Redesain Proses Dengan Metode FMEA

Diunggah oleh

Jose MillerJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Redesain Proses Dengan Metode FMEA

Diunggah oleh

Jose MillerHak Cipta:

Format Tersedia

6/9/14

Redesain Proses dengan metode

Failure Mode Effect Analysis (FMEA)

dr Arjaty W Daud MARS

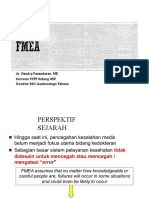

Perspektif Sejarah

n Hingga saat ini, pencegahan kesalahan medis

belum menjadi fokus utama bidang kedokteran

n Sebagian besar sistem pelayanan kesehatan

tidak didesain untuk mencegah atau

mencegah / mengatasi error

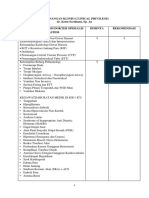

REDESAIN PROSES DENGAN

ANALISA PROAKTIF (FMEA)

Arjaty Daud/IMRK /FMEA

6/9/14

Arjaty

Daud/IMRK /FMEA

3

Advanced Patient safety in US since 1999, NPCS,

August 2004, www,patientsafety.gov

What is FMEA ?

Adalah metode perbaikan kinerja dgn mengidentifikasi

dan mencegah Potensi Kegagalan sebelum terjadi. Hal

tersebut didesain untuk meningkatkan keselamatan

pasien.

Adalah Proses Proaktif, dimana kesalahan dpt dicegah

& diprediksi.

Mengantisipasi kesalahan akan meminimalkan dampak

buruk

Arjaty Daud/IMRK /FMEA

6/9/14

FAILURE MODE AND EFFECTS ANALYSIS /

ANALISIS MODUS KEGAGALAN DAN DAMPAK

Analisis (A)

Penyelidikan secara detail suatu proses

Mode (M)

Cara atau Perilaku yang dapat menimbulkan kegagalan

Kegagalan (K)

Saat sistem atau bagian dari sistem tidak sesuai yang

diharapkan baik disengaja maupun tidak

Dampak (D)

Dampak atau Konsekuensi Modus Kegagalan

Arjaty Daud/IMRK /FMEA

FMEA

FMEA bisa dilakukan pada :

- Proses yang telah dilakukan saat ini

- Proses yang belum dilakukan atau baru

akan dilakukan mis :

Implementasi Elektronik Rekam Medis

Pembelian alat baru

Redesain ruan, Kamar Operasi, dll

Arjaty Daud/IMRK /FMEA

6/9/14

FMEA

vs

1. Pilih Proses Berisiko .nggi dan

bentuk Tim

2. Diagram / gambarkan Alur Proses

& Brainstorming Modus Kegagalan

3. Menentukan Dampak / Eects

4. Prioritas Modus Kegagalan

5. Iden.kasi Penyebab / Causes

6. Redesain Proses

7. Analisa dan Uji coba Proses

8. Implementasi & Monitor Proses

baru

HFMEA

1. Tetapkan Proses

2. Bentuk Tim

3. Gambarkan Alur

Proses

4. Buat Hazard

Analysis

5. Tindakan dan

Pengukuran

Outcome

7

Arjaty Daud/IMRK /FMEA

LANGKAH- LANGKAH FMEA

1. Pilih Proses Berisiko .nggi dan bentuk Tim

2. Diagram / gambarkan Alur Proses & Brainstorming

Modus Kegagalan / Failure Mode

3. Menentukan Dampak / Eects

4. Prioritas Modus Kegagalan

5. Iden.kasi Penyebab / Causes

6. Redesain Proses

7. Analisa dan Uji coba Proses

8. Implementasi & Monitor Proses baru

6/9/14

Langkah 1 : PILIH PROSES BERISIKO TINGGI

Proses baru

Misalnya : proses mengoperasikan alat infus baru untuk pasien

rawat jalan

Proses yang sedang berjalan

MIsalnya : proses pengadaan dan penyimpanan gas medis di

rumah sakit

Proses dalam klinis

Misalnya : proses pemeriksaan darah di laboratorium

Proses non-klinis

Misalnya : proses mengkomunikasikan hasil pemeriksaan (lab)

