Ceklist Inspeksi Sebelum Pengoperasian Bulldozer

Diunggah oleh

hendra kurniawanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ceklist Inspeksi Sebelum Pengoperasian Bulldozer

Diunggah oleh

hendra kurniawanHak Cipta:

Format Tersedia

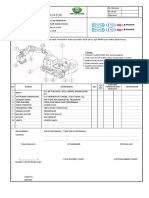

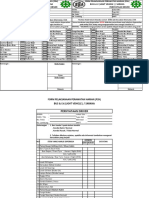

CEKLIST INSPEKSI SEBELUM PENGOPERASIAN

BULLDOZER

Tanggal Inspeksi :

Nama Proyek :

Nama Pemilik :

NKI (Jika Milik HKI) :

Merk/Type :

Serial Number :

Kapasitas :

Tahun Pembuatan :

HM Awal :

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

1 Pemeriksaan Dengan Mengelilingi Alat (Walk Arround

Inspection)

-

Periksa peralatan kerja (work equipment), silinder,

sambungan (linkage) dan pipa-pipa karet (hoes)

untuk kemungkinan terjadi retak, longgar/aus

-

Bersihkan kotoran dan debu disekitar engine,

battery, radiator. Periksa dan bersihkan juga bahan

(material) yang mudah terbakar (daun kering,

rerumputan, ranting, dsb.)

- Periksa kebocoran air dan minyak di sekitar engine,

kebocoran air dari sistem pendingin

-

Periksa kebocoran minyak dari kotak power train,

kotak penggerak akhir, tangki hidrolik, pipa-pipa

(hose) dan sambungan-sambungan

-

Periksa under carriage (track, sprocket, idler, guard)

dari kemungkinan terjadi kerusakan, aus, baut-baut

longgar, atau kebocoran minyak dari rol- rol

- Periksa tempat pegangan (hand rails) untuk

kemungkinan ada kerusakan atau baut yang kendur

-

Periksa kemungkinan ada kerusakan pada meter-

meter (gauges), lampu- lampu pada instrumen panel,

baut-baut yang kendur

- Periksa sabuk keselamatan (seat belt) dan klem-klem

pemasangnya (mounting clamps)

2 Memeriksa dan Menambah Air Pendingin

3 Memeriksa Level Minyak Pelumas Engine

4 Pemeriksaan Level Minyak Power Train

5 Pemeriksaan Bahan Bakar

6 Penceratan (Drain) Air dan Endapan Dari Tangki Bahan

Bakar

7 Pembuangan Air dan Endapan Dalam Water Separator

(Pemisah Air)

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

8 Pemeriksaan Air Batere (Accu)

9 Periksa Level Minyak Damper Case

10 Pemeriksaan Level Minyak Hidrolik

11 Pemeriksaan Dust Indicator

12 Pemeriksaan Pedal Rem

13 Pemeriksaan Kabel-Kabel Listrik

Rekomendasi : DAPAT DIGUNAKAN/TIDAK DAPAT DIGUNAKAN

Catatan :

SUBKONTRAKTOR KONTRAKTOR KONSULTAN OWNER

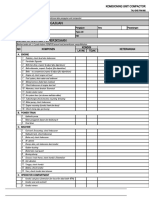

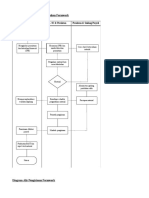

CEKLIST INSPEKSI SEBELUM PENGOPERASIAN

EXCAVATOR

Tanggal Inspeksi :

Nama Proyek :

Nama Pemilik :

NKI (Jika Milik HKI) :

Merk/Type :

Serial Number :

Kapasitas :

Tahun Pembuatan :

HM Awal :

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

1 Attachment

- Hose

- Cylinder bucket

- Cylinder arm

- Cylinder boom

- Pin

- Kuku bucket

2 Under carriage

- Kekencangan track

3 Bagiah bawah

- Radiator

- Pompa hydraulic

- Motor swing

- Tangki hydraulic

- Tangki bahan bakar

4 Bagian atas

- Air pendingin

- Level oli mesin

- Kekecangan tali kipas

- Level oli motor swing

- Level oli hydraulik

- Water separator

- Battery

5 Pelumasan (grease)

- Kepala silinder boom

- Persambungan boom, stick dan bucket

6 Cabin

- Indikator dan meteran “Uji”

