Pt. BBG G 2500 - Proyek Pengadaan Mrs g2500 Operasi Jawa Timur - Tw-Evc1 - WFC - Print - Out

Diunggah oleh

adjiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pt. BBG G 2500 - Proyek Pengadaan Mrs g2500 Operasi Jawa Timur - Tw-Evc1 - WFC - Print - Out

Diunggah oleh

adjiHak Cipta:

Format Tersedia

WIKA Alexander Wiegand SE & Co.

KG

Pressure and

Temperature Measurement

Customer: PT. BBG G 2500 Name: ADJI

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Strae

Project: PROYEK PENGADAAN MRS G2500 OPERASI

Date: JAWA TIMUR

05/05/2014

63911 Klingenberg

Ref. -No.: Reference

phone: +49 9372 132-0

fax: +49 9372 132-406

Calculation email: info@wika.de

Tag-No.: TW-EVC1

result:

good web: http://www.wika.de

WIKA thermowell calculation program v2.2

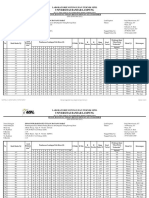

Results to ASME PTC 19.3 TW - 2010

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42

Description Description

WIKA / ASME WIKA / ASME

Result: Process data: 0

Result Eval. good Temperature T 50,00 C

Frequency ratio r 0,25 fw/fnc Pressure P 5,00 bar

Ratio limit fw/fnc rmax_ 0,40 inline? Max.velocity v 12,34 m/s

Safety fatigue dyn 45,65 / Med.density rho 21,14 kg/m3

Safety bending stat 362,83 / Dyn.viscosity eta mm2/s

Safety pressure Sp 81,32 /

Reduced length (rmax) Ured / Lred mm

Note code /

Pipe data:

Inner diameter Di 254,000 mm

Shielded length SL / Lo mm

Usable nozzle length *) UNL / mm

Nozzle inner diameter *) NID / mm

*) for support collar

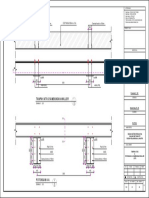

Thermowell sketch

Thermowell data:

WIKA model TW15 Name

Connection screwed

Shape tapered Name

Insertion length U/L 152,000 mm

New insertion length Unew / mm

Reduced length Ured / mm

Stepped length US / Ls 0,000 mm

Step radius RS / rB 0,000 mm

Root radius RQ / rA 0,000 mm

Bore diameter B / db 6,600 mm

Root diameter Q/B 22,000 mm

4a aw taperedV / TW15,

Tip diameter A 16,000TW50

mm

Tip thickness Tt / Tt 6,400 mm

Material data:

Grade mat 316L Name

Spec. weight D(T) 7,999 kg/dm3

Youngs modul E(T) 192,9 GPa

Factor for temp. FT 0,982 /

Fatigue strength Sf(T) 36,5 MPa

Max.all.stress 1.5S(T) 167,0 MPa

Press. strength S(T) 111,4 MPa

Fatigue class class B

WIKA has made every reasonable attempt to validate the calculation procedure contained in this spread sheet, however, responsibility for validation rests solely with the user.

This WIKA ASME PTC 19.3 TW 2010 spread sheet copyright 2010 (compatible with Excel 2007/2010) is intended to assist the experienced designer of thermowells and should

not be considered as a replacement for professional engineering.The end user is responsible to assure that the calculation method is compatible to the process conditions.

For further information see Operation Instruction.

Anda mungkin juga menyukai

- Spesifikasi Material ElektrikalDokumen6 halamanSpesifikasi Material ElektrikalSAMUELBelum ada peringkat

- KWI SL WeldingDokumen26 halamanKWI SL WeldingRiki GanaBelum ada peringkat

- Cek Alat Listrik Harian (Angle Grinder Machine)Dokumen5 halamanCek Alat Listrik Harian (Angle Grinder Machine)maryamBelum ada peringkat

- MEP Panel MuliaDokumen4 halamanMEP Panel MuliasarochimBelum ada peringkat

- Verifikasi Alat AgustDokumen6 halamanVerifikasi Alat Agustarifin salehBelum ada peringkat

