Technical Drawing Notes

Diunggah oleh

Fakhrul HidayatHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Technical Drawing Notes

Diunggah oleh

Fakhrul HidayatHak Cipta:

Format Tersedia

Standar Dan Perjanjian Tanda Untuk Garis

Garis dalam gambar teknik bukan sekedar menunjukkan geometri dari obyek, tetapi

juga menunjukkan dimensi, posisi potongan dan penjelasan lain dari obyek. Sehingga

dalam gambar teknik perlu diperhatikan penggunaan jenis garis yang sesuai.

Ketebalan Garis

Secara umum dalam gambar teknik diperlukan dua jenis ketebalan, yaitu garis tebal

dan garis tipis. Tebal garis tipis, umumnya adalah setengah garis tebal.

Garis sangat tebal untuk menunjukkan besi-besi tulangan

(reinforcing bars),

Garis tebal yang menerus digunakan untuk sisi-sisi yang

terlihat dan garis-garis luar dari obyek.

Garis tipis digunakan untuk arsiran, dimensi, proyeksi dan

penjelasan lain dari obyek.

Jenis Garis

Batas luar dari obyek.

Perubahan bentuk geometri yang terlihat.

Batas material yang berbeda.

Arsiran.

Garis tengah yang sangat pendek.

Garis diagonal yang menunjukkan adanya void atau

lubang.

Kontur

Digunakan untuk menunjukkan garis yang melewati

pusat obyek (center lines).

Garis simetri

Untuk menunjukkan detail-detail penting yang tersembunyi

Batas partial obyek.

Dimensi

Dimensi harus menggunakan garis tipis yang menerus (continuous thin lines).

Dua garis proyeksi menunjukkan posisi awal dan akhir dari dimensi. Dua garis

proyeksi ini tidak boleh menyentuh obyek dan digambar tegaklurus dengan

elemen dari obyek yang diukur.

Secara umum, unit dari dimensi dapat tidak ditulis apabila penjelasan tentang

unit dinyatakan secara eksplisit di dalam gambar dan dipergunakan secara

konsisten.

Semua dimensi yang lebih kecil dari satu (1) harus dituliskan angka nol sebelum

koma, seperti . .35 harus ditulis 0.35.

Teknik Penulisan Dimensi

Parallel dimensioning

Pada teknik ini

pengukuran dilakukan

terhadap satu garis

referensi

Superimposed

Running Dimensions

Teknik ini

menyederhanakan teknik

parallel dimensions untuk

mengurangi ruang

penulisan.

Chain Dimensioning

Teknik ini digunakan

apabila efek dari

akumulasi toleransi tidak

berpengaruh banyak pada

fungsi dari obyek.

Combined

Dimensions

Mengkombinasikan chain

dan parallel

dimensioning.

0 10 30 45 53 63 70

Dimensioning by Co-

ordinates

Teknik ini menggunakan

teknik Superimposed

Running Dimensions

dalam dua arah. Umunya

untuk menunjukkan posisi

lubang atau baut.

Simplified

dimensioning by co-

ordinates

Teknik ini

menyederhanakan metoda

koordinat dengan

menggunakan simbol-

simbol dan penjelasan

menggunakan tabel.

Pendimensian untuk Obyek Yang Kecil

Pendimensian pada area yang sempit dapat dilakukan dengan beberapa teknik seperti

terlihat dalam gambar di bawah ini.

Pendimensian untuk Lingkaran

All dimensions of circles are proceeded by this symbol; . There are several

conventions used for dimensioning circles:

(a) shows two common methods of dimensioning a circle. One method dimensions the

circle between two lines projected from two diametrically opposite points. The second

method dimensions the circle internally.

(b) is used when the circle is too small for the dimension to be easily read if it was

placed inside the circle. A leader line is used to display the dimension.

(c) the final method is to dimension the circle from outside the circle using an arrow

which points directly towards the centre of the circle.

Pendimensian untuk Lubang

When dimensioning holes the method of manufacture is not specified unless they

necessary for the function of the product. The word hole doesn't have to be added

unless it is considered necessary. The depth of the hole is usually indicated if it is isn't

indicated on another view. The depth of the hole refers to the depth of the cylindrical

portion of the hole and not the bit of the hole caused by the tip of the drip.