kepada dokter atau proses Identifikasi pasien yang berisiko

jatuh

Arjaty Daud/IMRK /FMEA

Memilih Proses FMEA

Sen.nel Event Alert yang dipublikasikan JCAHO

Infant Abduc.on

Wrong site surgery

Delay Treatment

Sasaran Keselamatan Pasien JCAHO

Proses berisiko .nggi di RS

6/9/14

Salah satu kriteria pemilihan Proses adalah :

Proses potensial memberikan Dampak yang .dak diharapkan

pada pasien.

Pertanyaan untuk memilih Proses :

1. Proses pelayanan apa saja yang dapat berdampak (aect)

pada keselamatan pasien ?

2. Proses pelayanan apa yang potensial .nggi volume ?

3. Proses pelayanan apa saja yang banyak hubungan /

keterkaitan dalam pelayanan kepada pasien? Dan jika terjadi

masalah, sering memberikan dampak dalam proses2 tsb.

Ruang lingkup Proses yang akan dianalisa perlu

dibatasi agar Tim lebih fokus memberikan ide.

Contoh :

Proses pemberian obat parenteral pasien rawat jalan

Proses

: 6

Sub proses

: 67

Potensial Modus Kegagalan : 217

6/9/14

Ke.ka membuat Alur Proses, Tim harus menjawab beberapa

pertanyaan :

1. Apa langkah-langkah dalam proses ?

Jika proses sudah ada, bagaimana langkah2 yang sudah

dikerjakan?

Jika proses belum ada, bagaimana seharusnya dikerjakan ?

2. Bagaimana hubungan antar langkah dalam proses ?

(mis. Berurutan atau simultan )

3. Bagaimana proses berhubungan dengan proses yang lain?

4. Apa tools yang digunakan dalam membuat alur / diagram

proses?

Membentuk Tim

Multidisiplin

Tidak lebih dari 10 orang (idealnya 4 8

orang)

Memiliki pengetahuan tentang proses yg

akan dianalisis (subject matter / process

expert) & komitmen pada performance

improvement

Mewakili bidang yg akan dianalisis dan unit

yang akan terkena perubahan

Mengikutkan orang yang tidak terlibat dlm

proses tapi memiliki analytical skill

Setidaknya ada satu pembuat keputusan

(leader)

Satu orang yg memiliki critical thinking

saat perubahan akan dilaksanakan

Arjaty Daud/IMRK /FMEA

14

6/9/14

TIME LINE AND TEAM ACTIVITIES

Pra meeting

Identifikasi topik dan beri motivasi pada tim

1st

Gambarkan proses, identifikasi subproses, verifikasi ruang lingkup

team meeting

2rd team meeting

Kunjungi unit kerja untuk observasi proses, verifikasi semua langkah proses &

subproses apakah sudah benar (Langkah 3)

3 rd team meeting

Brainstorming modus kegagalan, tugaskan anggota tim untuk berdiskusi

dengan peetugas pada unit yang terlibat dalam proses (Langkah 3)

4rd team meeting

Identifikasi penyebab modus kegagalan, tugaskan anggota tim untuk berdiskusi

dengan petugas pada unit yang terlibat dalam proses untuk memperoleh

masukan tambahan (Langkah 3)

5th team meeting

Tuangkan modus kegagalan dan penyebabnya pada lembar kerja HFMEA

(langkah 3). Lakukan analisa hazard (langkah4)

Identifikasi tindakan perbaikan dan tindaklanjuti tanggungjawabnya (Langkah 5)

6th,7th , 8th. team

meeting plus 1

Tugaskan anggota tim menindaklanjuti PIC untuk setiap tindakan perbaikan

team meeting plus 2

Tindakan perbaikan berbasis umpan balik

team meeting plus 3

Uji perubahan yang diajukan

team meeting plus 4

Pertemuan dengan Pimpinan untuk persetujuan semua tindakan perbaikan

Postteam meeting

Konsultan menindaklanjuti

sampai

Arjaty Daud/IMRK

/FMEA semua tindakan telah lengkap

15

LANGKAH 2 : BUAT ALUR PROSES &

BRAINSTORMING MODUS KEGAGALAN

1.

