Cover Dan Kelengkapan

Diunggah oleh

ririnHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Cover Dan Kelengkapan

Diunggah oleh

ririnHak Cipta:

Format Tersedia

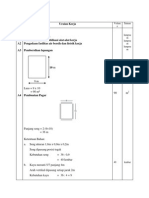

LAMPIRAN

Rumus Perhitungan Cadangan Dengan Metode Luas Area Pengaruh

untuk Semua Notasi

Rumus Perhitungan Cadangan Dengan Metode Area Pengaruh:

a. Menghitung Luas Area Pengaruh

Luas Area Pengaruh = Grid x grid

b. Menghitung Volume OB

Volume OB = Luas Area Pengaruh x Tebal Lapisan OB

c. Menghitung Volume Ore

Volume Ore = Luas Area Pengaruh x Tebal Lapisan Ore

d. Menghitung Unwashed

Unwashed Ore= Volume Ore x Density

e. Menghitung Washed

Washed Ore = Unwashed Ore x CF

f. Menghitung Cadangan

Cadangan = Washed Ore x Kadar Analisa

NOTASI A

1. TEST PIT TPSL-06 AY

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 x 1,80 m = 4.500 m3

Volume Ore = 2.500 m2 x 1,20 m = 3.000 m3

Tonase

Unwashed Ore = 3.000 m3 x 1,6 ton/m3 = 4.800 ton/m3

Washed Ore = 4.000 ton x 58,06 % = 276.672 ton/m3.

Cadangan Al2O3 = 276.672 ton x 40,00 % = 110668,80 ton

Cadangan SiO2 = 276.672 ton x 5,56 % = 15.382,96 ton

Cadangan Fe2O3 = 276.672 ton x 11,48 % = 31.761,95 ton

Cadangan TiO2 = 276.672 ton x 0,30 % = 830,02 ton

2. TEST PIT TPSL-17 AY

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 x 1,60 =4.000

Volume Ore = 2.500 m2 x 1,00 m = 2.500 m3

Tonase

Unwashed Ore = 2.500 m3 x 1,6 ton/m3 = 4.000 ton/m3

Washed Ore = 4.000 ton x 52,86 % = 211.428,57 ton/m3.

Cadangan Al2O3 = 211.428,57 ton x 52,20 % = 110.365,71 ton

Cadangan SiO2 = 211.428,57 ton x 9,25 % = 19.557,14 ton

Cadangan Fe2O3 = 211.428,57 ton x 12,48 % = 26.386,29 ton

Cadangan TiO2 = 211.428,57 ton x 0,25 % = 528,57 ton

3. TEST PIT TPSL-16AY

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 1.40 m = 3.500 m3

Volume Ore = 2.500 m2 x 1,00 m = 2.500 m3

Tonase

Unwashed Ore = 2.500 m3 x 1,6 ton/m3 = 4.000 ton/m3

Washed Ore = 4.000 ton x 58,06 % = 232.258,06 ton/m3.

Cadangan Al2O3 = 232.258,06 ton x 54,51 % = 126.603,87 ton

Cadangan SiO2 = 232.258,06 ton x 6,83 % = 15.863,23 ton

Cadangan Fe2O3 = 232.258,06 ton x 10,28 % = 23.876,13 ton

Cadangan TiO2 = 232.258,06 ton x 0,43 % = 998,71 ton

4. TEST PIT TPSL-763MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 1,70 m = 4250 m3

Volume Ore = 2.500 m2 x 1,00 m = 2.500 m3

Tonase

Unwashed Ore = 1. m3 x 1,6 ton/m3 = 4.000 ton/m3

Washed Ore = 4.000 ton x 69,32 % = 277272,73 ton/m3.

Cadangan Al2O3 = 277.272,73 ton x 56,86 % = 157.657,27 ton

Cadangan SiO2 = 277.272,73 ton x 6,56 % = 18.189,09 ton

Cadangan Fe2O3 = 277.272,73 ton x 6,89 % = 19.104,09 ton

Cadangan TiO2 = 277.272,73 ton x 0,40 % = 1.109,09 ton

5. TEST PIT TPSL-764MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 2,00 m = 5.000 m3

Volume Ore = 2.500 m2 x 1,00 m = 2.500 m3

Tonase

Unwashed Ore = 1. m3 x 1,6 ton/m3 = 4.000 ton/m3

Washed Ore = 4.000 ton x 59,72 % = 238.888,89 ton/m3.

Cadangan Al2O3 = 238.888,89 ton x 55,17 % = 131.795 ton

Cadangan SiO2 = 238.888,89 ton x 8,80 % = 21.022,22 ton

Cadangan Fe2O3 = 238.888,89 ton x 7,69 % = 18.370,56 ton

Cadangan TiO2 = 238888,89 ton x 0,44 % = 1051,11 ton

6. TEST PIT TPSL-765MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 2,30 m = 5750 m3

Volume Ore = 2.500 m2 x 1,00 m = 2.500 m3

Tonase

Unwashed Ore = 1. m3 x 1,6 ton/m3 = 4.000 ton/m3

Washed Ore = 4.000 ton x 65,71 % = 262.857,14 ton/m3.