Dimensioning Radial

All radial dimensions are proceeded by the capital R. All dimension arrows and lines

should be drawn perpendicular to the radius so that the line passes through the centre

of the arc. All dimensions should only have one arrowhead which should point to the

line being dimensioned. There are two methods for dimensioning radii.

(a) shows a radius dimensioned with the centre of the radius located on the drawing.

(b) shows how to dimension radii which do not need their centers locating.

Tolerancing

It is not possible in practice to manufacture products to the exact figures displayed on

an engineering drawing. The accuracy depends largely on the manufacturing process

used and the care taken to manufacture a product. A tolerance value shows the

manufacturing department the maximum permissible variation from the dimension.

Each dimension on a drawing must include a tolerance value. This can appear either

as:

a general tolerance value applicable to several dimensions. i.e. a note

specifying that the General Tolerance +/- 0.5 mm.

or a tolerance specific to that dimension

The method of expressing a tolerance on a dimension as recommended by the British

standards is shown below:

Note the larger size limit is placed above the lower limit.

All tolerances should be expressed to the appropriate number to the decimal points for

the degree of accuracy intended from manufacturing, even if the value is limit is a

zero. For example. 44.80 should not be expressed as 44.8

Lettering

All notes and dimensions should be clear and easy to read. In general all notes should

be written in capital letters to aid legibility. All lettering should be of the same size

and preferably no smaller than 3mm. An example typeface is shown below.

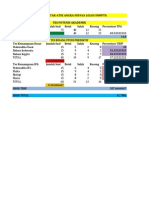

The layout of an engineering drawing

It is important that you follow some simple rules when producing an engineering

drawing which although may not be useful now, will be useful when working in

industry.

All engineering drawings should feature an information box. An example is shown

below.

Common information recorded on an engineering drawing

TITLE

The title of the drawing.

NAME

The name of the person who produced the drawing. This is important for

quality control so that problems with the drawing can be traced back to their

origin.

CHECKED

In many engineering firms, drawings are checked by a second person before

they are sent to manufacture, so that any potential problems can be identified

early.

VERSION

Many drawings will get amended over the period of the parts life. Giving each

drawing a version number helps people identify if they are using the most

recent version of the drawing.

DATE

The date the drawing was created or amended on.

SCALE

The scale of the drawing. Large parts won't fit on paper so the scale provides a

quick guide to the final size of the product.

PROJECTION SYSTEM

The projection system used to create the drawing should be identified to help

people read the drawing. (Projection systems will be covered later).

COMPANY NAME

Many CAD drawings may be distributed outside the company so the company

name is usually added to identify the source.

Hatching

On sections and sectional views solid area should be hatched to indicate this fact.

Hatching is drawn with a thin continuous line, equally spaced (preferably about 4mm

apart, though never less than 1mm) and preferably at an angle of 45 degrees.

Hatching a single object

When you are hatching an object, but the objects has areas that are separated, all areas

of the object should be hatched in the same direction and with the same spacing.

Hatching Adjacent objects

When hatching assembled parts, the direction of the hatching should ideally be

reversed on adjacent parts. If more than two parts are adjacent, then the hatching

should be staggered to emphasise the fact that these parts are separate.

Reverse hatching Staggered Hatching

Hatching thin materials

Sometimes, it is difficult to hatch very thin sections. To emphasise solid wall the

walls can be filled in. This should only be used when the wall thickness size is less

than 1mm

.

Hatching large areas

When hatching large areas in order to aid readabilty, the hatching can be limited to the

area near the edges of the part.

Gambar Potongan

Sections and sectional views are used to show hidden detail more clearly. They are

created by using a cutting plane to cut the object.

A section is a view of no thickness and shows the outline of the object at the cutting

plane. Visible outlines beyond the cutting plane are not drawn.

A sectional view, displays the outline of the cutting plane and all visible outlines

which can be seen beyond the cutting plane. The diagram below shows a sectional

view, and how a cutting plane works.