Alur

Proses

Buat

Alur

Proses,

bila

perlu

dibuat

Subproses

dan

buat

masing-masing

Diagramnya.

Bila

Proses

Baru:

Bagaimana

seharusnya

Bila

Proses

Lama:

Bagaimana

saat

ini

Buat

Flowchart

untuk

diagram

proses

2.

Modus

Kegagalan

Perilaku

yang

dapat

mengakibatkan

kegagalan

- Tanyakan bagaimana bisa gagal?

- Iden.kasi semua modus kegagalan

-beberapa langkah dapat .dak memiliki modus kegagalan

-beberapa langkah dapat memiliki banyak modus kegagalan

6/9/14

Starting Point

PROCESS

STEP

STEP

1

STEP

2

STEP

3

Establish Process Steps for Process Flow

Step 1: _________________________

Step 2: _________________________

Step 3: _________________________

What is the process for delivering

medications to the unit?

Physician examines pa.ent

Physician writes medica.on order

Medica.on order pulled from chart

Order transcribed into Medica.on

Administra.on Record (MAR)

Medica.on request delivered to

pharmacy

Medica.on delivered to unit

Flow Charting

Five to eight steps

process

Stay high level

Be as linear as

possible. Avoid If X,

then Y splits

Each step describes

something that is

being done.

18

6/9/14

Why diagram the process?

Diagrams clarify things between members

Narrows the topic goes from broad topic

e.g. narco.c use process to narrow topic

e.g. morphine removed from narco.c drawer

10

6/9/14

11

6/9/14

Failure Modes, Effects, and Causes

Failure Mode

What we observe that

tells us a failure may be

occurring

A failure mode is usually:

A warning (check engine light)

A symptom (fever is a failure mode

for infection)

A failure mode is not the cause of the

failure.

Brainstorm Potential Failure Modes, Causes, and Effects

Order not pulled in

Timely manner

Physician

Writes Order

Writing illegible

Order incomplete

Non-formulary drug

Used felt pen

Confusing abbrev. Used

Look-alike drug ordered

Contrary to approved

clinical protocol

Medication

Order

Order Pulled

From Chart

Order Transcribed

By Unit Clerk into

MAR

NCR copy of

order sent to

pharmacy

Transcription error

Order Transcribed

By Pharm Tech

Into Pharmacy System

12

6/9/14

LANGKAH 3 MENENTUKAN DAMPAK

Menentukan kemungkinan Dampak jika kegagalan

tersebut terjadi dengan Brainstorming / Diskusi

diantara Anggota Tim

13

6/9/14

Failure Modes, Effects, and Causes

Poten.al Eects of

Failure

Definition: What we

observe that tells us a

failure may be

occurring

Definition: How might

this failure impact our

customer?

The effect

describes the

impact of the

failure that is

indicated by

the failure

mode.

Explosion

Repair

Late

Failure Mode

27

14

6/9/14

LANGKAH 5

IDENTIFIKASI PENYEBAB MODUS KEGAGALAN

Mencari

kemungkinan

penyebab

Modus

Kegagalan

Pronsipnya

adalah

Kegagalan

dimasa

datang

bisa

dicegah.

Kalaupun

.dak

dapat

dicegah,

pasien

harus

di

proteksi

terhadap

dampak

kegagalan

tsb

atau

Dampak

di

mi.gasi.

Failure Modes, Effects, and Causes

Failure

Poten.al

Causes

of

Failure

Definition: How might

this failure impact our

customer?

Definition: The element

that creates/allows the

failure

Loose oil cap

Late

Faulty warning light

Low oil level

Repair

Definition: What we

observe that tells us a

failure may be

occurring

Poten.al Eects of

Explosion

Failure Mode

Blocked air-filter has caused

the engine to seize

Faulty warning light

Dirt in the fuel line is

choking the engine

Filled gas tank with Diesel

fuel

Others.

