Test Projext Lks 17

Diunggah oleh

Aneka Info BagusDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Test Projext Lks 17

Diunggah oleh

Aneka Info BagusHak Cipta:

Format Tersedia

Dokumen-dokumen dalam lembar soal berikut meliputi beberapa

bagian diantaranya adalah :

1. LKS2018_TPRA.doc Bagian A : Kisi-Kisi Lomba

2. LKS2018_TPRA.doc Bagian B : Petunjuk Lomba

3. LKS2018_TPRA.doc Bagian C : Soal – Soal Lomba

4. LKS2018_TPRA.doc Bagian D : Gambar / Drawing

5. LKS2018_TPRA.doc Bagian E : Peralatanan Perlengkapan

6. LKS2018_TPRA.doc Bagian F : Skematik Penilaian

7. LKS2018_TPRA.doc Lampiran detail Alat dan Bahan

Daftar Isi

Daftar Isi .......................................................................................................................................................1

BAGIAN A - KISI-KISI LOMBA ...................................................................................................................2

1. Pendahuluan ......................................................................................................................................3

2. Spesifikasi Kompetensi.....................................................................................................................3

3. Strategi Asesmen dan Spesifikasi ...................................................................................................5

4. Skema Penilaian ................................................................................................................................6

5. Test Project (Proyek Uji LKS) ........................................................................................................7

6. Keterampilan Manajemen danKomunikasi ....................................................................................8

7. Persyaratan Keamanan ....................................................................................................................8

8. Alat dan Bahan ..................................................................................................................................8

9. JADWAL LOMBA (Tentative) ...........................................................................................................9

10. Usulan Area Kompetisi (lay out Kompetisi)................................................................................ 10

11. Sarana bagi Pengunjung dan Media ........................................................................................... 10

12. Keberlanjutan/ sustainability ........................................................................................................ 10

BAGIAN B - PETUNJUK LOMBA .............................................................................................................. 11

PETUNJUK UNTUK PESERTA LOMBA ................................................................................................ 12

Informasi Keselamatan (Safety) ........................................................................................................ 13

BAGIAN C - Test Project (Proyek Uji LKS) ......................................................................................... 14

COMPETITION DETAILS - MODULE A (TASK 1) ....................................................................................... 15

COMPONENT FABRICATION AND BRAZING ........................................................................................... 15

COMPETITION DETAILS - MODULE B (TASK 2) ....................................................................................... 16

REFRIGERATION SYSTEM INSTALLATION AND COMMISSIONING .......................................................... 16

COMPETITION DETAILS - MODULE C (TASK 3) ....................................................................................... 23

AIR CONDITIONING INSTALLATION & COMMISSIONING ....................................................................... 23

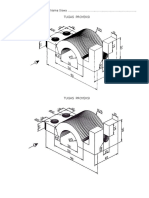

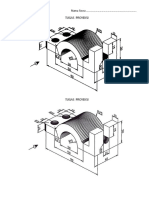

BAGIAN D - GAMBAR / DRAWING ..................................................................................................... 28

BAGIAN E - PERALATAN & PERLENGKAPAN ................................................................................ 69

A. Peralatan yang disiapkan peserta .............................................................................................. 70

B. Peralatan & Perlengkapan yang Disiapkan Panitia/Penyelenggara ........................................... 71

BAGIAN F- SKEMA PENILAIAN ........................................................................................................... 72

LAMPIRAN ............................................................................................................................................... 74

Catatan :.................................................................................................................................................... 75

Detail Bahan.............................................................................................................................................. 76

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 1

LKS2018_TPRA.doc Bagian A

BAGIAN A

KISI-KISI LOMBA

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 2

1. Pendahuluan

LKS (lomba Keterampilan Siswa) SMK merupakan salah satu uapaya pemerintah dalam

meningkatkan kompetensi siswa SMK dan merupakan jenjang untuk menuju di level

ASEAN dan dunia. Dokumen ini dibuat sebagai garis besar panduan bagi pelaksana

kompetisi, juri dan kompetitor bidang Refrigeration and AC guna menyamakan persepsi

tentang lomba, persiapan sarana dan prasarana, persiapan penilaian dan persiapan bagi

kompetitor dalam menghadapi kompetisi.

1.1. Nama dan Deskripsi Keterampilan

1.1.1. Nama bidang Keterampilan/ Skill adalah Refrigeration and Air Conditioning

1.1.2. Deskripsi Keterampilan

Teknisi refrigeration (HVAC/R) marus mampu melakukan pekerjaan instalasi,

komisioning, perawatan dan perbaikan sistem refrigeration dengan transfer panas yang

berarti uap dan kompresi siklur refrigeration; mis. Sistem refrigeration pada pendinginan

ruangan, freezer, sistem tata udara, liquid cooler dan heat pump. Sistem harus

beroperasi dengan menggunakan refrigerant yang umum digunakan (HFC) atau

menggunakan natural refrigerant yang umum digunakan.

1.1.3. Persyaratan kompetitor

- Peserta Lomba dipilih oleh propinsinya masing-masing.

- Syarat peserta adalah siswa SMK yang sesuai dengan jurusan Teknik Pendingin dan

Tata Udara

- Kompetisidilakukansecara individual. Jumlahpesertadalam 1 team mewakili 1 SMK

dan 1 team terdiridari 1 orang.

1.2. Ruang Lingkup

Setiap Juri dan kompetitor serta panitia penyelenggara dan team teknis lapangan harus

memahami technical description ini.

2. Spesifikasi Kompetensi

Kompetisi adalah demonstrasi dan penilaian dari kompetensi yang terkait dengan bidang

keterampilan tertentu. Test project hanya terdiri dari pekerjaan praktek.

2.1. Component fabrication

2.1.1. Component fabrication

Kompetitor harus mengetahui dan memahami :

Prinsip dasar pemipaan

Komponendasar

Pemilihan filler material

Pengelasan

Technical drawing

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 3

Kompetitor harus mampu:

Membaca diagram pemipaan (gambar teknik)

Melakukan pekerjaan pemipaan (bending, swaging, flaring, reaming)

Melakukan pengaturan api torch brazing.

Melakukan proses penyambungan brazing.

Menggunakan aliran nitrogen pada proses pengelasan.

Melakukan pekerjaan dengan aman.

2.1.2. Pemasangan sistem Refrigeration dan Komisioning;

Kompetitor harus mengetahui dan memahami:

Prinsip dasar refrigeration

Standar Worldskills Refrigeration

Prinsip Dasar plumbing dalam sistem refrigeration and air conditioning, termasuk

drainase.

