(W-PD-SL-CEM006) Armature Page1

(W-PD-SL-CEM006) Armature Page1

Diunggah oleh

SumaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

(W-PD-SL-CEM006) Armature Page1

(W-PD-SL-CEM006) Armature Page1

Diunggah oleh

SumaHak Cipta:

Format Tersedia

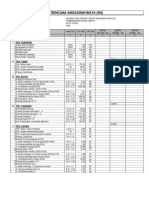

CHECKING AND SELECTION WORK INSTRUCTION

Customer Name CANON ELECTRONICS (M) Reference Number W-PD-SL-CEM006

Part Name ALL ARMATURE PART Part Number ALL ARMATURE PART

A. STONE CHECK

Langkah-langkah Pemeriksaan Batu

1. Keluarkan part dari beg plastik dan letakkan di atas meja. Untuk proses

ini, pin gauge perlu digunakan untuk membuang batu pada part.

1. Take out part from plastic bag. For stone check process

2. Periksa appearance part tersebut. Pastikan tiada batu terlekat

pada part dan part reject seperti sticking.

2. Check appearance . Make sure no stone sticking on part

* Jika terjumpa part batu dan sticking, pengasingan perlu dilakukan.

Asingkan part tersebut ke dalam bekas-bekas yang disediakan.

* If found part and stone sticking , separate defect part into provided

container

CONTOH GAMBAR

'BATU'

BEKAS 'BATU' BEKAS REJECT EX. STICKING

3. Untuk memeriksa permukaan belakang part, plat bermagnet perlu

digunakan dengan cara meletakkannya ke atas part.

3. Use plate magnet to check bottom side part

Angkat plat tersebut dan periksa permukaan belakang setiap part

tersebut. Pastikan tiada reject seperti yang telah dinyatakan di atas.

Hold the plat magnet and check bottom surface part

Langkah-langkah Pembuangan Batu

4.1 Keluarkan part dari bekas 'BATU'.

4.1 take out part

4.2 Buang batu yang terdapat di celah-celah lubang part

menggunakan pin gauge. (lihat gambar sebelah)

4.2 Remove the stone from part

4.3 Pastikan part bersih dari sebarang batu.

4.3 Make sure part clean from stone

5a. Setelah semua part dibuang batu dan wajib check part tersebut dibawah

magnifying glass

5a. After take out the stone from part, please check back part under

magnifying glass

Date Rev. Revise Reason Prepared by : Checked by : Approved by:

24/02/2021 /6\ Standardize NG Container

MPD MPD MPD

07/02/2022 /7\ Revise no.13 Add in defect picture (Hole burr) PROD PACKING PROD

11/09/2022 /8\ Add in check point no. 5 and no 6. Add in NG photo 11 SEP 2022 11 SEP 2022 11 SEP 2022

/9\ KHALIL NATHAN

YATHIRAJ

/10\

CHECKING AND SELECTION WORK INSTRUCTION

Customer Name CANON ELECTRONICS (M) Reference Number W-PD-SL-CEM006

Part Name ALL ARMATURE PART Part Number ALL ARMATURE PART

5b. pastikan part yang selesai process buang batu bebas dari semua defect

asing jika part tersebut ada defect seperti gambar dibawah

5b. make sure no defect allowed that after stone takeout process, please

separate the defect to defect container

EXAMPLE

CB3-8713

NG

OK SCRATCHES

6. Kesemua part yang telah diperiksa dan didapati tidak mengalami

sebarang reject akan dimasukkan ke dalam bekas yang berlabel

OK.

6. After selection, put All selection part (OK part) into OK container

Date Rev. Revise Reason Prepared by : Checked by : Approved by:

24/02/2021 /6\ Standardize NG Container MPD MPD MPD

07/02/2022 /7\ Revise no.13 Add in defect picture (Hole burr) PROD PACKING PROD

11/09/2022 /8\ Add in check point no. 5 and no 6. Add in NG photo 11 SEP 2022 11 SEP 2022 11 SEP 2022

/9\ YATHIRAJ KHALIL NATHAN

/10\

Matomek Precision Die Sdn.Bhd. (214140-K) Page 2 of 4

CHECKING AND SELECTION WORK INSTRUCTION

Customer Name CANON ELECTRONICS (M) Reference Number W-PD-SL-CEM006

Part Name ALL ARMATURE PART Part Number ALL ARMATURE PART

B. APPEARANCE CHECK

7. Operator perlu memakai hand-glove dan finger coat sebelum

menjalankan proses 'Checking and Selection'.