30

15

6/9/14

Assess Criticality Score

RPN (Risk Priority Number) Score / CI (Criticality Index)

Priori.ze the failure modes based on their RPN / CI

Computer cri.cality index (CI) :

Occurrence X Severity X Detec.on

* CI and RPN are basically the same: but, both terms are used in the literature.

16

6/9/14

Memilih Skala Peringkat

JCI .dak secara spesik menentukan skala mana yang harus

digunakan dalam menilai modus kegagalan.

Pimpinan dan staf bebas memilih skala yang dipercaya efek.f, dan

organisasi harus menggunakannya secara konsisten.

Mis. Organisasi bisa memilih skala 1-10 atau 1-5.

Tidak masalah, apapun metode (FMEA / HFMEA) dan

penentuan skala ( 1-10 atau 1-5) yang digunakan oleh

tim, Anggota tim harus setuju dan mengerti skala apa

yang telah ditetapkan.

Mis. Jika tim sepakat menggunakan skala 1-10, mereka

harus setuju pada definisi tiap rating.

Sample Severity Scale 1- 10

RATING

1

DESKRIPSI

DEFINISI

Minor effect or no effect

Would not be noticeable to individual served

and would not affect the process

2

3

May affect the individual served and would

result in some effect on the process

4

5

Moderate effect

May affect the individual served and would

result in a major effect on the process

Minor injury

Would affect the individual and result in a

major effect on the process

Major injury

Would result in a major injury for the individual

served and have a major efect on the process

Catastrophic effect, a terminal

injury or death

Extremely dangerous, failure would result in

death of the individual served and have a major

effect on the process

7

8

9

10

Arjaty Daud/IMRK /FMEA

34

17

6/9/14

Sample Severity Scale 1- 5

SEVERITY RATING

(Modified by IMRK)

CATASTROPHIC

5

Patient

Outcome

Death

MAJOR

4

MODERATE

3

MINOR

2

INSIGNICANT

1

Injury with

permanent

loss of

function

Injury with no

permanent loss of

function

No injury but

increased

LOS to

monitor

effects

No injury

Visitor

Outcome

Death,

hospitalization

of 3 or more

Injury with

permanent loss of

function

Or Hospitalization

of 1 or 2

visitors

Injury with no

permanent loss of

function or

Evaluation &

treatment for

1 or 2 visitors

(less than

hospitalizatin )

Evaluated &

First aid

treatment

No injury

Staff

Outcome

Death or

hospitalization

of 3 or more

staff

Hospitalization

of 1 or 2 staff or

3 or more staff

experiencing lost

time or restricted

duty

injuries or

illnesses

Medical expenses,

lost time or

restricted duty

injuries or

illness for 1 or

2 staff

First aid

treatment

only with no

lost time, nor

restricted

duty injuries

nor illnesses

No injury

Sample Probability of occurrence scale 1- 10

Rating

1

Deskripsi

Probability of Detection

Definisi

Remote to

nonexixtent

1 in 10.000

No or little known occurrence, highly

unlikely that condition will ever occur

Low likelihood

1 in 5000

Possible, but no known data, the

condition occurs in isolated cases, but

chances are low

Moderate likelihood

1 in 200

Documented, but infrequently the

condition has a reasonable chance to

occur

High likelihood

1 in 100

Documented & frequent, the condition

occurs very regularly and / or during a

reasonable amount of time

Certain to occur

1 in 20

Documented, almost certain, the

condition will inevitably occur during long

period typical for the step or link

2

3

4

5

6

7

8

9

10

Arjaty Daud/IMRK /FMEA

36

18

6/9/14

Sample Probability of occurrence scale 1- 5

PROBABILITY

Rating

Description

Rare

Very Unlikely to occur

(may happen sometime in 5 to 30 years)

Definition

Unlikely

Unlikely to occur

(may happen sometimes in 2 to 5 years)

Possible

Likely

Almost certain

Possible will occur

(may happen several times in 1 to 2 years)

Likely to occur immediately or within a short period

(may happen several times in one year )

Very likely to occur every month

Menentukan Kemampuan Deteksi

(Detectability)

Detectability adalah derajat dimana sesuatu dapat

ditemukan atau dicatat

Pertanyaannya :

Jika modus kegagalan terjadi , bagaimana hal tersebut

dapat diketahui (terdeteksi) ?