Cadangan Al2O3 = 262.857,14 ton x 56,47 % = 14.835,43 ton

Cadangan SiO2 = 262.857,14 ton x 8,80 % = 23.131,43 ton

Cadangan Fe2O3 = 262.857,14 ton x 5,69 % = 14.956,57 ton

Cadangan TiO2 = 262.857,14 ton x 0,36 % = 946,29 ton

7. TEST PIT TPSL-766MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 0,80 m = 2.000 m3

Volume Ore = 2.500 m2 x 1,00 m = 2.500 m3

Tonase

Unwashed Ore = 2.500 m3 x 1,6 ton/m3 = 4.000 ton/m3

Washed Ore = 4.000 ton x 64,86 % = 259.459,46 ton/m3.

Cadangan Al2O3 = 262.857,14 ton x 53,64 % = 139.174,05 ton

Cadangan SiO2 = 262.857,14 ton x 7,02 % = 18,214.05 ton

Cadangan Fe2O3 = 262.857,14 ton x 11.08% = 28.748,11 ton

Cadangan TiO2 = 262.857,14 ton x 0,44 % = 1.141,62 ton

8. TEST PIT TPSL-873MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 1,10 m = 2.750 m3

Volume Ore = 2.500 m2 x 1,00 m = 2.500 m3

Tonase

Unwashed Ore = 2.500 m3 x 1,6 ton/m3 = 4.000 ton/m3

Washed Ore = 4.000 ton x 53,75 % = 215.000 ton/m3.

Cadangan Al2O3 = 215.000ton x 54,24 % = 116.616, ton

Cadangan SiO2 = 215.000 ton x 6,96 % = 14.964, ton

Cadangan Fe2O3 = 215.000 ton x 11,98 % = 25.757 ton

Cadangan TiO2 = 215.000 ton x 0,31 % = 666,50 ton

9. TEST PIT TPSL-5AY

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 0,90 m = 2250 m3

Volume Ore = 2.500 m2 x 1,10 m = 2750 m3

Tonase

Unwashed Ore = 2.750m3 x 1,6 ton/m3 = 4.400 ton/m3

Washed Ore = 4.400 ton x 50,56 % = 222.471,91 ton/m3.

Cadangan Al2O3 = 222.471,91 ton x 56,92 % = 126.631,01 ton

Cadangan SiO2 = 222.471,91 ton x 5,98 % = 13.303,01 ton

Cadangan Fe2O3 = 222.471,91 ton x 8,16 % = 18.153,71 ton

Cadangan TiO2 = 222.471,91 ton x 0,38 % = 845,39 ton

10. TEST PIT TPSL-3AY

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 1,20 m = 2.250 m3

Volume Ore = 2.500 m2 x 1,00 m = 2.500 m3

Tonase

Unwashed Ore = 2500m3 x 1,6 ton/m3 = 4.000 ton/m3

Washed Ore = 4.000 ton x 61,11 % = 244.444,44 ton/m3.

Cadangan Al2O3 = 244.444,44 ton x 52,31 % = 127.868 ton

Cadangan SiO2 = 244.444,44 ton x 11,69 % = 28.575,56 ton

Cadangan Fe2O3 = 244.444,44 ton x 8,78 % = 21.462,22 ton

Cadangan TiO2 = 244.444,44 ton x 0,19 % = 464,44 ton

11. TEST PIT TPSL-4AY

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 1,80 m = 4.500 m3

Volume Ore = 2.500 m2 x 1,20 m = 3.000 m3

Tonase

Unwashed Ore = 3.000 m3 x 1,6 ton/m3 = 4.800 ton/m3

Washed Ore = 4.800 ton x 51,72 % = 248.275,86 ton/m3.

Cadangan Al2O3 = 248.275,86 ton x 55,93 % = 138.860,69 ton

Cadangan SiO2 = 248275,86 ton x 6,34 % = 15.740,69 ton

Cadangan Fe2O3 = 248275,86 ton x 8,98 % = 22.295,17 ton

Cadangan TiO2 = 248275,86 ton x 0,31 % = 769,66 ton

12. TEST PIT TPSL-805MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 1,80 m = 4.500 m3

Volume Ore = 2.500 m2 x 1,00 m = 2.500 m3

Tonase

Unwashed Ore = 2.500 m3 x 1,6 ton/m3 = 4.000 ton/m3

Washed Ore = 4.000 ton x 65,00 % = 260.000 ton/m3.