Orthographic projection

The aim of an engineering drawing is to convey all the necessary information of how

to make the part to the manufacturing department. For most parts, the information

cannot be conveyed in a single view. Rather than using several sheets of paper with

different views of the part, several views can be combined on a single drawing using

one of the two available projection systems, first angle, and third angle projection.

First Projection

TYPES OF DRAWINGS AND DIAGRAMS

The types of drawings to be discussed here include working drawings, architectural

drawings, mechanical drawings, shop drawings, and electrical diagrams.

CONSTRUCTION DRAWINGS

A construction drawing is any drawing that furnishes the information required by

the craftsmen to rough in equipment or erect a structure. The terms working drawings

and construction drawings are sometimes used interchangeably.

Information presented in a set of working drawings, along with the specifications,

should be complete so the craftsman who uses them will require no further

information.

Working drawings show the size, quantity, location, and relationship of the

building parts. Generally, working drawings may be divided into three main

categories: architectural, mechanical, and electrical.

Regardless of the category, working drawings serve several functions:

They provide a basis for making material, labor, and equipment estimates

before construction starts.

They give instructions for construction, showing the sixes and location

of the various parts.

They provide a means of coordination between the different ratings.

They complement the specifications; one source of information is

incomplete without the other when drawings are used for construction

work.

Architectural Drawings

Architectural drawings consist of all the drawings that describe the structural

members of the building and their relationship to each other. This includes

foundation plans, floor plans, framing plans, elevations, sections, details,

schedules, and bills of materials.

Plans

A plan is actually a part of the architectural drawing that represents a view of the

project from above. Two types of plans will be discussed here: plot plans and floor

plans.

PLOT PLANS.A plot plan (also called a site plan) includes not only the project

but also the surrounding area. The project may be represented only by an outline.

The grades at fixed points are shown throughout the area. This is done to show how

the land slopes before construction is started and the finished grade after construction

is completed. The north arrow symbol, used for orientation of the drawing, is shown.

The Construction Electrician may have to have a plot plan to construct a pole line to

the project site at or near the earliest phase of construction. Another example is when

the slope and grade of the surrounding area is to be changed and you have to bury

cable or conduit. You must know what the finished grade is and how deep to dig. This

type of work requires close coordination between you, the Engineering Aids,

Equipment Operators, and Builders. By looking over the plot plan, you will know

what to do to prepare for the job.

FLOOR PLANS. .Imagine that you want to know the outline of a building,

including each partition.This building is shown in figure 2-10, view A, and you are

equipped with a huge saw. If you sawed the building in half horizontally and

looked down on it from above, you would see the complete outline of the

building (view B).

This particular view directly above would be called a floor plan (view C). Architects

and engineers project their thoughts of a building, not yet built, onto a piece of paper

and call it a floor plan. It does not matter that the heights of the outlets, appliances, or

building parts are different. These heights will be indicated by figures in inches or

feet, next to the symbols that represent them. Electrical construction drawings are

floor plans modified by the inclusion of electrical symbols.

Figure 2-11 shows an electrical layout superimposed on an outline taken from

an architectural floor plan. The service line that brings power into the house is a three-

wire line in 1 1/4-inch conduit. The service line feeds power by way of a service

switch to a lighting panel, from which three branch circuits run to the lighting fixtures

and convenience outlets in the rooms. The symbols for these fixtures and outlets and

the service switch are shown at the bottom of figure 2-11. Elevations An elevation is a

drawing that represents a view of the finished structure as you would see it from the

front, back, left, or right.

There are interior elevations, such as a view of a fireplace, as well as exterior

elevations, as shown in the elevations of a small building shown in figure 2-12. Doors,

windows, shapes of roof, chimneys, and exterior materials are shown. These views

provide the viewer with a finished appearance. Few dimensions are given on

elevations. Only those vertical dimensions that cannot be shown on the plan are

generally included on an elevation view.

A Construction Electrician can quickly see from any one of the elevations in figure 2-

12 that there is an attic where easy access would be provided to electrical wiring. This

is important where there is a requirement for junction boxes that must be

accessible. The electrician can also see a foundation wall where, if a service lateral is

required, a conduit or sleeve must be placed (for a later run of conduit). This

knowledge will allow the electrician to plan ahead to work with the Builders when

they build the forms. The conduit will be placed in or through the form before the

concrete is poured.