Contoh : mengiden.kasi isi gas berdasarkan label

yang tertera pada tabung. Jika label hilang maka akan

sangat berbahaya karena .dak diketahui isi tabung

tsb.

19

6/9/14

Sample Detectability scale 1 - 10

Rating

1

Deskripsi

Definisi

Definition

Certain to

detect

10 out of 10

Almost always detected immadiately

High likelihood

7 out of 10

Likely to be detected

Moderate

likelihood

5 out of 10

Moderate likelihood of detection

Low likelihood

2 out of 10

Unlikely to be detected

Almost certain

not to detect

0 out of 10

Detection not possible at any point

2

3

4

5

6

7

8

9

10

Arjaty

Daud/IMRK

/FMEA

Sample Detectability

Probability of

Detection

39

Scale

Rating

Description

Definition

Certain to detect

10 out to 10

Almost always detected immediately

High likelihood

7 out of 10

Likely to be detected

Moderate

likelihood

5 out of 10

Moderate likelihood of detection

Low likelihood

2 out 0f 10

Unlikely to be detected

Almost certain

not to detect

0 out of 10

Detection not possible at any point

20

6/9/14

LANGKAH 4 : PRIORITAS MODUS

KEGAGALAN

Skala Peringkat Modus Kegagalan

Beberapa Metode yang digunakan untuk menilai

peringkat Modus kegagalan :

1. Risk Priority number (RPN) : - FMEA

Fokus pada severity, probability dan detec.bility

RPN : Severity x Probability x Detec.bility

1. Hazard score : HFMEA

Fokus pada kegawatan severity, probability.

Hazard Score : Severity x Probability

Decision tree

21

6/9/14

Prioritaskan Modus Kegagalan

Modus kegagalan harus dilakukan prioritas sesuai dengan

prioritas .ndakan.

Jika modus kegagalan menggunakan RPN, mungkin dapat

memilih cut o point untuk menentukan prioritas.

Nilai dibawah cuto point .dak memerlukan .ndakan

segera kecuali tersedia waktu .

Nilai di atas cuto point , harus dilakukan eksplorasi.

Risk Priority Number (RPN)

FM #

Cuttof

point

Failure Mode

Severity

Frequency

Detectabilit

y

RPN

Choose incorrect medication

10

490

No double check

10

490

Error due to Baker Cells

10

480

Poor flow of refilling process

10

420

Dispense not documented in computer

10

350

Labeled Incorrectly

168

Illegible initials

10

160

No double check of bag contents

147

Count incorrect quantity

10

140

Prescription bagged incorrectly

16

44

10

4

Arjaty

Daud/IMRK

/FMEA

22

6/9/14

Ranking by RPN

Use the RPN to determine where to

focus your limited resources

We are looking for failures that are most

severe, occur often, and are hard to

detect.

RPN

Rank

168

360

54

210

45

Step 5: Develop and Implement

Solutions

It is the job of management not only to assess risk, but

also to identify effective courses of action to eliminate or

mitigate that risk

This commitment to implementing risk reduction methods

transforms risk assessment into risk management

Use a FMEA/RCA method to identify root causes and

potential solutions

23

6/9/14

LANGKAH 6 : REDESAIN PROSES

Develop and implement risk reduction solutions for each failure mode

Focus: elemen re-desain yg kri.s

Pelajari RS lain bagaimana cara mengatasi hal tsb.

Take a deep breath

Conduct a literature search to gather relevant information from

the professional literature.