Prinsip electrical

Diagram pemipaan sistem refrigeration

Diagram electric

Kompetitor harus mampu:

Membaca diagram pemipaan, electrical diagram, plans and specifications

Melengkapi komponen dan bahanyang diperlukan untuk instalasi

Melakukan pekerjaan brazing dan menyambung dua bahan logam yang berbeda

jenis yang biasa ditemui dalamsistem refrigeration and air conditioning misalnya

kuningan dan besi

Merakit komponen sistem

Memasang pemipaan sistem refrigeration sesuai dengan standar world skills

Memasang komponen kontrol dan regulator sesuai dengan standar world skills

Memasang kontrol elektrik dan komponennya

Memasan electronic controls dan peralatan yang terkait seperti sensor dan tranducer

Memeasang electrical wiring sesuai denganWorldskills standards

Melakukan Pressure test sesuai denganWorldskills standards

Malakukan Evakuasi pada sistem sesuai denganWorldskills standards

Mengevaluasi electrical wiringunruk tujuan keamanan sebelum dihubungkan ke

sumber tegangan

Bekerja dengan aman.

2.1.3. Pemasangan sistem AC dan komisioning:

Kompetitor harus mengetahui dan memahami:

Menjelaskan parameter desain

Memahami Worldskills Refrigeration standards

Memahami prinsip dasar refrigeration

Menangani refrigerant dengan aman

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 4

Kompetitor harus mampu:

Melakukan pengisian sistem dengan jenis refrigerant dan jumlah yang tepat untuk

tujuan efisiensi operasi sistem

Mengoperasikan sistem refrigeration dengan benar.

Melakukan pemeriksaan dan verifikasi sistem distribusi udara dengan benar.

Melakukan pemeriksaan dan pengujian istalasi kelistrikan dengan benar

Melakukan pengaturan seting peralatan pengendali/ control aliran refrigerant untuk

kinerja sistem yang optimal.

Melakukan pengaturan kontrol electrical dan electronic controls untuk kinerja sistem

yang optimal.

Menggunakan alat ukur

Mencatat parameter operasi sistem

Bekerja dengan aman

Pengetahuan Teori

A. Pengetahuan teori diperlukan tetapi tidak diuji secara explisit.

B. Pemahaman tentang aturan dan regulasi tidak diujikan.

Pekerjaan Praktek

Test Project di desain untuk uji skill bagi kompetitor sebagaimana disebutkan pada poin

2.1(Spesifikasi Kompetensi)

a. Refrigeration pipe-work

b. Electrical wiring

c. Component & system installation

d. Commissioning & adjustment

e. Work practices and safety

3. StrategiAsesmendanSpesifikasi

Penilaian diberikan berdasarkan standar. Masing-masing pekerjaan di dibreakdown

menjadi pekerjaan sekunder dan diberikan bobot penilaian secara proporsional dengan

berbagai pertimbangan (misal tingkat kesulitan, waktu yang dibutuhkan, proses yang

harus dilalui), sehingga menghasilkan penilaian standar yang obyektif dengan kriteria

yang jelas.

Secara umum aspek penilaian adalah aspek standar pemasangan komponen, waktu

kerja sesuai dengan standar yang ditetapkan (waktu yang disediakan dalam kompetisi

ini), proses kerja (sesuai dengan SOP dan memperhatikan aspek lingkungan), standar

hasil (apakah memenuhi kriteria standar yang ditetapkan/ berlaku) dan aspek safety

practice.

Semua penilaian pada masing masing aspek akan diakumulasi dan peserta yang berhasil

mengumpulkan nilai tertinggi, adalah peserta yang menang.

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 5

4. SkemaPenilaian

Setiap Test Project harus memiliki skema penilaian berdasarkan kriteria penilaian yang

dijelaskan pada poin 3.2.

A. Usulan skema penilaian dibuat oleh orang yang mengembangkan Test Project.

Skema penilaian final dikembangkan dan disetujui oleh semua juri pada saat

kompetisi (TCM juri)

B. Draft skema penilaiandiberikan kepada calon kompetitor yang akan mengikuti

kompetisi maksimal 2 bulan sebelum hari H kompetisi.

4.1. Kriteria penilaian

Bagian ini menjelaskan kriteria penilaian dan jumlah nilai (subyektif dan obyektif) yang

diberikan. Total jumlah nilai untuk semua kriteria penilaian adalah 100 poin.

Marks

Subjective

Section Criterion

(if Objective Total

applicable)

A Component Fabrication 15 15

Refrigeration System installation 50

B 50

and Commisioning

Air conditioning Installation and 20

C 20

Commisioning

D Work practices and safety 15 15

Total 100 100

4.2. Penilaian Subyektif

Tidak digunakan.

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 6

4.3. Spesifikasi penilaian Keterampilan

Kriteria penilaian keterampilan jelas berdasarkan spesifikasi aspek yang menjelaskan

bagaimana dan alasan penilaian diberikan.

modules

Section Criterion Total

1 2 3

A Component Fabrication 15 15

B Refrigeration System installation and 50

50

Commisioning

C Air conditioning Installation and

20 20

Commisioning

D Work practices and safety 5 5 5 15

Total 20 55 25 100

5. Test Project (ProyekUji LKS)

5.1. Format / Struktur Test Project

Test project didesain secara berurutan dan dipisahkan menjadi modul-modul.

Test Project dibagi menjadi 2 bagian, bagian A dan bagian B. Bagian A terdiri dari

deskripsi pekerjaan. Bagian B terdiri dari instruksi bagi kompetitor, spesifikasi dan

manual operasi dari peralatan.

Test Project terdiri dari modul berikut :

Module 1: Component fabrication and brazing

Module 2: Refrigeration equipment, installation, commissioning and adjustment

Module 3: Air Conditioning equipment installation, commissioning and adjustment

5.2. Persyaratandesain Test Project

Secara keseluruhan, test project harus:

Berbentuk moduler

Sesuai dengan deskripsi teknik

Sesuai dengan WorldSkills Refrigeration Standard terkini.

Sesuai dengan persyaratan dan standard penomoran WorldSkills.

Sesuai dengan skala penilaian yang akan di finalisasi pada saat kompetisi sesuai

dengan poin 3.2.

Akan disupply dalam bentuk soft/ hard copy

Mencantumkan daftar material

Kriteria penilaian harus dibuat untuk menilai project secara obyektif.