- Sabuk pengaman

- Alarm travel

Rekomendasi : DAPAT DIGUNAKAN/TIDAK DAPAT DIGUNAKAN

Catatan :

SUBKONTRAKTOR KONTRAKTOR KONSULTAN OWNER

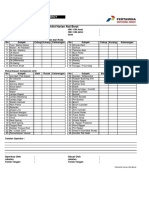

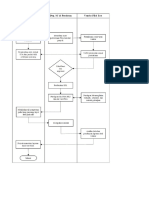

CEKLIST INSPEKSI SEBELUM PENGOPERASIAN

ROUGHTER CRANE

Tanggal Inspeksi :

Nama Proyek :

Nama Pemilik :

NKI (Jika Milik HKI) :

Merk/Type :

Serial Number :

Kapasitas :

Tahun Pembuatan :

HM Awal :

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

1 Check levels of engine oil, coolant and transmission fluid

2 Drain fuel-water separator.

3 Check crank case breather tube for cracks, ice or sludge.

4 Check cooling fan.

5 Check exhaust system for cracks or leaks

6 Check air cleaner intake system for cracks or looseness.

Check air filter restriction indicator if equipped.

7 Check general condition of tires.

8 Visually inspect for loose pins, bolts, physical damage and

leaks.

Check hydraulic hoses, particularly those that

9 flex during crane operation.

10 Check hydraulic oil level.

11 Check fuel level

12 Check engine oil pressure.

13 Check engine coolant temperature.

14 Check battery charging voltage.

15 Check transmission temperature.

16 Check hydraulic filter indicator gauge after running at

least twenty minutes.

17

Check hydraulic brake operation. Check warning light

operation,

18 Check parking brake operation.

19 Check power steering operation.

20 Observe chassis for normal driving operation.

21 Observe boom operation for normal power and speed.

22 Check load line and hooks for damage.

23 Check condition of sheaves and load line retainers.

24 Check anti-two-block system for proper operation.

25 Check horn, back-up alarm, and outrigger alarms for

proper operation.

26 Check operation of all transmission gears, forward and

reverse.

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

27 Clean all glass and check for cracks.

28 Check operation of all warning and safety devices.

30 Check operation of Rated Capacity Limiter

31 Check that the Drum Rotation Indicator is functioning.

32 Check the outrigger warning light for proper operation

Rekomendasi : DAPAT DIGUNAKAN/TIDAK DAPAT DIGUNAKAN

Catatan :

SUBKONTRAKTOR KONTRAKTOR KONSULTAN OWNER

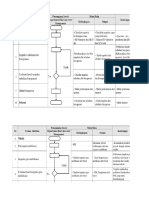

CEKLIST INSPEKSI SEBELUM PENGOPERASIAN

CRAWLER CRANE

Tanggal Inspeksi :

Nama Proyek :

Nama Pemilik :

NKI (Jika Milik HKI) :

Merk/Type :

Serial Number :

Kapasitas :

Tahun Pembuatan :

HM Awal :

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

CHECKING BEFORE STARTING ENGINE (visual inspection)

