VCmaster US Catalog 01concrete01-51.en - Id

VCmaster US Catalog 01concrete01-51.en - Id

Diunggah oleh

Tony WangJudul Asli

Hak Cipta

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniVCmaster US Catalog 01concrete01-51.en - Id

VCmaster US Catalog 01concrete01-51.en - Id

Diunggah oleh

Tony WangContoh untuk ACI, AISC dan ASCE KAMI

Perhitungan Template interaktif dengan kode AS Halaman 1

Contoh untuk ACI, AISC dan ASCE

KAMI

Perhitungan Template interaktif dengan kode AS

ACI 318-11

Tidak ada yang mengalahkan TEMPLATE BESAR

Kata pengantar

kadar

bantu desain interaktif sesuai dengan kode US ACI 318-11, AISC 14 th Edisi dan ASCE-7-10

Pedoman penggunaan

Setelah menginstal percobaan atau demo versi gratis template interaktif akan tersedia secara gratis. Satu-satunya persyaratan adalah

pendaftaran di www.VCmaster.com.

Contoh-contoh yang telah dibuat menggunakan VCmaster. Semua dijelaskan dan alat bantu desain diilustrasikan dapat digunakan sebagai dasar

untuk membuat template sendiri. Untuk melakukan ini versi lengkap dari VCmaster diperlukan.

Semua template terkait dengan berbagai database oleh TAB () - atau SEL () fungsi. Untuk tujuan instruksional link ini ditampilkan dalam

dokumen ini, tetapi juga dapat disembunyikan saat mencetak.

Apa VCmaster?

VCmaster adalah aplikasi perangkat lunak untuk dokumentasi teknis khusus dirancang untuk insinyur. Konsep perangkat lunak yang unik

mengintegrasikan semua desain dan CAD struktural software. antarmuka Universal menjamin transfer data yang mudah, sehingga output

dari semua program dapat dialihkan.

Disamping fungsinya untuk dokumentasi, VCmaster menawarkan konsep intuitif memungkinkan para insinyur untuk melakukan perhitungan.

Masukan dari rumus matematika dapat dilaksanakan dalam notasi alami langsung dalam dokumen itu sendiri. Perangkat lunak ini secara

signifikan mendukung penggunaan kembali perhitungan struktural dan dokumen. VCmaster menyederhanakan modifikasi dan penyesuaian dan

mengotomatisasi tugas-tugas standar. Kolaborasi dengan pekerjaan-kelompok atau dengan kantor-kantor lain dan klien tidak rumit juga.

Akibatnya, waktu pemrosesan dan biaya dapat sangat dikurangi.

Persyaratan sistem

VCmaster 2017 atau yang lebih baru

Pengembangan dan Hak Cipta

VCmaster telah dikembangkan di Jerman VCmaster adalah

merek dagang terdaftar Semua template yang dibuat di

Amerika Serikat © Veit Christoph GmbH 1995-2018

www.VCmaster.com

Interaktif Desain Aids untuk Engineers Struktural

Contoh untuk ACI, AISC dan ASCE KAMI

Perhitungan Template interaktif dengan kode AS Halaman 2

Isi

Bab 1: Desain Beton 4

Corbel Desain 4

Pracetak gerbang Beam untuk Gabungan Shear dan Torsion 7

Beam Ledge Desain 11

Rectangular Bagian dengan Ketegangan Penguatan 14

Rectangular Bagian dengan Kompresi Penguatan 16

Tulangan Geser untuk Bagian Tunduk Q & N 19

Tulangan Geser untuk Bagian Tunduk Q & T 22

Defleksi Bagian Composite ditopang 24

Desain lentur Bagian bergelang 28

Cracking Momen Kekuatan untuk Bagian Pratekan 31

Kekuatan lentur Pratekan Anggota 32

Ketegangan Controlled Batas untuk Pratekan Lentur Anggota 34

Kerugian Prestress 36

Meninju Tulangan Geser pada Slab 39

One Way balok silang 41

Dua Way Slab Dilihat Metode Desain Direct 47

Pengembangan Panjang Bar di Tension 50

Kelompok Berambut Studs di Ketegangan dekat Ujung 52

Geser Kekuatan Slab pada Dukungan Kolom 54

Sederhana Span Jauh Beam oleh Strut-and-Tie Model 56

Terus menerus Jauh Beam oleh Strut-and-Tie Model 60

Transfer Horizontal Angkatan di Base of Kolom 65

Bantalan Dinding dengan Metode Empiris 67

Geser Desain Dinding 70

Gesekan geser 73

Tunggal Adhesive jangkar di Ketegangan 75

Tunggal Berambut Jangkar Bolt di Ketegangan 77

Tunggal Berambut Jangkar Bolt di Shear dekat Ujung 79

Defleksi Beam Sederhana 81

Tulangan Geser untuk Bagian Tunduk Q & M 84

Penguatan geser pada Pembukaan 87

Horisontal Shear untuk Komposit Slab dan Precast Beam 90

Interaktif Desain Aids untuk Engineers Struktural

Contoh untuk ACI, AISC dan ASCE KAMI

Perhitungan Template interaktif dengan kode AS Halaman: 3

Bab 2: Yayasan Desain 92

Penguatan Yayasan Dangkal 92

Kedalaman Yayasan Dangkal 95

Mendalam untuk Pile Cap 98

Slab di kelas 101

Bab 3: Baja Desain 102

W-Bentuk dalam Kuat Axis Bending, Bersiap di Beberapa Poin 102

W-Shape di Kuat Axis Bending, Terus Bersiap 106

W-Shape di Kecil Axis Bending 109

W-Shape Dikenakan Angkatan Ketegangan dan Bending Moments 112

W-Bentuk dalam Axial Kompresi 117

WT-Bentuk dalam Axial Kompresi 120

Built-Up W-Shapes dengan Slender Elements 124

W-Bentuk Dikenakan Kompresi dan Lentur 128

W-Shape Dikenakan P dan M termasuk Effect Orde Kedua 134

HSS-Shape di Kuat Axis Bending 140

W-Shape Dikenakan Angkatan Ketegangan di Connection baut: 143

WT-Shape Dikenakan Angkatan Ketegangan di Koneksi Dilas 146

Interior Panel dari Built-Up Girder dengan Transverse pengaku 149

End Panel dari Built-Up Girder dengan Transverse pengaku 151

Komposit Beam Dikenakan Lentur 153

Bab 4: Desain Connection 159

Plat dasar Dikenakan Memuat konsentris 159

Plat dasar Dikenakan Eksentrisitas Kecil 161

Plat dasar Dikenakan Eksentrisitas Besar 164

Lug geser 167

Fillet Weld Dikenakan Longitudinal Shear Angkatan 169

Baut di Bantalan Jenis Koneksi Dikenakan T & V 171

Menyelinap Kritis Koneksi dengan Short-Slotted Lubang 173

Bab 5: Banyak Desain 175

beban angin untuk Walls berdiri bebas Solid & Tanda 175

Banyak salju untuk Roof datar 178

Banyak salju untuk miring Atap 179

Seismik Basis Shear 180

Interaktif Desain Aids untuk Engineers Struktural

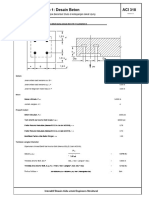

Bab 1: Desain Beton ACI 318

Corbel Desain Halaman: 4

Bab 1: Desain Beton

ACI 318

Desain Corbel sesuai ACI 318-11 Bab 11

Corbel Desain

vu

asc av

NUC

23 d

h d co

ah

Sistem

Corbel Lebar, b = 14,0 di

Corbel Tinggi, h = 12,0 di

Beton Cover, co = 1.0 di

Corbel Kedalaman, d = co- h = 12.0 1.0

- = 11.0 di

Jarak dari Kolom Tatap beban vertikal, sebuah v = 3.0 di

Beban

Beban Ultimate vertikal, V u = 88,8 kips

Ultimate Horizontal beban, NUC = 32,0 kips

Properti materi

Beton Kekuatan, f' c = 5000 psi

Yield Kekuatan Tulangan, f y = 60000 psi

Kekuatan Geser Faktor Reduksi (Menurut Cl.9.3.2 dari ACI318), • = 0,75

Modifikasi Factor untuk Beton Ringan, •• • 1.00

Gesekan Factor (Menurut Cl.11.6.4.3 dari ACI318), • = 1,4 * • = 1,40

Interaktif Desain Aids untuk Engineers Struktural

Bab 1: Desain Beton ACI 318

Corbel Desain Halaman: 5

Periksa Vertikal Kapasitas Angkut

V = n1 0,2 * f' c * b * d / 1000 = 154,0 Kips

V = n2 (480 + 0,08 * f' c) * b * d / 1000 = 135,5 Kips

V = n3 1600 * b * d / 1000 = 246.4 Kips

Nominal Kapasitas Vertikal (Menurut Cl.11.8.3.2.1 dari ACI318),

• Vn= • • MIN (V n1; V n2; V n3) = 101,6 Kips

Vertikal Kapasitas Angkut = IF (V u> • V n;" Tidak Lulus ";" Lulus ") = Lulus

Tentukan Shear Gesekan Tulangan (A vf)

Diperlukan Luas Tulangan untuk Gesekan Shear (Menurut Cl.11.6.4.1 dari ACI318), A vf =

V u 1000 • / ו × × f y •• = 1,41 in²

Tentukan Ketegangan Penguatan Langsung (A n)

Minimum Horizontal Angkatan pada Corbel, Nuc_min = 0,2 V×u = 17,8 Kips

Horizontal Angkatan pada Corbel, Nuc_act = MAX (NUC; Nuc_min) = 32,0 kips

Diperlukan Luas Tulangan untuk Tension Langsung (Menurut Cl.11.8.3.1 dari ACI318), A n =

* •

Nuc_act 1000 / •• • * fy • = 0,71 in²

Tentukan Tulangan Lentur (A f)

Mu= V u * Sebuah v + Nuc_act * (hd) = 298,4 kip * di

Diperlukan Luas Tulangan untuk Lentur (Menurut Cl.11.8.3.3 dari ACI318), A f =

M u 1000 • / ו × × f 0,9

y d× • = 0,67 in²

Tentukan Penguatan Ketegangan Primer (A sc)

Diperlukan Luas Tulangan untuk Tension Primer (Menurut Cl.11.8.3.5 dari ACI318),

SEBUAH sc = MAX ((2/3 * A vf) + SEBUAH n; SEBUAH f + SEBUAH n) = 1,65 di 2

Lokasi minimal Tulangan untuk Tension Primer (Menurut Cl.11.8.5 dari ACI318), A sc_min =

0,04 * / F' c f*y bd

* = 0,51 in²

SEBUAH sc_Req = MAX (A sc; SEBUAH sc_min) = 1,65 in²

Asalkan Penguatan, Bar = SEL ( "ACI / Bar"; Bar;) = no.9

Tersedia Area Bar Penguatan, A sb = TAB ( "ACI / Bar"; Asb; Bar = Bar) = 1.00 di 2

