BERITA ACARA MAINTENANCE PM Data

Diunggah oleh

Rahmawati BkmmJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

BERITA ACARA MAINTENANCE PM Data

Diunggah oleh

Rahmawati BkmmHak Cipta:

Format Tersedia

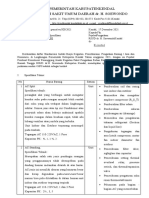

BERITA ACARA MAINTENANCE

No. 001/BAM-DMMandiri/I/2023

Padahariini, Senin tanggal 2 bulan Januari tahun 2023 yang bertanda tangan di bawah ini:

1. Nama : Muh. Usdar Galung

Jabatan : Pimdept. Infrastruktur & Jaringan Divisi TI PT. Bank Sulselbar

Selanjutnya disebut sebagai “Pihak Pertama”

2. Nama : Darman B, ST.

Jabatan : Direktur CV. DM Mandiri VAC

Selanjutnya disebut “Pihak Kedua”

Dengan ini menerangkan bahwa :

Berdasarkan Kontrak/SPK Nomor : SR/924/R/DUM/IV/2022 tanggal 22 Desember 2022, Pihak

pertama telah melakukan Pemeliharaan PAC (Precision Air Conditioner) Data Centre dan

Disaster Recovery Center PT. Bank sulselbar sesuai ketentuan kontrak/SPK oleh tim

pendukung/tim teknis. Kedua belah pihak telah sepakat untuk mengadakan serah terima

pekerjaan sesuai dengan ketentuan Kontrak/Surat Perintah Kerja Sebagai Berikut :

No. Uraian QTY Satuan Ket

1. BlueBoxDatatech UEDA 66.2 CH 54 KW 2 Unit Data Centre

2. Vertiv/Libert DME 07 KW 2 Unit Data Centre

3. RC GroupPegassus 7 KW 2 Unit Disaster Recovery Center

4. Vertiv/Libert DME 07 KW 1 Unit Disaster Recovery Center

Selanjutnya pihak kedua telah melakukan Pemeliharaan PAC (Precision Air Conditioner) Data

Centre dan Disaster Recovery Centers emua item pekerjaan yang di perjanjikan dalam kontrak.

Demikian Berita Acara Maintenance dibuatdan ditandatangani oleh kedua belah pihak.

Makassar, 2 Januari 2023

Pihak Pertama Pihak Kedua

( Muh. Usdar Galung ) (Darman B, ST.)

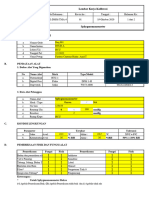

SERVICE REPORT MAINTENANCE

CV. DM MANDIRI VAC

FORM Preventive Corrective Breackdown

-I -II -III-IV -V -VI

Costumer

Company Name

: PT. Bank Sulselbar Email :

Address

: Jl. DR. Sam Ratulangi No. 16 Makassar Phone :

Cooling System : Air Colled (Precision Air Conditioner) S/N :

(Air Cooled-Water Cooled-Water Ciller) Unit Address :

Merk : :

Refrigerant

Model/Type : :

Capacity

IP Address : Subnet Mask : Default Gateway :

Engineering : DATE :

Project : Preventive Maintenance Precision Air Conditioner Data Centre& Disaster Recovery Centre

PT. Bank Sulselbar

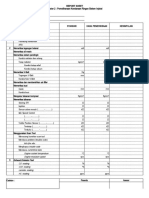

A. Visual Inspection & Maintenance

Maintenance Maintenance

Item Result Item Result

components components

Check forrestricted air flow Humidifier(ifappli Checkifthewatertrayisclogged.

Filter Check the filter cable) Checkthehumidifierlamp

Clean the filter Checkthesedimentofwatertray

Indoorunitfan Impellers free of debris and move Drain Checkandcleanoutunitdrainpipes,

freely system(including humidifier and tray, condensate

condensate pump and building drain pipes

Bearingsin good condition pump)

PowerSPD Check forindicator color Electricboard Check the

(ifapplicable) surfaceforsignsofcorrosion

Compressor Sign sofoilleaks Check electrical connections

Vibrationi solation Air- Condenserc oil is clean

Refrigerantsyst Suction pressure cooledcondenser Motor mountedtightly

em Discharge pressure Bearingin good condition

Superheat Refrigerant pipesproperly supported

Evaporatorin tight and clean SystemGeneralA Check Condenser Coil

condition

Charging capacity of refrigerant rrangement Check Evaporator Coil

Evident temperature difference Check Valve

Low- betweenbeforeandafterthefilterdri

Check for the liquid level of the Check Thermal Expansion Valve

Temp refrigerantinfluidreservoirandlea Check Valve Core

low- k ofthefluidreservoirfittings Check Male Connector

temperat Checkwhethertheheatingbeltof Check Female Connector

ureunit thefluidreservoirworksnormally Check Licuid Pipe

Check Sensing Bulb

Electricheater Check for signsofcorrosion Check Sensing Bulb

Humidifier Check if the water trayisclogged Check Suction Pipe

Check the humidifier lamp Check Filter Dryer

Check the sedimentofwatertray Check Connecting Discharge Pipe

Check and fix connectors Check Connecting Water Drain Pipe

B. Operation Measurement Inspection

Indoor Section Pressure Discharge Pressure Current Voltage (A)