7. Operator must wearing glove and finger coat before do the

'Checking and Selection'.

8. Keluarkan part dari beg plastik dan periksa rusty dan dented

pada part.

8. Take out part from plastic bag and check rusty, Dented and others

defect on part

9. Gunakan plat bermagnet untuk memeriksa permukaan belakang part.

Pastikan tiada rusty atau dented pada permukaan part.

9. Use magnet plate to check at bottom side part.

10. Part yang mengalami reject perlu diasingkan dan dimasukkan ke dalam

bekas yang telah disediakan.

10. Put the defect part into provided container

11. Kesemua part yang telah diperiksa dan didapati tidak mengalami

sebarang reject akan dimasukkan ke dalam bekas yang berlabel

OK.

11. After selection, put All selection part (OK part) into OK container

Date Rev. Revise Reason Prepared by : Checked by : Approved by:

24/02/2021 /6\ Standardize NG Container

MPD MPD MPD

07/02/2022 /7\ Revise no.13 Add in defect picture (Hole burr) PACKING PROD

PROD

11/09/2022 /8\ Add in check point no. 5 and no 6. Add in NG photo 11 SEP 2022 11 SEP 2022

11 SEP 2022

/9\ KHALIL NATHAN

YATHIRAJ

/10\

Matomek Precision Die Sdn.Bhd. (214140-K) Page 3 of 4

CHECKING AND SELECTION WORK INSTRUCTION

Customer Name CANON ELECTRONICS (M) Reference Number W-PD-SL-CEM006

Part Name ALL ARMATURE PART Part Number ALL ARMATURE PART

C. APPEARANCE CHECK

Pemeriksaan Mikroskop

12. Operator must wearing glove and finger coat before do the

'Checking and Selection'.

13. Keluarkan part dari beg plastik dan masukkan ke dalam bekas

yang disediakan.

13. Take out part from plastic bag

14. Periksa appearance part tersebut menggunakan Mikroskop 10X.

Pastikan tiada reject seperti berikut:

Hole Burr

14. Check appearance part use Microscope 10X.

Make sure no Defect part as per below:

a. Stain c. Scratches

b. Dented d. Hole Burr

* Sila rujuk 'IMPORTANT APPEARANCE CHECKING

METHOD' yang dilampirkan (W-QA-A002)

15. Jika terjumpa part yang reject, pengasingan perlu dilakukan.

Asingkan part yang reject ke dalam bekas-bekas yang disediakan.

15. Put the defect part into provided container

STAIN DENTED SCRATCHES OTHERS

16. Kesemua part yang telah diperiksa dan didapati tidak mengalami

sebarang reject akan dimasukkan ke dalam bekas yang berlabel

OK.

16. After selection, put All selection part (OK part) into OK container

Date Rev. Revise Reason Prepared by : Checked by : Approved by:

24/02/2021 /6\ Standardize NG Container

MPD MPD MPD

07/02/2022 /7\ Revise no.13 Add in defect picture (Hole burr) PROD PACKING PROD

11/09/2022 /8\ Add in check point no. 5 and no 6. Add in NG photo 11 SEP 2022 11 SEP 2022 11 SEP 2022

/9\ KHALIL NATHAN

YATHIRAJ

/10\

Matomek Precision Die Sdn.Bhd. (214140-K) Page 4 of 4

Anda mungkin juga menyukai

- Job Safety AnalysisDokumen3 halamanJob Safety AnalysisAenul Nul100% (9)

- Metode GroutingDokumen13 halamanMetode GroutingFaujia HamidBelum ada peringkat

- SILO RTC Kobelco RK500 Kap 50 Ton Expired 01 Desember 202101Dokumen24 halamanSILO RTC Kobelco RK500 Kap 50 Ton Expired 01 Desember 202101Hendrias Ari SujarwoBelum ada peringkat

- SOP - Coal - 2015 - Rev 8Dokumen46 halamanSOP - Coal - 2015 - Rev 8Indrasmaya Adi100% (1)