1 Inspection around crane

2 Inspection of wire rope

3 Inspection of hook block

4 Inspection around upper slewing body

5 Inspection of cabin

6 Inspection around carrier

7 Checking/refilling engine collant

8 Checking/refilling oil level in engine oil pan

9 Checking/refueling fuel level in fuel tank

10 Checking/refilling oil level in hydraulic oil tank

11 Inspection of dust indicator

12 Inspection water separator and draining contaminant

water/deposits

13 Draining contaminant water/deposits in fuel tank

14 Checking electric wiring

15 Checking working lamp

16 Checking horn for funtion

17 Adjusting the operator seat

18 Adjusment of mirror

19 Angle adjusment of rear view camera

20 Checking battery electrolyte level

CHECKING AFTER STARTING ENGINE

21 Checking ease of engine cranking and abnormal noise

22 Checking low speed and acceleration state of engine

23 Checking engine exhaust gas colour, abnormal noise

vibration

24 Checking crane operations

25 Checking over hoist prevention device

26 Inspection of moment limiter

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

IRREGULAR MAINTENANCE

27 Replacement of winch wire rope

28 Checking/adjusting main boom telescoping wire rope

29 Checking/cleaning/replacing air cleaner

30 Cleaning engine cooling system

31 Checking and re-tightening rubber track blots

32 Checking/adjusting rubber track tension

33 Cheking/replenishing window wasger solution

34 Cheking and servicing air cinditioner

35 Checking/cleaning/greasing doors rails and rollers

36 Levelling instrument

Rekomendasi : DAPAT DIGUNAKAN/TIDAK DAPAT DIGUNAKAN

Catatan :

SUBKONTRAKTOR KONTRAKTOR KONSULTAN OWNER

CEKLIST INSPEKSI SEBELUM PENGOPERASIAN

MOBILE CRANE

Tanggal Inspeksi :

Nama Proyek :

Nama Pemilik :

NKI (Jika Milik HKI) :

Merk/Type :

Serial Number :

Kapasitas :

Tahun Pembuatan :

HM Awal :

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

1 Engine

- Check engine oil level

- Check the coolant level in the equalising reservoir

2 Air filter

- Check monitoring device

3 Rope winches

- Check for leaks

4 Hoist gear brake

- Check for leaks

5 Crane ropes

- Visual inspection for cracks and deformation

6 Cabin

- Check armatures/instrument for function

- Check indicatir light for function

- Check luid level in expansion tank of engine control

7 Overload protection

- Check for correct function

8 Fuel system

- Check for leaks

9 Slewing gear

- Check for leaks

10 Pump distributor gear

- Check for leaks

11 Hydraulic hose line

- Check for leaks and damage

12 Hydraulic system

- Check the oil level

13 Telescopic boom guying

- Check guy winch for leaks

Rekomendasi : DAPAT DIGUNAKAN/TIDAK DAPAT DIGUNAKAN

Catatan :

SUBKONTRAKTOR KONTRAKTOR KONSULTAN OWNER

CEKLIST INSPEKSI SEBELUM PENGOPERASIAN

TRUCK MOUNTED CRANE

Tanggal Inspeksi :

Nama Proyek :

Nama Pemilik :

NKI (Jika Milik HKI) :

Merk/Type :

Serial Number :

Kapasitas :

Tahun Pembuatan :

HM Awal :

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

1 Labels

All load charts, safety & warning labels, & control

labels are present and legible

2 Crane

Check all safety devices for proper operation.

3 Controls

Control mechanisms for proper operation of all

functions, leaks & cracks

4 Station

Control and operator’s station for dirt, contamination

by lubricants, & foreign materials

5 Hyd System

Hydraulic system (hoses, tubes & fittings) for leakage

& proper oil level

6 Hook

Presence & proper operation of hook safety latches

7 Wire Rope

Inspect for apparent deficiencies per applicable

requirements and manufacturer’s specifications.

8 Pins

Proper engagement of all connecting pins & pin

retaining devices.

9 General cover

Overall observation of crane for damaged or missing

parts, cracked welds & presence of safety covers.

10 Operation

During operation, observe crane for abnormal

performance, unusual wear (loose pins, wire rope

damage, etc.). If observed, discontinue use &

determine cause & severity of hazard.

11 Remote controls

Operate remote control devices to check for proper

operation.

12 Electrical

Operate all lights, alarms, etc. to check for proper

operation

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

13 Anti Two-Block or Two-Block Damage Prevention

Operate anti-two-blocking or two-block prevention

devices to check for proper operation

14 Tires

Check tires (when in use) for proper inflation and

condition.

15 Ground

Ground conditions around the equipment for proper

support, including ground settling under and

conditions around and around stabilizers and

supporting foundations, ground water accumulation,

or similar

16 Level

Position The equipment for level position within

tolerances specified by the equipment

manufacturer’s recommendations, both before each

shift and after each move and setup.

17 Operator Cab

Significant cracks, breaks, or other deficiencies that

would hamper the operator’s view. Windows

18 Rails, rail stops, clamps, supporting surfaces

Rail, rail stops, Rails, rail stops, rail clamps and

supporting surfaces when the equipment has rail

traveling. clamps, supporting surfaces.