Jumlah bar Asalkan, n = 2

Tersedia Area Penguatan, A sc_Prov = n * A sb = 2.00 di 2

Periksa Validitas = JIKA SEBUAH sc_Prov • SEBUAH sc_Req; " Hari "; "valid") = Sah

Interaktif Desain Aids untuk Engineers Struktural

Bab 1: Desain Beton ACI 318

Corbel Desain Halaman: 6

Tentukan Horizontal Penguatan (A h)

Diperlukan Luas Tulangan untuk Horizontal geser (Menurut Cl.11.8.4 dari ACI318), A h_Req =

0,5 * (A sc_Prov- SEBUAH n) = 0.65 in²

Asalkan Penguatan, Bar = SEL ( "ACI / Bar"; Bar;) = Nomor 3

Tersedia Area Bar Penguatan, A sb = TAB ( "ACI / Bar"; Asb; Bar = Bar) = 0,11 di 2

Jumlah bar Asalkan, n = 6

Tersedia Area Penguatan, A h_Prov = n * A sb = 0,66 di 2

Periksa Validitas = JIKA SEBUAH h_Prov • SEBUAH h_Req; " Hari "; "valid") = Sah

Mendistribusikan dalam dua-pertiga dari Corbel Efektif Kedalaman berdekatan dengan A sc

desain Ringkasan

Daerah Tulangan untuk Ketegangan Primer A sc = SEBUAH sc_Prov = 2.00 in²

Daerah Tulangan untuk Horizontal Shear, A h = SEBUAH h_Prov = 0,66 in²

Mendistribusikan dalam dua-pertiga dari Corbel Efektif Kedalaman berdekatan dengan A sc

Interaktif Desain Aids untuk Engineers Struktural

Bab 1: Desain Beton ACI 318

Pracetak gerbang Beam untuk Gabungan Shear dan Torsion Halaman: 7

Design Precast Spandrel Beam for Combined Shear and Torsion as per ACI 318-11 Chapter 11

Precast Spandrel Beam for Combined Shear and Torsion

A' v

AlA

h sc

hL

b bL

System

Width of Beam, b= 16.0 in

Height of Beam, h= 48.0 in

Width of Beam Ledge, b L= 8.0 in

Height of Beam Ledge, h L= 16.0 in

Concrete Cover, co= 2.50 in

Concrete Cover to Center of Stirrup, co'= 1.50 in

Effective Depth of Beam, d= co- h = 45.50 in

Load

Ultimate Bending Moment, M u= 1316.0 kip*ft

Ultimate Torsional Moment, T u= 108.6 kip*ft

Ultimate Shear Force, V u= 127.2 kips

Material Properties

Concrete Strength, f' c= 5000 psi

Yield Strength of Reinforcement, f y= 60000 psi

Yield Strength of Stirrups Reinforcement, f yt= 60000 psi

Shear Strength Reduction Factor (According to Cl.9.3.2 of ACI318), • s= 0.75

Tension Strength Reduction Factor (According to Cl.9.3.2 of ACI318), • t= 0.90

Modification Factor for Lightweight Concrete, •• • 1.00

Friction Factor (According to Cl.11.6.4.3 of ACI318), •= 1.4* • = 1.40

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Precast Spandrel Beam for Combined Shear and Torsion Page: 8

Determine Concrete Cracking Torque

Area Enclosed by Outside Perimeter of Spandrel Beam Including the Ledge,

A cp= b*h+bL*hL = 896 in 2

Outside Perimeter of Spandrel Beam Including the Ledge, P cp=

2 * (b + b L + h) = 144 in

2

A cp

4* • f' c * / 12000

Concrete Cracking Torque, T cr= *

• P cp

= 131.4 kip*ft

Torsional Moment should be: IF(T u< • s* T cr/ 4;"Neglected";"Checked") = Checked

Calculation of Torsion Reinforcement

Area Enclosed by Centerline of The Outermost Closed Transverse Torsional Reinforcement (According to

Cl.11.5.3.6 of ACI318),

A oh= (h-2*co')*(b-2*co')+(b L)*( h L- 2*co') = 689.0 in 2

A o= 0.85*A oh = 585.6 in 2

Angle of Compression Diagonal Struts (According to 11.5.3.6 of ACI318),

• = 45 o

Required Area for Torsion Shear per Stirrups Spacing (According to Eq. 11-20, 21 of ACI318),

T u 12000

*

A' vt= = 0.025 in 2 per in

2* • * A o * f yt •* / 1 tan •• • •

s

Calculation of Shear Reinforcement

Nominal Shear Strength Provided by Concrete (According to Eq.11-3 of ACI318) •

*bd

V c= * •2 * • f'c * 1000 = 102.95 kips

Nominal Shear Strength Provided by Reinforcement (According to Eq.11-2 of ACI318) •

V s= V u/ • s • V c = 66.65 kips

Required Area for Direct Shear per Stirrups Spacing (According to Eq. 11-1, 2 of ACI318),

V s 1000

*

A' vs= = 0.024 in 2 per in

f yt d*

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Precast Spandrel Beam for Combined Shear and Torsion Page: 9

Calculation of Combined Shear and Torsion Reinforcement

Total Required Area for Torsion & Shear per Stirrups Spacing (According to Cl.11.5.3.8 of ACI318),

A' v= A' vt+ A' vs/ 2 = 0.037 in 2 per in per leg

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.4

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 0.20 in 2

Required Stirrups Spacing, s_ Req= A sb/ A' v = 5.41 in

Provided Stirrups Spacing, s_ Prov= 5.00 in

Check Validity= IF(s_ Prov • s_ Req; " Valid"; "Invalid") = Valid

Perimeter of Stirrups, Ph= *2• -2

b co'

* + -2

h co'

* • + *2bL = 132.00 in

Maximum Stirrups Spacing Due to Torsion (According to Cl.11.6.6 of ACI318), s max_t=

MIN(Ph/8; 12) = 12.00 in

Maximum Stirrups Spacing Due to Shear (According to Cl.11.4.5 of ACI318), s max_v=

MIN(d/2; 24) = 22.75 in

Maximum Stirrups Spacing, s max= MIN(s max_t; s max_v) = 12.00 in

Check Validity= IF(s_ Prov • s max; " Valid"; "Invalid") = Valid

Calculation of Longitudinal Torsion Reinforcement

Required Area of Longitudinal Torsion Reinforcement (According to Cl.11.5.3.7 of ACI318),

*

A' vt Ph f yt

A l_i= * = 3.30 in 2

2 fy

tan • • •

Minimum Area of Longidudinal Torsion Reinforcement (According to Eq.11-24 of ACI318),

5*

• f' c A* cp

A l_min= - A' vt * Ph f*yt = 1.98 in 2

fy fy

A l_Req= MAX( A l_i ; A l_min) = 3.30 in 2

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.5

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 0.31 in 2

Number of Bars, n= 12

Provided Longitudinal Reinforcement, A l_Prov= A sb * n = 3.72 in 2

Check Validity= IF(A l_Prov • A l_Req; " Valid"; "Invalid") = Valid

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Precast Spandrel Beam for Combined Shear and Torsion Page: 10

Calculation of Required Flexural Reinforcement

M u * 12 1000

*

R n= = 530 psi

• t

* *bd2

• ••

0.85 f' *c *2Rn

• =

fy

* -1 1

0.85 f' *c

• = 0.0095

Area of Flexural Reinforcement, A s= • * b*d = 6.92 in 2

Calculation of Total Bottom Reinforcement at Mid-Span

Percentage of Torsional Reinforcement Concentrated on Bottom Side, Per= 16 %

Total Area of Bottom Reinforcement at Mid-Span, A sc_Req=

A l_Req * / Per 100

+ As = 7.45 in 2

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.11

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 1.56 in 2

Number of Bars, n= 5

Total Area of Bottom Reinforcement, A sc_Prov= A sb * n = 7.80 in 2

Check Validity= IF(A sc_Prov • A sc_Req; " Valid"; "Invalid") = Valid

Design Summary

Total Required Area for Torsion & Shear per Stirrups Spacing,

A' v= A' v = 0.037 in 2 per in per leg

Provided Stirrups Spacing, s_ Prov= s_ Prov = 5.00 in

Provided Longitudinal Reinforcement, A l_Prov= A l_Prov = 3.72 in 2

Total Area of Bottom Reinforcement, A sc_Prov= A sc_Prov = 7.80 in 2

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Beam Ledge Design Page: 11

Design of Beam Ledge as per ACI 318-11 Chapters 9 & 11

Beam Ledge Design

aS

Pu

co

h

L

d Lh L W

b bL bw

Ah Asc

System

Width of Beam, b= 7.0 in

Height of Beam, h= 36.0 in

Width of Beam Ledge, b L= 6.0 in

Height of Beam Ledge, h L= 12.0 in

Concrete Cover, co= 1.25 in

Width of Bearing Pad, W= 4.5 in

Length of Bearing Pad, L= 4.5 in

Thickness of Bearing Pad, t b= 0.3 in

Gap Spacing, a s= 1.0 in

Shear Spacing, a v= 2/3 * L + a s = 4.0 in

Flexural Spacing, a f= a v + co = 5.25 in

Effective Width According to Shear Requirements, b ws= W + 4 * a v = 20.5 in

Effective Width According to Flexural Requirements, b wf= W + 5 * a f = 30.8 in

Effective Depth of Beam Ledge, d L= -

h L co = 10.75 in

Load

Dead Load, P D= 11.0 kips

Live Load, P L= 6.5 kips

Service Load, P= PD+PL = 17.5 kips

Ultimate Load, P u= 1.2 * P D + 1.6 * P L = 23.6 kips

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Beam Ledge Design Page: 12

Material Properties

Concrete Strength, f' c= 5000 psi

Yield Strength of Reinforcement, f y= 60000 psi

Shear Strength Reduction Factor (According to Cl.9.3.2 of ACI318), • s= 0.75

Bearing Strength Reduction Factor (According to Cl.9.3.2 of ACI318), • b= 0.65

Modification Factor for Lightweight Concrete, •• • 1.00

Friction Factor (According to Cl.11.6.4.3 of ACI318), •= 1.4* • = 1.40

Maximum Service Load for Bearing Pads, q= 1000 psi

Check Bearing Plate Dimension

Capacity of Bearing Plate, B p= W * L * q /1000 = 20.25 kips

Check Validity= IF( B p> P;"Valid" ;"Increase Dimension" ) = Valid

Check Concrete Bearing Strength

Bearing Strength of Concrete, • P nb= • b

* 0.85 * f' c * L* /W

1000 = 55.9 kips

Check Validity= IF( • P nb> Pu;"Valid" ;"Invalid" ) = Valid

Check Maximum Nominal Shear-Transfer by Effective Section

Nominal Shear by Effective Section (According to Cl.11.9.3.2.1 of ACI318), V n1=

0.2 * f' c * b ws * d L / 1000 = 220.4 kips

V n2= (480 + 0.08 * f' c) * b ws * d L / 1000 = 193.9 kips

V n3= 1600 * b ws * d L / 1000 = 352.6 kips

• V n= • s* MIN(V n1; V n2; V n3) = 145.4 kips

Check Validity= IF( • V n> P u;" Valid" ;"Increase Dimension" ) = Valid

Determine Shear Friction Reinforcement (A vf)

