12.1. Maintenance Budgeting - PT GNA

12.1. Maintenance Budgeting - PT GNA

Diunggah oleh

Asyraf Al AzuardiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

12.1. Maintenance Budgeting - PT GNA

12.1. Maintenance Budgeting - PT GNA

Diunggah oleh

Asyraf Al AzuardiHak Cipta:

Format Tersedia

MODUL MAINTENANCE BUDGETING

MAINTENANCE BUDGETING

PT GENTA NUSA ARSANA 1

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

BIODATA

Nama :

Alamat :

Telepon :

Nomor ID :

Instansi :

………………………. , / /

( ……………………………)

PT GENTA NUSA ARSANA 2

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

Puji syukur kami ucapkan kepada Tuhan Yang Maha Kuasa, atas segala

rahmat-Nya, sehingga Modul Maintenance Budgeting ini telah

terselesaikan dengan baik.

Maintenance Budgeting merupakan hal penting dalam penambangan

batubara. Maintenance Budgeting merupakan proses untuk melakukan

control terhadap budgeting dan planning budget agar kegiatan operasi

produksi dapat berjalan dengan efektif dan efisien. Di dalam modul ini

akan dibahas mengenai hal-hal yang mendukung agar proses

penambangan berjalan secara aman, efektif, efisien, dan sejalan dengan

visi & misi perusahaan. Materi-materi di dalam modul ini bersifat

aplikatif, sehingga mudah dicerna dan diterapkan di lingkungan

pekerjaan.

Modul ini bertujuan untuk meningkatkan kompetensi di bidang

Maintenance Budgeting di tambang tropis, baik secara hard skill maupun

soft skill. Adapun isi modul ini adalah Management Budgeting, Cost

Controlling, dan Plan Cost Structure.

Akhir kata kami berharap semoga Modul Maintenance Budgeting ini

dapat diaplikasikan di lapangan kerja, menambah kompetensi, dan

inspirasi dunia pertambangan.

Yogyakarta, Maret 2020

Tim Penyusun

PT GENTA NUSA ARSANA

– Genta ACADEMY

PT GENTA NUSA ARSANA 3

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

DAFTAR ISI

Hal

COVER......................................................................................... 1

BIODATA...................................................................................... 2

KATA PENGANTAR........................................................................ 3

DAFTAR ISI................................................................................... 4

BAB I MAINTENANCE BUDGETING………………………………………….… 5

1.1 Process in Maintenance Management System……………………… 7

1.2 Process Grouping to be

OrganizationStructure…………………………………………………………… 7

BAB II. MAINTENANCE PLANNING & BUDGETING………………………. 9

2.1 Definisi………………………………………………………………………………….. 10

2.2 Reference & Literatures ……………………………………………………….. 13

2.3 Cost Grouping – Chart of Account.………………………………………… 14

BAB II. LET’S PRACTICE………………………………….……………………………. 15

3.4 How to Control Cost……….……………………………………………………… 16

3.5 Plant Cost Structure………………………….…………………………………… 17

3.6 Maintenance Costing Flow Process……………………………………….. 17

3.7 Plant Cost Characteristic………………………………………………………… 18

3.8 Why Can be to Over or Tooless………………………………………………. 19

3.9 How to Control?.……………………………………………………………………. 19

LAMPIRAN………………………………….……………………………………………… 21

PT GENTA NUSA ARSANA 4

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

BAB I

MAINTENANCE

BUDGETING

PT GENTA NUSA ARSANA 5

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

MAINTENANCE MANAGEMENT

PT GENTA NUSA ARSANA 6

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

MAINTENANCE MANAGEMENT

1.1. Processes in MAINTENANCE MANAGEMENT SYSTEM :

• Maintenance Planning & Budgeting

• Maintenance Activities (Process)

• Backlog Management

• Performance Measurement (Technical & KPI)

• Technical Analysis, Development & Support

• Maintenance Improvement & Standardization

• Manpower Management (Planning & Development)