19 Safety Devices

Safety devices and operational aids for proper

operation

20 Electrical

Electrical apparatus for malfunctioning, signs of

apparent excessive deterioration, dirt or moisture

accumulation

Rekomendasi : DAPAT DIGUNAKAN/TIDAK DAPAT DIGUNAKAN

Catatan :

SUBKONTRAKTOR KONTRAKTOR KONSULTAN OWNER

CEKLIST INSPEKSI SEBELUM PENGOPERASIAN

TOWER CRANE

Tanggal Inspeksi :

Nama Proyek :

Nama Pemilik :

NKI (Jika Milik HKI) :

Merk/Type :

Serial Number :

Kapasitas :

Tahun Pembuatan :

HM Awal :

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

1 Inspect limit switches

2 Inspect bolt and pin connection

3 Inspect wire ropes

Rekomendasi : DAPAT DIGUNAKAN/TIDAK DAPAT DIGUNAKAN

Catatan :

SUBKONTRAKTOR KONTRAKTOR KONSULTAN OWNER

CEKLIST INSPEKSI SEBELUM PENGOPERASIAN

ASPHALT FINISHER

Tanggal Inspeksi :

Nama Proyek :

Nama Pemilik :

NKI (Jika Milik HKI) :

Merk/Type :

Serial Number :

Kapasitas :

Tahun Pembuatan :

HM Awal :

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

Conveyor

1 Konveyor

- Conveyor chain - Check tightness

Rantai konveyor - Periksa kekencangannya

2 Auger Assembly

Perakitam auger

- Outer auger bearing - Lubricate

Bantalan auger luar - Lumasi

3 Engine Assembly

Perakitan Engine

- Engine fuel system - Fuel filter (drain the water

separator)

Sistem bahan bakar mesin - Filter bahan bakar

(pembuangan air separator)

- Fuel tank Check filling level

Tangki bahan bakar Periksa level pengisian

- Engine lube oil system Check oil leve

Sistem oli pelumas mesin Periksa ketinggian oli

- Engine air filter Check air filter

Filter udara mesin Periksa filter udara

- Engine air filter Dust collector Emptying

Filter udara mesin Pengumpul debu Pengosongan

- Engine cooling system Check radiator fins

Sistem pendingin mesin Periksa sirip radiator

4 Hydraulic System

Sistem Hidrolik

- Hydraulic oil tank - Check fill level

Tangki oli hidraulik - Periksa level pengisian

- Hydraulic oil tank - Check maintenance indicator

Tangki oli hidrolik - Periksa indikator perawatan

- High-pressure filter - Check maintenance indicator

Filter tekanan tinggi - Periksa indikator perawatan

- Hydraulic hoses - Visual inspection

Selang hidrolik - Inspeksi visual

- Hydraulic system Leak test

Uji kebocoran sistem hidrolik

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

5 Travel drive, Steering

Kemudi

- Drive wheels - Check tyres for damage

Roda penggerak - Periksa ban dari kerusakan

- Drive wheels - Check wheel nuts

Roda penggerak - Periksa mur roda

6 Lubricating Points

Titik pelumasan

- Check lubricant tank fill level

Periksa level pengisian tangki pelumas

- Check pressure limiting valve

Periksa katup pembatas tekanan

7 Tests, checks, cleaning, stopping

Pengujian, pemeriksaan, pembersihan, penghentian

- General visual inspection

Inspeksi visual umum

Rekomendasi : DAPAT DIGUNAKAN/TIDAK DAPAT DIGUNAKAN

Catatan :

SUBKONTRAKTOR KONTRAKTOR KONSULTAN OWNER

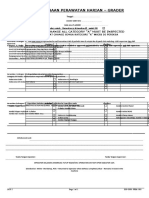

CEKLIST INSPEKSI SEBELUM PENGOPERASIAN

TANDEM ROLLER

Tanggal Inspeksi :

Nama Proyek :

Nama Pemilik :

NKI (Jika Milik HKI) :

Merk/Type :

Serial Number :

Kapasitas :