Required Reinforcement for Shear Friction (According to Cl.11.6.4.1 of ACI318),

A vf= P u * 1000 / ( • s * f y * •) = 0.37 in 2 per bws

Determine Direct Tension Reinforcement (A n)

Required Reinforcement for Direct Tension (According to Cl.11.8.3.4 of ACI318),

A n= 0.2 * P u * 1000 / ( • s * f y) = 0.10 in 2 per bwf

Determine Flexural Reinforcement (A f)

M u= P u * a f + 0.2 * P u * ( h L - d L) = 129.8 kip*in

Required Reinforcement for Flexural (According to Cl.11.8.3.3 of ACI318),

A f= M u * 1000 / ( • s * f y * 0.8 * d L) = 0.34 in 2 per bwf

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Beam Ledge Design Page: 13

Determine Primary Tension Reinforcement (A sc)

Required Area of Reinforcement for Primary Tension (According to Cl.11.8.3.5 of ACI318),

A sc= MAX (2/3 * A vf/ b ws + A n/ b wf ; A f/ b wf + A n/ b wf) = 0.015 in 2 per in

Minimum Area of Reinforcement for Primary Tension (According to Cl.11.8.5 of ACI318), A sc_min=

0.04 * / f' c f *y d L = 0.036 in 2 per in

A sc_req= MAX (A sc; A sc_min) = 0.036 in 2 per in

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.5

Spacing between Bars, s= 8.0 in

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 0.31 in 2

Check Validity= IF(A sb/ A sc_req> s; "Valid"; "Invalid") = Valid

Determine Horizontal Reinforcement (A h)

Required Area of Reinforcement for Horizontal Shear (According to Cl.11.8.4 of ACI318),

A h= 0.5*(A sc_req- A n/ b wf) = 0.016 in 2 per in

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.4

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 0.20 in 2

Check Validity= IF(A sb/ A h> s; "Valid"; "Invalid") = Valid

Design Summary

Primary Tension Reinforcement, A sc_req= A sc_req = 0.036 in 2 per in

Horizontal Shear Reinforcement, A h= Ah = 0.016 in 2 per in

Distribute in two-thirds of Effective Ledge Depth adjacent to A sc

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Rectangular Section with Tension Reinforcement Page: 14

Design of Rectangular Section with Tension Reinforcement only as per ACI 318-11 Chapters 9 & 10

Rectangular Section with Tension Reinforcement

•c

0.85 f'c

C

a a

c

N.A

d

h d-a/2

As

T

co •s

b

System

Width of Concrete Section, b= 12.0 in

Depth of Concrete Section, h= 16.0 in

Concrete Cover, co= 2.5 in

Effective Depth of Concrete Section, d= co- h = 16.0 2.5

- = 13.5 in

Load

Bending Moment due to Dead Load, M D= 56.0 kip*ft

Bending Moment due to Live Load, M L= 35.0 kip*ft

Ultimate Bending Moment, M U= • 1.2 M

*D • + • 1.6 M

*L • = 123.2 kip*ft

Material Properties

Concrete Strength, f' c= 4000 psi

Yield Strength of Reinforcement, f y= 60000 psi

Tension Strength Reduction Factor (According to Cl.9.3.2 of ACI318), •= 0.90

Factor for Rectangular Compressive Stress Block (According to Cl.10.2.7.3),

• 1=

IF(f' c • 4000;0.85;IF(f' c • 8000;0.65;1.05-0.00005*f' c)) = 0.85

Area of Reinforcement

M U 12000

*

R n= = 751.1 psi

• * *bd2

• = 0.85 f' *c

fy •

* -1 ••1

*2Rn

0.85 f' *c

• = 0.0143

Area of Reinforcement, A s= • * d* b = 2.32 in 2

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Rectangular Section with Tension Reinforcement Page: 15

Minimum Area of Reinforcement (According to Cl.10.5 of ACI318),

* 3 • f' c * *b

A s_min1= dfy = 0.51 in 2

200 ** b d f y

A s_min2= = 0.54 in 2

A s_min= MAX(A s_min1 ; A s_min2) = 0.54 in 2

Required Area of Reinforcement, A sc_Req= MAX(A s; A s_min) = 2.32 in 2

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.10

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 1.27 in 2

Number of Bars, n= 2

Vertical Reinforcement, A sc_Prov= A sb * n = 2.54 in 2

Check Validity= IF(A sc_Prov • A sc_Req; " Valid"; "Invalid") = Valid

Check Tension Controlled

A sc_Prov *fy

Depth of Rectangular Stress Block, a= = 3.74 in

0.85 * f' c b*

Distance from Extreme Compression Fiber to Neutral Axis, c=a/ • 1 = 4.40 in

c/d = /

/ c d = 4.40 13.5 = 0.326

IF(c/d>0.375; "Add Com. RFT"; "Tension Controlled" ) = Tension Controlled

Design Summary

Required Area of Reinforcement, A sc= A sc_Prov = 2.54 in 2

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Rectangular Section with Compression Reinforcement Page: 16

Design of Rectangular Section with Compression Reinforcement as per ACI 318-11 Chapters 9 & 10

Rectangular Section with Compression Reinforcement

•c

0.85 f'c

d' C' s

As' • s' a

c Cc

N.A

dt d

h d-a/2

s

As

T

co •s

System

Width of Concrete Section, b= 12.0 in

Depth of Concrete Section, h= 32.5 in

Concrete Cover, co= 2.5 in

Effective Depth of Concrete Section to Extreme Layer , d t= co- h = 32.5 2.5

- = 30.0 in

Distance between C.G of Tension Reinforcement and Extreme Layer, s= 1.2 in

Effective Depth of Concrete Section to C.G of Tension Reinforcement, d= - dts= 28.8 in

Depth of Compression Reinforcement, d'= 2.5 in

Load

Bending Moment due to Dead Load, M D= 430.0 kip*ft

Bending Moment due to Live Load, M L= 175.0 kip*ft

Ultimate Bending Moment, M U= • 1.2 M

*D • + • 1.6 M

*L • = 796.0 kip*ft

Material Properties

Concrete Strength, f' c= 4000 psi

Yield Strength of Reinforcement, f y= 60000 psi

Modulus of Elasticity of Reinforcement, E s= 29000000 psi

Tension Strength Reduction Factor (According to Cl.9.3.2 of ACI318), •= 0.90

Factor for Rectangular Compressive Stress Block (According to Cl.10.2.7.3),

• 1=

IF(f' c • 4000;0.85;IF(f' c • 8000;0.65;1.05-0.00005*f' c)) = 0.85

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Rectangular Section with Compression Reinforcement Page: 17

Check If Compression Reinforcement is Required

• t=

0.31875* • 1 = 0.271

R nt= • t*( 1-0.59* • t)* f' c = 910.7 pci

M U 12000

*

R n= = 982.7 psi

2

• * d t* b

Compression Reinforcement is: IF(R n> R nt;" Required";"Not Required") = Required

Determine Required Moment Resisted by Compression Reinforcement

• t=

0.31875* • 1 = 0.271

• t=

0.31875 * f' c * • 1 / f y = 0.01806

• = • t* d t/ d = 0.01881

• = • * f y/ f' c = 0.28215

f' c * *bd2

Moment Resisted by Tension RFT, M nt= • *•1 - 0.59 • * • * = 780.3 kip*ft

12000

Moment Resisted by Compression RFT, M' n= M U/ ••• M nt = 104.1 kip*ft

Required Area of Compression Reinforcement

fy

d'/c limit= 1 - = 0.31

*

E s 0.003

•fy •

c limit=

• 1 -

E s 0.003

* dt • * = 9.3 in

c cal= 0.375*d t = 11.3 in

d'/c cal= • / d' c cal • = 0.22

f' si= MIN(0.003*E s*( 1- d'/c cal); f y ) = 60000 psi

f' s= IF(d'/c cal • d'/c limit; f y ; f' si ) = 60000 psi

M' n 12000

*

Required Reinforcement Area for Compression, A' s= = 0.79 in 2

f' s •* d' - d •

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.6

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 0.44 in 2

Number of Bars, n= 2

Vertical Reinforcement, A' s_Prov= A sb * n = 0.88 in 2

Check Validity= IF(A' s_Prov • A' s; " Valid"; "Invalid") = Valid

Required Reinforcement Area for Tension, A s= A' s + ( •• b*d) = 7.29 in 2

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Rectangular Section with Compression Reinforcement Page: 18

Minimum Area of Reinforcement (According to Cl.10.5 of ACI318),

* 3 • f' c * *b

A s_min1= dfy = 1.09 in 2

200 ** b d f y

A s_min2= = 1.15 in 2

A s_min= MAX(A s_min1 ; A s_min2) = 1.15 in 2

Required Area of Reinforcement, A sc_Req= MAX(A s; A s_min) = 7.29 in 2

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.10

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 1.27 in 2

Number of Bars, n= 6

Vertical Reinforcement, A sc_Prov= A sb * n = 7.62 in 2

Check Validity= IF(A sc_Prov • A sc_Req; " Valid"; "Invalid") = Valid

Design Summary

Required Reinforcement Area for Compression, A' s= A' s_Prov = 0.88 in 2

Required Area of Reinforcement, A sc= A sc_Prov = 7.62 in 2

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Shear Reinforcement for Section Subject to Q & N Page: 19

Design of Shear Reinforcement for Section Subject to Shear & Axial Compression As per ACI318-11

Shear Reinforcement for Section Subject to Q & N

Av

d Nu

co h Vu

b

s

System

Width of Concrete Section, b= 12.0 in

Depth of Concrete Section, h= 16.0 in

Concrete Cover, co= 2.25 in

Effective Depth of Concrete Section, d= co- h = 13.75 in

Load

Shear Force due to Dead Load, V D= 10.0 kips

Shear Force due to Live Load, V L= 5.0 kips

Ultimate Shear Force, V u= • 1.2 V* D • + • 1.6 V* L • = 20.0 kips

Axial Compression Force due to Dead Load, N D= 4.2 kips

Axial Compression Force due to Live Load, N L= 3.1 kips

Ultimate Axial Compression Force, N u= • 1.2 N* D • + • 1.6 N* L • = 10.0 kips

Material Properties

Concrete Strength, f' c= 4000 psi

Yield Strength of Reinforcement, f y= 60000 psi

Shear Strength Reduction Factor (According to Cl.9.3.2 of ACI318), •= 0.75

Modification Factor for Lightweight Concrete, •• • 1.00

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Shear Reinforcement for Section Subject to Q & N Page: 20

