Diagram Alir Massa 3

Diunggah oleh

Apriyanto AhmadDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Diagram Alir Massa 3

Diunggah oleh

Apriyanto AhmadHak Cipta:

Format Tersedia

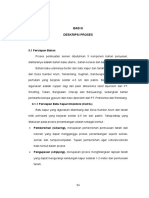

Basis : 1 jam operasi (jam 15.00 WIB tanggal 16 Maret 2016) dengan jumlah umpan 757.

310 kg

Satuan : kg

Feed= 757.310 kg

mix(limestone

dan clay)

= 639.170,0

Limestone

= 103.680,0

Copper slag

= 9.160,0

Pasir Silika

= 5.300,00

udara panas masuk raw mill= 540.944,588

Udara tersier = 218.058,885

Dust loss dari SP = 47.607,992

Umpan batu bara = 28.990

Bahan masuk

Cyclone

= 726.044,155

Raw

Mill

Cyclone

=773

Bahan masuk

Blending Silo

=675.221,064

Umpan batubara = 17.130,00

Udara primer = 12.884,4248

GHP di Kiln

= 141.078,494

Bahan masuk SP

=477.800

Blending

Silo

Suspention

Preheater

Umpan Kiln

= 295.514,415

Udara sekunder = 115.959,8232

produk klinker

= 282.270,554

Kiln

Debu Keluar Cyclone

= 50.823,091

Udara keluar

Raw Mill

=540.944,588

material tinggal di LOW

= 248.193,332

EP

Debu masuk Blending

Silo dari EP = 50.772,268

H2O teruapkan

= 78.873,837

CO2 hasil kalsinasi = 15.133,301

H2O dalam batubara = 2.836,728

N2 dalam batubara = 169,587

Debu keluar EP

= 50,823

Reject = 33.403,055

Gypsum = 11.290,031

Trass = 47.982,635

Produk semen dari

cyclone

cyclone

= 279.583,570

produk semen

= 299.575,598

Bahan ke cyclone

Bahan dari ball mill

= 300.627,495

= 334030,55

Separator

semen tersirkulasi

= 19.991,728

Ball Mill

semen tersirkulasi

= 31.892,364

Bag

Filter I

Gam

debu masuk EP

= 19.758,9

H2O teruapkan = 5.814,366

Bahan masuk bag filter I

= 33.570,909

Debu terbuang= 1.052,197

Klinker dingin

= 262.511,654

Cooler

Bahan masuk bag filter II =

21.043,925

Bag

Filter II

Udara pendingin = 592.768,164

klinker masuk Ball Mill

= 282.250,795

Debu terbuang= 1.678,545

EP

Debu sirkulasi = 19.739,141

udara keluar EP

= 258.749,456

Debu terbuang = 19,759

Gambar 14. Diagram Alir Neraca Massa Keseluruhan Proses Pembuatan Semen PPC

PT Semen Indonesia (Persero) Tbk Jam 15.00 WIB 16 Maret 2016

136

Anda mungkin juga menyukai

- Neraca Massa Dan Energi Vertical Roller MillnDokumen143 halamanNeraca Massa Dan Energi Vertical Roller Millnabdul azizBelum ada peringkat

- NERACA MASSA Kiln Section Pembuatan SemenDokumen43 halamanNERACA MASSA Kiln Section Pembuatan SemenFegi KurniawatyBelum ada peringkat

- Jenis Biomassa Yang DipilihDokumen9 halamanJenis Biomassa Yang DipilihGodeliva FristianingrumBelum ada peringkat

- Lampiran 12Dokumen33 halamanLampiran 12Apriyanto AhmadBelum ada peringkat

- Lampiran 1Dokumen33 halamanLampiran 1Apriyanto AhmadBelum ada peringkat

- Presentasi KP Semen IndonesiaDokumen54 halamanPresentasi KP Semen IndonesiaUkas RiyupiBelum ada peringkat

- Lampiran ADokumen8 halamanLampiran AMutia febrianaBelum ada peringkat

- LAMPIRAN II Rapi Neraca Panas AjiDokumen35 halamanLAMPIRAN II Rapi Neraca Panas AjiAlan BayuBelum ada peringkat

- Tugas Khusus KP Semen IndonesiaDokumen38 halamanTugas Khusus KP Semen IndonesiaDany SatrioBelum ada peringkat

- Lampiran ADokumen8 halamanLampiran AMutia FebrianaBelum ada peringkat

- Presentasi KP IndocementDokumen20 halamanPresentasi KP IndocementVinsenBelum ada peringkat