• Tools & Facilities Management

• Equipment Management (Insurance, Warranty Claim, Dispose &

Movement, Maintenance Contract)

• Internal Maintenance Audit System

• Material Supply Management

• Safety, Health & Environment Management

1.2. Process Grouping to be Organization Structure

PT GENTA NUSA ARSANA 7

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

MAINTENANCE MANAGEMENT

PT GENTA NUSA ARSANA 8

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

BAB II

MAINTENANCE

PLANNING & BUDGETING

PT GENTA NUSA ARSANA 9

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

MAINTENANCE PLANNING & BUDGETING

2.1. Definisi

Sebuah perhitungan untuk membuat Perencanaan dalam Maintenance yang

menggunakan formula tertentu dan membutuhkan data sbb:

• Equipment Population Data (Manufacturer & Model)

• Service Meter Reading (SMR/HM) – Actual & Updated

• Working Hours of Equipment – Planning & Actual

• Maintenance Interval Replacement Time (Every Material for Maintenance :

Service Part, Oil, Grease, & Component)

Output dari perhitungan ini adalah Scheduling (Jadwal Part/Component

Replacement)

Scheduling Time (Hour, Date, Week, Month & Year) or Quantity Maintenance /

Replacement per Week, Month & Year.

PT GENTA NUSA ARSANA 10

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

MAINTENANCE PLANNING

PT GENTA NUSA ARSANA 11

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

MAINTENANCE PLANNING

PT GENTA NUSA ARSANA 12

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

MAINTENANCE PLANNING to be BUDGETING

2.2. References and Literatures

• Part Book or Part Catalog

• Operation & Maintenance Manual

• Service & Shop Manual

• Equipment Performance Hand Book

• Equipment Sales Mates

• Equipment Data from Manufacturer

• Part & Component Price List

• Standard Man hour for Maintenance

• Microsoft Excel Guidance

• Microsoft Access Guidance

• Others Program Guidance

PT GENTA NUSA ARSANA 13

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

MAINTENANCE BUDGETING

2.3. Cost Grouping – Chart of Account

• Consumables

• Fuel

• Oil, Grease & Coolant

• Tire

• Undercarriage

• Ground Engaging Tools (GET)

• Drilling Accessories

• Explosives

• Other Consumables

• Repair & Maintenance

• Spare Part (Periodical Service & PCR)

• External Service

• Tools Maintenance (Calibration)

• Maintenance Contract

Cost Grouping is made to facilitate analysis

PT GENTA NUSA ARSANA 14

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

BAB III

LET’S PRACTICE

PT GENTA NUSA ARSANA 15

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

MAINTENANCE COST CONTROLLING

3.1. How to Control CO$T?

Steps of Maintenance Cost Control

• Plant Cost Structure

• Business Flow Process

• Plant Cost Characteristics

• Why can be too Over or to Less?

• How to Control?

PT GENTA NUSA ARSANA 16

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

MAINTENANCE COST CONTROLLING

3.2. Plant Cost Structure

• Consumables

• 422-01 Fuel

• 422-02 Oil & Grease

• 422-03 GET

• 422-04 Tire

• 422-05 Explosives

• 422-06 Drilling Accessories

• 422-07 Undercarriage

• 422-99 Other Consumer

• Repair & Maintenance

• 423-01 Spare Part

• 423-02 External Service Fee

• 423-03 External Service Material

• 423-04 Workshop Tools

• 423-05 General Supplies

• 423-06 FMC

3.3. Maintenance Costing Flow Process

PT GENTA NUSA ARSANA 17

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

MAINTENANCE COST CONTROLLING

3.4. Plant Cost Characteristics

• Daily Moving

• Fuel

• Oil & Grease

• Other Consumables

• Non Daily Moving

• GET

• Tire

• Drilling Accessories

• Spare Part

• External Service

• Maintenance Contract

PT GENTA NUSA ARSANA 18

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

MAINTENANCE COST CONTROLLING

3.5. Why can be too Over or too Less?

• PLANT

• Scheduled Maintenance Activity Not match to Plan

• Unscheduled Repair Too big

• Wrong Budgeting Wrong SPO

• LOGISTIC

• Part Check Out Time Late or not match to Budget

• Part Availability & Lead Time Supply Bad

• Wrong Account Code Wrong choose Account Code

(Not Match with Material)

3 . 6 . H o w t o C o n t r o l ?