Determine Concrete Shear Strength

Nominal Shear Strength provided by Concrete (According to Eq. 11-4 of ACI318),

• •

N u 1000

* f' c * *b

V c= *2 1 +

2000 * * h b

• *• * d 1000 = 21.4 kips

Shear Reinforcement is : IF(V u> •• V c;" Required";"Not Required") = Required

Determine Area of Shear Reinforcement

Nominal Shear Strength provided by Reinforcement (According to Eq. 11-2 of ACI318),

Vu -• * Vc

V s= = 5.3 kips

•

Maximum Allowable Shear Strength provided by Reinforcement (According to Cl.11.4.7.9 of ACI318),

f' c * *b

•

V s_max= * •8 * d 1000 = 83.5 kips

IF(V s> V s_max; " Increase Beam Dimension"; "OK" ) = OK

Spacing of Provided Stirrups, s= 6.75 in

Vs * * s 1000

Required Area of Reinforcement, A v= = 0.04 in 2

*fyd

Minimum Area of Reinforcement (According to Cl.11.4.6.3 of ACI318),

0.75 • *f' c * *b

A v_min1= sfy = 0.06 in 2

50 ** b s f y

A v_min2= = 0.07 in 2

A v_min= MAX(A v_min1 ; A v_min2) = 0.07 in 2

Required Area of Reinforcement, A vc_Req= MAX(A v; A v_min) = 0.07 in 2

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.3

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 0.11 in 2

Number of Stirrups, n= 1

Provided Area of Reinforcement, A vc_Prov= A sb * n * 2 = 0.22 in 2

Check Validity= IF(A vc_Prov • A vc_Req; " Valid"; "Invalid") = Valid

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Shear Reinforcement for Section Subject to Q & N Page: 21

Determine Maximum Permissible Spacing of Stirrups

Allowable Shear Strength provided by Reinforcement for Spacing Limit (According to Cl.11.4.5.3 of ACI318), V s_limit=

* •4 * f' c * b * / d 1000

• = 41.7 kips

Factor for Maximum Spacing of Stirrups, Fac=IF(V s • V s_limit; 1;0.5) = 1.0

Maximum Spacing of Stirrups (According to Cl.11.4.5.1 of ACI318), s max=

MIN(d/2;24 ) * Fac = 6.88 in

Check Validity= IF(s • s max;" Valid"; "Invalid") = Valid

Design Summary

Provided Area of Shear Reinforcement, A vc_Prov= A vc_Prov = 0.22 in 2

Spacing of Stirrups, s= s = 6.75 in

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Shear Reinforcement for Section Subject to Q & T Page: 22

Design of Shear Reinforcement for Section Subject to Shear & Axial Tension As per ACI318-11

Shear Reinforcement for Section Subject to Q & T

Av

d Nu

co h Vu

b

s

System

Width of Concrete Section, b= 10.5 in

Depth of Concrete Section, h= 18.0 in

Concrete Cover, co= 2.0 in

Effective Depth of Concrete Section, d= - h co = 16.0 in

Load

Shear Force due to Dead Load, V D= 12.8 kips

Shear Force due to Live Load, V L= 9.0 kips

Ultimate Shear Force, V u= • 1.2 V* D • + • 1.6 V* L • = 29.8 kips

Axial Tension Force due to Dead Load, N D= - 2.0 kips

Axial Tension Force due to Live Load, N L= - 15.2 kips

Ultimate Axial Tension Force, N u= • 1.2 N* D • + • 1.6 N* L • = - 26.7 kips

Material Properties

Concrete Strength, f' c= 3600 psi

Yield Strength of Reinforcement, f y= 40000 psi

Shear Strength Reduction Factor (According to Cl.9.3.2 of ACI318), •= 0.75

Modification Factor for Lightweight Concrete, •• • 0.85

Determine Concrete Shear Strength

Nominal Shear Strength provided by Concrete (According to Eq. 11-8 of ACI318),

• •

N u 1000

* f' c * *b

V c= *2 1 +

500 ** h b

• *• * d 1000 = 12.3 kips

Shear Reinforcement is : IF(V u> •• V c;" Required";"Not Required") = Required

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Shear Reinforcement for Section Subject to Q & T Page: 23

Determine Area of Shear Reinforcement

Nominal Shear Strength provided by Reinforcement (According to Eq. 11-2 of ACI318),

Vu -• * Vc

V s= = 27.4 kips

•

Maximum Allowable Shear Strength provided by Reinforcement (According to Cl.11.4.7.9 of ACI318),

f' c * *b

•

V s_max= * •8 * d 1000 = 68.5 kips

IF(V s> V s_max; " Increase Beam Dimension"; "OK" ) = OK

Spacing of Provided Stirrups, s= 5.0 in

Vs * * s 1000

Required Area of Reinforcement, A v= = 0.21 in 2

*fyd

Minimum Area of Reinforcement (According to Cl.11.4.6.3 of ACI318),

0.75 • *f' c * *b

A v_min1= sfy = 0.06 in 2

50 ** b s f y

A v_min2= = 0.07 in 2

A v_min= MAX(A v_min1 ; A v_min2) = 0.07 in 2

Required Area of Reinforcement, A vc_Req= MAX(A v; A v_min) = 0.21 in 2

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.3

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 0.11 in 2

Number of Stirrups, n= 1

Provided Area of Reinforcement, A vc_Prov= A sb * n * 2 = 0.22 in 2

Check Validity= IF(A vc_Prov • A vc_Req; " Valid"; "Invalid") = Valid

Determine Maximum Permissible Spacing of Stirrups

Allowable Shear Strength provided by Reinforcement for Spacing Limit (According to Cl.11.4.5.3 of ACI318),

f' c * *b

•

V s_limit= * •4 * d 1000 = 34.3 kips

Factor for Maximum Spacing of Stirrups, Fac= IF(V s • V s_limit; 1;0.5) = 1.0

Maximum Spacing of Stirrups (According to Cl.11.4.5.1 of ACI318), s max=

MIN(d / 2;24 ) * Fac = 8.00 in

Check Validity= IF(s • s max;" Valid"; "Invalid") = Valid

Design Summary

Provided Area of Shear Reinforcement, A vc_Prov= A vc_Prov = 0.22 in 2

Spacing of Stirrups, s= s = 5.00 in

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Deflection of Shored Composite Section Page: 24

Calculation of Deflection of Shored Nonprestressed Simple Support Concrete Composite Section As per ACI318-11 Chapter 9

Deflection of Shored Composite Section

be

hf

Cast in Situ Slab

h Precast Beam

As

co

System

Beam Span, L= 26.0 ft

Beam Spacing, S= 8.0 ft

Width of Precast Beam, b= 12.0 in

Depth of Precast Beam, h= 20.0 in

Thickness of Cast in Situ Slab, h f= 4.0 in

Area of Tension Reinforcement for Precast Beam, A s= 3.00 in 2

Concrete Cover for Precast Beam, co= 2.5 in

Effective Width of Slab, b e1= L*12 / 4 = 78.0 in

Effective Width of Slab, b e2= S*12 = 96.0 in

Effective Width of Slab, b e3= 16*hf + b = 76.0 in

Effective Width of Slab, b e= MIN(b e1; b e2; b e3) = 76.0 in

Material Properties

Concrete Strength of Cast in Situ Slab, f' c1= 3000 psi

Concrete Strength of Precast Beam, f' c2= 4000 psi

Yield Strength of Reinforcement, f y= 40000 psi

Modulus of Elasticity of Reinforcement, E s= 29000000 psi

Modification Factor for Lightweight Concrete, •• • 1.00

Concrete Density, w c= 150 psi

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Deflection of Shored Composite Section Page: 25

Load

Superimposed Dead Load, SDL= 10.00 psf

Live Load, LL= 75.00 psf

Dead Load per Unit Length for Slab, w d1= SDL*S + w c* S*12*h f/ 144 = 480.0 Ib/ft

Dead Load per Unit Length for Beam, w d2= w c* b*h/144 = 250.0 Ib/ft

Live Load per Unit Length, w l= LL*S = 600.0 Ib/ft

Percentage of Sustained Live Load, Sus= 20 %

Bending Moment of Dead Load 1, M D1= 1/1000 * w d1* L 2/ 8 = 40.6 kip*ft

Bending Moment of Dead Load 2, M D2= 1/1000 * w d2* L 2/ 8 = 21.1 kip*ft

Bending Moment of Live Load, M L= 1/1000 * w l* L 2/ 8 = 50.7 kip*ft

Bending Moment of Sustained Load, M sus= M D1 + M D2 + ( Sus/100) * M L = 71.8 kip*ft

Calculation of Modular Ratio

For Cast in Situ Slab:

Modulus of Elasticity of Concrete (According to Cl. 8.5.1 of ACI318),

1.5

E c1= wc * 33 •* f' c1 = 3320561 psi

7.5 ** • f' c1

Modulus of rupture (According to Eq. 9-10 of ACI318), f r1=

• = 411 psi

For Precast Beam:

Modulus of Elasticity of Concrete (According to Cl. 8.5.1 of ACI318),

1.5

E c2= wc * 33 •* f' c2 = 3834254 psi

7.5 ** • f' c2

Modulus of rupture (According to Eq. 9-10 of ACI318), f r2=

• = 474 psi

n c= E c2 / E c1 = 1.15

n s= E s / E c2 = 7.56

Width of Slab considering relative Concrete Strength, bs= be/n c = 66.09 in

Calculation of Moment of Inertia for Cracked Section

For Precast Beam

Effective Depth of Section, d= 17.5 in

I g1= b*h 3/ 12 = 8000 in 4

B= b/(n s* A s) = 0.53 1/in

• *d

2+* B 1 1 B-

kd= = 6.5 in

* b kd 3

I cr1= + n s * A s •* - d kd•2 = 3842.8 in 4

3

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Deflection of Shored Composite Section Page: 26