Kompetitor harus menyelesaikan seluruh modul dengan menggunakan bahan dan

sarana dan prasarana yang disediakan oleh panitia (tools disediakan oleh masing-

masing kompetitor)

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 7

5.3. Detail Proyek Uji

Detail soaldibahaspada“Bagian C”dokumenini,dimulai dari halaman 15.

6. KeterampilanManajemendanKomunikasi

5.1. Diskusi

Sebelum kompetisi, kompetitor sebaiknya melakukan diskusi, komunikasi terkait dengan

materi test project dan kompetisi dengan pihak terkait (pelaksana kompetisi, expert/

pembimbing) utnuk mendapatkan gambaran yang jelas tentang kompetisi yang belum

dipahami dan kemungkinan progres terkini terkait dengan kompetisi.

5.2. Informasi kompetitor

Semua informasi terkait dengan kompetisi dapat diasses secara online di portal milik LKS

SMK.

Informasi tersebut dapat berupa:

• Aturan kompetisi

• Deskripsi teknik

• Materi (test project)

• Dan informasi yang lain terkait dengan kompetisi

7. PersyaratanKeamanan

Berdasarkan UU no 1 tahun 1970 tentang Keselamatan kerja.

• Seluruhkompetitorharusmenggunakankacamatasafetyketikamenggunakanperalatanta

ngan/ mesin yang mungkinmenyebabkanbahayabendaasingmasukkemata.

• Juriakanmenggunakanperangkat safety yang sesuaisaatmelakukaninspeksi,

pengecekan atau bekerja di area project kompetitor

8. AlatdanBahan

8.1. Daftar Infrastruktur

Daftar Infrastruktur dalam proses penyusunan dan dapat selalu di update pada website

LKS.

Organizer kompetisi menggunakan dokumen ini sebagai acuan untuk menyediakan

fasilitas dan infrastruktur lomba.

Spesifikasi infrastruktur dan itemnya diajukan oleh juri untuk kompetisi yang akan

dilaksanakan. Organizer kompetisi secara bertahap mengupdate infrastruktur sesuai

dengan kondisi aktual.

Pada saat kompetisi, juri harus mereview dan mengupdate daftar infrastruktur utnuk

persiapan kompetisi. Juri memberikan saran kepada tim teknis jika ada kebutuhan

tambahan ruangan atau peralatan.

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 8

8.2. Bahan , Peralatan, dan tool yang harus dibawa kompetitor

Setiap kompetitor harus membawa peralatan tangan yang diperlukan untuk

mengerjakan setiap modul kompetisi, dan tidak ada persyaratan yang mengharuskan

pelaksana untuk menyediakan tools cadangan.

Daftar peralatan peserta dapat mengacu pada bagian E, dokumen ini

8.3. Bahan, alat dan tools untuk juri

Disediakan oleh pelaksana kompetisi.

Kompetitor tidak diizinkan untuk menggunakan tools yang disediakan untuk juri.

8.4. Bahan dan alat yang dilarang di area kompetisi

Kompetiitor tidak diijinkan untuk menggunakan bahan yang dibawa sendiri utnuk

menyelesaikan pekerjaan.

9. JADWAL LOMBA (Tentative)

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 9

10. UsulanArea Kompetisi (lay out Kompetisi)

Gambar Lay out Arena Kompetisi

General layout arena kompetisi dibuat untuk memenuhi kriteria tertentu, memastikan

bahwa memiliki ruangan yang cukuo untuk booth dan seluruh area kerja kompetitor,

tidak boleh kurang dari 25m x 25 meter untuk 17 kompetitor. (lihat gambar lay out

arena kompetisi dalam buku ini). Gambar Lay out termuat pada halaman 66 (R.009)

dalam doukumen ini.

11. Sarana bagi Pengunjung dan Media

Disediakan ruang bagi pengunjung yang ingin menyaksikan atau media yang

mengekspose lomba. Dalam gambar lay out (R.009) tampak tersedia area bagi media,

pengunjung dan penjelasan denah pada umumnya.

12. Keberlanjutan/ sustainability

Kesempatan sangat terbuka bagi kompetitor yang memiliki kompetensi mendekati

standar kompetisi yang ditetapkan. Dengan modal kompetensi yang dimiliki, kompetitor

memiliki peluang untuk bekerja dibidang Refrigeration and AC diperusahaan atau

peluang wirausaha yang memiliki potensi margin yang menjanjikan. Kompetitor yang

berprestasi berpeluang menjadi mentor bagi adik-adik kelasnya sehingga akan

menularkan strategi kompetisi yang tentu saja ikut membantu bangsa ini semakin maju

dengan potensi yang dimiliki angkatan kerjanya akan semakin luas. Kompetitor yang

berprestasi akan menjadi virus untuk membangkitkan kesadaran penguasaan

kompetensi bagi masyarakat dan inilah impact yang diharapkan dari pelaksanaan

kompetisi keterampilan.

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 10

LKS2018_TPRA.doc Bagian B

BAGIAN B

PETUNJUK LOMBA

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 11

PETUNJUK UNTUK PESERTA LOMBA

Soal LKS ini dibuat untuk menguji peserta Lomba dalam memasang atau merakit peralatan

sistem refrigerasi dan Tata Udara (split air conditioner), termasuk melakukan proses perbaikan

pada peralatan tersebut.

A. Soal Lomba

Ada Lima (3) soal lomba yang akan diujikan dengan total waktu adalah 17,5 jam.

A Component Fabrication 20 POIN 4 JAM

B Refrigeration System installation and 55 POIN 10 JAM

Commisioning

C Air conditioning Installation and Commisioning 25 POIN 3,5 JAM

B. Informasi Tambahan

Beberapa informasi tambahan berkenaan dengan lomba akan diberikan pada saat kompetisi

diantaranya adalah :

- Jadwal detail lomba.

- Persyaratan yang berhubungan dengan keselamatan dan kesehatan kerja (K3)

- Kategori peraturan dan prosedur lomba

- Dan beberapa informasi lain yang dianggap perlu untuk disampaikan

C. Alokasi Waktu Penyelesaian Soal

Setiap peserta lomba diwajibkan untuk dapat menyelesaikan soal sesuai dengan waktu yang

telah ditetapkan dan tidak diberikan penambahan nilai pada saat peserta dapat

menyelesaikan soal lebih cepat daripada waktu yang telah ditetapkan. Penambahan waktu

tidak akan diberikan kepada seluruh peserta.

Pada saat peserta telah menyelesaikan pemipaan peserta harus meminta juri menilai

pekerjaannya dengan melakukan test kebocoran kurang lebih 15 menit sebelum melanjutkan

pada tahap berikutnya, dan juga 10 menit untuk menilai hasil proses pemvakuman yang

dilakukan oleh peserta.