• PLANT

Wajib & selalu kontinyu memonitor pergerakan Daily Cost dan

melakukan hal-hal sbb:

• Scheduled Maintenance Activity

Di-prepare setepat mungkin sesuai dengan schedule/budget

• Unscheduled Repair

Di-minimize agar budget tidak menjadi Over dengan cara

melakukan Maintenance Management System yang

excellent

• Wrong Budgeting

Selalu mempelajari hasil analisa Cost dan Technical serta

mencari data-data referensi untuk bahan perhitungan

budget yang lebih akurat

• Bekerja sama dengan Logistic dalam memanage Part Check Out

Time dan selalu mengingatkan tentang Part Availability & Lead

Time Supply

PT GENTA NUSA ARSANA 19

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

MAINTENANCE COST CONTROLLING

• LOGISTIC

• Part Check Out Time

Ikut memonitor pergerakan cost dan selalu menyesuaikan

dengan budget pada kondisi-kondisi tertentu

Tidak menunda pekerjaan Check Out untuk Cost dengan

kategori Daily Moving

• Part Availability & Lead Time Supply

Selalu memperbaiki Part Availability & Lead Time Supply

• Wrong Account Code

Selalu memasukkan material yang menjadi Cost sesuai

dengan Account Code

PT GENTA NUSA ARSANA 20

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

LAMPIRAN

PT GENTA NUSA ARSANA 21

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

PT GENTA NUSA ARSANA 22

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

PT GENTA NUSA ARSANA 23

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

PT GENTA NUSA ARSANA 24

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

PN

MAN MODEL PART NUMBER DESCRIPTION QTY LIFE TIME PRICE USD AMOUNT

REPLACEMENT MAN HOUR

B01 KOMATSU HD465-7 600-211-1231 FULL FLOW FILTER 2 500 11,08 22,17 1,00

B02 KOMATSU HD465-7 600-311-3110 FUEL FILTER 3 500 85,11 255,34 1,50

B03 KOMATSU HD465-7 424-16-11140 TRANSMISSION FILTER 2 500 7,43 14,86 1,00

B04 KOMATSU HD465-7 600-411-1171 CORROSION RESISTOR 1 1000 79,66 79,66 0,50

B05 KOMATSU HD465-7 569-43-83920 BRAKE OIL FILTER 1 1000 92,52 92,52 0,50

B06 KOMATSU HD465-7 07063-51210 REAR BRAKE COOLING 2 1000 135,90 271,80 1,00

B07 KOMATSU HD465-7 600-185-6100 ELEMENT ASS'Y 2 1000 299,88 599,75 1,00

B08 KOMATSU HD465-7 07000-12014 ORING 2 1000 52,16 104,32 1,00

B09 KOMATSU HD465-7 07000-12125 ORING 2 1000 4,07 8,13 1,00

B10 KOMATSU HD465-7 07063-51210 HYDRAULIC FILTER 2 2000 135,90 271,80 1,00

B11 KOMATSU HD465-7 07000-F5180 ORING 2 1000 178,32 356,64 1,00

PRICE PER

MAN MODEL OIL COMPONENT QTY LIFE TIME AMOUNT MANHOURS

LITTER

C01 KOMATSU HD465-7 SAE 30 ENGINE 57 500 1,80 102,60 0,86

C02 KOMATSU HD465-7 SAE 30 BRAKE COOLING 238 2000 1,80 428,40 3,57

C03 KOMATSU HD465-7 SAE 10W FRONT BRAKE 2 6000 1,80 3,60 0,03

C04 KOMATSU HD465-7 SAE 10 STEERING HOIST 122 2000 1,80 219,60 1,83