For Composite Section

Effective Depth of Section, d= (h+hf) - co = 21.5 in

h1 = h + hf = 24.0 in

bs1 = bs - b = 54.1 in

Distance from Centroidal Axis of Gross Section to Tension Face,

1 bs1 hf* 2 + * b h1 2

yt= h1 *- = 16.3 in

2 bs1 +* hf h1

*b

2 2

• •*

bs1 hf* 3 * b h1 3 hf 2 yt

I g2=

12

+

12

+ bs1 * * hf h + -

• + b * h1 -

yt h1

2

• = 26468.49 in 4

B= bs • / *

n s As • = 2.91 1/in

• 2* d * + B 1- 1

kd= B = 3.5 in

bs kd

* 3

I cr2= + n s * As • * - d kd•2 = 8292.9 in 4

3

I g1 I cr1

Ratio between Cracking & Gross Inertia, r=

•I g2

+

I cr2 • /2 = 0.383

Cracking Moment (According to Eq. 9-9 of ACI318),

f r2 I*g1

Cracking Moment for Beam Section, M cr1= = 31.60 kip*ft

/ h 2* 12000

f r2 I*g2

Cracking Moment for Beam Section, M cr2= = 64.14 kip*ft

yt 12000

*

Effective Moment of Inertia for Composite Section,

3

3

• • ••

M cr1

• •

M cr1

I e1,2= * I g1 + -1 * I cr1 = 4401 in 4

M D1 M+D2 M D1 M+D2

3

3

• • ••

M cr2

• •

M cr2

I ed,l= * I g2 + -1 * I cr2 = 11670 in 4

M D1 + M D2 M+L

M D1 + M D2 M+L

Check Validity= IF(I e1.2< I g1; " Valid"; "Invalid") = Valid

Short Term Deflection

Short Term Deflection of composite section Due to Dead Load,

5* • M D1 M+D2 • * L 2 12

* 3

• i1,2=

= 0.074 in

48 * E c2 I g2 /

* 1000

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Deflection of Shored Composite Section Page: 27

Deflection Due to Shrinkage

For Simple Span, Ksh= 0.125

*

A s 100

• = = 1.16 %

d *b

(According to Fig.10-3 of PCA Note on ACI318), Ash= 0.789

Time Dependant Shrinkage Strain, • sht= 400 10-

* 6 = 0.00040

Deflection Due to Shrinkage, • sh= 0.64 * Ksh * Ash * • sht L*2 12 2* * /rh= 0.047 in

Deflection Due to Creep

For No Compression Reinforcement Factor of, k r= 0.85

Average Creep Coefficient (According to Cl.2.3.4 of ACI435), Cu= 1.67

Deflection Due to Creep, • cp= Cu * • *

i1,2 k r

= 0.105 in

Deflection Due to Live Load

5* • M D1 + M D2 M+L • * L 2 12

* 3

Deflection Due to Live Load , • L= - • i1,2 = 0.232 in

48 * E c2 I ed,l /

* 1000

Deflection Due to Creep Sustained Live Load, • cp, L= Cu Sus

* *• *

Lkr

= 0.066 in

100

Total Long Term Deflection

Total Deflection, • u= • *

i1,2 3.53

+• sh

+ • cp • +L = 0.65 in

Calculation Summary

Total Deflection, • u= • *

i1,2 3.53

+• sh

+ • cp • +L = 0.65 in

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Flexural Design of Flanged Section Page: 28

Design of Flanged Section with Tension Reinforcement only as per ACI 318-11 Chapters 9 & 10

Flexural Design of Flanged Section

bf bf

a hf hf

a

d As d As

h h

co co

bw bw

Design as Rectangular Section Design as Flanged Section

System

Width of Concrete Flange, b f= 30.0 in

Width of Concrete Web, b w= 10.0 in

Depth of Concrete Section, h= 20.0 in

Thickness of Top Flange, h f= 2.5 in

Concrete Cover, co= 1.0 in

Effective Depth of Concrete Section, d= co- h = 20.0 1.0

- = 19.0 in

Load

Bending Moment due to Dead Load, M D= 72.0 kip*ft

Bending Moment due to Live Load, M L= 196.0 kip*ft

Ultimate Bending Moment, M U= • 1.2 M

*D • + • 1.6 M

*L • = 400.0 kip*ft

Material Properties

Concrete Strength, f' c= 4000 psi

Yield Strength of Reinforcement, f y= 60000 psi

Tension Strength Reduction Factor (According to Cl.9.3.2 of ACI318), •= 0.90

Factor for Rectangular Compressive Stress Block (According to Cl.10.2.7.3 of ACI318),

• 1=

IF(f' c • 4000;0.85;IF(f' c • 8000;0.65;1.05-0.00005*f' c)) = 0.85

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Flexural Design of Flanged Section Page: 29

Design as Flanged Section

b f b- w

Compressive Strength of Flange, C f= 0.85 * f' c h* f * = 170.0 kips

1000

Cf

Area of Reinforcement for Flange in Compression, A sf= * 1000 = 2.83 in 2

fy

A sf * f y

•

hf

Nominal Moment for Flange, M nf=

12000 • * -d

2

= 251.2 kip*ft

Nominal Moment for Web, M nw= / M U- • M nf = 193.24 kip*ft

M nw 12000

*

R nw= = 713.7 psi

• * b w d *2

• w=

0.85 * / f' c f y* • •• -1 1

* 2 R nw

0.85 f' *c

• = 0.0135

Area of Reinforcement for Web in Compression, A sw= • w * b w * d = 2.56 in 2

Required Area of Reinforcement, A s_T= A sf + A sw = 5.39 in 2

A sw f y*

Depth of Rectangular Stress Block for Web, a w= = 4.52 in

0.85 * f' c b* w

Design as Rectangular Section

M U 12000

*

R n= = 492.46 psi

• * b f d*2

• = 0.85 f' *c

fy •* -1 •• 1

*2Rn

0.85 f' *c

• = 0.0089

Area of Reinforcement, A s_R= • •* b f * d = 5.07 in 2

A s_R f y*

Depth of Rectangular Stress Block, a= = 2.98 in

0.85 * f' c b* f

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Flexural Design of Flanged Section Page: 30

Section Type and Reinforcement

Section Design as: IF(a>h f; " Flanged Sec."; "Rectangular Sec." ) = Flanged Sec.

Area of Reinforcement, A s= IF(a>h f; A s_T; A s_R ) = 5.39 in 2

Minimum Area of Reinforcement (According to Cl.10.5 of ACI318),

f' c * b f d*fy

3*

•

A s_min1= = 1.80 in 2

200 * b f d*fy

A s_min2= = 1.90 in 2

A s_min= MAX(A s_min1 ; A s_min2) = 1.90 in 2

Required Area of Reinforcement, A sc_Req= MAX(A s; A s_min) = 5.39 in 2

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.10

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 1.27 in 2

Number of Bars, n= 5

Vertical Reinforcement, A sc_Prov= A sb * n = 6.35 in 2

Check Validity= IF(A sc_Prov • A sc_Req; " Valid"; "Invalid") = Valid

Check Tension Controlled

Distance from Extreme Compression Fiber to Neutral Axis, c=

IF(a>h f; a w/ • 1; a/ • 1 ) = 5.32 in

c/d = /

/ c d = 5.32 19.0 = 0.280

IF(c/d>0.375; "Add Com. RFT"; "Tension Controlled" ) = Tension Controlled

Design Summary

Required Area of Reinforcement, A sc= A sc_Prov = 6.35 in 2

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Cracking Moment Strength for Prestressed Sections Page: 31

Cracking Moment Strength for Prestressed Sections as per ACI 318-11 Chapter 18

Cracking Moment Strength for Prestressed Sections

d

h

n.As

co

System

Width of Concrete Section, b= 12.0 in

Depth of Concrete Section, h= 24.0 in

Concrete Cover, co= 2.0 in

Effective Depth of Concrete Section, d= co- h = 24.0 2.0

- = 22.0 in

Number of Strands, n= 6.0

Area of One Strand, A s= 0.153 in 2

Material Properties

Concrete Strength, f' c= 5000 psi

Tensile Strength of Prestressed Steel, f pu= 270000 psi

Jacking Stress, J s= 0.7 * f pu = 189000 psi

Percentage of Losses, L s= 20.00 %

Modification Factor for Lightweight Concrete, •• • 1.00

7.5 ** •

Modulus of Rupture (According to Eq. 9-10 of ACI318), f r=

• f' c = 530 psi

Calculation of Cracking Moment Strength

Area of Concrete, A c= b*h = 288.0 in 2

Concrete Section Modulus, S b= b*h2/6 = 1152.0 in 3

Eccentricity of Prestressing, e= h/2 - co = 10.0 in

Effective Prestress Force, P se= (1-L s/ 100) * n * A s * J s / 1000 = 138.8 kips

fr P se Sb

• •

e

Cracking Moment Strength, M cr= + * + P se * = 212.8 kip*ft

1000 Ac 12 12

Calculation Summary

Cracking Moment Strength, M cr= M cr = 212.8 kip*ft

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Flexural Strength of Prestressed Member Page: 32

Flexural Strength of Prestressed Member Using Approximate Value of f ps As per ACI 318-11

Flexural Strength of Prestressed Member

d

h

n.As

co

System

Width of Concrete Section, b= 12.0 in

Depth of Concrete Section, h= 24.0 in

Concrete Cover, co= 2.0 in

Effective Depth of Concrete Section, d= co- h = 24.0 2.0

- = 22.0 in

Number of Strands, n= 6

Area of One Strand, A s= 0.153 in 2

Material Properties

Concrete Strength, f' c= 5000 psi

Tensile Strength of Prestressed Steel, f pu= 270000 psi

Yield Strength of Prestressed Steel, f py= 0.9 * f pu = 243000 psi

Factor for Type of Prestressing Steel (According to Cl.18.7.2 of ACI318), • p= 0.28

Factor for Rectangular Compressive Stress Block (According to Cl.10.2.7.3 of ACI318),

• 1=

IF(f' c • 4000;0.85;IF(f' c • 8000;0.65;1.05-0.00005*f' c)) = 0.80

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Flexural Strength of Prestressed Member Page: 33

Calculation of Stress for Prestressed Reinforcement

Prestressed Reinforcement Ratio, • p= n * A s / ( b * d) = 0.00348

Prestressing Force (According to Eq. 18-1 of ACI318),

f pu •p f pu

f ps=

1000 • * 1 -

•1

*• p *

f' c • = 252 ksi

Calculation of Nominal Moment Strength

* n A s* f ps

Distance of Compression Block, a= = 4.54 in

0.85 * *b / f' c 1000

* n A s* f ps a

Nominal Moment Strength, M n=

12

*

• -d

2

• = 380.4 kip*ft

Calculation Summary

Nominal Moment Strength, M n= Mn = 380.4 kip*ft

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Tension Controlled Limit for Prestressed Flexural Member Page: 34

Tension Controlled Limit for Prestressed Flexural Member as per ACI 318-11 Chapters 10 & 18