D. Poin Pengecekan

Hal penting dalam lomba ini adalah adanya prosedur yang menghendaki setiap peserta

untuk meminta kepada juri untuk mengobservasi setiap langkah kerja yang dilakukannya.

Sebagai contoh pada saat peserta telah menyelesaikan proses pemvakuman unit, maka

peserta meminta salah seorang juri untuk melakukan observasi hasil pekerjaannya dan

meminta juri untuk menandatangani kotak proses vakum yang tersedia dalam soal.

Silahkanlihatpadacontohberikut :

Proses Pemvakuman Sistem Juri:

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 12

InformasiKeselamatan (Safety)

Selama Lomba, seluruh peserta diwajibkan mengikuti dan melaksanakan aturan keselamatan

yang telah ditetapkan, yaitu :

1. Sepatu Kerja :

Diwajibkan untuk menggunakan sepatu keselamatan (Safety Shoes).

2. Pakaian Kerja :

• Menggunakan baju kerja dengan bagian tangan dan kaki sepenuhnya terlindungi

(trousers or overalls).

• Tubuh bagian atas selalu tertutup.

• Lengan harus tertutup dengan menggunakan pakaian lengan panjang pada saat

pengelasan dan penanganan Refrigerant.

3. Pelindung Mata

• Wajib mengenakan pelindung mata (Kaca Mata) putih atau Clear Glasses.

• Terutama untuk pekerjaan brazing, soldering, filing, reaming, hack-sawing, drilling,

grinding dan penanganan refrigerant, dry nitrogent dan udara bertekanan., termasuk

ketika sedang mengerjakan pekerjaan kelistrikan.

4. Sarung Tangan

• Harus digunakan pada saat Brazing dan penanganan refrigerants

• Wajib digunakan pada saat melakukan pekerjaan kelistrikan termasuk pengujian

kelistrikan.

5. Kelistrikan

Seluruh peserta wajib untuk meminta izin dari Juri pada saat ingin mengoperasikan semua

peralatan listrik kecuali peralatan kerja seperti Bor dan hand power tools lainnya.

Setiap peserta yang terindikasi tidak menggunakan peralatan keselamatan yang telah

ditentukan dapat diberhentikan aktivitasnya oleh Juri sampai peserta tersebut memenuhi

persyaratan keselamatan yang dimaksud.

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 13

LKS2018_TPRA.doc Bagian C

BAGIAN C

Test Project (Proyek Uji LKS)

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 14

COMPETITION DETAILS - MODULE A (TASK 1)

COMPONENT FABRICATION AND BRAZING

MAXIMUM TIME ALLOWED - 4 HOURS 20 MARKS

SCOPE

The Competitors are required to fabricate a copper tubing part of the refrigerant circuit that will

form the hot gas side heat exchanger, this coil will be incorporated into the design of the

system at a later stage. The coil is constructed according the drawing R.001. This entire will be

mounted on the working cradle (R.002) and sit also in the bottom of a tank to heat up the

water with the potential of the hot gas temperature being installed in Module B.

TIMING

Competitors are to all complete the copper tubing construction at the same time in the morning

of C1, this will allow for marking to take place in the afternoon, any Competitors that do not

finish Module A in the allocated time will be required to submit the unfinished project for

assessment. Competitors will receive additional points for completing this module in less than

the allocated time (as defined in the marking summary) providing that the fabricated

component does not leak when pressure tested.

ASSESSMENT

Competitors will be assessed as per technical description, the marking scale will reflect

dimensions and tolerances for assessment in addition to the quality of brazed joints. Fabricated

component will be tested for leaks by pressure testing with dry nitrogen to ensure no leaks are

present. Any Competitor who does not complete Module A in the required time (3 hours) will be

allowed to complete it after it is assessed and handed back to them during Module B – no

additional time will be allowed for either Module A or Module B for those who do not complete

the fabrication in the allotted time.

DRAWINGS

R.001 Construction part Hot gas tube in tube heat exchanger(project detail 8 sheets, task 1

for Competitors)

R.002 Components General Lay Out

COMPONENTS

Components to be installed are shown in drawing R.001

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 15

COMPETITION DETAILS - MODULE B (TASK 2)

REFRIGERATION SYSTEM INSTALLATION AND COMMISSIONING

MAXIMUM TIME ALLOWED - 10 HOURS 55 MARKS

SCOPE

Competitors are to install a refrigeration system to refrigerate a small-scale ice rink and use the

hot gas side to heat up water for heat pump application. This system shows the potential of a

refrigerant circuit to cool down water on one hand and heat up water for using it for hand

washing for example.

The Competitors are required to use the supplied components along with the coil fabricated in

Module A to form a refrigeration system for cooling down water to form ice and heat up water

with the hot gas side. If the hot water reaches a fixed temperature the system has to switch

with the solenoid valves direct to the condenser. A capacity control valve is used to ensure

suction pressure does not drop below design. Refrigerant is R134a.

Competitors are required to connect all components to a prewired electrical panel

TIMING

Competitors are to all complete the installation over C1, C2, and C3. The completed project with ice rink

frozen may be left running and displayed on C4.

ASSESSMENT

Competitors will be assessed as per technical description with particular weighting on the

commissioning and operation of the project.

DRAWINGS

R.001 Construction part Hot gas tube in tube heat exchanger (and detail construction - 8

sheets)

R.002 Componentns General Lay Out and Task 2’s bay (and detail construction - 12 sheets)

R.003 Evaporator Coil For Ice Rink (and detail construction - 8 sheets)

R.004 Hot and Freeze Water Box (and detail construction - 3 sheets)

R.005 Refrigerant flow diagram (1 sheet)

R.006 Electrical switch box (1 sheet)

R.007 Electrical diagram (1 sheet)

R.008 Craddle frame for task 3 (1 sheet)

R.009 AC Lay Out (1 sheet)

R.010 Competition Area (2 sheets)

R.011 Psychrometric Chart SI and IP (2 sheets)

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 16

COMPONENTS

Components to be installed will include the following;

Compressor (Copeland RRT10K1E-PFZ959)r

Condensor Coil assembly (Copeland 566-1167-01)

Liquid Receiver (Copeland 577-0315-05)

Filter Drier (Emerson Climate EK-0525))

Sight Glass (Emerson Climate HMI-1TT2)

Thermostatic Expansion Valve (Sporlan)

Hot gas regulator (Danfoss KVC 12)

Suction Accumulator (Alltemp)

Solenoid Valves (Sporlan)

Check Valve (Danfoss)

Service Valves (NDL)

Pressure Relief Valves (Superior)

High and Low Pressure Control (Ranco)

Electrical switchboard

Electronic Temperature Controls (Johnson Controls (A421ABC-02C) for cold water and hot

water

SYSTEM DESIGN SPECIFICATIONS

The following system design specifications for the installation should be used for commissioning

and control setting and are as follows:

SYSTEM SPECIFICATIONS

Refrigerant = R134a

Maximum ambient temperature = 35°C Db, 28°C Wb

Design saturated suction temperature = -15 °C

Suction line pressure drop = 1 K

CONTROL AND SAFETY SETTING

Low Pressure Controller cut off 5K lower than design saturated suction temperature (SST).