Tahun Pembuatan :

HM Awal :

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

1 Check the engine oil level Refer to the engine manual

Periksa level oli mesin Lihat manual mesin

2 Check the engine coolant coolant level

Periksa level cairan pendingin engine

3 Check the hydraulic hydraulic reservoir reservoir level

Periksa level reservoir reservoir hidrolik hidrolik

4 Fill the water tanks

Isi tangki air

5 Refuel

Mengisi bahan bakar

6 Check the sprinkler system

Periksa sistem sprinkler

7 Check the Emergency watering (Extra pump in pump

system)

Periksa penyiraman Darurat (Pompa ekstra dalam sistem

pompa)

8 Check the scraper setting

Periksa pengaturan scraper

Rekomendasi : DAPAT DIGUNAKAN/TIDAK DAPAT DIGUNAKAN

Catatan :

SUBKONTRAKTOR KONTRAKTOR KONSULTAN OWNER

CEKLIST INSPEKSI SEBELUM PENGOPERASIAN

PNEUMATIC TYRE ROLLER (PTR)

Tanggal Inspeksi :

Nama Proyek :

Nama Pemilik :

NKI (Jika Milik HKI) :

Merk/Type :

Serial Number :

Kapasitas :

Tahun Pembuatan :

HM Awal :

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

1 Check the engine oil level

Periksa level oli mesin

2 Check the engine coolant level

Periksa level cairan pendingin mesin

3 Check the hydraulic reservoir level

Periksa level reservoir hidrolik

4 Refuel

Mengisi bahan bakar

5 Fill the water tanks

Isi tangki air

6 Check the sprinkler system

Periksa sistem sprinkler

7 Check the scraper setting

Periksa pengaturan scraper

Rekomendasi : DAPAT DIGUNAKAN/TIDAK DAPAT DIGUNAKAN

Catatan :

SUBKONTRAKTOR KONTRAKTOR KONSULTAN OWNER

CEKLIST INSPEKSI SEBELUM PENGOPERASIAN

ASPHALT SPRAYER

Tanggal Inspeksi :

Nama Proyek :

Nama Pemilik :

NKI (Jika Milik HKI) :

Merk/Type :

Serial Number :

Kapasitas :

Tahun Pembuatan :

HM Awal :

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

1 Check Fuel Tank Level

2 Check engine oil level

3 Check hydraulic oil tank level

4 Check hydraulic system for leaks

5 Check fuel filter, drain water accumulation

6 Lube grease fitting

7 Check back up alarm

Rekomendasi : DAPAT DIGUNAKAN/TIDAK DAPAT DIGUNAKAN

Catatan :

SUBKONTRAKTOR KONTRAKTOR KONSULTAN OWNER

CEKLIST INSPEKSI SEBELUM PENGOPERASIAN

CONCRETE PUMP

Tanggal Inspeksi :

Nama Proyek :

Nama Pemilik :

NKI (Jika Milik HKI) :

Merk/Type :

Serial Number :

Kapasitas :

Tahun Pembuatan :

HM Awal :

KONDISI

No ITEM KETERANGAN

No ITEM KETERANGAN

GOOD FAIR POOR N/A

PUMP

1 Hydraulic System

Sistem Hidrolik

- Drain the condensed water off

Tiriskan air kentalnya

- Check hydraulic oil level

Periksa level oli hidrolik

- Check the leakage at fitting/lines

Periksa kebocoran pada fitting/saluran

- Check the contamination indicators of filters

Periksa indikator kontaminasi filter

2 Pumping Kit

Kit Pemompaan

- Check the wear of wear ring/wear plate

Periksa keausan cincin aus/pelat aus

- Clearance check between wear ring and s-valve

Pemeriksaan jarak bebas antara ring keausan dan s-

valve

- Check the wear of delivery pistons

Periksa keausan piston pengiriman

Electricity

Listrik

- Check the function of emergency shout-off buttons

Periksa fungsi tombol teriakan darurat

- Check visual inspection of wirings

Periksa inspeksi visual wirings

- Check the function of electrical switches and buttons

Periksa fungsi sakelar dan tombol listrik

3 Greasing

Grease

- Check of the greasing system

Periksa sistem pelumasan

- Grease all grease nipples of the boom/outriggers

Lumasi semua puting gemuk dari boom/outriggers

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

4 Air

- Check water level into water tank

Periksa ketinggian air ke dalam tangki air

5 Delivery line

Jalur pengiriman

- Check wall thickness

Periksa ketebalan dinding

- Fastening safaty of couplings

Keamanan pengikat kopling

Rekomendasi : DAPAT DIGUNAKAN/TIDAK DAPAT DIGUNAKAN

Catatan :