Tension Controlled Limit for Prestressed Flexural Member

hf

b

d

h d p

co p

b w/2 b w/2

co

System

Width of Concrete Double Tee Section, b= 84.0 in

Width of Web of Concrete Double Tee Section, b w= 15.5 in

Depth of Concrete Double Tee Section, h= 32.0 in

Thickness of Concrete Top Slab, h f= 2.0 in

Concrete Cover, co= 2.0 in

Concrete Cover to CG of Prestressed Steel, co p= 4.5 in

Effective Depth of Concrete Section, d= co- h = 30.0 in

Effective Depth of Concrete Section, d p= - h co p = 27.5 in

Number of Strands, n= 22.0

Area of One Strand, A s= 0.153 in 2

Material Properties

Concrete Strength, f' c= 5000 psi

Tensile Strength of Prestressed Steel, f pu= 270000 psi

Yield Strength of Prestressed Steel, f py= 0.9 * f pu = 243000 psi

Factor for Type of Prestressing Steel (According to Cl.18.7.2 of ACI318), • p= 0.28

Factor for Rectangular Compressive Stress Block (According to Cl.10.2.7.3 of ACI318),

• 1=

IF(f' c • 4000; 0.85; IF(f' c • 8000; 0.65; 1.05-0.00005*f' c)) = 0.80

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Tension Controlled Limit for Prestressed Flexural Member Page: 35

Calculation of Stress in Prestressed Reinforcement

• pu=

(n * A s) * f pu / ( b * d p * f' c) = 0.079

Prestressing Force (According to Eq.18-1 of ACI318),

f ps= f pu •

* 1 -

•p

• 1

*• pu • = 262535 psi

Area of Reinforcement for Compression in Flange,

A pf= 0.85 * h f * f' c * ( b-b w) / f pu = 2.16 in 2

Calculation of Depth of Concrete Stress Block

a i= (n * A s) * f ps / ( 0.85 * b * f' c) = 2.48 in

For a i > h f:

a 1= (n * A s - A pf) * f ps / ( 0.85 * b w * f' c) = 4.81 in

For a i • h f:

a 2= ai = 2.48 in

a= IF(a i> h f ; a 1 ; a 2) = 4.81 in

c= a/•1 = 6.01 in

Check Tension Controlled

c/d = c/d = 0.200

IF(c/d>0.375; "Compression Controlled"; "Tension Controlled" ) = Tension Controlled

Calculation Summary

Type of Section:

IF(c/d>0.375; "Compression Controlled"; "Tension Controlled" ) = Tension Controlled

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Prestress Losses Page: 36

Estimating Prestress Losses as per ACI 318-11 Chapter 18

Prestress Losses

y

t N.A

h

y

b

System

Area of Concrete Section, A c= 449 in 2

Depth of Concrete Section, h= 24 in

Concrete Cover, co= 2 in

Effective Depth of Concrete Section, d= co- h = 22 in

Moment of Inertia for Concrete Section, I c= 22469 in 4

Distance from Bottom Fiber to Neutral Axis, y b= 17.77 in

Distance from Top Fiber to Neutral Axis, y t= -hyb = 6.23 in

Number of Strands, n= 8.0

Area of One Strand, A s= 0.153 in 2

Eccentricity of Strands, e= 9.77 in

Volume per Surface Area, V.S= 1.35 in

Average Relative Humidity, RH= 75.00 %

Load

Factored Moment due to Dead Load, M D= 1617 kip*in

Factored Moment due to Superimposed Dead Load, M SD= 691 kip*in

Factored Moment due to Live Load, M L= 1382.00 kip*in

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Prestress Losses Page: 37

Material Properties

Concrete Strength, f' ci= 3500 psi

Concrete Strength, f' c= 5000 psi

Tensile Strength of Prestressed Steel, f pu= 270000 psi

Yield Strength of Prestressed Steel, f py= 0.9 * f pu = 243000 psi

Jacking Stress, J s= 0.74 * f pu = 199800 psi

Modification Factor for Lightweight Concrete, •• • 1.00

7.5 ** • f' c =

Modulus of Rupture (According to Eq. 9-10 of ACI318), f r=

• 530 psi

Concrete Density, w c= 150 psi

Modulus of Elasticity of Concrete (According to Cl. 8.5.1 of ACI318),

1.5

Modulus of Elasticity for Initial Concrete, E ci= wc * 33 •* f' ci = 3586616 psi

1.5

Modulus of Elasticity for Concrete, E c= wc * 33 •* f' c = 4286826 psi

Modulus of Elasticity of Prestressed Steel, E s= 28500000 psi

Calculation of Losses

1- Elastic Shortening of Concrete (ES) Initial Force of

Prestress, P pi= J s * ( n * A s)/ 1000 = 244.6 kips

Prestress Type= SEL("ACI/Kes" ;Type; ) = Pretensioned

K es= TAB("ACI/Kes" ;Kes ;Type=Type ) = 1.00

K cir= TAB("ACI/Kcir" ;Kcir ;Type=Type ) = 0.90

• P pi P pi M D e*I c

f cir= K cir *

Ac

+

Ic

* e2

• - = 0.722 ksi

Elastic Shortening of Concrete, ES= K es * E s * / f cir E ci = 5.74 ksi

2- Creep of Concrete (CR) Prestress

Type= SEL("ACI/Kcr" ;Type; ) = Pretensioned

Factor of, Kcr= TAB("ACI/Kcr" ;Kcr ;Type=Type ) = 2.00

Es eIc

Creep Losses, CR= K cr *

Ec •

* f cir - M SD *

• = 5.61 ksi

3- Shrinkage of Concrete (SH) Prestress

Type= SEL("ACI/Ksh" ;Type; ) = Pretensioned

Factor of, K sh= TAB("ACI/Ksh" ;Ksh ;Type=Type ) = 1.00

Es

Shrinkage Losses, SH= 8.2 * 10- 6 * K sh * *•1 - * •

0.06 V.S • -

* 100 RH • = 5.37 ksi

1000

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Prestress Losses Page: 38

4- Relaxation of Tendon (RE) Prestress

Type= SEL("ACI/KreJ" ;Type; ) = relaxation strand-Grade Low 270

Factor of, K re= TAB("ACI/KreJ" ;Kre ;Type=Type ) = 5000 psi

Factor of, J= TAB("ACI/KreJ" ;J ;Type=Type ) = 0.04

Ratio of f pi/ f pu, r= SEL("ACI/r" ;r; ) = 0.74

Factor of, C= TAB("ACI/r" ;C ;r=r ) = 0.95

K re

Relaxation of Tendon, RE=

•1000 * - J• SH + CR ES

+ C •

•* = 4.11 ksi

5- Total Allowance of Losses and Effective Prestress Force after all Losses Total Allowance of Losses, L s=

ES + CR + SH RE

+ = 21 ksi

Effective Prestress Stress, f se= / J s 1000- L s = 179 ksi

Effective Prestress Force after All Losses, P e= fse • * * n A s• = 219 kips

Calculation Summary

Total Allowance of Losses, L s= Ls = 21 ksi

Effective Prestress Force after All Losses, P e= P e = 219 kips

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Punching Shear Reinforcement on Slab Page: 39

Design Shear Reinforcement for Slab which to resist Punching Stress around Interior Square Column As per ACI318-11 Chapter 11

Punching Shear Reinforcement on Slab

2d

a√2

b1

d/2 c d/2

• Vc/2

d/2

Critical Section for Punching s

Shear Action

a c

System

Column Dimension, c= 12.0 in

Thickness of Concrete Slab, h= 7.5 in

Concrete Cover, co= 1.5 in

Effective Depth of Concrete Section, d= co- h = 7.5 1.5

- = 6.0 in

Bar Diameter of Shear Reinforcement, Dia= 0.375 in

Load

Ultimate Shear Force, V u= 120.0 kips

Material Properties

Concrete Strength, f' c= 4000 psi

Yield Strength of Reinforcement, f y= 60000 psi

Shear Strength Reduction Factor (According to Cl.9.3.2 of ACI318), •= 0.75

Modification Factor for Lightweight Concrete, •• • 1.00

Determine Concrete Shear Strength

b 1= c+d = 18.0 in

Perimeter of Critical Section, b 0= 4 * b 1 = 72.0 in

Nominal Shear Strength provided by Concrete (According to Eq. 11-33 of ACI318), V c=

* •4 * f' c * b 0 * / d 1000

• = 109.3 kips

Punching Shear Reinforcement is : IF(V u> •• V c;" Required";"Not Required") = Required

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Punching Shear Reinforcement on Slab Page: 40

Determine Area of Shear Reinforcement

Minimum Effective Depth of Slab with Shear Reinforcement (According to Cl.11.11.3 of ACI318), d min=

MIN(6;16*Dia ) = 6.0 in

Effective Depth of Slab : IF(d>d min;" Should Increase";"OK") = OK

Maximum Shear Strength of Slab with Shear Reinforcement (According to Cl.11.11.3.2 of ACI318), V n=

* 6 • f' c * b 0 d* 1000

/ = 163.9 kips

Validity : IF(V u> •• V n;" Not Valid";"Valid") = Valid

Shear Strength provided by Concrete with Shear RFT (According to Cl.11.11.3.1 of ACI318), V ci=

* •2 * f' c * b 0 * / d 1000

• = 54.6 kips

Nominal Shear Strength provided by Reinforcement (According to Eq. 11-2 of ACI318),

V u - • * V ci

V s= = 105.4 kips

•

Spacing of Provided Bars, s= 3.0 in

Vs * * s 1000

Required Area of Reinforcement, A v= = 0.88 in 2

*fyd

Required Area of Reinforcement for each side of Column, A v_side= /Av4 = 0.22 in 2

Perimeter of Critical Section where Shear Reinforcement may be terminated,

V u 1000

*

b' 0= = 210.8 in

• * * •2 *

• f' c d*

Distance from Column Face where Shear Reinforcement may be terminated,

b' 0

a=

• 4 c -• 2 •/ = 28.8 in

Design Summary

Required Area of Reinforcement, A v= A v = 0.88 in 2

Distance from Column Face where Shear Reinforcement may be terminated: a = 28.8 in

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

One Way Joist Page: 41

Design of One Way Joist as per ACI 318-11 Chapters 9 & 11

One Way Joist

Lne Lni

ts b

Lne Lni

System

Width of Beam, b= 30.0 in

Width of Joist, b j= 6.0 in

Spacing between Joists, s= 36.0 in

Slab Thickness, t s= 3.5 in

Exterior Joist Span, L ne= 27.5 ft

Interior Joist Span, L ni= 27.0 ft

Concrete Cover, co= 1.25 in

Load

Dead Load, DL= 130 psf

Live Load, LL= 60 psf

1.2 * DL + 1.6 LL

* s

Ultimate Load, w u= * = 0.756 kip/ft

1000 12

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

One Way Joist Page: 42

Material Properties

Concrete Strength, f' c= 4000 psi

Yield Strength of Reinforcement, f y= 60000 psi

Tension Strength Reduction Factor (According to Cl.9.3.2 of ACI318), •= 0.90

Modification Factor for Lightweight Concrete, •• • 1.00

Factor for Rectangular Compressive Stress Block (According to Cl.10.2.7.3),

• 1=

IF(f' c • 4000;0.85;IF(f' c • 8000;0.65;1.05-0.00005*f' c)) = 0.85

Moment Distribution for Joist

1. End Span

2

w u L* ne

Edge Negative Moment for Exterior Joist, M nee= = 23.8 kip*ft

24

2

w u L* ne

Positive Moment for Exterior Joist, M pe= = 40.8 kip*ft

14

w u •* • L ne L +ni • / 2 2•

Negative Moment for Exterior Joist, M ne= = 56.1 kip*ft

10

2. Interior Spans

2

w u L* ni

Negative Moment for Interior Joist, M ni= = 50.1 kip*ft

11

2

w u L* ni

Positive Moment for Interior Joist , M pi= = 34.4 kip*ft

16

3. Maximum Moment M max=

MAX(M nee; M pe; M ne; M ni; M pi) = 56.1 kip*ft

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

One Way Joist Page: 43

Calculation of Required Depth for Joist

• t=

0.319 * f' c * • 1 / f y = 0.01808

For Reasonable Deflection Control, choose a Reinforcement Ratio ( •)• equal to about one-half ( • t) •

