembatan Kolam TandonDokumen24 halamanHitung Gudang Jembatan Kolam TandonBilly Harel TawaangBelum ada peringkat

- Perhitungan Pembebanan Proyek Hotel 5 LantaiDokumen39 halamanPerhitungan Pembebanan Proyek Hotel 5 LantaiLeonhart HeartilyBelum ada peringkat

- Bab III AnalisisDokumen19 halamanBab III AnalisisSanti NurhayatiBelum ada peringkat

- Perencanaan Rangka Atap BajaDokumen63 halamanPerencanaan Rangka Atap Bajaes2345100% (2)

- Laporan Praktikum Kelompok A-39Dokumen114 halamanLaporan Praktikum Kelompok A-39ais82603Belum ada peringkat

- Sni 7973 2013Dokumen10 halamanSni 7973 2013Mohammad Abdul RohmanBelum ada peringkat

- Bab 4 An Struktur AtapDokumen49 halamanBab 4 An Struktur AtapAinul YaqienBelum ada peringkat

- Latihan Coba2Dokumen31 halamanLatihan Coba2Sandro Nainggolan BrabBelum ada peringkat

- Contoh Laporan Lab Beton Teknik Sipil ExelDokumen104 halamanContoh Laporan Lab Beton Teknik Sipil ExelUmam PoraBelum ada peringkat

- Perhitungan Struktur Gedung Lantai 2Dokumen35 halamanPerhitungan Struktur Gedung Lantai 2Zaka Riyadi, ST100% (2)

- Hitung Tangga PrecastDokumen28 halamanHitung Tangga PrecastFakhrurozi FaniBelum ada peringkat

- 2027 Chapter Va Perhitungan BajaDokumen61 halaman2027 Chapter Va Perhitungan BajaekosipilumBelum ada peringkat

- Pelat LantaiDokumen10 halamanPelat LantaiChusnul AyuBelum ada peringkat

- Perencanaan Rangka Atap BajaDokumen37 halamanPerencanaan Rangka Atap BajaReinetta Imbarwati89% (9)

- Fixperhitungan Jangkar Dan Tali Tambat EdyDokumen12 halamanFixperhitungan Jangkar Dan Tali Tambat Edythegik100% (1)