SUBKONTRAKTOR KONTRAKTOR KONSULTAN OWNER

CEKLIST INSPEKSI SEBELUM PENGOPERASIAN

TRUCK MIXER

Tanggal Inspeksi :

Nama Proyek :

Nama Pemilik :

NKI (Jika Milik HKI) :

Merk/Type :

Serial Number :

Kapasitas :

Tahun Pembuatan :

HM Awal :

KONDISI

No ITEM KETERANGAN

GOOD FAIR POOR N/A

TRUCK

1 Kondisi fisik kabin

2 Kondisi kaca jendela

3 Kondisi spion

4 Kondisi fisik ban

5 Kekencangan mur roda

6 Kondisi saringan udara

7 Kondisi kaca depan

8 Kondisi lampu-lampu

9 Kondisi penghapus kaca

10 Air pembersih kaca

11 Air radiator

12 Kondisi minyak kopling

13 Filter udara kabin

14 Kondisi oli mesin

15 Kondisi oli power steering

16 Kondisi tutup radiator

17 Kondisi kipas radiator

18 Battery (electrolite level)

19 Kondisi watre separator

20 Kondisi tangki, selang, dan tutup tangki bbm

21 Kondisi tangki udara

22 Kondisi air dryer

23 Kondisi rem parkir

24 Pabel instrumen

25 Tuas transmisi

MIXER

1 Check reducer oil level

2 Lubricate the rolling ring of the drum

Rekomendasi : DAPAT DIGUNAKAN/TIDAK DAPAT DIGUNAKAN

Catatan :

SUBKONTRAKTOR KONTRAKTOR KONSULTAN OWNER

:

:

:

:

:

:

:

:

Anda mungkin juga menyukai

- Form P2H TRUCKDokumen1 halamanForm P2H TRUCKWidodo PangestuBelum ada peringkat

- Form Check List Inspeksi Wheel LoaderDokumen2 halamanForm Check List Inspeksi Wheel Loaderhendrik subagioBelum ada peringkat

- P2H LVDokumen1 halamanP2H LVaye ownBelum ada peringkat

- DPP-F-SAF-018 Program P2H (Version 1)Dokumen15 halamanDPP-F-SAF-018 Program P2H (Version 1)Bahama SyafrulBelum ada peringkat

- Form Checklist Inspeksi Dump TruckDokumen1 halamanForm Checklist Inspeksi Dump Trucksiaga imt100% (1)

- P2H ExcavatorDokumen1 halamanP2H ExcavatorAnaw 123Belum ada peringkat

- P2H TruckDokumen1 halamanP2H TruckNur IreneBelum ada peringkat

- TAJ-SHE-FM-066 Komisioning CompactorDokumen2 halamanTAJ-SHE-FM-066 Komisioning CompactorAndre FernandoBelum ada peringkat

- Format P2H & Time SheetDokumen1 halamanFormat P2H & Time SheetDonny Prasetya ManginsihBelum ada peringkat

- Form P2H Unit LT Dan A2B SosialisasiDokumen2 halamanForm P2H Unit LT Dan A2B Sosialisasitri sutrisna100% (1)

- Cheklist ALat Berat & Peralatan (1) TDokumen23 halamanCheklist ALat Berat & Peralatan (1) TalbrightBelum ada peringkat

- Tes LV 2019Dokumen6 halamanTes LV 2019Amang BegedekBelum ada peringkat

- SHE - FM - 058.formulir Assessment Light Truck - R0Dokumen5 halamanSHE - FM - 058.formulir Assessment Light Truck - R0aliyah29Belum ada peringkat