Cadangan Al2O3 = 260.000 ton x 58,38 % = 151.788, ton

Cadangan SiO2 = 260.000 ton x 5,35 % = 13.910 ton

Cadangan Fe2O3 = 260.000 ton x 6,19 % = 16.094, ton

Cadangan TiO2 = 260.000 ton x 0,46 % = 1.196 ton

13. TEST PIT TPSL-806MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 2,30 m = 5750 m3

Volume Ore = 2.500 m2 x 1,40 m = 3.500 m3

Tonase

Unwashed Ore = 3.500 m3 x 1,6 ton/m3 = 5.600 ton/m3

Washed Ore = 5.600 ton x 56,86 % = 318.431,37 ton/m3.

Cadangan Al2O3 = 318.431,37 ton x 58,06 % = 186.791,84 ton

Cadangan SiO2 = 318.431,37 ton x 6,69 % = 21.303,06 ton

Cadangan Fe2O3 = 318.431,37 ton x 4,79 % = 15.252,86 ton

Cadangan TiO2 = 318.431,37 ton x 0,38 % = 1.210,04 ton

14. TEST PIT TPSL-807MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 1,90 m = 4.750 m3

Volume Ore = 2.500 m2 x 0,90 m = 2.250 m3

Tonase

Unwashed Ore = 2.250m3 x 1,6 ton/m3 = 3.600 ton/m3

Washed Ore = 3.600 ton x 49,33 % = 177.600 ton/m3.

Cadangan Al2O3 = 177.600 ton x 57,72 % = 102.510,72 ton

Cadangan SiO2 = 177.600 ton x 6,37 % = 11.313,12 ton

Cadangan Fe2O3 = 177.600 ton x 6,59 % = 11.703,84 ton

Cadangan TiO2 = 177.600 ton x 0,26 % = 461,76 ton

15. TEST PIT TPSL-807MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 1,10 m = 2750 m3

Volume Ore = 2.500 m2 x 1,40 m = 3.500 m3

Tonase

Unwashed Ore = 3.500 m3 x 1,6 ton/m3 = 5.600 ton/m3

Washed Ore = 5.600 ton x 59,38 % = 332.528 ton/m3.

Cadangan Al2O3 = 332.528 ton x 54,76 % = 182.077 ton

Cadangan SiO2 = 332.528 ton x 10,92 % = 36.309 ton

Cadanagan Fe2O3 = 332.528 ton x 6,99 % = 23.241,75 ton

Cadanagan TiO2 = 332.528 ton x 0,31 % = 1.030,75 ton

16. TEST PIT TPSL-669MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 1,10 m = 2.750 m3

Volume Ore = 2.500 m2 x 0,90 m = 2.250 m3

Tonase

Unwashed Ore = 2.250 m3 x 1,6 ton/m3 = 3.600 ton/m3

Washed Ore = 3.600 ton x 33,60 % = 120.960 ton/m3.

Cadangan Al2O3 = 120.960 ton x 52,62 % = 63.649,15 ton

Cadangan SiO2 = 120.960 ton x 9,03 % = 10.922,69 ton

Cadangan Fe2O3 = 120.960 ton x 10,18 % = 12.313,73 ton

Cadangan TiO2 = 120.960 ton x 0,21 % = 254,02 ton

17. TEST PIT TPSL-670MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 1,10 m = 2.750 m3

Volume Ore = 2.500 m2 x 0,80 m = 2.000 m3

Tonase

Unwashed Ore = 2.000 m3 x 1,6 ton/m3 = 3.200 ton/m3

Washed Ore = 3.200 ton x 18,00 % = 57.600 ton/m3.

Cadangan Al2O3 = 57.600 ton x 49,46 % = 28.488,96 ton

Cadangan SiO2 = 57.600 ton x 16,72 % = 9.630,72 ton

Cadangan Fe2O3 = 57.600 ton x 8,38 % = 4.826,88 ton

Cadangan TiO2 = 57.600 ton x 0,40 % = 230,40 ton

18. TEST PIT TPSL-668MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 0,50 m = 1.250 m3

Volume Ore = 2.500 m2 x 0,80 m = 2.000 m3

Tonase

Unwashed Ore = 2.500 m3 x 1,6 ton/m3 = 4.000 ton/m3

Washed Ore = 4.000 ton x 55,00 % = 220.000 ton/m3.

Cadangan Al2O3 = 220.000 ton x 50,31 % = 110.682 ton

Cadangan SiO2 = 220.000 ton x 8,21 % = 18.062 ton

Cadangan Fe2O3= 220.000 ton x 14,57 % = 32.054 ton

Cadangan TiO2= 220.000 ton x 0,38 % = 836 ton

19. TEST PIT TPSL-792MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 1,00 m = 2.500 m3

Volume Ore = 2.500 m2 x 0,60 m = 1.500 m3

Tonase

Unwashed Ore = 1.500 m3 x 1,6 ton/m3 = 2.400 ton/m3

Washed Ore = 2.400 ton x 52,31 % = 125.538,46 ton/m3.