C05 KOMATSU HD465-7 SAE 30 TRANSMISSION 89 1000 1,80 160,20 1,34

C06 KOMATSU HD465-7 SAE 10W FRONT SUSPENSION 34 12000 1,80 61,20 0,51

C07 KOMATSU HD465-7 NITROGEN FRONT SUSPENSION NITROGEN 82 1000 1,80 147,60 1,23

C08 KOMATSU HD465-7 SAE 10W REAR SUSPENSION 19 12000 1,80 34,20 0,29

C09 KOMATSU HD465-7 NITROGEN REAR SUSPENSION NITROGEN 82 1000 1,80 147,60 1,23

C10 KOMATSU HD465-7 SAE 30 FINAL DRIVE CASE 42 2000 1,80 75,60 0,63

C11 KOMATSU HD465-7 SAE 30 DIFFERENTIAL CASE 95 2000 1,80 171,00 1,43

C12 KOMATSU HD465-7 NLGI-2 GREASE 20 250 2,66 53,20 0,30

PT GENTA NUSA ARSANA 25

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

PT GENTA NUSA ARSANA 26

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

PT GENTA NUSA ARSANA 27

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

PT GENTA NUSA ARSANA 28

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

PT GENTA NUSA ARSANA 29

www.gentanusaarsana.com

MODUL MAINTENANCE BUDGETING

PT GENTA NUSA ARSANA 30

www.gentanusaarsana.com

31

Anda mungkin juga menyukai

- Bahasa Inggris Sistem 52M Volume 1Dari EverandBahasa Inggris Sistem 52M Volume 1Penilaian: 3.5 dari 5 bintang3.5/5 (40)

- Asset Management PDFDokumen59 halamanAsset Management PDFDhe Mulyadi100% (1)

- 2021 - Draft QHSE Manual Rev 03Dokumen66 halaman2021 - Draft QHSE Manual Rev 03Al-fackhry RojiBelum ada peringkat

- Track Type Tractor Maintenance Training PDFDokumen124 halamanTrack Type Tractor Maintenance Training PDFRahmat Gonggong100% (1)

- Bahasa Inggris Sistem 52M Volume 3Dari EverandBahasa Inggris Sistem 52M Volume 3Penilaian: 3 dari 5 bintang3/5 (3)

- Tugas - 2 FixDokumen8 halamanTugas - 2 FixAdi WidyaBelum ada peringkat

- 138150028Dokumen57 halaman138150028PramonoBelum ada peringkat

- OPHAR PembangkitDokumen43 halamanOPHAR PembangkitSeto M. Pramono100% (3)

- Laporan PendahuluanDokumen26 halamanLaporan PendahuluanRizqy OctavianaBelum ada peringkat

- Laporan PKLDokumen16 halamanLaporan PKLFitri Ekayanti100% (3)

- Revisi Proposal Skripsi 26 Mei 2020Dokumen34 halamanRevisi Proposal Skripsi 26 Mei 2020rifqi fBelum ada peringkat

- MP 08-Dasar PemeliharaanDokumen48 halamanMP 08-Dasar PemeliharaanEkky Meidy Dwiatna100% (1)

- Laporan Perawatan Mesin BubutDokumen19 halamanLaporan Perawatan Mesin BubutrafiBelum ada peringkat

- Laporan Kerja Praktek PT PindadDokumen79 halamanLaporan Kerja Praktek PT PindadMauly Handsan100% (1)

- Makalah MSDMDokumen15 halamanMakalah MSDMTiara poetri NabilaBelum ada peringkat

- MAKALAHmini Plaant (SULTAN) 2Dokumen32 halamanMAKALAHmini Plaant (SULTAN) 2Hari Hari GuaBelum ada peringkat

- Halaman Indentitas Laporan OJT Bernadette Priyanka Ezra PramestiDokumen32 halamanHalaman Indentitas Laporan OJT Bernadette Priyanka Ezra PramestiKms arifBelum ada peringkat