- Form Pemeriksaan LV-002 (Adm) Pt. SPPDokumen3 halamanForm Pemeriksaan LV-002 (Adm) Pt. SPPdelviBelum ada peringkat

- Contoh Form CommissioningDokumen3 halamanContoh Form Commissioningclara pesikBelum ada peringkat

- Checklist Harian Alat Berat PDFDokumen1 halamanChecklist Harian Alat Berat PDFCold Enzeth100% (1)

- P2H Pt. MBLDokumen5 halamanP2H Pt. MBLEndro SuhadiBelum ada peringkat

- P2H EksaDokumen1 halamanP2H EksaYoseph Sembiring100% (1)

- FM - HSE.MBL.001. Bulldozer, Wheel Loader, Excavator, Grader, Shovel, Compactor, Haul TruckDokumen2 halamanFM - HSE.MBL.001. Bulldozer, Wheel Loader, Excavator, Grader, Shovel, Compactor, Haul Truckricho naiborhu100% (1)

- FM-KE-QHSE-010 Form Commisioning A2BDokumen2 halamanFM-KE-QHSE-010 Form Commisioning A2BWahyu Balboa100% (1)

- p2h ExcaDokumen1 halamanp2h ExcaAnjar AsterinaBelum ada peringkat

- FORM CHECKLIST P2H Heavy EquipmentDokumen2 halamanFORM CHECKLIST P2H Heavy Equipmentirfan maulanaBelum ada peringkat

- Form P2H Mixer Truck: Kode Pemeriksaan Pemeriksaan Checklist Bugar SelamatDokumen1 halamanForm P2H Mixer Truck: Kode Pemeriksaan Pemeriksaan Checklist Bugar SelamatNur IreneBelum ada peringkat

- Formulir Checklist Inspeksi Terencana CrusherDokumen2 halamanFormulir Checklist Inspeksi Terencana Crusherheru gunawan100% (1)

- Checklist Harian Alat BeratDokumen1 halamanChecklist Harian Alat BeratRid Hal0% (1)

- FM - SHE.09.002 Commissioning Heavy Equipments - OKDokumen3 halamanFM - SHE.09.002 Commissioning Heavy Equipments - OKirfan maulanaBelum ada peringkat

- Form Serah Terima DumptruckDokumen1 halamanForm Serah Terima DumptruckAulia'Angga'Erlangga100% (1)

- Form Permintaan Part1Dokumen2 halamanForm Permintaan Part1Deni DianaBelum ada peringkat

- FORM INSPEKSI ALAT BERAT CRANE - RevDokumen2 halamanFORM INSPEKSI ALAT BERAT CRANE - RevRestianingBelum ada peringkat

- Form SimperDokumen2 halamanForm Simperwildan ikhwanBelum ada peringkat

- Buldozer ChecklistDokumen2 halamanBuldozer ChecklistDinita ArsitaBelum ada peringkat

- P2H-Grader-1Dokumen1 halamanP2H-Grader-1randi saimonaBelum ada peringkat

- Standart Operating Procedure S o P DriveDokumen24 halamanStandart Operating Procedure S o P DriveToto RustamBelum ada peringkat

- Form p2h SaranaDokumen3 halamanForm p2h SaranaEndrew ChristianBelum ada peringkat

- Form Inspeksi Kendaraan Dump TruckDokumen1 halamanForm Inspeksi Kendaraan Dump TruckAlfin100% (2)

- Form Checklist Inspeksi BulldozerDokumen1 halamanForm Checklist Inspeksi BulldozerobiBelum ada peringkat

- Form Komisioning LVDokumen5 halamanForm Komisioning LVImam AliBelum ada peringkat

- 54 - SOP-DP-RM-LHT-54 - Comisioning Unit OK (P RS)Dokumen3 halaman54 - SOP-DP-RM-LHT-54 - Comisioning Unit OK (P RS)wibi aryodanuBelum ada peringkat

- Bir - Fm.she-07.03 CommissioningDokumen26 halamanBir - Fm.she-07.03 CommissioningNoor Iman RustamBelum ada peringkat