Cadangan Al2O3 = 125.538,46 ton x 33,42 % = 41.954,95 ton

Cadangan SiO2 = 125.538,46 ton x 35,30 % = 44.315,08 ton

Cadangan Fe2O3 = 125.538,46 ton x 17,67 % = 22.182,65 ton

Cadangan TiO2 = 125.538,46 ton x 0,44 % = 552,37 ton

20. TEST PIT TPSL-793MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 0,90 m = 2.250 m3

Volume Ore = 2.500 m2 x 0,60 m = 2.500 m3

Tonase

Unwashed Ore = 2.500 m3 x 1,6 ton/m3 = 4.000 ton/m3

Washed Ore = 4.000 ton x 52,00 % = 208.000 ton/m3.

Cadangan Al2O3 = 208.000 ton x 44,03 % = 91.582,40 ton

Cadangan SiO2 = 208.000 ton x 10,21 % = 21.236,80 ton

Cadangan Fe2O3 = 208.000 ton x 22,96 % = 47.756,80 ton

Cadangan TiO2 = 208.000 ton x 0,38 % = 790,40 ton

21. TEST PIT TPSL-794MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 0,70 m = 1.750 m3

Volume Ore = 2.500 m2 x 1,00 m = 2.500 m3

Tonase

Unwashed Ore = 2.500 m3 x 1,6 ton/m3 = 4.000 ton/m3

Washed Ore = 4.000 ton x 52,73 % = 210.909 ton/m3.

Cadangan Al2O3 = 210.909 ton x 38,05 % = 80.250,9 ton

Cadangan SiO2 = 210.909 ton x 12,31 % = 25.962,91 ton

Cadangan Fe2O3 = 210.909 ton x 29,35 % = 61.901,82 ton

Cadangan TiO2 = 210.909 ton x 0,41 % = 864,73 ton

22. TEST PIT TPSL-795MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 1,5 m = 3750 m3

Volume Ore = 2.500 m2 x 0,70 m = 1.750 m3

Tonase

Unwashed Ore = 1.750 m3 x 1,6 ton/m3 = 2.800 ton/m3

Washed Ore = 2.800 ton x 61,54 % = 172.307,69 ton/m3.

Cadangan Al2O3 = 172.307,69 ton x 38,08 % = 65.614,77 ton

Cadangan SiO2 = 172.307,69 ton x 10,38 % = 17.885,54 ton

Cadangan Fe2O3 = 172.307,69 ton x 31,44 % = 54.173,54 ton

Caadangan TiO2 = 172.307,69 ton x 0,35 % = 603,08 ton

23. TEST PIT TPSL-796MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 1,60 m = 4.000 m3

Volume Ore = 2.500 m2 x 0,90 m = 2.250 m3

Tonase

Unwashed ore = 2.250 m3 x 1,6 ton/m3 = 3.600 ton/m3

Washed Ore = 3.600 ton x 58,52 % = 210.666,67 ton/m3.

Cadangan Al2O3 = 172.307,69 ton x 30,34 % = 63.916,27 ton

Cadangan SiO2 = 172.307,69 ton x 10,26 % = 21.614,08 ton

Cadangan Fe2O3 = 172307,69 ton x 41,52 % = 87468,,80 ton

Cadangan TiO2 = 172.307,69 ton x 0,35 % = 737,33 ton

24. TEST PIT TPSL-796MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume OB = 2.500 m2 x 2,00 m = 5.000 m3

Volume Ore = 2.500 m2 x 0,60 m = 1.500 m3

Tonase

Unwashed Ore = 1.500 m3 x 1,6 ton/m3 = 24.00 ton/m3

Washed Ore = 2.400 ton x 40,00 % = 96.000 ton/m3.

Cadangan Al2O3 = 96.000 ton x 33,90 % = 32.544 ton

Cadangan SiO2 = 96.000 ton x 20,73 % = 19.900,80 ton

Cadangan Fe2O3 = 96.000 ton x 27,52 % = 26.160 ton

Cadangan TiO2 = 96.000 ton x 0,38 % = 364,80 ton

NOTASI B

25. TEST PIT TPSL-06AY

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume Ore = 2.500 m2 x 0,60 m = 1.500 m3

Tonase

Unwashed Ore = 1.500 m3 x 1,6 ton/m3 = 24.00 ton/m3

Washed Ore = 2.400 ton x 57,69 % = 138.461,54 ton/m3.