Compressor

Unit Low High R S T

1 PSI PSI

2 PSI PSI

Current Voltage (A) Current Voltage (A)

Fan Fan

Evaporator R S R R S R

1 2

Current Voltage (A) Current Voltage (A)

Heater 1 R S T 2 R S T

Current Voltage (A) Current Voltage (A)

Dehumidifier 1 R S T 2 R S T

Outdoor Current Voltage (A) Current Voltage (A)

Condensor

unit 1 R S T 2 R S T

Fan

Input Voltage (Volt) R-N S-N T-N R-S S-T T-R PE/NG Frekuensi

Current Load R S T

Voltage(Ampere)

Equipment 1. Temperatur Set Piont Actual

2. Humidity Set Point Actual

Test Pressure

C. Analysis/Remark

Costumer Attended By: Service Attended By:

Signed ____________________ Signed ___________________

Name Name

Lampiran Dokumentasi :

- InstalasiKondensor

- InstalasiPipa

- Instalasi Tray

Anda mungkin juga menyukai

- LK Infusion PumpDokumen3 halamanLK Infusion PumpChoi Rin SparkyuYoungsterBelum ada peringkat

- Job Sheet Pelatihan TkroDokumen7 halamanJob Sheet Pelatihan TkroKantorBelum ada peringkat

- PERAWATAN AIR CONDITIONING Rev 1Dokumen1 halamanPERAWATAN AIR CONDITIONING Rev 1fatkhur rahmanBelum ada peringkat

- Fire Protection Check SheetDokumen21 halamanFire Protection Check SheetNovri Young GunnersBelum ada peringkat

- Form-Test Report Pipa Drain ACDokumen2 halamanForm-Test Report Pipa Drain ACMadania RealtyBelum ada peringkat

- Cleaning Service Ac Split DuctDokumen8 halamanCleaning Service Ac Split Ductwahyu nugroho75% (4)

- Dokumen Pengadaan Beban Pemeliharaan Alat Kantor Dan Rumah Tangga - FinalDokumen13 halamanDokumen Pengadaan Beban Pemeliharaan Alat Kantor Dan Rumah Tangga - FinalAulia AuliaBelum ada peringkat

- Summary Report Maintenance Service Kencana 2022Dokumen14 halamanSummary Report Maintenance Service Kencana 2022Riko MaulanaBelum ada peringkat

- Draft Mengajar BoilerDokumen40 halamanDraft Mengajar BoilerIka YuliyaniBelum ada peringkat

- SOP Pencucian ACDokumen5 halamanSOP Pencucian ACHabil Habibi100% (2)

- PL Book BahasaDokumen389 halamanPL Book BahasaDarwin Rauf100% (3)

- Motor Listrik 3 PhasaDokumen51 halamanMotor Listrik 3 PhasaBarep Sopan MubarokBelum ada peringkat

- Spesifikasi Teknis Pompa 30 LPD Spam Ikk Sungai Apit Dan Spam Ikk K. GasibDokumen5 halamanSpesifikasi Teknis Pompa 30 LPD Spam Ikk Sungai Apit Dan Spam Ikk K. GasibBudimanBelum ada peringkat

- Tensimeter Digital (BPM) (2023)Dokumen16 halamanTensimeter Digital (BPM) (2023)melky dominggusBelum ada peringkat

- FAT Form Panel MDPDokumen3 halamanFAT Form Panel MDPMuhammad Nico PermanaBelum ada peringkat

- Kalibrasi Nebulizer KompresorDokumen4 halamanKalibrasi Nebulizer KompresorBrama SaktiBelum ada peringkat

- Job Sheet Tune Up InjeksiDokumen2 halamanJob Sheet Tune Up InjeksidadoenBelum ada peringkat

- 3.2 Monitoring Peralatan GI - Vokasi SMKDokumen27 halaman3.2 Monitoring Peralatan GI - Vokasi SMKGanjar CandraBelum ada peringkat

- Balance of PlantDokumen49 halamanBalance of PlantIka YuliyaniBelum ada peringkat

- Service Package GENSET & Lighting PlantDokumen4 halamanService Package GENSET & Lighting Plantirwan yuniardiBelum ada peringkat

- IK Corective GeneratorDokumen17 halamanIK Corective GeneratorJimianta S.S.TBelum ada peringkat

- IK CV Hydrolic BypassDokumen12 halamanIK CV Hydrolic BypassShigeru AkiseBelum ada peringkat

- Form-Test Tekan Fire HydrantDokumen2 halamanForm-Test Tekan Fire HydrantBayu Pradana100% (2)

- Laporan Visual CheckDokumen7 halamanLaporan Visual CheckFarahadibah RamadhantyBelum ada peringkat