- Juknis Tata Kelola Dan SPIDokumen47 halamanJuknis Tata Kelola Dan SPIyudha100% (1)

- Praktikum Pengendalian Dan Perencanaan Produksi (Teknik Industri)Dokumen128 halamanPraktikum Pengendalian Dan Perencanaan Produksi (Teknik Industri)riza.gustiarBelum ada peringkat

- PA Fahmi Prawira NegaraDokumen53 halamanPA Fahmi Prawira NegaraRizky NBelum ada peringkat

- 12 Pengenalan Dasar Pemeliharaan PembangkitDokumen40 halaman12 Pengenalan Dasar Pemeliharaan PembangkityudhiprasetyoBelum ada peringkat

- Tugas 2 (MPM) - RRDokumen18 halamanTugas 2 (MPM) - RRAlwi BakhtiarBelum ada peringkat

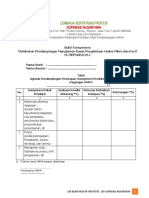

- Melakukan Pendampingan Manajemen Dasar Pengelolaan Usaha Mikro Dan KecilDokumen7 halamanMelakukan Pendampingan Manajemen Dasar Pengelolaan Usaha Mikro Dan KecilDeden DarmawanBelum ada peringkat

- Qhse PDFDokumen32 halamanQhse PDFArdhy Lazuardy100% (2)

- Makalah - Mo - Perencanaan Agregat - Intan & NoviDokumen21 halamanMakalah - Mo - Perencanaan Agregat - Intan & NoviWidiyanto Pratama YonathanBelum ada peringkat

- Laporan TopografiDokumen4 halamanLaporan TopografimohabpelangiBelum ada peringkat

- Tugas TPP 1Dokumen30 halamanTugas TPP 1AryaBelum ada peringkat

- Skripsi FixDokumen66 halamanSkripsi Fixrafihabibi404Belum ada peringkat

- Laporan Praktik Kerja Lapangan MaintenanDokumen70 halamanLaporan Praktik Kerja Lapangan MaintenanMuhammad Dwiki FadhillahBelum ada peringkat

- Kelompok 15Dokumen111 halamanKelompok 15RianandaBelum ada peringkat

- Manual Simral 2017 Eplanning Draft IDokumen154 halamanManual Simral 2017 Eplanning Draft Iomjee zaivBelum ada peringkat

- Tugas AkhirDokumen6 halamanTugas AkhirRiko RajagukgukBelum ada peringkat

- Laporan KP - Devi Kurnia - 3ATENDokumen72 halamanLaporan KP - Devi Kurnia - 3ATEN1A TEN - Devi KurniaBelum ada peringkat

- Putri Yuliawati (J1B118048)Dokumen16 halamanPutri Yuliawati (J1B118048)Sadiga MardiyahBelum ada peringkat

- Laporan Praktikum - ThersherDokumen12 halamanLaporan Praktikum - ThersherDIAN AL-MUNAWAR ZUHRIBelum ada peringkat

- Makalah CNCDokumen66 halamanMakalah CNCYudha RamadhaniBelum ada peringkat

- UntitledDokumen105 halamanUntitledfinBelum ada peringkat

- 02 Asl-Q-PlcDokumen24 halaman02 Asl-Q-PlcMarwotoBelum ada peringkat

- Lap. Pendahuluan Irigasi Distrik JairDokumen128 halamanLap. Pendahuluan Irigasi Distrik JairArnold SoenBelum ada peringkat

- Laporan Praktik Kerja LapanganDokumen57 halamanLaporan Praktik Kerja LapanganRandu Brehenkk BallackshembilandBelum ada peringkat

- Rps SisprodDokumen52 halamanRps SisprodIshak PndBelum ada peringkat

- MP Persampahan Kab. Kepulauan Mentawai - 2016Dokumen364 halamanMP Persampahan Kab. Kepulauan Mentawai - 2016Agnes Tyagita AyudyaningtyasBelum ada peringkat

- Laporan SkripsiDokumen53 halamanLaporan SkripsiSabiran As-singkilyBelum ada peringkat