Low Pressure Controller cut in at -10 °C saturated suction temperature

Capacity control valve to maintain -15 °C saturated suction temperature

High Pressure cut out the system when the Condensing temperature reaches 55 °C

Temperature controller cut out at -15 °C

Temperature controller cut in at -10 °C

Temperature controller cut in at 46 °C to switch the solenoid valves & cut out at 35 °C to

start heating water again

SYSTEM OPERATION

Capacity control valve set to maintain -15 °C saturated suction temperature and limit

temperature cycling to safety only (unit should run continually and not cycle on and off)

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 17

INSTALL AND COMMISSION REFRIGERATION SYSTEM

All Competitors will be required to perform the following tasks to complete this module, task 6

has an Expert sign off sheet which needs to be filled in and signed prior to moving ahead on

this task

1. INSTALL REFRIGERATION SYSTEM

All Competitors will supplied with all necessary equipment and materials to complete the

installation of the refrigeration system in accordance with test project drawings and WorldSkills

International Standard for Refrigeration and Air Conditioning.

Refer to the following project drawings to assist to complete this task

R.001 hot gas tube in tube heat exchanger (Previous task)

R.002 Components General Lay Out

R.003 Evaporator Coil(provide by competition committe)

R.004 Hot and Freeze Water Box(provide by competition technical committe)

R.005 Refrigerant flow diagram

R.006 Electrical switch box (pre wired/ provide or installed by competition technical

committe)

R.007 Electrical diagram (provide by competition technical committe)

2. INSTALL ELECTRICAL SYSTEM

All Competitors will supplied with all necessary equipment and materials to complete the

installation of the refrigeration system in accordance with test project drawings and WorldSkills

International Standard for Refrigeration and Air Conditioning.

Refer to the following project drawings to assist to complete this task

R.005 Electrical switch box

R.006 Electrical diagram

3. PRESSURE TEST SYSTEM

Carry out a staged pressure test of the primary refrigeration system (R134a) in accordance with

manufacturer’s equipment instructions and WorldSkills standards. The pressure test point

should not drop from the starting point in the fifteen (15) minutes after the pressure test is

isolated from the Nitrogen cylinder. If the pressure test has not been achieved, the Competitor

can continue to fix the leak and achieve the pressure test, however the full mark for Pressure

Test will be lost. The pressure test will be monitored remotely via a data logging process to

ensure all Competitors achieve the required pressure and standing time.

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 18

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 19

Comments :

Refrigeration evacuation test Jury 1 initial :

Jury 2 Initial :

Jury 3 Initial :

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 20

Comments :

Refrigeration systems electrical Jury 1 initial :

test

Jury 2 Initial :

Jury 3 Initial :

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 21

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 22

COMPETITION DETAILS - MODULE C (TASK 3)

AIR CONDITIONING INSTALLATION& COMMISSIONING

MAXIMUM TIME ALLOWED 3 HOURS 25 MARKS

SCOPE

Competitors will be provided with an air conditioning system that has been leak tested and

verified to have no leaks. Competitors will be required to install the supplied air conditioning

systems, Competitors will then be required to commission the system and plot operating

conditions on a psychometric chart.

TIMING

Competitors are all to complete this module on C4 at the same time

ASSESSMENT

Competitors will be assessed as per technical description with particular weighting on working

process and commissioning of the project.

DRAWINGS

R.009 lay out AC (will be provide in competition according to conditions)

R.011 Psychometric chart (SI and IP units)

1. PRESSURE TEST SYSTEM

Carry out a staged pressure test of system in accordance with manufacturer’s equipment

instructions and WorldSkills standards. The pressure test point should not drop from the

starting point in the fifteen (15) minutes after the pressure test is isolated from the Nitrogen

cylinder. If the pressure test has not been achieved, the Competitor can continue to fix the leak

and achieve the pressure test, however the full mark for Pressure Test will be lost. The pressure

test will be monitored remotely via a data logging process to ensure all Competitors achieve the

required pressure and standing time.

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 23

To be filled in by COMPETITORS under supervision by an Expert

PRESSURE TEST ATTEMPT #1

Starting test pressure : __________________________□ kPa □ psi

Starting Time : _________________________

Test pressure after standing time : __________________________□ kPa □ psi

Finishing Time : __________________________

PRESSURE TEST ATTEMPT #2

Starting test pressure : __________________________□ kPa □ psi

Starting Time : __________________________

Test pressure after standing time : __________________________□ kPa □ psi

Finishing Time : __________________________

Comments :

Air Conditioning Pressure test Jury 1 initial :

Jury 2 Initial :

Jury 3 Initial :

2. EVACUATION

Evacuate the refrigeration system in accordance with manufacturer’s instructions and

WorldSkills standards using the Deep Vacuum Method to hold a vacuum of at least 1000

microns (130Pa absolute) of mercury. The evacuation point should not rise to a value greater

than 1000 microns in the Ten (10) minutes after the vacuum pump is isolated from the system

under test.

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 24

To be filled in by EXPERTS ONLY

Evacuation Test

Starting evacuation level : __________________________□ microns

Starting Time : __________________________

Evacuation level after standing time : __________________________□ microns

Finishing Time : __________________________

Comments:

Air Conditioning Evacuation test Jury 1 initial :

Jury 2 Initial :

Jury 3 Initial :

3. ELECTRICAL TESTING

Under the supervision of an Expert, perform all necessary safety checks to ensure the Test

Project is safe to energize.

PLEASE FILL IN THE EXPERT CHECK POINT SHEET BELOW BEFORE PROCEEDING

ANY FURTHER

To be filled in by EXPERTS ONLY

Competitor Name:

Competitor Country:

All wiring inspected by Expert prior to energizing: □ Yes

Electrical safety checks performed prior to energizing: □ Yes

Comments:

Air Conditioning Electrical Test Jury 1 initial :

Jury 2 Initial :

Jury 3 Initial :

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 25

4. COMMISSION THE SYSTEM

Competitors are to commission the system for operation in accordance with the manufacturers

specifications supplied. Please fill out the following commissioning document with the system

fully operational, on Cooling mode, indoor fan on highest speed and as close to operating

temperatures as possible. Please indicate units by checking appropriate boxes.