Cadangan Al2O3 = 138.461,54 ton x 57,10 % = 79.061,54 ton

Cadangan SiO2 = 138.461,54 ton x 7,38 % = 10.218,46 ton

Cadangan Fe2O3 = 138.461,54 ton x 8,28 % = 11.464,62 ton

Cadangan TiO2 = 138.461,54 ton x 0,33 % = 456,92 ton

26. TEST PIT TPSL-763MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume Ore = 2.500 m2 x 0,70 m = 1.750 m3

Tonase

Unwashed Ore = 1.750 m3 x 1,6 ton/m3 = 2.800 ton/m3

Washed Ore = 2.800 ton x 64,29 % = 180.000 ton/m3.

Cadangan Al2O3 = 180.000 ton x 56,34 % = 101.412, ton

Cadangan SiO2 = 180.000 ton x 8,93 % = 16.074 ton

Cadangan Fe2O3 = 180.000 ton x 5,49 % = 9.882 ton

Cadangan TiO2 = 180.000 ton x 0,43 % = 774 ton

27. TEST PIT TPSL-764MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume Ore = 2.500 m2 x 0,50 m = 1.250 m3

Tonase

Unwashed Ore = 1.250 m3 x 1,6 ton/m3 = 2.000 ton/m3

Washed Ore = 2.000 ton x 67,74 % = 135.483,87 ton/m3.

Cadangan Al2O3 = 135.483,87 ton x 53,80 % = 71.914,84 ton

Cadangan SiO2 = 135.483,87 ton x 14,41 % = 19.523,23 ton

Cadangan Fe2O3 = 135.483,87 ton x 5,59 % = 7.573,55ton

Cadangan TiO2 = 135.483,87 ton x 0,40 % = 541,94 ton

28. TEST PIT TPSL-765MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume Ore = 2.500 m2 x 0,60 m = 1.500 m3

Tonase

Unwashed Ore = 1.500 m3 x 1,6 ton/m3 = 2.400 ton/m3

Washed Ore = 2.400 ton x 60,77 % = 145.846,15 ton/m3.

Cadangan Al2O3 = 145.846,15 ton x 35,04 % = 51.104,49 ton

Cadangan SiO2 = 145.846,15 ton x 13,69 % = 19.966,34 ton

Cadangan Fe2O3 = 145.846,15 ton x 3,69 % = 5.381,72 ton

Cadangan TiO2 = 145.846,15 ton x 0,25 % = 364,62 ton

29. TEST PIT TPSL-766MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume Ore = 2.500 m2 x 0,50 m = 1.250 m3

Tonase

Unwashed Ore = 1.250 m3 x 1,6 ton/m3 = 2.000 ton/m3

Washed Ore = 2.000 ton x 63,64 % = 127.271,73 ton/m3.

Cadangan Al2O3 = 127.271,73 ton x 55,03 % = 70.038,18 ton

Cadangan SiO2 = 127.271,73 ton x 10,49 % = 13.350,91 ton

Cadangan Fe2O3 = 127.271,73 ton x 5,99 % = 7.623,64 ton

Cadangan TiO2 = 127.271,73 ton x 0,41 % = 521,82 ton

30. TEST PIT TPSL-873MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume Ore = 2.500 m2 x 0,70 m = 1.750 m3

Tonase

Unwashed Ore = 1.750 m3 x 1,6 ton/m3 = 2.800 ton/m3

Washed Ore = 2.800 ton x 48,33 % = 135.333,33 ton/m3.

Cadangan Al2O3 = 127.271,73 ton x 33,78 % = 45.715,60 ton

Cadangan SiO2 = 127.271,73 ton x 9,83 % = 13.303,27 ton

Cadangan Fe2O3 = 127.271,73 ton x 35,83 % = 48.489,93 ton

Cadangan TiO2 = 127.271,73 ton x 0,44 % = 595,47 ton

31. TEST PIT TPSL-3AY

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume Ore = 2.500 m2 x 1,30 m = 3.250 m3

Tonase

Unwashed Ore = 3.250 m3 x 1,6 ton/m3 = 5.200 ton/m3

Washed Ore = 5.200 ton x 58,06 % = 301.935,48 ton/m3.

Cadangan Al2O3 = 301.935,48 ton x 41,63 % = 125.695,74 ton

Cadangan SiO2 = 301.935,48 ton x 15,13 % = 456.82,84 ton

Cadangan Fe2O3 = 301.935,48 ton x 7,59 % = 22.916,90 ton

Cadangan TiO2 = 301.935,48 ton x 0,21 % = 634,06 ton

32. TEST PIT TPSL-805MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume Ore = 2.500 m2 x 1,00 m = 2.500 m3

Tonase

Unwashed Ore = 2.500 m3 x 1,6 ton/m3 = 4.000 ton/m3

Washed Ore = 4.000 ton x 70,25 % = 280991,74 ton/m3.