Reinforcement Ratio, •= • t/ 2 = 0.00904

fy

• = • * = 0.13560

f' c

M max 12000

*

Required Depth, d=

• • * bj * f'c *• *•1 - 0.59 • * •

= 15.8 in

Required Thickness, h req= d + co = 17.1 in

h min= MAX(L ne* 12+b; L ni* 12+b;)/18.5 = 19.5 in

Provided Thickness, h= MAX(h req; h min) = 19.5 in

Effective Depth of Joist, d j= h-co = 18.25 in

Calculation of Required Reinforcement for Exterior Negative Moment of End Span (A sc1)

M nee 12000

*

R n1= = 159 psi

2

• * *bjdj

Reinforcement Ratio, • •= 0.85 f' *c

fy •

* -1 ••

1 * 2 R n1

0.85 f' *c

• = 0.0027

Area of Reinforcement, A s1= • •

*bj*dj = 0.30 in 2

Minimum Area of Reinforcement (According to Cl.10.5 of ACI318),

* 3 • f' c * *bjdj

A s_min1= = 0.35 in 2

fy

200 * *bjdj

A s_min2= = 0.36 in 2

fy

A s_min= MAX(A s_min1 ; A s_min2) = 0.36 in 2

Required Area of Reinforcement, A sc1= MAX(A s1; A s_min) = 0.36 in 2

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.3

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 0.11 in 2

Number of Bars, n= 4

Vertical Reinforcement, A sc1_Prov= A sb * n = 0.44 in 2

Check Validity= IF(A sc1_Prov • A sc1; " Valid"; "Invalid") = Valid

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

One Way Joist Page: 44

Calculation of Required Reinforcement for Positive Moment of End Span (A sc2)

M pe 12000

*

R n2= = 272 psi

2

• * *bjdj

Reinforcement Ratio, • •= 0.85 f' *c

fy •* -1 ••

1 * 2 R n2

0.85 f' *c

• = 0.0047

Area of Reinforcement, A s2= • •

*bj*dj = 0.51 in 2

Minimum Area of Reinforcement (According to Cl.10.5 of ACI318),

* 3 • f' c * *bjdj

A s_min1= = 0.35 in 2

fy

200 * *bjdj

A s_min2= = 0.36 in 2

fy

A s_min= MAX(A s_min1 ; A s_min2) = 0.36 in 2

Required Area of Reinforcement, A sc2= MAX(A s2; A s_min) = 0.51 in 2

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.5

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 0.31 in 2

Number of Bars, n= 2

Vertical Reinforcement, A sc2_Prov= A sb * n = 0.62 in 2

Check Validity= IF(A sc2_Prov • A sc2; " Valid"; "Invalid") = Valid

Calculation of Required Reinforcement for Interior Negative Moment of End Span (A sc3)

M ne 12000

*

R n3= = 374 psi

2

• * *bjdj

Reinforcement Ratio, • •= 0.85 f' *c

fy •* -1 ••

1 * 2 R n3

0.85 f' *c

• = 0.0066

Area of Reinforcement, A s3= • •

*bj*dj = 0.72 in 2

Minimum Area of Reinforcement (According to Cl.10.5 of ACI318),

* 3 • f' c * *bjdj

A s_min1= = 0.35 in 2

fy

200 * *bjdj

A s_min2= = 0.36 in 2

fy

A s_min= MAX(A s_min1 ; A s_min2) = 0.36 in 2

Required Area of Reinforcement, A sc3= MAX(A s3; A s_min) = 0.72 in 2

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

One Way Joist Page: 45

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.5

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 0.31 in 2

Number of Bars, n= 3

Vertical Reinforcement, A sc3_Prov= A sb * n = 0.93 in 2

Check Validity= IF(A sc3_Prov • A sc3; " Valid"; "Invalid") = Valid

Calculation of Required Reinforcement for Interior Negative Moment of Interior Span (A sc4)

M ni 12000

*

R n4= = 334 psi

2

• * *bjdj

Reinforcement Ratio, • •= 0.85 f' *c

fy •* -1 ••

1 * 2 R n4

0.85 f' *c

• = 0.0059

Area of Reinforcement, A s4= • •

*bj*dj = 0.65 in 2

Minimum Area of Reinforcement (According to Cl.10.5 of ACI318),

* 3 • f' c * *bjdj

A s_min1= = 0.35 in 2

fy

200 * *bjdj

A s_min2= = 0.36 in 2

fy

A s_min= MAX(A s_min1 ; A s_min2) = 0.36 in 2

Required Area of Reinforcement, A sc4= MAX(A s4; A s_min) = 0.65 in 2

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.5

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 0.31 in 2

Number of Bars, n= 3

Vertical Reinforcement, A sc4_Prov= A sb * n = 0.93 in 2

Check Validity= IF(A sc4_Prov • A sc4; " Valid"; "Invalid") = Valid

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

One Way Joist Page: 46

Calculation of Required Reinforcement for Interior Positive Moment of Interior Span (A sc5)

M pi 12000

*

R n5= = 230 psi

2

• * *bjdj

Reinforcement Ratio, • •= 0.85 f' *c

fy •* -1 ••

1 * 2 R n5

0.85 f' *c

• = 0.0040

Area of Reinforcement, A s5= • •

*bj*dj = 0.44 in 2

Minimum Area of Reinforcement (According to Cl.10.5 of ACI318),

* 3 • f' c * *bjdj

A s_min1= = 0.35 in 2

fy

200 * *bjdj

A s_min2= = 0.36 in 2

fy

A s_min= MAX(A s_min1 ; A s_min2) = 0.36 in 2

Required Area of Reinforcement, A sc5= MAX(A s5; A s_min) = 0.44 in 2

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.5

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 0.31 in 2

Number of Bars, n= 2

Vertical Reinforcement, A sc5_Prov= A sb * n = 0.62 in 2

Check Validity= IF(A sc5_Prov • A sc5; " Valid"; "Invalid") = Valid

Design Summary

Area of Reinforcement for Exterior Negative Moment of End Span: A sc1_Prov = 0.44 in 2

Area of Reinforcement for Positive Moment of End Span: A sc2_Prov = 0.62 in 2

Area of Reinforcement for Interior Negative Moment of End Span: A sc3_Prov = 0.93 in 2

Area of Reinforcement for Interior Negative Moment of Interior Span: A sc4_Prov = 0.93 in 2

Area of Reinforcement for Interior Positive Moment of Interior Span: A sc5_Prov = 0.62 in 2

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Two-Way Slab Analyzed by the Direct Design Method Page: 47

Design Two-Way Slab without Beams Analyzed by the Direct Design Method As per ACI 318-11

Two-Way Slab Analyzed by the Direct Design Method

Design

Strip

Ln

Ln

Ln

Ls Ls Ls

System

Longer Span for Two-Way Slab, L n= 18.00 ft

Shorter Span for Two-Way Slab, L s= 14.00 ft

Thickness of Slab, h= 7.00 in

Concrete Cover, co= 1.25 in

Depth of Slab, d= h-co = 5.75 in

Square Column Dimension, b c= 16.00 in

Width of Column Strip, b= Ls*12 / 2 = 84 in

Width of Middle Strip, b m= Ls*12 - b = 84 in

Load

Slab Self Weight, q s= h/12 * 150 = 87.50 psf

Partition Load, q p= 20.00 psf

Dead Load, q D= qs+qp = 107.50 psf

Live Load, q L= 40.00 psf

Ultimate Load, q U= 1.2 * q D + 1.6 * q L = 193.00 psf

Material Properties

Concrete Strength, f' c= 3000 psi

Yield Strength of Reinforcement, f y= 60000 psi

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Two-Way Slab Analyzed by the Direct Design Method Page: 48

Tension Strength Reduction Factor (According to Cl.9.3.2 of ACI318), •= 0.90

Minimum Reinforcement Ratio (According to Cl.7.12.2 of ACI318),

• min=

IF(f y • 50000;0.002;IF(f y • 77143;0.0014;0.0018)) = 0.0018

Total Static Moment of Slab

Total Factored Static Moment Per Span (According to Eq. 13-4 of ACI318),

2

q U L* s bc

M 0=

* 8 1000 •

* Ln -

12

• = 93.82 kip*ft

Flexural Reinforcement Required for Negative Moment of Column Strip

M 0 12000

* 0.53*

R n1= = 239 psi

• * *bd2

• ••

0.85 f' *c * 2 R n1

Ratio of RFT, • •=

fy

* -1 1

0.85 f' *c

• = 0.00419

Area of Steel, A s1_Req= MAX( • 1; • min) * b * d = 2.02 in²

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.6

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 0.44 in 2

Number of Bars, n= 5

Vertical Reinforcement, A s1_Prov= A sb * n = 2.20 in 2

Check Validity= IF(A s1_Prov • A s1_Req; " Valid"; "Invalid") = Valid

Flexural Reinforcement Required for Positive Moment of Column Strip

M 0 12000

* 0.31*

R n2= = 140 psi

• * *bd2

• ••

0.85 f' *c * 2 R n2

Ratio of RFT, • •=

fy

* -1 1

0.85 f' *c

• = 0.00240

Area of Steel, A s2_Req= MAX( • 2; • min) * b * d = 1.16 in²

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.6

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 0.44 in 2

Number of Bars, n= 3

Vertical Reinforcement, A s2_Prov= A sb * n = 1.32 in 2

Check Validity= IF(A s2_Prov • A s2_Req; " Valid"; "Invalid") = Valid

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Two-Way Slab Analyzed by the Direct Design Method Page: 49