Ambient Temperature : _____________ • Celsius • Fahrenheit

Return Air Dry Bulb Temperature : _____________ • Celsius • Fahrenheit

Return Air Wet Bulb Temperature : _____________ • Celsius • Fahrenheit

Supply Air Dry Bulb Temperature : _____________ • Celsius • Fahrenheit

Supply Air Wet Bulb Temperature : _____________ • Celsius • Fahrenheit

Air Velocity of indoor unit : _____________ • m/sec• ft/sec

Air Volume of indoor unit : _____________ • m3/sec • cfm

Indoor Fan Speed : • High • Medium • Low

Mode of Operation : • Cooling • Heating

Refrigerant Type : _____________ •

Mass of Refrigerant Charge : _____________ • grams • pounds

Suction Pressure : _____________ • kPa • psi

Discharge Pressure : _____________ • kPa • psi

Condenser Subcooling : _____________ • Kelvin • Fahrenheit Degrees

Total System Superheat : _____________ • Kelvin • Fahrenheit Degrees

Compressor Operating Current : _____________ • Amps

Indoor Fan Operating Current : _____________ • Amps

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 26

5. COOLING PROCESS

Plot the supply and return air conditions as specified in your commissioning report on the

psychrometric chart supplied. Join the supply and return conditions with a line as per below

example.

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 27

LKS2018_TPRA.doc Bagian D

BAGIAN D

GAMBAR / DRAWING

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 28

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 29

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 30

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 31

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 32

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 33

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 34

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 35

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 36

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 37

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 38

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 39

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 40

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 41

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 42

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 43

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 44

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 45

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 46

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 47

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 48

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 49

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 50

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 51

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 52

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 53

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 54

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 55

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 56

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 57

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 58

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 59

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 60

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 61

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 62

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 63

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 64

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 65

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 66

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 67

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 68

LKS2018_TPRA.doc Bagian E

BAGIAN E

PERALATAN & PERLENGKAPAN

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 69

A. PERALATAN YANG DISIAPKAN PESERTA

Peralatan berikut merupakan peralatan minimum yang dibawa oleh setiap peserta lomba dan

yang akan digunakan selama lomba berlangsung, peserta diperbolehkan membawa peralatan

lain yang dianggap perlu dan membantu dalam proses mengerjakan soal lomba.

Competitor Supply

Measuring, Preparatory pahse Refrigeration

Writing equipment, including, pencils, Set of gauges R-134a and R410A and R 32

coloured

pens, paper, highlighters Gauge manifold set R134a and R410A and R

32

Tape measure: 5 m Vacuum gauge, down to 50 Pascal

Centre punch Weighing Scale

Pipe reamer Ratchet key

Sand papper Schrader valve key

Set of drills: 1-10 mm Allen keys – imperial and metric

Water Level Digital Thermometers with at least 2 sensors

Ampere Clamp Electronic Leak Detector

Metal Rule: 300 mm Sling Psychrometric

Knife

Hammer

Hacksaw

Screw drivers Electrical Work

Try-square Wire Strippers

Set squares Electrician’s pliers

Long nose pliers Multigrips

Electrical Crimping Tools

Mechanical tasks Insulation Tester

Tube cutter, up to 22 mm Multi-meter

Files: flat, half round and round

Pipe Bending Machine 6 mm Safety

Pipe Bending Machine 10 mm Clothing, long sleeves, long work trousers

Pipe Bending Machine 12 mm Emergency cloth

Set of spanners up to 25 mm Safety shoes

Shifting spanners Clear Safety glasses

Side cutting pliers Gloves

Steel wool

Oil can

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 70

B. PERALATAN &PERLENGKAPAN YANG DISIAPKAN PANITIA/PENYELENGGARA

Daftar berikut merupakan peralatan dan perlengkapan yang harus disediakan oleh

panitia/penyelenggara lomba untuk digunakan selama lomba berlangsung.

DisediakanPanitia

PeralatanLomba PerlengkapanPenunjang

Vacuum Pump LCD Projector

Digital Vacuum Gauge Printer

Brazing Equipment White Board

Table Work Stop Watch

Ragum Vernier Caliper

Ledder/Tangga Ruler

Leak Detector Solution (air sabun/

Water Container (leak test)

busa sabun)

R.003 Evaporator Coil (sudah jadi dan

disiapkan panitia)

R.004 Hot and Freeze Water Box

(sudah jadi dan disiapkan panitia)

R.006 Electrical switch box

(sudah terinstall rangkaian kontrol

peserta hanya tinggal mmemasang

input output / tidak merangkai electric

control system)

KebutuhanJuri

PeralatanTulis (Pulpen, pensil, spidol, kertas A4)

Mejadankursi

Safety Pointer

First Aid (Kotak P3K) Roll Kabel

APAR (AlatPemadamApiRingan)

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 71

LKS2018_TPRA.doc Bagian F

BAGIAN F

SKEMA PENILAIAN

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 72

SKEMA PENILAIAN

Berikut ini adalah rangkuman skala penilaian untuk bidang Refrigerasi & Air Conditioning yang

harus dipersiapkan oleh seluruh kompetitor.

Lembar penilaian mengacu pada skema penilaian ini dan detail lembar penilaian akan diberikan

pada saat lomba

Gambaran teknis untuk Refrigerasi & Air Conditioning pada bagian F merupakan daftar

keterampilan yang harus dipenuhi oleh peserta lomba dan kriteria penilaian akan di berikan

untuk semua modul berikut:

Kriteria Keterampilan (Skill) Nilai Maksimum

A Component fabrication 15.00

B Refrigeration Installation and commisioning 50.00

C Air Conditioning Installation and Commisioning 20.00

D Health and Safety 15.00

Total 100.00

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 73

LKS2018_TPRA.doc Bagian F

LAMPIRAN

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 74

Catatan :

Dasar dari pembuatan dokumen ini adalah soal Worldskills competition. Kelancaran

pelaksanaan kegiatan LKS Nasional bidang RAC secara teknis harus memperhatikan beberapa

hal berikut :

Dokumen ini diperuntukkan sebagai petunjuk bagi panitia penyelenggara, calon

kompetitor dan juri.