- Cek Alat Listrik Harian (Hand Drill Machine)Dokumen6 halamanCek Alat Listrik Harian (Hand Drill Machine)maryamBelum ada peringkat

- Pengelasan PipaDokumen5 halamanPengelasan PipaMuhammad Luthfi NaufalBelum ada peringkat

- PANEL UJI FUNGSIDokumen3 halamanPANEL UJI FUNGSIMuhammad Nico PermanaBelum ada peringkat

- REKAPITULASI PRE CASTDokumen1 halamanREKAPITULASI PRE CASTMajid abdulBelum ada peringkat

- Cek Alat Listrik Harian (Speed Cutter Machine No 1)Dokumen2 halamanCek Alat Listrik Harian (Speed Cutter Machine No 1)maryamBelum ada peringkat

- 074 - SURAT PENGAJUAN ULANG SHOP DRAWING JAKADENDA-signedDokumen6 halaman074 - SURAT PENGAJUAN ULANG SHOP DRAWING JAKADENDA-signedJoeNindyaBelum ada peringkat

- KARAKTERISTIK FETDokumen8 halamanKARAKTERISTIK FETAnnisa Suci AndariniBelum ada peringkat

- Chemical AnchorDokumen1 halamanChemical AnchorFarid HamdaniBelum ada peringkat

- CHECKLIST CAPASITORDokumen12 halamanCHECKLIST CAPASITORFajar Ismoyo100% (2)

- DESIGN CALCULATION OF VENTILATION AND AIR CONDITIONING SYSTEM-signed R2 - ADokumen8 halamanDESIGN CALCULATION OF VENTILATION AND AIR CONDITIONING SYSTEM-signed R2 - ABidang Dalkon QAQCBelum ada peringkat

- Data Pemeliharaan Rutin RshuDokumen4 halamanData Pemeliharaan Rutin Rshuwahyu yulianiBelum ada peringkat

- Spring 2Dokumen1 halamanSpring 2Rafael KusumaBelum ada peringkat

- Form Test WelderDokumen18 halamanForm Test WelderRizaldi Akhmad SungkawaBelum ada peringkat

- Hammer TestDokumen41 halamanHammer TestkameliaBelum ada peringkat

- Tugas Elektronika Daya - Dandi Rama Hidayat - g1d019007Dokumen9 halamanTugas Elektronika Daya - Dandi Rama Hidayat - g1d019007rolanda m alfatihBelum ada peringkat

- OCO Barata Bay Segoro 1Dokumen1 halamanOCO Barata Bay Segoro 1engineering uptgrkBelum ada peringkat

- Definisi DiodaDokumen8 halamanDefinisi DiodaAhmad ZainiBelum ada peringkat

- TAE4X2C OYTV89znpj0S1W4m3fkiiZkT4ryUufvg4OqvvJOMMgpeTyxuKVnw99kZ0W32 UsPwrR3lCRNtwy7cGAAGwg4tkDOcu2hOtxprRV6 (Recovered)Dokumen14 halamanTAE4X2C OYTV89znpj0S1W4m3fkiiZkT4ryUufvg4OqvvJOMMgpeTyxuKVnw99kZ0W32 UsPwrR3lCRNtwy7cGAAGwg4tkDOcu2hOtxprRV6 (Recovered)Tommy AriyantoBelum ada peringkat

- ID Analisa Kegagalan Blade Baris Terakhir PDokumen6 halamanID Analisa Kegagalan Blade Baris Terakhir PNofri KurniaBelum ada peringkat

- PRAKTIK TEKNIK PENGELASAN LANJUT Proses Sambungan T LAs GMAWDokumen7 halamanPRAKTIK TEKNIK PENGELASAN LANJUT Proses Sambungan T LAs GMAWFakhri IqbalBelum ada peringkat

- MOS-FETDokumen8 halamanMOS-FETBanGkit ChenelBelum ada peringkat

- LEGENDA ELEKTRIKDokumen8 halamanLEGENDA ELEKTRIKZeps SaepudinBelum ada peringkat

- Penyearah Setengah Gelombang Dengan Beban Tahanan MurniDokumen4 halamanPenyearah Setengah Gelombang Dengan Beban Tahanan MurniSubandi Saputra StrongholdBelum ada peringkat