- TS AlDokumen29 halamanTS AlRizqi Chocs 2633% (3)

- SOP Pemeliharaan DCDokumen6 halamanSOP Pemeliharaan DCsofyan053Belum ada peringkat

- Peralatan Pendingin PLTGUDokumen18 halamanPeralatan Pendingin PLTGUFirman RizalBelum ada peringkat

- p10. Terminologi Unik Dan StandarDokumen12 halamanp10. Terminologi Unik Dan StandarredhoBelum ada peringkat

- Temuan Thermografi PLTU RopaDokumen1 halamanTemuan Thermografi PLTU RopasandrositohangBelum ada peringkat

- IK Corective GeneratorDokumen18 halamanIK Corective GeneratorJimianta S.S.TBelum ada peringkat

- Tugasan Buku Log 3eteDokumen5 halamanTugasan Buku Log 3eterafiuddin07Belum ada peringkat

- Training Operasionl CT SNC ModelDokumen14 halamanTraining Operasionl CT SNC ModelSunardi prawirorejoBelum ada peringkat

- Media Pembelajaran UKIN-Suri Kartika Wati-19030541310238Dokumen24 halamanMedia Pembelajaran UKIN-Suri Kartika Wati-19030541310238Aqiilah Bani AbiidahBelum ada peringkat

- IKRB-312-14-2.1.1.b.e-009 - IK Pengendalian Kualitas Air Closed Cooling SystemDokumen8 halamanIKRB-312-14-2.1.1.b.e-009 - IK Pengendalian Kualitas Air Closed Cooling SystemasifBelum ada peringkat

- Tugas Mandiri Sistem Kontrol D.III Dan D.IV - Minggu 1Dokumen27 halamanTugas Mandiri Sistem Kontrol D.III Dan D.IV - Minggu 1Laso Alfasa YusufBelum ada peringkat

- Sop Pemeliharaan AcDokumen2 halamanSop Pemeliharaan Acaj pandapotanBelum ada peringkat

- PPMB BoilerDokumen2 halamanPPMB BoilerAlam RizkyBelum ada peringkat

- Balance of PlantDokumen49 halamanBalance of PlantMeidiantoro Agung SetiadiBelum ada peringkat

- UntitledDokumen3 halamanUntitledRenaldy TulungenBelum ada peringkat

- Contoh Spek Material MEP GedungDokumen35 halamanContoh Spek Material MEP Gedungtechnology01100% (1)

- PhototeraphyDokumen13 halamanPhototeraphymelky dominggusBelum ada peringkat

- Master Laporan PKL Calon AK3L - Kel 2 Revisi Sabtu 2023Dokumen48 halamanMaster Laporan PKL Calon AK3L - Kel 2 Revisi Sabtu 2023dita rahmawatiBelum ada peringkat

- B - K3 P&idDokumen21 halamanB - K3 P&idqurobiBelum ada peringkat

- Syringe Pump (2023)Dokumen13 halamanSyringe Pump (2023)melky dominggusBelum ada peringkat

- SOP PendinginDokumen1 halamanSOP Pendinginsabriyadi100% (1)

- Basic of Pressure VesselDokumen23 halamanBasic of Pressure VesselPutra EngineerBelum ada peringkat

- P&ID Dan SensorDokumen17 halamanP&ID Dan Sensorbangkit swadiBelum ada peringkat

- Infusion Pump (2023)Dokumen13 halamanInfusion Pump (2023)melky dominggusBelum ada peringkat

- 005 - GD3472-ENG-SP-E-005 - Spesifikasi Utility (AC, Pompa) For MessDokumen8 halaman005 - GD3472-ENG-SP-E-005 - Spesifikasi Utility (AC, Pompa) For MessZeps SaepudinBelum ada peringkat

- Checklist RSGH-1Dokumen1 halamanChecklist RSGH-1SugiBelum ada peringkat

- Bejana Tekan (CNG)Dokumen68 halamanBejana Tekan (CNG)Fadli Ryan ArikundoBelum ada peringkat

- Tune Up Motor Bensin KonvensionalDokumen44 halamanTune Up Motor Bensin KonvensionalArrifah Putri Nadila100% (4)

- Instrumentasi Pabrik Gula BaruDokumen36 halamanInstrumentasi Pabrik Gula Baruinstalasi TBBelum ada peringkat

- Tune Up Mesin Bensin Part 1Dokumen21 halamanTune Up Mesin Bensin Part 1Samsudin SyahroniBelum ada peringkat

- Pemeliharaan Kapasitor, Reaktor Dan SVCDokumen37 halamanPemeliharaan Kapasitor, Reaktor Dan SVChanifzuraidaBelum ada peringkat

- Form Maint CondDokumen1 halamanForm Maint CondAgus WibowoBelum ada peringkat

- SK Inspeksi PLTA BesarDokumen22 halamanSK Inspeksi PLTA BesarraitoBelum ada peringkat

- Tugas DDTP 2Dokumen9 halamanTugas DDTP 2Prihalisa NingendahBelum ada peringkat