Network with colleagues

Recommit to out-of-the-box thinking

Arjaty Daud/IMRK /FMEA

47

LANGKAH 7 :

ANALISA & UJI COBA PROSES BARU

Organizing

for

redesign

implementa.on

Tes.ng

the

New

Process

The

Plan-Do-Study-Act

(PDSA)

The

analysis,

tes.ng,

implementa.on

and

monitoring

of

a

process

are

all

linked

To

help

teams

keep

track

of

the

two

nal

steps

of

the

FMEA

process,

an

organiza.on

might

want

to

consider

using

a

quality

improvement

tool

such

as

the

PDSA

cycle

Arjaty Daud/IMRK /FMEA

48

24

6/9/14

TESTING NEW PROCESS

Pilot Tes.ng

- Tim mengimplementasikan redesain dalam skala kecil,

monitor hasilnya, dan lakukan redesain sesuai kebutuan

tanpa mengambil risiko jika diimplementasikan dalam skala

besar

- Kumpulkan umpan balik dari staf yang terlibat dalam proses

di skala kecil tersebut

- Per.mbngkan pre dan pot survey staf yang terlibat dalam

pilot tes.ng. Hali ini akan memberikan informasi tentang

bagaimana kelompok membandingkan proses sebelum dan

sesudah redesain

Arjaty Daud/IMRK /FMEA

49

LANGKAH 8 :

IMPLEMENTING & MONITORING THE NEW PROCESS

Implementing the redesigned process is

all about introducing change into ongoing

health care process

Sustaining the Redesigned Process

Arjaty Daud/IMRK /FMEA

50

25

6/9/14

Re-calculate the RPN scores based on

risk reduction actions

600

Sebelum redisain

500

RPN

400

Sesudah redisain

300

200

100

0

2

10

FAILURE MODE

Arjaty

Daud/IMRK

/FMEA

51

Contoh FMEA

26

6/9/14

27

6/9/14

AMKD / FMEA

Proses lama

yg high risk

Alur

Proses

Modus

Kegagalan

Efek /

Dampak

RPN

Redesain

RPN

baru

Failure

Mode

Desain

Proses baru

Penyebab

Arjaty Daud/IMRK /FMEA

56

28

6/9/14

Compliance Questions

1. Does organization have a prioritize list of high risk

processes?

2. Can the organization demonstrate how a risk assessment

method was used to prioritize the high risk processes?

3. Can the organization demonstrate the correct use of

FMEA?

4. Was a reasonable RCA done after the RPN score was

calculated?

5. Was the RPN score re-calculated after development of

solutions?

Patient safety

Is everybody

business

Dont hurt me,

Heal me,

Be nice to me

Arjaty Daud/IMRK /FMEA

58

29

Anda mungkin juga menyukai

- Laporan PMKP Tahun 2018Dokumen195 halamanLaporan PMKP Tahun 2018anita100% (1)

- Root Cause Analysis (Dorisnita)Dokumen53 halamanRoot Cause Analysis (Dorisnita)Ade Zetri Rahman100% (1)

- Tugas RcaDokumen12 halamanTugas Rcawahyu romadhonBelum ada peringkat

- JCI Survey Process Guide 6th Edition - IND PDFDokumen193 halamanJCI Survey Process Guide 6th Edition - IND PDFRDII YANMEDRSDS100% (2)

- Panduan Asesmen Listrik 2014Dokumen10 halamanPanduan Asesmen Listrik 2014Desi KurniawatiBelum ada peringkat

- Rincian Kewenangan Klinis Dokter Spesialis AnastesiDokumen2 halamanRincian Kewenangan Klinis Dokter Spesialis AnastesiEndangBelum ada peringkat

- Pedoman Pelayanan Promosi Kesehatan Rumah SakitDokumen14 halamanPedoman Pelayanan Promosi Kesehatan Rumah SakitJose Miller100% (4)

- Tor Magang Rs Annisa TangerangDokumen3 halamanTor Magang Rs Annisa TangerangKedokteran Shop100% (1)