- Temuan Thermografi CCWP 1A PLTU TembilahanDokumen1 halamanTemuan Thermografi CCWP 1A PLTU TembilahansandrositohangBelum ada peringkat

- STANDARISASI BERITA ACARADokumen9 halamanSTANDARISASI BERITA ACARABeno DigoBelum ada peringkat

- Monthly 220930090822Dokumen110 halamanMonthly 220930090822Alip utamaBelum ada peringkat

- OPTIMAL ALAT UKURDokumen5 halamanOPTIMAL ALAT UKURarifin salehBelum ada peringkat

- RK 273Dokumen1 halamanRK 273Marjuna U LatiaraBelum ada peringkat

- Elektrikal panel dan kabel isolasi pengukuranDokumen5 halamanElektrikal panel dan kabel isolasi pengukuranIsnanto AjaBelum ada peringkat

- Cibaduyu BDG Ib - KopoDokumen15 halamanCibaduyu BDG Ib - Kopooki_wahyuBelum ada peringkat

- DAFTAR HARGA PANEL TM DAN TRANSFORMATORDokumen14 halamanDAFTAR HARGA PANEL TM DAN TRANSFORMATOREvi JayanthiBelum ada peringkat

- LCM Gi Cikumpay Dan Gi Pabuaran 2022Dokumen3 halamanLCM Gi Cikumpay Dan Gi Pabuaran 2022Victor HombingBelum ada peringkat

- OPTIMASI DIODADokumen86 halamanOPTIMASI DIODASiis Ichsan AremaniaBelum ada peringkat

- Laporan Laboratorium Elka Analog Ke-2 GARIS BEBAN DIODADokumen16 halamanLaporan Laboratorium Elka Analog Ke-2 GARIS BEBAN DIODASugeng Rizky DarmawantoBelum ada peringkat

- PST 023 01 - RDBI JL C No 12Dokumen2 halamanPST 023 01 - RDBI JL C No 12brian taufik wBelum ada peringkat

- Komponen MesinDokumen12 halamanKomponen MesinNoval Navi'anBelum ada peringkat

- WG Rdbi Mep Eng Apm 00016 00 Lampu Gantung (Philips) (C)Dokumen6 halamanWG Rdbi Mep Eng Apm 00016 00 Lampu Gantung (Philips) (C)dimas.tupang95Belum ada peringkat

- Checklist Pemantauan Fungsi Alat MedisDokumen3 halamanChecklist Pemantauan Fungsi Alat MedisambalyabuyBelum ada peringkat

- ThermographyDokumen8 halamanThermographyNana MurdianaBelum ada peringkat

- PENYEARAH SETENGAH GELOMBANGDokumen7 halamanPENYEARAH SETENGAH GELOMBANGSyaiful Fuad100% (1)

- Spek MekanikalDokumen13 halamanSpek MekanikalAziz Bagus SasongkoBelum ada peringkat

- STRUKTUR BAJADokumen56 halamanSTRUKTUR BAJABagas IndraBelum ada peringkat

- Penerimaan CB52G SchneiderDokumen1 halamanPenerimaan CB52G SchneiderQ-YAI OBYBelum ada peringkat

- BDRF-ELE-DTS-100-001 Data Sheet For 20kV Switchgear R.00ADokumen7 halamanBDRF-ELE-DTS-100-001 Data Sheet For 20kV Switchgear R.00Afaridd ariiBelum ada peringkat

- Final Report - Tower Crossing Pulau Galang-Pulau Ayar-Pulau NguanDokumen20 halamanFinal Report - Tower Crossing Pulau Galang-Pulau Ayar-Pulau NguanRidwanBelum ada peringkat

- Ba CDC AmmanDokumen4 halamanBa CDC AmmanEdy SanyoBelum ada peringkat

- Qa5 S6D155-4Dokumen11 halamanQa5 S6D155-4Faruq AhmadBelum ada peringkat

- AttachmentDokumen22 halamanAttachmentArei Rahadianto100% (1)

- LP CF RC091VG2 EU - Id ID - PROF.CFDokumen5 halamanLP CF RC091VG2 EU - Id ID - PROF.CFteguh arifinBelum ada peringkat