Cadangan Al2O3 = 280.991,74 ton x 42,75 % = 120.123,97 ton

cadangan SiO2 = 280.991,74 ton x 5,33 % = 14.976,86 ton

Cadangan Fe2O3 = 280.991,74 ton x 6,39 % = 17.955,37 ton

Cadangan TiO2 = 280.991,74 ton x 0,50 % = 1.404,96 ton

33. TEST PIT TPSL-668MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume Ore = 2.500 m2 x 0,50 m = 1.250 m3

Tonase

Unwashed Ore = 1.250 m3 x 1,6 ton/m3 = 2.000 ton/m3

Washed Ore = 2.000 ton x 56,52 % = 113.043,48 ton/m3.

Cadangan Al2O3 = 113.043,48 ton x 46,11 % = 52.124,35 ton

Cadangan SiO2 = 113.043,48 ton x 9,26 % = 10.467,83 ton

Cadangan Fe2O3 = 113.043,48 ton x 18,37 % = 20.766,09 ton

Cadangan TiO2 = 113.043,48 ton x 0,46 % = 520 ton

34. TEST PIT TPSL-668MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume Ore = 2.500 m2 x 0,50 m = 1.250 m3

Tonase

Unwashed Ore = 1.250 m3 x 1,6 ton/m3 = 2.000 ton/m3

Washed Ore = 2.000 ton x 46,67 % = 9.333,33 ton/m3.

Cadangan Al2O3 = 9.333,33 ton x 46,54 % = 43.437,33 ton

Cadangan SiO2 = 9.333,33 ton x 10,67 % = 9.958,67 ton

Cadangan Fe2O3 = 9.333,33 ton x 18,87 % = 17.612 ton

Cadangan TiO2 = 9.333,33 ton x 0,39 % = 364 ton

35. TEST PIT TPSL-668MS

Luas Area Pengaruh = 50 m x 50 m = 2.500 m2

Volume Ore = 2.500 m2 x 0,50 m = 1.250 m3

Tonase

Unwashed Ore = 1.250 m3 x 1,6 ton/meter3 = 2.000 ton/m3

Washed Ore = 2.000 ton x 50,63 % = 101.265,82 ton/m3.

Kadar tonase Al2O3 = 101.265,82 ton x 48,53 % = 49.144,30 ton

Kadar tonase SiO2 = 101.265,82 ton x 6,44 % = 6.521,52 ton

Kadar tonase Fe2O3 = 101.265,82 ton x 4,79 % = 4.850,63 ton

Kadar tonase TiO2 = 101.265,82 ton x 0,46 % = 465,82 ton

Anda mungkin juga menyukai

- Cara Perhitungan Volume Rumah TinggalDokumen48 halamanCara Perhitungan Volume Rumah TinggalAsnidarIrdayantiBelum ada peringkat

- Uraian Volume Pekerjaan Rumah Type 36Dokumen40 halamanUraian Volume Pekerjaan Rumah Type 36Zulfikar Abdul Aziz100% (1)

- Perhitungan Vibrating ScreenDokumen5 halamanPerhitungan Vibrating ScreenLeo SihombingBelum ada peringkat

- Oxidation DitchDokumen4 halamanOxidation DitchNafisa Meisa60% (5)

- Erika - PPT Pbpab 10Dokumen22 halamanErika - PPT Pbpab 10Tono SartonoBelum ada peringkat

- Bab 8 Pbpal (Pengolhana Kimia-Desinfeksi)Dokumen6 halamanBab 8 Pbpal (Pengolhana Kimia-Desinfeksi)bellaBelum ada peringkat

- Rangka AtapDokumen17 halamanRangka AtapErni MulyandariBelum ada peringkat

- Tangki NetralisasiDokumen9 halamanTangki NetralisasiauliarhhmnnBelum ada peringkat

- DIPERLUKANDokumen36 halamanDIPERLUKANkastonBelum ada peringkat

- PenawaranDokumen13 halamanPenawarankatacipengBelum ada peringkat

- Lampiran Neraca MasaDokumen3 halamanLampiran Neraca MasaRobby KurniawanBelum ada peringkat

- Atk Soal Paket Kel 1Dokumen22 halamanAtk Soal Paket Kel 1RoiiiikkkkBelum ada peringkat

- Penentuan Konsentrasi OzonDokumen5 halamanPenentuan Konsentrasi OzonAbdul Aziz Fathul IslamBelum ada peringkat

- Soal Dan Solusi Fluida Statis & Dinamis PDFDokumen24 halamanSoal Dan Solusi Fluida Statis & Dinamis PDFArif IsmantoBelum ada peringkat

- Menghitung Volume Sampai Tembok DindingDokumen16 halamanMenghitung Volume Sampai Tembok DindingwahyuBelum ada peringkat