- Metode Kerja Stone MasonryDokumen9 halamanMetode Kerja Stone Masonryqc ps2bBelum ada peringkat

- Pemasangan LRBDokumen19 halamanPemasangan LRBFarhan Fadhillah100% (1)

- JSA Mengganti Swing Circle Rusak Exc 012Dokumen3 halamanJSA Mengganti Swing Circle Rusak Exc 012irfan100% (2)

- Metode Ground AnchorDokumen21 halamanMetode Ground Anchoraresrestur100% (1)

- Metode Diafragma WallDokumen23 halamanMetode Diafragma WallHafiz Bahtiar0% (1)

- Quality Control Plan FinalDokumen50 halamanQuality Control Plan FinalDindin SholahuddinBelum ada peringkat

- 001 - Fin - Dinding Bata (Sardju) R02Dokumen4 halaman001 - Fin - Dinding Bata (Sardju) R02Wahyu WidiatmikaBelum ada peringkat

- KoplingDokumen10 halamanKoplingNike Nur FaridaBelum ada peringkat

- 5.slide Penggantian PanelDokumen53 halaman5.slide Penggantian PanelAkhmad Afif FaridBelum ada peringkat

- PengecoranDokumen1 halamanPengecoranFiki FajerinBelum ada peringkat

- Stage Plan - Installasi Culvert KM 73+400Dokumen15 halamanStage Plan - Installasi Culvert KM 73+400hengki sahanaBelum ada peringkat

- 3.form - Inspection - Report - Tumang Lor PijeranDokumen24 halaman3.form - Inspection - Report - Tumang Lor Pijeransharonfifa22Belum ada peringkat

- Jobsheet 1 & 2 NewDokumen12 halamanJobsheet 1 & 2 NewMahirezqiBelum ada peringkat

- Modul 12Dokumen11 halamanModul 12Cowo Rasa AlpukatBelum ada peringkat

- Lampiran BOQ MulyasariDokumen5 halamanLampiran BOQ MulyasariAdetiya KurniawanBelum ada peringkat

- PengecoranDokumen1 halamanPengecoranFiki FajerinBelum ada peringkat

- Optimalisasi PurifierDokumen12 halamanOptimalisasi Purifieryustina dwiBelum ada peringkat

- Laporan DiferensialDokumen11 halamanLaporan DiferensialDerizkaBelum ada peringkat

- Job Sheet DifferentialDokumen3 halamanJob Sheet DifferentialAnjing KacuBelum ada peringkat

- Work Method Statement U-DitchDokumen16 halamanWork Method Statement U-DitchMartinus EliantoBelum ada peringkat

- Contoh Pelaksanaan Uji Kelayakan Tangki TImbunDokumen28 halamanContoh Pelaksanaan Uji Kelayakan Tangki TImbunWidi Satria UtamaBelum ada peringkat

- Roda Dan Ban - 5202418007 - Teguh KurniawanDokumen8 halamanRoda Dan Ban - 5202418007 - Teguh KurniawanTeguh KurniawanBelum ada peringkat

- Summary MF 17Dokumen1 halamanSummary MF 17samsudinnor winataBelum ada peringkat

- Karburator JobshetDokumen5 halamanKarburator Jobshetdwi ahmad arif100% (1)

- BAB 2 Paving Block KEL 3Dokumen16 halamanBAB 2 Paving Block KEL 3Fazrul Fauzan MunadiBelum ada peringkat

- DhfgoDokumen20 halamanDhfgoDwiki PangestikoBelum ada peringkat

- 17-01-2023 - Quality Emergency Meeting - Follow Up Trouble SheetDokumen3 halaman17-01-2023 - Quality Emergency Meeting - Follow Up Trouble Sheetvina leviantyBelum ada peringkat

- DIFFERENTIAL - 5202418007 - Teguh KurniawanDokumen9 halamanDIFFERENTIAL - 5202418007 - Teguh KurniawanTeguh KurniawanBelum ada peringkat

- Summary MF 17Dokumen1 halamanSummary MF 17samsudinnor winataBelum ada peringkat

- Ceklist Area Bobok BalokDokumen4 halamanCeklist Area Bobok BalokJadi FriendBelum ada peringkat