MECHANICAL DRAWINGS.---Mechanical drawings include all drawings and

notes that have something to do with the water supply, sewage, drainage, heating

and ventilating, refrigeration, air conditioning, and gas supply systems. It may also

include other drawings that are necessary to present the system properly in relation to

the other portions of the project.

Shop Drawings - Shop drawings are drawings and related data used to show some

portion of the work prepared by the construction contractor, manufacturer, distributor,

or supplier. Product data, such as brochures, illustrations, standard schedules,

performance charts, and other information, are furnished by the contractor or the

manufacturer to show a material, product, or system for some portion of the

work. Engineering Aids are sometimes required to draft shop drawings for minor

shop and field projects. These drawings may include shop items, such as doors,

cabinets, and small portable buildings (prefabricated berthing quarters and

modifications of existing structures), or they may come from portions of design

drawings, specifications, or freehand sketches given by the design engineer.

Working from a shop drawing is much like working from other working drawings.

You convert the ideas you get from your interpretation of the lines and symbols

into the product represented by the drawing.

ELECTRICAL DIAGRAMS-In addition to the construction drawings discussed

above, you will be working with other types of electrical drawings or diagrams. These

drawings show the arrangement and relationship of parts. Electrical diagrams are

usually used to show how the parts of one or more pieces of equipment are wired

together. There are several types of these diagrams. They are similar, yet different in

some way. The short description of each that follows should enable you to recognize

their differences. Isometric Diagram The isometric diagram is not often seen in

electrical work. It may be used to show the electrical wiring system in multilevel

buildings. Appliances sometimes have an isometric diagram glued to an access panel

so that it may be referred to for a quick look at an entire wiring system. (See fig. 2-

13.)

BLOCK DIAGRAM.-- A block diagram is a simple drawing showing the

relationships of major parts of a wiring circuit or system. Figure 2-14 shows a block

diagram of a motor control system You can easily see how it gets its name.

Sometimes the blocks are connected with only one line that may represent one or

more conductors or cables. Either major or minor components or parts may be

represented by blocks. This type of diagram is often used to show something of

the relationship of components in a power distribution system. The block diagram

provides little help in troubleshooting.

Axonometric Projection

For objects which are fairly small in size and reasonably close to the observer we

often use a form of drawing known as axonometric projection. The word axonometric

means 'measured axes'. Axonometric drawings often appear distorted because they

ignore the foreshortening effects of perspective (foreshortening means the way things

appear to get smaller in both height and depth as they recede into the distance.

All axonometric drawings use vertical lines for those lines representing height and

sloping parallel edges for all other sides. There are a number of axonometric

drawings.

ISOMETRIC PROJECTION

An Isometric Projection is constructed from 3 axes created by dividing a circle into 3

equal angles of 120

0

DIMETRIC PROJECTION

A Dimetric projection is created using 3 axes but only two of these have equal angles.

The smaller these angles are the less we see of the top surface. The angle is usually

around 105

0

.

TRIMETRIC PROJECTION

A Trimetric projection is created using 3 axes where each of the angles between them

is different (there are no equal angles)

The three methods of projection described above have one corner of the object facing

the observer and none of the visible faces are their true shape.

OBLIQUE PROJECTION

Oblique projection is created by drawing one side of the object facing the observer.

This side is always drawn as a true shape (in this case a square).

The receding lines are usually drawn at 45

0

(although other angles could be used) and

one half their true size, to avoid undue distortion.

PLANOMETRIC or PLAN OBLIQUE

This is similar to oblique in that the top surface is drawn true shape and size. It is

usually rotated so that the angles shown are 45

0

- 45

0

or 60

0

- 30

0

.

'CRATING'

'Crating' is a means of drawing complicated shapes, by fitting them into a box or

'crate'. A crate or box can be drawn using any of the techniques shown above, by

following the procedure shown below.

Difficult shapes can be drawn by starting with the box or crate that the finished object

will fit into and then adding or removing the bits that are not required.