- 11 FluidaDokumen2 halaman11 FluidaKantorBelum ada peringkat

- Lat FisikaDokumen6 halamanLat FisikaIndraNugrahaBelum ada peringkat

- List Item Penambahan Pekerjaan LT1Dokumen4 halamanList Item Penambahan Pekerjaan LT1B MRGRBelum ada peringkat

- Berikut Perhitungan RAB Sumur Resapan PT. Jin MyoungDokumen5 halamanBerikut Perhitungan RAB Sumur Resapan PT. Jin Myoungadhianalis_140533399Belum ada peringkat

- Soal Soalfisika 120228233559 Phpapp01Dokumen13 halamanSoal Soalfisika 120228233559 Phpapp01octavianusbryan_20Belum ada peringkat

- Rab Pembuatan Jamban KeluargaDokumen9 halamanRab Pembuatan Jamban KeluargaResti DwiBelum ada peringkat

- Data Cerobong KNIDokumen16 halamanData Cerobong KNIHaris IfroniBelum ada peringkat

- Spek Alat Revisi FixDokumen165 halamanSpek Alat Revisi FixAyu LarasatiBelum ada peringkat

- Volume Campuran SalinanDokumen6 halamanVolume Campuran SalinanKgs M IqbalBelum ada peringkat

- Endrika Nisworo Struktur Kayu Ii PDFDokumen2 halamanEndrika Nisworo Struktur Kayu Ii PDFAlvianZuhriZuhriBelum ada peringkat

- Bab 1 Plat LantaiDokumen22 halamanBab 1 Plat LantaiErni MulyandariBelum ada peringkat

- Jawaban Fluida Statis Dan DinamisDokumen5 halamanJawaban Fluida Statis Dan DinamisRirin WirdayaniBelum ada peringkat

- Hitung Luas Settling PondDokumen1 halamanHitung Luas Settling PondFatonahRikovinoBelum ada peringkat

- Latihan SoalDokumen16 halamanLatihan SoalDyah ArumBelum ada peringkat

- Uas-Teknik Bangunan 4-Hotel Semarang (Ta)Dokumen63 halamanUas-Teknik Bangunan 4-Hotel Semarang (Ta)Lionel Andres HanifBelum ada peringkat

- Perhitungan Mengolah Air Limbah Pabrik GulaDokumen8 halamanPerhitungan Mengolah Air Limbah Pabrik GulaYuni InkasariBelum ada peringkat

- Bubble ColumnDokumen9 halamanBubble ColumnSatriya Baskara PutraBelum ada peringkat

- Kelompok 2b Pengolahan LumpurDokumen54 halamanKelompok 2b Pengolahan LumpurMaulydiaBelum ada peringkat

- Analisa KSLL-kirimDokumen39 halamanAnalisa KSLL-kirimshrakBelum ada peringkat

- AerasiDokumen4 halamanAerasiMarizz MaristiyantoBelum ada peringkat

- LajuDokumen3 halamanLajuRiki HaryantoBelum ada peringkat

- Lampiran Perhitungan Sistem Penirisan TambangDokumen6 halamanLampiran Perhitungan Sistem Penirisan TambangAldi Rinaldi RahmatBelum ada peringkat

- Smmi TM 8 Dertha FDokumen7 halamanSmmi TM 8 Dertha FDertha FanitullahBelum ada peringkat

- H TangkiDokumen28 halamanH TangkiyusufluckBelum ada peringkat

- Pompa 1Dokumen13 halamanPompa 1Lalan SuksesBelum ada peringkat

- Solusi Latihan Soal 271118Dokumen6 halamanSolusi Latihan Soal 271118Nadhira SyifaBelum ada peringkat

- Struktur BajaDokumen12 halamanStruktur BajaDhiya UlhaqBelum ada peringkat

- Modul 9. PERENCANAAN PONDASI TIANG PANCANG INDIVIDUAL PILE DATA TANAH STANDARD PENETRATION TEST (SPT)Dokumen15 halamanModul 9. PERENCANAAN PONDASI TIANG PANCANG INDIVIDUAL PILE DATA TANAH STANDARD PENETRATION TEST (SPT)Kemas Doyu TatsakaBelum ada peringkat

- Tekanan HidrostatisDokumen9 halamanTekanan HidrostatisAry FujiandiBelum ada peringkat

- Perhitungan PenyanggaDokumen10 halamanPerhitungan PenyanggaLodsObellBelum ada peringkat

- 1.beban Balok Pelat LantaiDokumen88 halaman1.beban Balok Pelat LantaiSendy PratamaBelum ada peringkat

- Alat Fixedddd !!!!!!!!!!!!!!Dokumen378 halamanAlat Fixedddd !!!!!!!!!!!!!!TaufikBelum ada peringkat

- Lampiran Tugas 3Dokumen7 halamanLampiran Tugas 3Maulina Nur LailiBelum ada peringkat