- Form Laporan Kualifikasi MigasDokumen14 halamanForm Laporan Kualifikasi MigasRizaldi Akhmad SungkawaBelum ada peringkat

- 24 Januari 2022 - Ba Trafo Rusak LLTB - KP TikepDokumen2 halaman24 Januari 2022 - Ba Trafo Rusak LLTB - KP TikepAbdi KurniawanBelum ada peringkat

- Beninca Kem4 RiDokumen24 halamanBeninca Kem4 RiCamaras-ipWifiBelum ada peringkat

- 58Dokumen1 halaman58wiraarkana23Belum ada peringkat

- 4.a.STandard KonstruksiDokumen52 halaman4.a.STandard KonstruksiDJAFRIBelum ada peringkat

- PTK 007 Buku Kedua Rev 04 PDFDokumen112 halamanPTK 007 Buku Kedua Rev 04 PDFDiarista Thoma Saputra100% (1)

- 02 Harga Satuan Upah PDFDokumen12 halaman02 Harga Satuan Upah PDFPiia Auliya Fitria100% (1)

- Katalog BajaRingan 2018Dokumen186 halamanKatalog BajaRingan 2018ALIANDA33% (3)

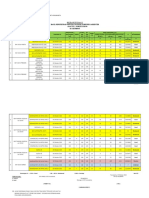

- Bill of Quantity Material-Vendor ListDokumen1 halamanBill of Quantity Material-Vendor ListadjiBelum ada peringkat

- Hewan Dan Jenis MakananDokumen2 halamanHewan Dan Jenis MakananadjiBelum ada peringkat

- Tugas Pembelajaran DaringDokumen1 halamanTugas Pembelajaran DaringadjiBelum ada peringkat

- Form Electric Power Planning and Water PlanningDokumen3 halamanForm Electric Power Planning and Water PlanningadjiBelum ada peringkat

- Permendikbud No 18 Tahun 2016 LampiranDokumen2 halamanPermendikbud No 18 Tahun 2016 LampiransamsudinBelum ada peringkat

- Bab Ii PDFDokumen24 halamanBab Ii PDFJoni JoniBelum ada peringkat

- 1 Public Speaking PDFDokumen145 halaman1 Public Speaking PDFEndi UbaedillahBelum ada peringkat

- Tugas Pembelajaran DaringDokumen1 halamanTugas Pembelajaran DaringadjiBelum ada peringkat

- EBTKE Bahan Paparan Sosialisasi Plts Atap Medan - Compressed PDFDokumen23 halamanEBTKE Bahan Paparan Sosialisasi Plts Atap Medan - Compressed PDFZULKIFLI ZULKIFLIBelum ada peringkat

- EBTKE Bahan Paparan Sosialisasi Plts Atap Medan - Compressed PDFDokumen23 halamanEBTKE Bahan Paparan Sosialisasi Plts Atap Medan - Compressed PDFZULKIFLI ZULKIFLIBelum ada peringkat

- Penggunaan Sistem PLTSA Oleh Konsumen PLNDokumen27 halamanPenggunaan Sistem PLTSA Oleh Konsumen PLNdony arisandiBelum ada peringkat

- Buku Penghubung Siswa 7Dokumen2 halamanBuku Penghubung Siswa 7adjiBelum ada peringkat

- Buku Keterampilan Berbicara PDFDokumen136 halamanBuku Keterampilan Berbicara PDFMinyunkii meowBelum ada peringkat

- BERCERITA TENTANG OBJEK DI LINGKUNGAN DAERAH ASALDokumen25 halamanBERCERITA TENTANG OBJEK DI LINGKUNGAN DAERAH ASALamabelistaBelum ada peringkat

- Pengumuman Lelang ConocoDokumen3 halamanPengumuman Lelang ConocoadjiBelum ada peringkat

- Pidato Bahasa IndonesiaDokumen6 halamanPidato Bahasa Indonesiamunto hirinBelum ada peringkat

- PidatoDokumen20 halamanPidatoadjiBelum ada peringkat

- Itenerary Tour Belitung 3d2nDokumen2 halamanItenerary Tour Belitung 3d2nadjiBelum ada peringkat