- Cara Menghitung Kebutuhan Bahan Bakar BoilerDokumen3 halamanCara Menghitung Kebutuhan Bahan Bakar BoilerAldaJuliyantiBelum ada peringkat

- Lampiran 2 Neraca PanasDokumen54 halamanLampiran 2 Neraca Panasvhajar_3269141950% (2)

- 5.tugas Khusus Furnace-5Dokumen18 halaman5.tugas Khusus Furnace-5ariyantans82Belum ada peringkat

- Neraca Panas Di Raw Mill Basis 1 JamDokumen8 halamanNeraca Panas Di Raw Mill Basis 1 JamNaufal FachriBelum ada peringkat

- Appendix 4 PDFDokumen204 halamanAppendix 4 PDFImam ArifinBelum ada peringkat

- Perhitungan Neraca Massa Raw MillDokumen9 halamanPerhitungan Neraca Massa Raw MillDella Fajar PBelum ada peringkat

- Perhitungan Neraca Massa Di Cement MillDokumen3 halamanPerhitungan Neraca Massa Di Cement MillWahyuddin Shabir Wa DzakirBelum ada peringkat

- Archbab IV AbulDokumen5 halamanArchbab IV AbulRandikaBelum ada peringkat

- Lampiran B FixDokumen2 halamanLampiran B FixMutia FebrianaBelum ada peringkat

- Boiler EnergiDokumen4 halamanBoiler EnergiAriston Tobok HutaurukBelum ada peringkat

- Final Hasriyani 22960070Dokumen3 halamanFinal Hasriyani 22960070shinboyosihideBelum ada peringkat

- PerhitunganDokumen49 halamanPerhitunganDhiyaul IhsantiBelum ada peringkat

- UiiipanasDokumen824 halamanUiiipanasNo PiBelum ada peringkat

- Lampiran Perhitungan SementaraDokumen20 halamanLampiran Perhitungan SementaraGelorawan AditBelum ada peringkat

- Ash Handling ArinDokumen6 halamanAsh Handling ArinArin SuharyadiBelum ada peringkat

- Berikut Perhitungan RAB Sumur Resapan PT. Jin MyoungDokumen5 halamanBerikut Perhitungan RAB Sumur Resapan PT. Jin Myoungadhianalis_140533399Belum ada peringkat

- Neraca Energi PendinginanDokumen2 halamanNeraca Energi PendinginanAmeiga CautsarinaBelum ada peringkat

- BAB 4 FixDokumen3 halamanBAB 4 Fixastin randaBelum ada peringkat

- Daftar Obat Resep ApotekDokumen4 halamanDaftar Obat Resep Apotekmatahari superBelum ada peringkat

- LAMPIRAN 5 SepDokumen9 halamanLAMPIRAN 5 SepDwi TarisaBelum ada peringkat

- Perhitungan Neraca Panas KilnDokumen11 halamanPerhitungan Neraca Panas KilnResi Levi Permadani100% (3)

- Tekanan Masuk TDokumen5 halamanTekanan Masuk TizunBelum ada peringkat

- Analisa Menentukan Nilai Kalori Bahan Bakar BoilerDokumen8 halamanAnalisa Menentukan Nilai Kalori Bahan Bakar BoilerNur Ali SaidBelum ada peringkat

- Neraca MassaDokumen6 halamanNeraca MassadhiyaulBelum ada peringkat

- Mas Bokep Titip CCRDokumen2 halamanMas Bokep Titip CCRTommyAdamBachtiar100% (1)

- Desain PLTUDokumen21 halamanDesain PLTUKhanieva Harnum ZaenuryBelum ada peringkat

- Perhitungan PompaDokumen10 halamanPerhitungan PompaEl CoolBelum ada peringkat

- Pengeringan Pakaian Dengan PemanasDokumen33 halamanPengeringan Pakaian Dengan PemanasMiftahurrohim El-hakiemBelum ada peringkat

- Bab 6 Analisis Data Benar (Hal 69 - 78)Dokumen12 halamanBab 6 Analisis Data Benar (Hal 69 - 78)RikonaJayaPurbaBelum ada peringkat

- Es BalokDokumen15 halamanEs BalokArri Kurniawan100% (2)

- Extraction TestDokumen8 halamanExtraction TestAnisa AstutiBelum ada peringkat

- Bab 6 Spesifikasi AlatDokumen28 halamanBab 6 Spesifikasi AlatEXCELLINABelum ada peringkat

- Analisa Menentukan Nilai Kalori Bahan Bakar BoilerDokumen8 halamanAnalisa Menentukan Nilai Kalori Bahan Bakar BoilerNur Ali Said100% (1)