- Perancangan EvaporatorDokumen21 halamanPerancangan EvaporatorRyo AquinoBelum ada peringkat

- BAB V LAPORAN ALIRAN FLUIDADokumen12 halamanBAB V LAPORAN ALIRAN FLUIDASiti Widya SafrianiBelum ada peringkat

- Rencana Anggaran Biaya PagarDokumen78 halamanRencana Anggaran Biaya PagarBrayen ObstinateBelum ada peringkat

- FisikaDokumen47 halamanFisikaNurul AisyahBelum ada peringkat

- Volume RABDokumen29 halamanVolume RABBogie Prastowo MahardhikaBelum ada peringkat

- TOS LapenDokumen1 halamanTOS Lapensyaf rianBelum ada peringkat

- Unit Ukuran Untuk Jarak TanahDokumen3 halamanUnit Ukuran Untuk Jarak TanahandakBelum ada peringkat

- Daftar Konversi Satuan InternasionalDokumen15 halamanDaftar Konversi Satuan InternasionalRo ChimBelum ada peringkat

- Pengolahan Bahan GalianDokumen6 halamanPengolahan Bahan GalianM YazidBelum ada peringkat

- Dokumen - Tips Laporan Tetap So FluidisasiDokumen9 halamanDokumen - Tips Laporan Tetap So FluidisasiSavaniBelum ada peringkat

- Lampiran CDokumen213 halamanLampiran CIdha WahidahBelum ada peringkat

- CV Evi SuryantiDokumen3 halamanCV Evi SuryantiEvi Secawan KopiBelum ada peringkat

- Skripsi Bagus 14 PDFDokumen153 halamanSkripsi Bagus 14 PDFririnBelum ada peringkat

- CV Evi SuryantiDokumen3 halamanCV Evi SuryantiEvi Secawan KopiBelum ada peringkat

- Halaman PengesahanDokumen2 halamanHalaman PengesahanririnBelum ada peringkat

- CV Evi SuryantiDokumen3 halamanCV Evi SuryantiririnBelum ada peringkat

- Contoh Penulisan Tugas AkhirDokumen50 halamanContoh Penulisan Tugas AkhirFasdarsyahBelum ada peringkat

- CV RirinDokumen2 halamanCV RirinririnBelum ada peringkat

- DAFTAR PUSTAKA Lain-LainnyaDokumen1 halamanDAFTAR PUSTAKA Lain-LainnyaririnBelum ada peringkat

- Alumunium MayayoanDokumen17 halamanAlumunium MayayoanririnBelum ada peringkat

- CV RirinDokumen1 halamanCV RirinririnBelum ada peringkat

- Diagram AlirDokumen1 halamanDiagram AlirririnBelum ada peringkat

- Diangram AlirDokumen1 halamanDiangram AlirririnBelum ada peringkat

- BAB II Tinjauan PustakaDokumen30 halamanBAB II Tinjauan PustakaririnBelum ada peringkat

- Bab IDokumen2 halamanBab IririnBelum ada peringkat

- DAFTAR PUSTAKA Lain-LainnyaDokumen1 halamanDAFTAR PUSTAKA Lain-LainnyaririnBelum ada peringkat

- Cover Dan KelengkapanDokumen6 halamanCover Dan KelengkapanRirin Tri MurniatiBelum ada peringkat

- Daftar PustakaDokumen2 halamanDaftar PustakaririnBelum ada peringkat

- Teori Terbentuknya Kulit BumiDokumen32 halamanTeori Terbentuknya Kulit BumiririnBelum ada peringkat

- Pedoman Umum Penyelenggaraan Sa-2017Dokumen2 halamanPedoman Umum Penyelenggaraan Sa-2017ririnBelum ada peringkat

- Inilah Keutamaan Puasa DzulhijjahDokumen4 halamanInilah Keutamaan Puasa DzulhijjahririnBelum ada peringkat

- Mineral IndustriDokumen30 halamanMineral IndustriririnBelum ada peringkat

- Bijih (Ore)Dokumen23 halamanBijih (Ore)ririn100% (1)

- Alat BeratDokumen23 halamanAlat BeratririnBelum ada peringkat

- Tambang Bawah TanahDokumen16 halamanTambang Bawah TanahririnBelum ada peringkat

- Makalah MinpetDokumen26 halamanMakalah MinpetririnBelum ada peringkat

- Inilah Keutamaan Puasa DzulhijjahDokumen4 halamanInilah Keutamaan Puasa DzulhijjahririnBelum ada peringkat

- Asmaul Husna Dan KhasiatnyaDokumen10 halamanAsmaul Husna Dan KhasiatnyaririnBelum ada peringkat

- Teori Tektonik LempengDokumen8 halamanTeori Tektonik LempengririnBelum ada peringkat

- Endapan MineralDokumen111 halamanEndapan MineralririnBelum ada peringkat