CIRCLES DRAWN IN AXONOMETRIC VIEWS

A circle drawn on a sloping surface in axonometric projection will be drawn as an

ellipse. An ellipse is a circle turned through an angle. All the examples shown above

were box shapes without any curved surfaces. In order to draw curved surfaces we

need to know how to draw ellipses.

If you draw a circle and rotate it slowly, it will become an ellipse. As it is turned

through 90

0

it will eventually become a straight line.

An ellipse has a major axis and a minor axis. The major axis is the axis about which

the ellipse is being turned. The minor axis becomes smaller as the angle through

which the ellipse is turned approaches 90

0

.

You can draw a cylinder using the technique shown on the right. The ellipses can

either be sketched freehand or drawn using an ellipse template.

Anda mungkin juga menyukai

- Buku Ajar Lines Plan 2013 Rev 6Dokumen83 halamanBuku Ajar Lines Plan 2013 Rev 6Indra WalshtenholmeBelum ada peringkat

- Metode Nilai SekarangDokumen27 halamanMetode Nilai SekarangMuhammad IkhsanBelum ada peringkat

- FRP PropertiesDokumen19 halamanFRP PropertiesPutra PanjaitanBelum ada peringkat

- Usulan Teknis Proyek Packing Plant Semen IndonesiaDokumen26 halamanUsulan Teknis Proyek Packing Plant Semen IndonesiaJoseGonzalezRomeroBelum ada peringkat

- Soal Teori Piping DraftingDokumen1 halamanSoal Teori Piping DraftingheruBelum ada peringkat

- STABILITAS PINTU AIRDokumen2 halamanSTABILITAS PINTU AIRYeckastoroJanuwisesaBelum ada peringkat

- Pintu Sorong dan Air LoncatDokumen15 halamanPintu Sorong dan Air LoncatMuh NuzulBelum ada peringkat

- Bab IiDokumen17 halamanBab IiasriniBelum ada peringkat

- Proposal Seminar ProgressDokumen63 halamanProposal Seminar ProgressIrsyad SyabanaBelum ada peringkat

- Perkerasan CYDokumen17 halamanPerkerasan CYLandi SinagaBelum ada peringkat

- Perencanaan OffshoreDokumen10 halamanPerencanaan OffshoreFeby Adryan Sitorus100% (1)

- 3 Stabilitas Benda TerapungDokumen27 halaman3 Stabilitas Benda TerapungHizbar ArsjadBelum ada peringkat

- Analisa Kekuatan Ramp Plate Untuk LoadouDokumen9 halamanAnalisa Kekuatan Ramp Plate Untuk LoadouKukuh PrastyoBelum ada peringkat

- Brosur ATAP TRIMDEK LYSAGHT PDFDokumen10 halamanBrosur ATAP TRIMDEK LYSAGHT PDFBudi KuncoroBelum ada peringkat

- KACA INDUSTRIDokumen25 halamanKACA INDUSTRIMuhammad Djody SatrianiBelum ada peringkat

- Sand Blasting StandardDokumen3 halamanSand Blasting Standardaswar_mhBelum ada peringkat

- Freeboard Calculation PM 39Dokumen6 halamanFreeboard Calculation PM 39afandybaharuddinBelum ada peringkat

- Pedoman Tata Batas FinalDokumen30 halamanPedoman Tata Batas Finaltinawati98Belum ada peringkat

- StatikaDokumen54 halamanStatikaAnisa Novi Alfiyana100% (1)

- Elemen TrussDokumen29 halamanElemen TrussAdha LuriBelum ada peringkat

- Kurva HidrostatikDokumen16 halamanKurva HidrostatikIlham Indrapraja IskandarBelum ada peringkat

- THC & CHCDokumen4 halamanTHC & CHCSiPoedjangga TjintaBelum ada peringkat

- Contoh Kurva S PerumahanDokumen2 halamanContoh Kurva S Perumahansipil2009100% (1)

- Sistem Dan Peralatan - Permanent Means of AccessDokumen34 halamanSistem Dan Peralatan - Permanent Means of AccessHendriyadiRustamarBelum ada peringkat