- Prosedur Dan Teknik Pembuatan Dan Pemasangan PembesianDokumen83 halamanProsedur Dan Teknik Pembuatan Dan Pemasangan Pembesiansjp cahya4Belum ada peringkat

- Jobsheet GardanDokumen2 halamanJobsheet Gardanafrizalbahri365Belum ada peringkat

- Metode Bore PileDokumen18 halamanMetode Bore PileHambali PutraBelum ada peringkat

- TWJO ITP GEN 0003 CHK 001revd Concrete Pour Checklist (Eng Ind)Dokumen2 halamanTWJO ITP GEN 0003 CHK 001revd Concrete Pour Checklist (Eng Ind)Bangkit SamosirBelum ada peringkat

- 8a Pengencangan Baut Final 1 PDFDokumen14 halaman8a Pengencangan Baut Final 1 PDFadi setya0% (1)

- U2003-004-DAP-C07-N0005 Metode Pile Head Mooring Dolphin Rev1ADokumen6 halamanU2003-004-DAP-C07-N0005 Metode Pile Head Mooring Dolphin Rev1Adata.dwardhanaBelum ada peringkat

- Instruksi Dan Daftar Simak PengawasanDokumen64 halamanInstruksi Dan Daftar Simak Pengawasana.umbara.mkBelum ada peringkat

- Instrumen UKK - SpooringDokumen2 halamanInstrumen UKK - SpooringRidwanBelum ada peringkat

- Amali 2 PojanDokumen8 halamanAmali 2 PojanIskandar IrwanBelum ada peringkat

- LaporanInspeksi 121605 2022080810Dokumen4 halamanLaporanInspeksi 121605 2022080810Mca DjiBelum ada peringkat

- ART1Dokumen19 halamanART1Heru HermansyahBelum ada peringkat

- Jobsheet Distributor 20504244003 Khaisal AffandiDokumen4 halamanJobsheet Distributor 20504244003 Khaisal AffandiDavid Yanuar Ade Saputra davidyanuar.2020Belum ada peringkat

- Laporan Hasil Pemeriksaan Dan PengujianDokumen21 halamanLaporan Hasil Pemeriksaan Dan PengujianHeru HermansyahBelum ada peringkat

- List Pengecekan PLAT S1Dokumen1 halamanList Pengecekan PLAT S1MahardikaBelum ada peringkat

- Teknologi BahanDokumen15 halamanTeknologi BahanSaima Putrini R HarahapBelum ada peringkat

- Instrumen UKK - SpooringDokumen2 halamanInstrumen UKK - SpooringRIDWAN PENAWALIBelum ada peringkat

- Job Sheet Servis Ban, Roda Dan Rantai TSMDokumen7 halamanJob Sheet Servis Ban, Roda Dan Rantai TSMRahma DaniBelum ada peringkat

- GardnDokumen21 halamanGardnpak khozBelum ada peringkat

- Loading Coal DG Excavator 350Dokumen3 halamanLoading Coal DG Excavator 350she.itu.admoBelum ada peringkat

- BQ SMP 9rabDokumen3 halamanBQ SMP 9rabganestia dewiBelum ada peringkat

- List Pengecekan BALOK B1 FIBDokumen1 halamanList Pengecekan BALOK B1 FIBMahardikaBelum ada peringkat

- Uraian Singkat Pelaksanaan PekerjaanDokumen4 halamanUraian Singkat Pelaksanaan Pekerjaankhairasakiah.ling.272Belum ada peringkat

- Test Commisioning GondolaDokumen5 halamanTest Commisioning GondolaadiBelum ada peringkat

- @TX - Spek 2018 Rev.2 - SEKSI 6-2 BURDA BURTUDokumen15 halaman@TX - Spek 2018 Rev.2 - SEKSI 6-2 BURDA BURTURIZAL prastomoBelum ada peringkat

- MHS10-MGOQC-SOP-004 Clean Up Ore Dari OB Silica Backhoe Cat 320-Rev03Dokumen4 halamanMHS10-MGOQC-SOP-004 Clean Up Ore Dari OB Silica Backhoe Cat 320-Rev03Mulya Bayu BangsawanBelum ada peringkat