Tim teknis panitia mencermati isi dokumen ini, sebagai acuan untuk mengetahui dan

memahami secara rinci batasan material, fasilitas dan infrastruktur mana yang harus

disiapkan panitia, dan mana yang harus disiapkan peserta/ kompetitor.

Untuk panitia teknis mohon dicermati dokumen ini pada bagian :

COMPETITION DETAILS - MODULE B (TASK 2) halaman 18 tentang fasilitas yang

harus disediakan panitia dan yang harus dibuat peserta

BagianE (peralatan & perlengkapan peserta serta peralatan & perlengkapan

disediakan panitia)

Kompetitor mencermati detail dokumen ini sebagai modal pemahaman terhadap

langkah kerja dan strategi saat kompetisi.

Calon juri mempelajari dan mencermati dokumen ini sebagai acuan umum dalam

melakukan penilaian kompetisi.

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 75

Detail Bahan

Test Project For Skills Refrigeration and Air Conditioning

National Vocational Students Skills Competition - 2018 Page 76

Anda mungkin juga menyukai

- Upload LKS 2015 Refrigation PDFDokumen34 halamanUpload LKS 2015 Refrigation PDFjokoBelum ada peringkat

- Test Project Refrigeration & Air Conditioning - LKS 2015 Provinsi AcehDokumen33 halamanTest Project Refrigeration & Air Conditioning - LKS 2015 Provinsi AcehJscIndraBelum ada peringkat

- Lks RefriDokumen41 halamanLks RefriAneka Info BagusBelum ada peringkat

- Kisi-Kisi Soal Refrigeration-LKS 2014Dokumen29 halamanKisi-Kisi Soal Refrigeration-LKS 2014Sujadi CherbondBelum ada peringkat

- Deskripsi Teknis LKS SMK 2019 - Industrial ControlDokumen76 halamanDeskripsi Teknis LKS SMK 2019 - Industrial Controladi folies100% (1)

- Deskripsi Teknis - MECAD - LKS SMK Kota Surabaya 2024Dokumen14 halamanDeskripsi Teknis - MECAD - LKS SMK Kota Surabaya 2024agung nurkholisBelum ada peringkat

- ADokumen16 halamanAakuBelum ada peringkat

- Soal LKS SMK 2019 Babel (Industrial Control)Dokumen22 halamanSoal LKS SMK 2019 Babel (Industrial Control)Angel FortuneBelum ada peringkat

- Analisis SKKD TKR, 2012-2013Dokumen10 halamanAnalisis SKKD TKR, 2012-2013firmanrusydiBelum ada peringkat

- 34 Mechanical Engineering CAD - Kisi2 Deskripsi Teknis LKS SMK Tk. Jatim 2024Dokumen16 halaman34 Mechanical Engineering CAD - Kisi2 Deskripsi Teknis LKS SMK Tk. Jatim 2024bayuBelum ada peringkat

- Teknik Dasar AcDokumen63 halamanTeknik Dasar AcyoudhiasthonBelum ada peringkat

- Kondensor Dan Cooling TowerDokumen76 halamanKondensor Dan Cooling TowerIlhamBelum ada peringkat

- Makalah Sistem AcDokumen33 halamanMakalah Sistem AcSetiawan WanBelum ada peringkat

- Log - Oo10.08.01Dokumen100 halamanLog - Oo10.08.01marrilynBelum ada peringkat

- Form Penilaian XiDokumen25 halamanForm Penilaian Xikomppak TVBelum ada peringkat

- SKKD Teknik Perbaikan Bodi Otomotif (WH) FPUPDokumen4 halamanSKKD Teknik Perbaikan Bodi Otomotif (WH) FPUPS Denny RamdhanyBelum ada peringkat

- 01 Template MODUL 2018 - RDokumen18 halaman01 Template MODUL 2018 - RAhmadBelum ada peringkat

- Memelihara TurbinDokumen50 halamanMemelihara TurbintrisnainvestBelum ada peringkat

- Deskripsi Teknis LKS SMK 2019 - CNC MillingDokumen26 halamanDeskripsi Teknis LKS SMK 2019 - CNC Millingafif udin100% (1)

- Deskripsi Teknis LKS SMK 2019 - Mobile RoboticsDokumen40 halamanDeskripsi Teknis LKS SMK 2019 - Mobile RoboticsDhani ChrisnaBelum ada peringkat

- Komponen Kontrol Refrigerasi Atau Air HandlingDokumen77 halamanKomponen Kontrol Refrigerasi Atau Air Handlingkomang kantun100% (8)

- 19 Electronics - Deskripsi Teknis LKS SMK Tk. Jatim Tahun 2024Dokumen29 halaman19 Electronics - Deskripsi Teknis LKS SMK Tk. Jatim Tahun 2024musaadinata5Belum ada peringkat

- Isi Buku InformasieditDokumen81 halamanIsi Buku InformasieditTopanis AbadiBelum ada peringkat

- Buku KerjaDokumen31 halamanBuku KerjaAep ApriatnaBelum ada peringkat

- DCE - 04 Spesifikasi Teknik Bidang SDA PDFDokumen103 halamanDCE - 04 Spesifikasi Teknik Bidang SDA PDFJorlens PalpialyBelum ada peringkat

- LKS Tptu 2021Dokumen23 halamanLKS Tptu 2021E DiBelum ada peringkat

- Standar Kompetensi Tenaga Teknis KetenagalistrikanDokumen50 halamanStandar Kompetensi Tenaga Teknis KetenagalistrikanCaleb ConnerBelum ada peringkat

- Pemeliharaan Servis Sistem PendinginDokumen50 halamanPemeliharaan Servis Sistem PendinginRudi HartonoBelum ada peringkat

- Deskripsi Teknis LKS SMK 2019 - Plumbing and HeatingDokumen35 halamanDeskripsi Teknis LKS SMK 2019 - Plumbing and HeatingAgus TamaBelum ada peringkat

- Bagian II Narasi Fabrikasi Perakitan Pes UdaraDokumen13 halamanBagian II Narasi Fabrikasi Perakitan Pes Udara아받Belum ada peringkat

- Pemeliharaan CondenserDokumen68 halamanPemeliharaan CondenserMuh SyahrulBelum ada peringkat

- Soal Ujikom ROUTINGDokumen3 halamanSoal Ujikom ROUTINGMelati A PertiwiBelum ada peringkat

- 302 Ahli Teknik Sistem Udara Dan Refrigerasi PDFDokumen12 halaman302 Ahli Teknik Sistem Udara Dan Refrigerasi PDFsatariahBelum ada peringkat