- Tugas 02Dokumen76 halamanTugas 02refinaBelum ada peringkat

- Teknologi Produksi Galangan Kapal PT. JMI Unit 2Dokumen6 halamanTeknologi Produksi Galangan Kapal PT. JMI Unit 2M. Bagus FirmansyahBelum ada peringkat

- BERAT JENISDokumen9 halamanBERAT JENISirfan rizqilahBelum ada peringkat

- PVD CVDDokumen15 halamanPVD CVDnovernandoBelum ada peringkat

- Crack PropagationDokumen15 halamanCrack PropagationMuhammadCaturNugrahaBelum ada peringkat

- Konsol PDFDokumen313 halamanKonsol PDFabdi andikaBelum ada peringkat

- BTA 009 Pipa PesatTTDokumen20 halamanBTA 009 Pipa PesatTTagungBelum ada peringkat

- Rangkuman Ppkgurg 1987 ADokumen5 halamanRangkuman Ppkgurg 1987 AsyontBelum ada peringkat

- SISTEM PERKAPALANDokumen147 halamanSISTEM PERKAPALANsuperdinandBelum ada peringkat

- PEMBANGUNAN KAPALDokumen10 halamanPEMBANGUNAN KAPALRizky ArmandaBelum ada peringkat

- Pradisain Small JettyDokumen18 halamanPradisain Small JettyWidyo LesmonoBelum ada peringkat

- Ilmu Bahan Logam dan Bukan LogamDokumen1 halamanIlmu Bahan Logam dan Bukan LogamIrfan PutraBelum ada peringkat

- Dokumen - Tips Hambatan Kapal Resistence of ShipDokumen26 halamanDokumen - Tips Hambatan Kapal Resistence of ShipKevin SarosaBelum ada peringkat

- Bab ViDokumen17 halamanBab Viifa mohammadBelum ada peringkat

- Beton Densitas TinggiDokumen8 halamanBeton Densitas TinggiRebecca FrancisBelum ada peringkat

- REVISI 3 Dermaga 187 Juni 2014Dokumen34 halamanREVISI 3 Dermaga 187 Juni 2014yeviputriagustia100% (1)

- RENCANA PENGEMBANGAN KAWASANDokumen57 halamanRENCANA PENGEMBANGAN KAWASANdedy setyo oetomoBelum ada peringkat

- Fsru PDFDokumen6 halamanFsru PDFMehmet HafizhogluBelum ada peringkat

- Fungsi dan Kegunaan Admixture BetonDokumen11 halamanFungsi dan Kegunaan Admixture Betonaryayoga100% (1)

- Perancangan Graving DockDokumen8 halamanPerancangan Graving DockRiyan PrayogoBelum ada peringkat

- NAMA1Dokumen4 halamanNAMA1Mo RizkiBelum ada peringkat

- Dinamis Analisis Dengan OffpipeDokumen4 halamanDinamis Analisis Dengan OffpipeReza Kurniawan100% (1)

- Studi Batimetri Dan Jenis Sedimen Dasar Laut Di Perairan SemarangDokumen10 halamanStudi Batimetri Dan Jenis Sedimen Dasar Laut Di Perairan SemarangAnonymous uEM21nqXBBelum ada peringkat

- DEWATERINGDokumen3 halamanDEWATERINGiqbal amdarBelum ada peringkat

- CT dan TLPDokumen30 halamanCT dan TLPa100% (1)

- GEOPOLIMER MORTARDokumen36 halamanGEOPOLIMER MORTARPuspaidi PutraBelum ada peringkat

- Modul Pelatihan ANSYS AqwaDokumen28 halamanModul Pelatihan ANSYS AqwaRezky NaufalBelum ada peringkat

- Teknik Pengecoran.BDokumen70 halamanTeknik Pengecoran.BFajarDikaNurohmanBelum ada peringkat

- Tugas 2 - 2 Feb 2015Dokumen3 halamanTugas 2 - 2 Feb 2015s2608Belum ada peringkat

- GAMBARMEKANIKDokumen17 halamanGAMBARMEKANIKHery SonawanBelum ada peringkat

- Pengertian Gambar KerjaDokumen5 halamanPengertian Gambar KerjaAchmad RoisBelum ada peringkat