- Tor Pelatihan Teknis Ina CbgsDokumen6 halamanTor Pelatihan Teknis Ina CbgssaefulBelum ada peringkat

- PROPOSAL IhtDokumen7 halamanPROPOSAL IhtMalisa LukmanBelum ada peringkat

- Tugas Sesi 5 - Edwin - 20190309022Dokumen6 halamanTugas Sesi 5 - Edwin - 20190309022Nikolas EdwinBelum ada peringkat

- JKN IndahDokumen15 halamanJKN IndahklinikBelum ada peringkat

- Sentinel FixDokumen2 halamanSentinel Fixnarni nikol putri sayakira awindaBelum ada peringkat

- Model Proses Analisis BisnisDokumen16 halamanModel Proses Analisis BisnisRio Prayoga SeptiadiBelum ada peringkat

- Soal Latihan Risk GradingDokumen2 halamanSoal Latihan Risk GradingSora KerovaBelum ada peringkat

- Aplikasi Lean Six Sigma Untuk Mengoptimalkan Waktu Tunggu Admisi Pada Instalasi Rawat Jalan Rsu Kumala Siwi KudusDokumen3 halamanAplikasi Lean Six Sigma Untuk Mengoptimalkan Waktu Tunggu Admisi Pada Instalasi Rawat Jalan Rsu Kumala Siwi KudusAhmad Ipul SyaifuddinBelum ada peringkat

- Fact Sheet QPS Edisi 7Dokumen9 halamanFact Sheet QPS Edisi 7dina hapsariBelum ada peringkat

- Sasaran 6 SKP Sop Pemasangan Gelang Resiko JatuhDokumen9 halamanSasaran 6 SKP Sop Pemasangan Gelang Resiko JatuhSusteny TenyBelum ada peringkat

- Kuliah Kars Manajemen MutuDokumen83 halamanKuliah Kars Manajemen MutuRegina AyediaBelum ada peringkat

- Soal Rca Dan FmeaDokumen3 halamanSoal Rca Dan FmeairmaBelum ada peringkat

- Root Cause AnalysisDokumen14 halamanRoot Cause AnalysisMeilyna PermanasariBelum ada peringkat

- Persiapan Akreditasi RSCMDokumen60 halamanPersiapan Akreditasi RSCMWace KiatBelum ada peringkat

- Modul Pelatihan - FmeaDokumen46 halamanModul Pelatihan - FmeaMuh Agung JBelum ada peringkat

- Pelatihan Pmkp-Indikator Mutu Tahun 2023-1Dokumen51 halamanPelatihan Pmkp-Indikator Mutu Tahun 2023-1Nofryady Eka PutraBelum ada peringkat

- Fishbone Diagram - ItaompedocDokumen22 halamanFishbone Diagram - ItaompedocMuhammad Abdi HaryonoBelum ada peringkat

- Materi Lengkap Budaya Keselamatan Di RS (Hanevi Djasri) PDFDokumen42 halamanMateri Lengkap Budaya Keselamatan Di RS (Hanevi Djasri) PDFLianingsihBelum ada peringkat

- Spo PicDokumen1 halamanSpo PicmutiaBelum ada peringkat

- Sistem Informasi Manajemen Rumah SakitDokumen30 halamanSistem Informasi Manajemen Rumah SakitkarnoBelum ada peringkat

- Contoh Analisis FMEADokumen42 halamanContoh Analisis FMEALovina Sutedja100% (1)

- MODUL 1 - Manajemen Stratejik EU - Sesi 1-2Dokumen23 halamanMODUL 1 - Manajemen Stratejik EU - Sesi 1-2Yune PareraBelum ada peringkat

- Individual TracerDokumen23 halamanIndividual TracerDwi KartikasariBelum ada peringkat

- Soal Ujian Tengah Semester Kelas 34 CDokumen2 halamanSoal Ujian Tengah Semester Kelas 34 CAnonymous 22OpnwBelum ada peringkat

- Sertifikat Manajemen Bangsal LumajangDokumen2 halamanSertifikat Manajemen Bangsal LumajangRetno Nya Herzon ErmyBelum ada peringkat

