Nerpan TNP Reaksi

Diunggah oleh

Febrianto0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

1 tayangan4 halamanJudul Asli

Nerpan tnp reaksi

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

1 tayangan4 halamanNerpan TNP Reaksi

Diunggah oleh

FebriantoHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 4

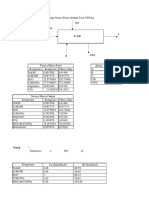

Menghitung neraca panas heat exchanger sebelum memasuki dryer

tank pada industri minyak kelapa sawit dengan feed Crude Palm Oil yang

masuk sebesar 10000 kg dan tidak terjadi perubahan suhu pada steam.

Steam

200

10000 Kg

CPO CPO

46 110

Steam

200

Gambar Skema Alat Heat Exchanger

Tabel Komponen feed

Kandungan Komposisi

CPO 70%

Air 30%

Tabel Komponen CPO

Kandungan Mr Komposisi

Asam Miristat 228 1,40%

Asam Palmiat 256 44%

Asam Stearat 284 3,60%

Asam Oleat 282 42%

Asam Linoleat 280 9%

Total 100,00%

Perhitungan Massa pada Feed

CPO = 70 % × Feed

= 70 % × 10000 kg/jam

= 7000 kg/jam

Air = 30 % × Feed

= 30 % × 10000 kg/jam

= 3000 kg/jam

Perhitung Massa Komponen CPO

Asam Miristat = 1,40 % × Massa CPO

= 1,40 % × 7000 kg/jam

= 98 kg/jam

Asam Palmitat = 44 % × Massa CPO

= 44 % × 7000 kg/jam

= 3080 kg/jam

Asam Stearat = 3,60 % × Massa CPO

= 3,60 % × 7000 kg/jam

= 252 kg/jam

Asam Oleat = 42 % × Massa CPO

= 42 % × 7000 kg/jam

= 2940 kg/jam

Asam Linoleat = 9 % × Massa CPO

= 9 % × 7000 kg/jam

= 630 kg/jam

Tabel Hasil perhitungan massa komponen CPO

Kandungan Komposisi Massa (Kg/jam)

Asam Miristat 1,40% 98

Asam Palmiat 44% 3080

Asam Stearat 3,60% 252

Asam Oleat 42% 2940

Asam Linoleat 9% 630

Total 100,00% 7000

Perhitungan Heat Capaciy (cp) komponen CPO

Berdasarkan Chemical Properties Handbook by Carl L. Yaws

Tabel Heat Capacity pada suhu 319,15 K

Kandungan (g) A B B D Cp (J/mol K) J/g.K

Asam Miristat 80,266 2,8162 -0,00601 5,1299E-06 533,6579264 2,340604941

Asam Palmiat 86,29 3,57237 -0,0073217 6,1001E-06 678,9469663 2,652136587

Asam Stearat 99,012 3,5874 -0,0072484 5,9035E-06 697,5408998 2,456129929

Asam Oleat 278,686 2,5434 -0,0054355 0,000004924 696,8371842 2,471053845

Asam Linoleat 241,348 2,3065 -0,0050663 4,7468E-06 615,7377092 2,199063247

Air 92,1 -0,04 -0,000211 0,000000535 75,2337831 4,179654617

Cp feed : 16,2986 KJ/Kg.K

Tabel Heat Capacity pada suhu 383,15 K

Kandungan (g) A B B D E Cp (J/mol K) J/g.K

Asam Miristat 80,266 2,8162 -0,00601 5,1299E-06 - 565,5476755 2,480472

Asam Palmiat 86,29 3,57237 -0,0073217 6,1001E-06 - 678,9469663 2,652137

Asam Stearat 99,012 3,5874 -0,0072484 5,9035E-06 - 697,5408998 2,45613

Asam Oleat 278,686 2,5434 -0,0054355 0,000004924 - 696,8371842 2,471054

Asam Linoleat 241,348 2,3065 -0,0050663 4,7468E-06 - 615,7377092 2,199063

- 3,69E-

Air 32,83051924

33,933 0,00842 0,000029906 -1,7825E-08 12 1,823918

Cp produk : 14,028 KJ/Kg.K

Perhitungan kalor dan massa steam

λ = 2793,2 – 852,45 KJ/Kg Cp steam = 1,93202

λ = 1940,75 KJ/Kg

Qsupply = msteam . λ

Qsupply = 1940,75x msteam.

Asume : Qloss = 5% Qsupply

Qloss = 5% . Qsupply

= 5% x 1940,75 msteam

= 97,0375 msteam.