- Rangkuman MateriDokumen25 halamanRangkuman Materikurniawan sanddyBelum ada peringkat

- Ukuran - Dimensi Pada Gambar TeknikDokumen14 halamanUkuran - Dimensi Pada Gambar TekniknurhrickyBelum ada peringkat

- GAMBAR KERJA PEMBUATANDokumen3 halamanGAMBAR KERJA PEMBUATANAmbar WiduriBelum ada peringkat

- M4 Autocad TBJP II Dimensi Pada AutocadDokumen37 halamanM4 Autocad TBJP II Dimensi Pada Autocadni'mah izati atiko putriBelum ada peringkat

- Aturan Pemberian UkuranDokumen11 halamanAturan Pemberian UkuranKEISYABelum ada peringkat

- INOVASIDokumen11 halamanINOVASIYogga AdhityaBelum ada peringkat

- Sirkulasi Jangka MengahDokumen1 halamanSirkulasi Jangka MengahFakhrul HidayatBelum ada peringkat

- Peta Eksisting ModelDokumen1 halamanPeta Eksisting ModelFakhrul HidayatBelum ada peringkat

- Sirkulasi Jangka MengahDokumen1 halamanSirkulasi Jangka MengahFakhrul HidayatBelum ada peringkat

- Bab 4 Rencana KerjaDokumen5 halamanBab 4 Rencana KerjaFakhrul HidayatBelum ada peringkat

- Panjang Tugas03 SWPDokumen2 halamanPanjang Tugas03 SWPFakhrul HidayatBelum ada peringkat

- Kajian Tarif Terhadap Vehicle Operation Cost NoPWDokumen8 halamanKajian Tarif Terhadap Vehicle Operation Cost NoPWFakhrul HidayatBelum ada peringkat

- Skkni 2016-107 PDFDokumen196 halamanSkkni 2016-107 PDFUlfi Widiiyya AstuthieBelum ada peringkat

- Fortofolio Peserta Kuliah PKNDokumen2 halamanFortofolio Peserta Kuliah PKNFakhrul HidayatBelum ada peringkat

- PKN 1Dokumen10 halamanPKN 1Fakhrul HidayatBelum ada peringkat

- Import HatchDokumen1 halamanImport HatchFakhrul HidayatBelum ada peringkat

- Sett-01 RevDokumen15 halamanSett-01 RevFakhrul HidayatBelum ada peringkat

- PKN Bela NegaraDokumen13 halamanPKN Bela NegaraFakhrul HidayatBelum ada peringkat

- Pancasila Sebagai Paradigma Penegakan HAMDokumen17 halamanPancasila Sebagai Paradigma Penegakan HAMFakhrul HidayatBelum ada peringkat

- Pancasila Sebagai Dasar IdeologiDokumen19 halamanPancasila Sebagai Dasar IdeologiFakhrul HidayatBelum ada peringkat

- Cara Analisis Stabilitas Kapal Menggunakan HydromaxDokumen3 halamanCara Analisis Stabilitas Kapal Menggunakan HydromaxFakhrul HidayatBelum ada peringkat

- Step HullspeedDokumen6 halamanStep HullspeedFakhrul HidayatBelum ada peringkat

- Penting! Petunjuk Instalasi The Sims 3Dokumen3 halamanPenting! Petunjuk Instalasi The Sims 3Fakhrul HidayatBelum ada peringkat

- Soal Tugas Besar Kapal 2014Dokumen3 halamanSoal Tugas Besar Kapal 2014Fakhrul HidayatBelum ada peringkat

- Daftar Pasang Surut Table - 20110117050009Dokumen678 halamanDaftar Pasang Surut Table - 20110117050009Fakhrul HidayatBelum ada peringkat

- HASIL UJI COBA TES POTENSI AKADEMIKDokumen4 halamanHASIL UJI COBA TES POTENSI AKADEMIKFakhrul HidayatBelum ada peringkat

- Ruang Terbuka Hijau Jalan CihampelasDokumen4 halamanRuang Terbuka Hijau Jalan CihampelasFakhrul HidayatBelum ada peringkat