- Abs TrakDokumen2 halamanAbs TrakM Fatah WibisenoBelum ada peringkat

- TUGAS Kls 2cDokumen1 halamanTUGAS Kls 2cAsri SaswitaBelum ada peringkat

- Crude Oil TankDokumen5 halamanCrude Oil TankRector KhanBelum ada peringkat

- Lampiran ADokumen11 halamanLampiran AlnurkholisBelum ada peringkat

- IP MelaminDokumen27 halamanIP MelaminMeylinda Mulyati0% (1)

- BAB II Stasiun GilinganDokumen16 halamanBAB II Stasiun GilinganNdemo Poernomo83% (6)

- Pindah Panas SolutionDokumen6 halamanPindah Panas SolutionKhairunnisyah HamzahBelum ada peringkat

- Perhitungan Daya Turbin Uap Dan GeneratorDokumen10 halamanPerhitungan Daya Turbin Uap Dan GeneratorRiski NandaBelum ada peringkat

- Bab ViDokumen33 halamanBab ViMuhammad TaufikBelum ada peringkat

- CONTOH SOAL PengeringanDokumen5 halamanCONTOH SOAL PengeringanArief Rahman100% (3)

- Tugas PP II Reza TrisnaDokumen66 halamanTugas PP II Reza TrisnaRezaTrisnaWahyudiBelum ada peringkat

- Peralatan Industri ProsesDokumen40 halamanPeralatan Industri ProsesJohannesMartuaHutagalungBelum ada peringkat

- MAKALAH PIK-WPS OfficeDokumen17 halamanMAKALAH PIK-WPS OfficeNurfadillahBelum ada peringkat

- Bab Viii ApriDokumen3 halamanBab Viii ApriApriyanto AhmadBelum ada peringkat

- Diagram Alir PT Semen IndonesiaDokumen1 halamanDiagram Alir PT Semen IndonesiaApriyanto Ahmad100% (1)

- Seksi Finish Mill TubanDokumen37 halamanSeksi Finish Mill TubanApriyanto AhmadBelum ada peringkat

- N HeksanaDokumen6 halamanN HeksanaJon Wafa AzwarBelum ada peringkat

- Indah Wuland 21030113060002Dokumen9 halamanIndah Wuland 21030113060002Apriyanto AhmadBelum ada peringkat

- Laras Pipih 21030113060019Dokumen13 halamanLaras Pipih 21030113060019Apriyanto AhmadBelum ada peringkat

- Bab III 2016Dokumen36 halamanBab III 2016Apriyanto AhmadBelum ada peringkat

- BAB II Mau PrintDokumen24 halamanBAB II Mau PrintApriyanto AhmadBelum ada peringkat

- Bab I Apri AccDokumen28 halamanBab I Apri AccApriyanto AhmadBelum ada peringkat

- BAB II ApriDokumen22 halamanBAB II ApriApriyanto AhmadBelum ada peringkat

- Bab III ApriDokumen23 halamanBab III ApriApriyanto AhmadBelum ada peringkat

- SkedulDokumen1 halamanSkedulApriyanto AhmadBelum ada peringkat

- Surat Keterangan Wali 4Dokumen7 halamanSurat Keterangan Wali 4Apriyanto AhmadBelum ada peringkat

- Rotary Kiln Merupakan Peralatan Paling Utama Pada Proses Pembuatan SemenDokumen3 halamanRotary Kiln Merupakan Peralatan Paling Utama Pada Proses Pembuatan SemenApriyanto AhmadBelum ada peringkat

- Kata Pengantar - Daftar IsiDokumen5 halamanKata Pengantar - Daftar IsiApriyanto AhmadBelum ada peringkat

- Laporan MKP Kertas Apri Dessi SELESAIDokumen25 halamanLaporan MKP Kertas Apri Dessi SELESAIApriyanto AhmadBelum ada peringkat

- Permohonan KP Holcim Cilacap 2016Dokumen1 halamanPermohonan KP Holcim Cilacap 2016Apriyanto AhmadBelum ada peringkat

- Laporan MKP Kertas Apri DessiDokumen22 halamanLaporan MKP Kertas Apri DessiApriyanto AhmadBelum ada peringkat

- Wilmar TDokumen18 halamanWilmar TApriyanto AhmadBelum ada peringkat

- Struktur Organisasi PT Semen Indonesia JadiDokumen1 halamanStruktur Organisasi PT Semen Indonesia JadiApriyanto AhmadBelum ada peringkat

- Proposal Kertas FixDokumen23 halamanProposal Kertas FixApriyanto AhmadBelum ada peringkat

- AbsorberDokumen37 halamanAbsorberApriyanto AhmadBelum ada peringkat