Menghitung ΔHin dan Δhout

Treference = 25℃

ΔHin = m x Cp x ΔT

= 10000 x 16,2986 x (319,15-298,15)

= 3422715,06 KJ

ΔHout = m x Cp x ΔT

= 10000 x 14,028 x (383,15-298,15)

= 11970358 KJ

Neraca Panas Overall :

Akumulasi = ΔHin + Qsupply - ΔHout – Qloss + ΔHreaksi

Asumsi,

Steady state maka akumulasi = 0 ;

Tidak terjadi reaksi, ΔHreaksi = 0

Sehingga neraca panas overall menjadi,

Akumulasi = ΔHin + Qsupply - ΔHout – Qloss + ΔHreaksi

0 = ΔHin + Qsupply - ΔHout – Qloss + 0

ΔHin + Qsupply = ΔHout + Qloss

3422715,06 + 1940,75 Ms = 11970358 + 97,0375 Ms

Ms = 4636,103 Kg

Maka,

Qsupply = 1940,75 x msteam. Qloss = 97,0375 msteam.

Qsupply = 8997518,42 KJ Qloss = 449875,92 KJ

Tabel Neraca Panas Overall dari Heat Exchanger

Neraca panas total

ΔHin (KJ) ΔHout (KJ)

ΔH 3422715,06 ΔH 11970358

Qsupply 8997518,42 Qloss 449875,92

Total 12420233,5 Total 12420233

Anda mungkin juga menyukai

- Nerpan TNP ReaksiDokumen4 halamanNerpan TNP ReaksiFebriantoBelum ada peringkat

- Perhitungan Neraca Massa Gabungan 1Dokumen12 halamanPerhitungan Neraca Massa Gabungan 1Vanesa Julian NababanBelum ada peringkat

- Lampiran A FiksDokumen26 halamanLampiran A FiksRahmadPRtgBelum ada peringkat

- Apendik B Perhitungan Neraca EnergiDokumen44 halamanApendik B Perhitungan Neraca EnergiHelmi KurniaBelum ada peringkat

- Lampiran A Perhitungan Neraca Massa Pada Unit SterilizerDokumen77 halamanLampiran A Perhitungan Neraca Massa Pada Unit Sterilizergunawan putraBelum ada peringkat

- Lamp - Perht.Neraca PanasDokumen30 halamanLamp - Perht.Neraca PanasSilvia Yana UtamaBelum ada peringkat

- Final Hasriyani 22960070Dokumen3 halamanFinal Hasriyani 22960070shinboyosihideBelum ada peringkat

- Peringkat BatubaraDokumen5 halamanPeringkat Batubarayusuf AkmalBelum ada peringkat

- Praktikum Terpadu Perpindahan Panas - PKS Tanah GambusDokumen10 halamanPraktikum Terpadu Perpindahan Panas - PKS Tanah GambusGita Rohani Br PardedeBelum ada peringkat

- New Lampiran Neraca Panas ALDODokumen56 halamanNew Lampiran Neraca Panas ALDOchelsie camariBelum ada peringkat

- Lamp. A - Neraca MassaDokumen24 halamanLamp. A - Neraca MassaAhmad HermanBelum ada peringkat

- Pompa Reprocicating PDFDokumen285 halamanPompa Reprocicating PDFyusufluckBelum ada peringkat

- Super Heater 44220012Dokumen11 halamanSuper Heater 44220012muhmmsaidBelum ada peringkat

- 4 - Imroati - F2401211124-Lemak Rancimat Dan GCDokumen13 halaman4 - Imroati - F2401211124-Lemak Rancimat Dan GCImroati FBelum ada peringkat

- Lampiran A - Neraca Massa FixDokumen24 halamanLampiran A - Neraca Massa FixbrieeleeBelum ada peringkat

- Berat Molekul Rata-Rata PDFDokumen306 halamanBerat Molekul Rata-Rata PDFO SugoiBelum ada peringkat

- Perancangan PLTU Dengan Daya 100 MWDokumen5 halamanPerancangan PLTU Dengan Daya 100 MWasri novhandiBelum ada peringkat

- Ref 10 12 Hal Merllin A.S Full Paper SntemDokumen12 halamanRef 10 12 Hal Merllin A.S Full Paper Sntemmuhammad reja AhadiBelum ada peringkat

- Laporan Tetap Penentuan Peringkat BatubaraDokumen11 halamanLaporan Tetap Penentuan Peringkat BatubaraBang BiBelum ada peringkat

- Lampiran Perhitungan 2Dokumen23 halamanLampiran Perhitungan 2trisnadewi0% (1)

- Latihan Soal Tekpem Kelas ADokumen16 halamanLatihan Soal Tekpem Kelas AFahimah Tsaqafatul IslamiyahBelum ada peringkat

- Lampiran 3Dokumen29 halamanLampiran 3SilviaBelum ada peringkat

- 08 Neraca Massa Pabrik Biofuel Dari CPODokumen74 halaman08 Neraca Massa Pabrik Biofuel Dari CPOYanuar Raka100% (1)

- Tugas ATK (14,27,25,44,11,24,19)Dokumen25 halamanTugas ATK (14,27,25,44,11,24,19)Fitri Hardianti Dhitriyandra50% (2)