Flexural Reinforcement Required for Negative Moment of Middle Strip

M 0 12000

* 0.17*

R n3= = 77 psi

• * *bd2

• ••

0.85 f'c* fy * 2 R n3

Ratio of RFT, • •= * -1 1

0.85 f'c*

• = 0.00130

Area of Steel, A s3_Req= MAX( • 3; • min) * b * d = 0.87 in²

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.6

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 0.44 in 2

Number of Bars, n= 2

Vertical Reinforcement, A s3_Prov= A sb * n = 0.88 in 2

Check Validity= IF(A s3_Prov • A s3_Req; " Valid"; "Invalid") = Valid

Flexural Reinforcement Required for Positive Moment of Middle Strip

M 0 12000

* 0.21*

R n4= = 95 psi

• * *bd2

• ••

0.85 f'c* fy * 2 R n4

Ratio of RFT, • •= * -1 1

0.85 f'c*

• = 0.00161

Area of Steel, A s4_Req= MAX( • 4; • min) * b * d = 0.87 in²

Provided Reinforcement, Bar= SEL("ACI/Bar"; Bar; ) = No.6

Provided Reinforcement, A sb= TAB("ACI/Bar"; Asb; Bar=Bar) = 0.44 in 2

Number of Bars, n= 2

Vertical Reinforcement, A s4_Prov= A sb * n = 0.88 in 2

Check Validity= IF(A s4_Prov • A s4_Req; " Valid"; "Invalid") = Valid

Design Summary

Area of Reinforcement Required for Negative Moment of Middle Strip,

A s1_Prov= A s1_Prov = 2.20 in 2

Area of Reinforcement Required for Negative Moment of Middle Strip,

A s2_Prov= A s2_Prov = 1.32 in 2

Area of Reinforcement Required for Negative Moment of Middle Strip,

A s3_Prov= A s3_Prov = 0.88 in 2

Area of Reinforcement Required for Positive Moment of Middle Strip,

A s4_Prov= A s4_Prov = 0.88 in 2

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Development Length of Bars in Tension Page: 50

Calculating Development Length of Bars in Tension as per ACI 318-11 Chapter 12

Development Length of Bars in Tension Lab Splice

Lab Splice

Material Properties

Concrete Strength, f' c= 4000 psi

Yield Strength of Reinforcement, f y= 60000 psi

Modification Factor for Lightweight Concrete, •• • 0.75

Factor of Development Length Based on RFT Location (According to Cl.12.2.4 of ACI318),

• t=

1.30

Factor of Development Length Based on RFT Coating (According to Cl.12.2.4 of ACI318),

• e=

1.50

Maximum Modifying Factor, • te= MIN( • t* • e; 1.7) = 1.70

Identification of, Bar= SEL("ACI/Bar" ;Bar; ) = No.7

Diameter of Bars, d b= TAB("ACI/Bar" ;Dia ;Bar=Bar ) = 0.88 in

Calculation of Development Length

1. Class A Splice

Development Length for Bars No.6 and Smaller (According to Cl.12.2.2 of ACI318),

* 3 f *y • te

L d_A1=

• 50 •* • f'* c

• * db = 114 in

Development Length for Bars No.7 and Greater (According to Cl.12.2.2 of ACI318),

* 3 f *y • te

L d_A2=

• 40 •* • f'* c

• * db = 142 in

L d_A= IF(d b • 0.75 ; L d_A1 ; L d_A2 ) = 142 in

2. Class B Splice

Development Length for Bars No.6 and Smaller (According to Cl.12.2.2 of ACI 318),

* 3 f *y • te

L d_B1=

• 50 •* • f'* c

• * 1.3 d* b = 148 in

Interactive Design Aids for Structural Engineers

Chapter 1: Concrete Design ACI 318

Development Length of Bars in Tension Page: 51

Development Length for Bars No.7 and Greater (According to Cl.12.2.2 of ACI318),

* 3 f *y • te

L d_B2=

• 40 •* • f'* c

• * 1.3 d* b = 184 in

L d_B= IF(d b • 0.75 ; L d_B1 ; L d_B2 ) = 184 in

Calculation Summary

Development Length for Class A, L d_A= L d_A = 142 in

Development Length for Class B, L d_B= L d_B = 184 in

Interactive Design Aids for Structural Engineers

Anda mungkin juga menyukai

- TS1042 Sambungan Baut 01 Ganjil 2015 PDFDokumen20 halamanTS1042 Sambungan Baut 01 Ganjil 2015 PDFVicky RamadiBelum ada peringkat

- 4 SBB DET3107 Flexure 2 DesainDokumen23 halaman4 SBB DET3107 Flexure 2 DesainDwi GintingBelum ada peringkat

- Sistem Sambungan Pada Bangunan Baja2Dokumen35 halamanSistem Sambungan Pada Bangunan Baja2Junaid Arrasyid Muhammad100% (2)

- 7962 IdDokumen20 halaman7962 IdesterBelum ada peringkat

- 05 Balok LenturDokumen48 halaman05 Balok LenturShendy Arnaldo ValentinoBelum ada peringkat

- 04 Long TermDokumen25 halaman04 Long TermNovi Andry100% (1)

- Kuliah 2 Analisis Kekuatan Balok Untuk LenturDokumen111 halamanKuliah 2 Analisis Kekuatan Balok Untuk LenturEster SianiparBelum ada peringkat

- Macam Macam Sambungan BajaDokumen22 halamanMacam Macam Sambungan Bajafiona100% (1)

- 3915 8401 1 SMDokumen8 halaman3915 8401 1 SMWawan DevBelum ada peringkat

- 2a Andre Rangga Nugraha 120130039 Tugas 2 Rek - GempaDokumen6 halaman2a Andre Rangga Nugraha 120130039 Tugas 2 Rek - GempaAndre RanggaBelum ada peringkat

- Metode Konstruksi Offshore Platform - 2017!4!4Dokumen108 halamanMetode Konstruksi Offshore Platform - 2017!4!4asyhanggraini100% (4)

- AFA Conecting RodDokumen54 halamanAFA Conecting RodmatieladelBelum ada peringkat

- Materi PelatihanDokumen123 halamanMateri PelatihanAndi Setiawan100% (2)

- Seminar ProposalDokumen19 halamanSeminar ProposalAni HardianiBelum ada peringkat

- Jembatan Rangka BajaDokumen84 halamanJembatan Rangka BajaBoncuBelum ada peringkat

- Rangkuman SNI 7973-2017Dokumen17 halamanRangkuman SNI 7973-2017Trifena TutuBelum ada peringkat

- Tekan-Lentur Kayu PDFDokumen7 halamanTekan-Lentur Kayu PDFYuliar Azmi AdhitamaBelum ada peringkat

- Pertemuan 1 Konstruksi Baja 3 Sambungan Baut 09022022Dokumen55 halamanPertemuan 1 Konstruksi Baja 3 Sambungan Baut 09022022Shahia RafaBelum ada peringkat

- 00 LongtermDokumen26 halaman00 LongtermHafizh MufadhalBelum ada peringkat

- Perubahan Dari SNI 1729 2015 Ke 1729 2020Dokumen61 halamanPerubahan Dari SNI 1729 2015 Ke 1729 2020Agus DermawanBelum ada peringkat

- Pengaruh Main HoopDokumen15 halamanPengaruh Main HoopRudy ArthaBelum ada peringkat

- Sambungan Baut Awal 2Dokumen47 halamanSambungan Baut Awal 2yemima RanaBelum ada peringkat

- Analisis Desain Kolom Pendek Terhadap Beban KonsentrikDokumen13 halamanAnalisis Desain Kolom Pendek Terhadap Beban KonsentrikclvndinoBelum ada peringkat

- Perhitungan Baja HoneycombDokumen43 halamanPerhitungan Baja Honeycombdeanz_7589% (9)

- Pengencangan BautDokumen36 halamanPengencangan Bautmunajat tiliBelum ada peringkat

- Pendahuluan Struktur Beton LanjutDokumen5 halamanPendahuluan Struktur Beton LanjutGilang Pandu WinataBelum ada peringkat

- Arfa'i Abdi Elyan - Tugas Terstruktur 5 SoalDokumen24 halamanArfa'i Abdi Elyan - Tugas Terstruktur 5 SoalArfa'i Abdi ElyanBelum ada peringkat

- TS1042 Batang Tarik Ganjil 2015 (Pert.3)Dokumen21 halamanTS1042 Batang Tarik Ganjil 2015 (Pert.3)David MarshalBelum ada peringkat

- BalokDokumen11 halamanBalokAhmad BaehaqiBelum ada peringkat

- Perencanaan Kolom PendekDokumen26 halamanPerencanaan Kolom PendekaryayyyBelum ada peringkat

- Jawaban Atas Pertanyaan Pada Pelatihan CIBE ITB (STRUKTUR) 2019 + FlowchartDokumen5 halamanJawaban Atas Pertanyaan Pada Pelatihan CIBE ITB (STRUKTUR) 2019 + FlowchartMadhaneBelum ada peringkat

- Sistem Struktur Rangka KakuDokumen29 halamanSistem Struktur Rangka KakuindraBelum ada peringkat

- 3053 9205 1 PBDokumen4 halaman3053 9205 1 PBANISAH KHUSNUL KHOTIMAHBelum ada peringkat

- FormatDokumen61 halamanFormatErwin Tallu SangrapuBelum ada peringkat

- Material Dan Proses Produksi RivetDokumen14 halamanMaterial Dan Proses Produksi RivetRefky FBelum ada peringkat

- Sistem Struktur R & FDokumen9 halamanSistem Struktur R & FWillzAgahariBelum ada peringkat

- Sistem Rangka KakuDokumen31 halamanSistem Rangka KakuAnthonio ZogenBelum ada peringkat

- Mbs Boxing DecentrasiDokumen9 halamanMbs Boxing DecentrasiHery Poernomo100% (1)

- PresentationDokumen29 halamanPresentationHananto imawanBelum ada peringkat

- Fungsional Cusp BevelDokumen8 halamanFungsional Cusp BevelBilly Anderson SinagaBelum ada peringkat

- Bantalan GelindingDokumen11 halamanBantalan GelindingDede PermanaBelum ada peringkat

- Struktur Batang (Ikhwan Andre H - 201745500173)Dokumen10 halamanStruktur Batang (Ikhwan Andre H - 201745500173)Muhammad Ikhwan NasutionBelum ada peringkat

- Modul 3Dokumen8 halamanModul 3Purnama Sakhrial PradiniBelum ada peringkat

- Sambungan Elemen MesinDokumen69 halamanSambungan Elemen MesinNovita Sari100% (1)

- Pertemuan 11 - Perencanaan Sambungan Las - 17-6-2022-DikompresiDokumen25 halamanPertemuan 11 - Perencanaan Sambungan Las - 17-6-2022-DikompresiBara PrakosaBelum ada peringkat

- 8778 28205 1 PBDokumen12 halaman8778 28205 1 PBAlfiananda RahmadiskaBelum ada peringkat

- Materi Struktur Baja - 2Dokumen32 halamanMateri Struktur Baja - 2Reske SufitriBelum ada peringkat