- Form P2H LVDokumen1 halamanForm P2H LVrasdi mulyadiBelum ada peringkat

- Form No FM-25-SHE-012 Pengecheckan Kelayakan Unit SaranaDokumen5 halamanForm No FM-25-SHE-012 Pengecheckan Kelayakan Unit Saranafahat fairuzzi100% (1)

- Inspeksi ExcavatorDokumen2 halamanInspeksi ExcavatorChandra FadhiansyahBelum ada peringkat

- CDC-FLT-015-F162 Form Inspeksi LV Kontraktor-Revisi 2021Dokumen4 halamanCDC-FLT-015-F162 Form Inspeksi LV Kontraktor-Revisi 2021Martin PanjaitanBelum ada peringkat

- Form Inspeksi AlatDokumen12 halamanForm Inspeksi Alattheo rahardjoBelum ada peringkat

- Form Checklist KendaraanDokumen4 halamanForm Checklist KendaraanSanti Hadi WidiyastomoBelum ada peringkat

- Form CommissioningDokumen1 halamanForm CommissioningRezha FebriansyahBelum ada peringkat

- Hasil Test SimperDokumen1 halamanHasil Test Simperpuput utomoBelum ada peringkat

- MUTU-OHS-FM-084-Commissioning LV-TRUCK-BUS Rev01Dokumen2 halamanMUTU-OHS-FM-084-Commissioning LV-TRUCK-BUS Rev01Agus HariantoBelum ada peringkat

- Orientasi DriverDokumen1 halamanOrientasi DriverAnggit Muhammad Syafa'atBelum ada peringkat

- Form Commissioning Umum NewDokumen3 halamanForm Commissioning Umum NewFeronika PurbaBelum ada peringkat

- P2H Kendaraan Rivisi AGT 01 1Dokumen1 halamanP2H Kendaraan Rivisi AGT 01 1danu wahyuBelum ada peringkat

- F-LAC-OHS-15-019 Form Komisioning Fuel TruckDokumen2 halamanF-LAC-OHS-15-019 Form Komisioning Fuel TruckIrham FaisalBelum ada peringkat

- Form Inspeksi - Light VehicleDokumen2 halamanForm Inspeksi - Light VehicleWinda Kartina SariBelum ada peringkat

- Form Pengecekan Alat Pra OperasiDokumen6 halamanForm Pengecekan Alat Pra Operasiridho fahmiBelum ada peringkat

- FORM P2H NEW 2019 KirimDokumen11 halamanFORM P2H NEW 2019 Kirimdevyan2250% (2)

- Sop DozerDokumen9 halamanSop Dozertemter gandaBelum ada peringkat

- ExcavatorDokumen1 halamanExcavatoragu rismanBelum ada peringkat

- P2H Alat BeratDokumen1 halamanP2H Alat Beratndorohenry100% (1)

- Form P2H Dump TruckDokumen1 halamanForm P2H Dump Truckviolentaxioxio 01100% (1)

- Appendix#3 Form Standar Pemeriksaan Kendaraan MekanicalDokumen4 halamanAppendix#3 Form Standar Pemeriksaan Kendaraan MekanicalirfanBelum ada peringkat

- Bagan Alir PemeliharaanDokumen14 halamanBagan Alir Pemeliharaanhendra kurniawanBelum ada peringkat

- Bagan Alir FormworkDokumen21 halamanBagan Alir Formworkhendra kurniawanBelum ada peringkat

- Bagan Alir PDADokumen3 halamanBagan Alir PDAhendra kurniawanBelum ada peringkat

- Bagan Alir Alat HotmixDokumen8 halamanBagan Alir Alat Hotmixhendra kurniawanBelum ada peringkat

- Buku KasDokumen12 halamanBuku Kashendra kurniawanBelum ada peringkat

- Bagan Alir PDADokumen3 halamanBagan Alir PDAhendra kurniawanBelum ada peringkat

- Time SheetDokumen3 halamanTime Sheethendra kurniawan100% (1)

- SPK Untuk ProsedurDokumen3 halamanSPK Untuk Prosedurhendra kurniawanBelum ada peringkat

- Makalah AgamaDokumen5 halamanMakalah Agamahendra kurniawanBelum ada peringkat

- Label InspeksiDokumen1 halamanLabel Inspeksihendra kurniawanBelum ada peringkat