- Mailanda Saputra - 1 KIJ - MigasDokumen3 halamanMailanda Saputra - 1 KIJ - Migasagung baskoroBelum ada peringkat

- Lampiran 3Dokumen28 halamanLampiran 3Anis WahyuBelum ada peringkat

- Termo Ulfa RinaDokumen10 halamanTermo Ulfa RinarinaBelum ada peringkat

- Neraca Masa PDFDokumen491 halamanNeraca Masa PDFdedi mulyadiBelum ada peringkat

- Neraca EnergiDokumen85 halamanNeraca EnergialmengarunBelum ada peringkat

- Bab V Neraca EnergiDokumen6 halamanBab V Neraca Energifadila siti rahmaBelum ada peringkat

- CD MD-01Dokumen25 halamanCD MD-01IrmaWija KusumastutiBelum ada peringkat

- Uas Pengolahan GasDokumen6 halamanUas Pengolahan GasFita ChanBelum ada peringkat

- Appendix 3 PDFDokumen268 halamanAppendix 3 PDFesiBelum ada peringkat

- 123dok Pra Rancangan Pabrik Pembuatan Asam Laurat Dari Crude Palm Kernel Oil Cpko Dengan Kapasitas ProdukDokumen393 halaman123dok Pra Rancangan Pabrik Pembuatan Asam Laurat Dari Crude Palm Kernel Oil Cpko Dengan Kapasitas Produkwilson hermanBelum ada peringkat

- Jenis Biomassa Yang DipilihDokumen9 halamanJenis Biomassa Yang DipilihGodeliva FristianingrumBelum ada peringkat

- Hydrogen ConsumptionDokumen35 halamanHydrogen ConsumptionadisampurnoBelum ada peringkat

- Lampiran B Gliserol Be1lum FixDokumen26 halamanLampiran B Gliserol Be1lum FixRory SiregarBelum ada peringkat

- BM TrigliseridaDokumen24 halamanBM TrigliseridahanifBelum ada peringkat

- Gabungan Soal SoalDokumen13 halamanGabungan Soal SoalDeppi Kurniawan0% (1)

- LAMP B Neraca PanasDokumen104 halamanLAMP B Neraca PanasyulBelum ada peringkat

- Tugas TRK II-Rev1Dokumen10 halamanTugas TRK II-Rev1Betaria A SBelum ada peringkat

- 40 Neraca MassaDokumen8 halaman40 Neraca Massaarifin554Belum ada peringkat

- Bab 6 Analisis Data Benar (Hal 69 - 78)Dokumen12 halamanBab 6 Analisis Data Benar (Hal 69 - 78)RikonaJayaPurbaBelum ada peringkat

- Lampiran A - Neraca MassaDokumen19 halamanLampiran A - Neraca MassaIwang Septo PriyogoBelum ada peringkat

- Bab V Neraca EnergiDokumen7 halamanBab V Neraca EnergiMutiara RahmadhaniBelum ada peringkat

- Reactor CSTRDokumen17 halamanReactor CSTRLena NaikofiBelum ada peringkat

- Pertemuan - 6 - ATK II - Heater Using SteamDokumen14 halamanPertemuan - 6 - ATK II - Heater Using Steamlintang cahyaniBelum ada peringkat

- Lampiran 2 Neraca PanasDokumen54 halamanLampiran 2 Neraca Panasvhajar_3269141950% (2)

- Lampiran Neraca Massa BaruDokumen6 halamanLampiran Neraca Massa Barumarthen togarBelum ada peringkat

- Prof. Farel NapitupuluDokumen6 halamanProf. Farel NapitupuluEfrin SimbolonBelum ada peringkat

- Bab 4.Dokumen11 halamanBab 4.Arly Demenz'ionBelum ada peringkat

- Perhitungan Neraca EnergiDokumen13 halamanPerhitungan Neraca EnergiAdi SagitariusBelum ada peringkat

- Termodinamika Dan Kesetimbangan EnergiDokumen55 halamanTermodinamika Dan Kesetimbangan EnergiEva PermataBelum ada peringkat

- Reaksi Eksotermis..Dokumen14 halamanReaksi Eksotermis..Adhilna JannahhBelum ada peringkat

- Neraca Massa WordDokumen21 halamanNeraca Massa WordRezaTrisnaWahyudiBelum ada peringkat

- Abstrak (Intisari)Dokumen1 halamanAbstrak (Intisari)FebriantoBelum ada peringkat

- File 1Dokumen25 halamanFile 1FebriantoBelum ada peringkat

- Nerpan DG ReaksiDokumen6 halamanNerpan DG ReaksiFebriantoBelum ada peringkat

- H3PO4Dokumen1 halamanH3PO4FebriantoBelum ada peringkat

- H3PO4Dokumen1 halamanH3PO4FebriantoBelum ada peringkat

- Laporan KKN DesinfektanDokumen19 halamanLaporan KKN DesinfektanFebriantoBelum ada peringkat