- 1218-KST-Teknik Pendingin Dan Tata UdaraDokumen3 halaman1218-KST-Teknik Pendingin Dan Tata UdaraReza Indra SatrioBelum ada peringkat

- Buku kerja-OH Sistem PendinginDokumen31 halamanBuku kerja-OH Sistem Pendinginhafiz alfataniBelum ada peringkat

- Mengoperasikan Mesin Diesel Generator PLTD BesarDokumen51 halamanMengoperasikan Mesin Diesel Generator PLTD BesarEGI GINANJAR -Belum ada peringkat

- Modul Perawatan Sistem Ac - Akhmad MahmudiDokumen50 halamanModul Perawatan Sistem Ac - Akhmad MahmudimahmudiBelum ada peringkat

- 2005-02-Sistem Manajemen K3 Dan RKL RPLDokumen74 halaman2005-02-Sistem Manajemen K3 Dan RKL RPLTaufik WahyudiantoBelum ada peringkat

- 9 Menggambar 2D Dengan Sistem CADDokumen4 halaman9 Menggambar 2D Dengan Sistem CADadhybrusBelum ada peringkat

- Laporan Visit IIDokumen11 halamanLaporan Visit IIRiskyjarimaBelum ada peringkat

- 022 DESKRIPSI SKKD Teknik Perbaikan BodiDokumen10 halaman022 DESKRIPSI SKKD Teknik Perbaikan BodiS Denny RamdhanyBelum ada peringkat

- Log - Oo18.031.011 BPDokumen30 halamanLog - Oo18.031.011 BPKukuh SetiyawanBelum ada peringkat

- Proposal Tugas Akhir Rev1Dokumen31 halamanProposal Tugas Akhir Rev1Mahmud100% (1)

- OTO - KR20.010.03 Memelihara-Servis Sistem Pendingin Dan Komponen KomponennyaDokumen118 halamanOTO - KR20.010.03 Memelihara-Servis Sistem Pendingin Dan Komponen KomponennyaJeki SumerahBelum ada peringkat

- Pemeliharaan Turbin Uap Dan Alat BantunyaDokumen50 halamanPemeliharaan Turbin Uap Dan Alat BantunyaUjanks Putra BorneoThea100% (7)

- Jobshhet CvavrDokumen20 halamanJobshhet CvavrismantoBelum ada peringkat

- Revisi/anindy Sesilia Melyn - 40040219650081 - Proporsal Metedologi Penelitian TerapanDokumen41 halamanRevisi/anindy Sesilia Melyn - 40040219650081 - Proporsal Metedologi Penelitian TerapanZuhdan RosidiBelum ada peringkat

- SKP Inspeksi PLTD PDFDokumen64 halamanSKP Inspeksi PLTD PDFQimpour Sibolang100% (1)

- Ri Oe RUIERP9 H YFFq BETc Y0 V8 Ood Ofc FWa JB9 Iw R4Dokumen31 halamanRi Oe RUIERP9 H YFFq BETc Y0 V8 Ood Ofc FWa JB9 Iw R4cendikia training centerBelum ada peringkat

- Peninjauan Konstruksi Pes - UapDokumen37 halamanPeninjauan Konstruksi Pes - UapFadli Ryan Arikundo100% (1)

- Job Sheet Ukk AcDokumen2 halamanJob Sheet Ukk AcTKRO SMK PUSPONEGORO TANJUNG100% (2)

- Proposal Laporan Akhir With Metode Pengambilan DataDokumen9 halamanProposal Laporan Akhir With Metode Pengambilan DataAnanto Sulistyo WidodoBelum ada peringkat

- LP Soft 003Dokumen4 halamanLP Soft 003Aneka Info BagusBelum ada peringkat

- Log Oo05 004 01 BPDokumen15 halamanLog Oo05 004 01 BPAneka Info BagusBelum ada peringkat

- Seven ToolDokumen32 halamanSeven ToolAneka Info BagusBelum ada peringkat

- Air Conditioning MachinesDokumen8 halamanAir Conditioning MachinesAneka Info BagusBelum ada peringkat

- LP Soft 004Dokumen4 halamanLP Soft 004Aneka Info BagusBelum ada peringkat

- Team BuildingDokumen34 halamanTeam BuildingAneka Info BagusBelum ada peringkat

- Sensor UltraDokumen7 halamanSensor UltraAneka Info BagusBelum ada peringkat

- LP Soft 005Dokumen4 halamanLP Soft 005Aneka Info Bagus100% (1)

- About Transduser and SensorDokumen43 halamanAbout Transduser and SensorAneka Info BagusBelum ada peringkat

- LP Soft 001Dokumen5 halamanLP Soft 001Aneka Info BagusBelum ada peringkat

- 2.tugas GarisDokumen2 halaman2.tugas GarisAneka Info BagusBelum ada peringkat

- Sensor 10Dokumen18 halamanSensor 10Aneka Info BagusBelum ada peringkat

- Sensor UltraDokumen7 halamanSensor UltraAneka Info BagusBelum ada peringkat

- 4 Gebang LogikaDokumen33 halaman4 Gebang LogikaAneka Info BagusBelum ada peringkat

- WaterflowDokumen7 halamanWaterflowAneka Info BagusBelum ada peringkat

- Contoh PresentasiDokumen14 halamanContoh PresentasiAneka Info BagusBelum ada peringkat

- Pendahuluan Materi Sistem DigDokumen35 halamanPendahuluan Materi Sistem DigAneka Info BagusBelum ada peringkat

- Modul Sensor Dan Transduser2Dokumen62 halamanModul Sensor Dan Transduser2yosferdi100% (1)

- TUGAS3 ProgramDokumen1 halamanTUGAS3 ProgramAneka Info BagusBelum ada peringkat

- Tugasdasar GamtekDokumen1 halamanTugasdasar GamtekAneka Info BagusBelum ada peringkat

- Konversi BilanganDokumen31 halamanKonversi BilanganAneka Info BagusBelum ada peringkat

- 4.TUGAS ProyeksiDokumen3 halaman4.TUGAS ProyeksiAneka Info BagusBelum ada peringkat

- Konversi BilanganDokumen31 halamanKonversi BilanganAneka Info BagusBelum ada peringkat

- PendahuluanDokumen16 halamanPendahuluanAneka Info BagusBelum ada peringkat

- Tugas GambarteknikDokumen3 halamanTugas GambarteknikAneka Info BagusBelum ada peringkat

- Modul Menginterpretasikan Gambar TeknikDokumen165 halamanModul Menginterpretasikan Gambar TeknikRudi Wijanarko80% (5)