- Desain Alat Uji Keserempakan Piston Damper - Muhammad Arifianto C (Rev 01)Dokumen48 halamanDesain Alat Uji Keserempakan Piston Damper - Muhammad Arifianto C (Rev 01)muhammad arifiantoBelum ada peringkat

- Basic Maintenance (Revisi 3 Final)Dokumen41 halamanBasic Maintenance (Revisi 3 Final)iwan winaryo100% (1)

- LAPORAN KERJA PRAKTIK PPSDM FixDokumen104 halamanLAPORAN KERJA PRAKTIK PPSDM FixDila FadilaBelum ada peringkat

- Proposal 7Dokumen51 halamanProposal 7lumalila researchBelum ada peringkat

- 8e5cb 2. Modul BP Pengelolaan UP Hasan Juni 2018Dokumen106 halaman8e5cb 2. Modul BP Pengelolaan UP Hasan Juni 2018Evan BrunanditoBelum ada peringkat

- TB 1 - Keandalan - Riandini Ardiningsih - 41619010014Dokumen18 halamanTB 1 - Keandalan - Riandini Ardiningsih - 41619010014diniBelum ada peringkat

- Laporan Proceeding WorkshopDokumen20 halamanLaporan Proceeding WorkshopBernie D. Teguenos100% (1)

- Pedoman PemeliharaanDokumen93 halamanPedoman PemeliharaanMuhammadThoriqAzmiBelum ada peringkat

- Modul 1 Pendahuluan MK Perawatan Mesin 2019Dokumen65 halamanModul 1 Pendahuluan MK Perawatan Mesin 2019bisa cryptoBelum ada peringkat

- Laporan LengkapDokumen78 halamanLaporan LengkapIMAM0% (1)

- Wiwik SuryanaDokumen59 halamanWiwik SuryanaAde Tri YulistianBelum ada peringkat

- Makalah Teknik Dasar Perawatan MesinDokumen28 halamanMakalah Teknik Dasar Perawatan MesinRivaldo GustianBelum ada peringkat

- Yunita Nur Cahyati - CKT 2117 - Divisi Enjinering, Mutu & K3LH - Proyek Epcc Revitalisasi PG Rendeng PDFDokumen37 halamanYunita Nur Cahyati - CKT 2117 - Divisi Enjinering, Mutu & K3LH - Proyek Epcc Revitalisasi PG Rendeng PDFSipil RendengBelum ada peringkat

- Kelompok 4 - Manajemen ProduksiDokumen14 halamanKelompok 4 - Manajemen ProduksiMochAriArekUsbBelum ada peringkat

- Laporan PERAMALAN DAN PERENCANAAN AGREGATDokumen59 halamanLaporan PERAMALAN DAN PERENCANAAN AGREGATmentariBelum ada peringkat

- LAPORAN PKL EkaaDokumen26 halamanLAPORAN PKL Ekaawilly agustianBelum ada peringkat

- Bahasa Inggris Sistem 52M Volume 2Dari EverandBahasa Inggris Sistem 52M Volume 2Penilaian: 4.5 dari 5 bintang4.5/5 (7)

- Materi Arief Mulyadi PT PNMDokumen22 halamanMateri Arief Mulyadi PT PNMAsyraf Al AzuardiBelum ada peringkat

- Soal Test KebumianDokumen3 halamanSoal Test KebumianAsyraf Al AzuardiBelum ada peringkat

- Tata Krama & Budi PekertiDokumen2 halamanTata Krama & Budi PekertiAsyraf Al Azuardi100% (2)

- PKM-P (Lazuardi Asri) : ANALISIS PERKEMBANGAN SEKTOR EKONOMI PROVINSI ACEH PASCA TSUNAMI 2004Dokumen27 halamanPKM-P (Lazuardi Asri) : ANALISIS PERKEMBANGAN SEKTOR EKONOMI PROVINSI ACEH PASCA TSUNAMI 2004Asyraf Al AzuardiBelum ada peringkat