- Contoh Risk RegisterDokumen4 halamanContoh Risk RegisterTeguhBelum ada peringkat

- 5 Langkah Pembuatan FmeaDokumen3 halaman5 Langkah Pembuatan Fmeahadi prayitnoBelum ada peringkat

- CV EvaDokumen8 halamanCV EvaPURIBelum ada peringkat

- Paper Penerapan Kebijakan Lean Di Rumah Sakit Yang Baru Dan Dampaknya Terhadap Kualitas Pelayanan Rumah SakiDokumen23 halamanPaper Penerapan Kebijakan Lean Di Rumah Sakit Yang Baru Dan Dampaknya Terhadap Kualitas Pelayanan Rumah SakiMayang Hawwin AphroditaBelum ada peringkat

- Omrs Sesi 6 Dan 7Dokumen2 halamanOmrs Sesi 6 Dan 7Salsa NabilaBelum ada peringkat

- Tactical Decision MakingDokumen17 halamanTactical Decision MakingErlia ParamithaBelum ada peringkat

- Kebijakan FmeaDokumen3 halamanKebijakan FmeaRetni Eva AveiNterBelum ada peringkat

- Edukasi Pasien Dan KeluargaDokumen15 halamanEdukasi Pasien Dan Keluargasugeng RiyantoBelum ada peringkat

- Tugas 13 Ars 201 Hospital Entrepreurial LeadershipDokumen1 halamanTugas 13 Ars 201 Hospital Entrepreurial LeadershipMarvelouzt AdityaBelum ada peringkat

- Anesthesia and Surgical Care (ASC: Rsupn DR - Cipto Mangunkusumo Goes To Joint Commission InternationalDokumen99 halamanAnesthesia and Surgical Care (ASC: Rsupn DR - Cipto Mangunkusumo Goes To Joint Commission InternationalWace KiatBelum ada peringkat

- Tugas ARS 301 Kelompok 3Dokumen3 halamanTugas ARS 301 Kelompok 3alitharachmaBelum ada peringkat

- COVER Bu RITA UASDokumen1 halamanCOVER Bu RITA UASPenti Maria UlfahBelum ada peringkat

- 102 Sesi 12Dokumen2 halaman102 Sesi 12Atsilah UlfahBelum ada peringkat

- Program Kerja KPRS 2011-2015Dokumen6 halamanProgram Kerja KPRS 2011-2015akhirBelum ada peringkat

- Investigasi Sederhana CiciDokumen5 halamanInvestigasi Sederhana CiciAstriBelum ada peringkat

- Manajemen Keuangan Dan Akuntansi Rumah SakitDokumen1 halamanManajemen Keuangan Dan Akuntansi Rumah Sakityusak tapakedingBelum ada peringkat

- Tugas UTS Dr. ANDRYDokumen6 halamanTugas UTS Dr. ANDRYyusak tapakedingBelum ada peringkat

- Tugas Ars 202.sesi-4Dokumen1 halamanTugas Ars 202.sesi-4Gado CampurBelum ada peringkat

- Akunbi KelompokDokumen6 halamanAkunbi KelompokAan EdisonBelum ada peringkat

- Ida Oliviani Arafah (1 5 4 1 0 5 1 0 9 5)Dokumen15 halamanIda Oliviani Arafah (1 5 4 1 0 5 1 0 9 5)Ida Oliviani ArafahBelum ada peringkat

- Critical Success Factor PDFDokumen8 halamanCritical Success Factor PDFAhmad Fahmi KaramiBelum ada peringkat

- Thesis FKM UI Perencanaan Strategis-Full TextDokumen184 halamanThesis FKM UI Perencanaan Strategis-Full TextDedelBelum ada peringkat

- FMEA - PPT (Compatibility Mode)Dokumen57 halamanFMEA - PPT (Compatibility Mode)DeviNamira100% (1)

- Analisa Risiko Dengan Metode FMEADokumen40 halamanAnalisa Risiko Dengan Metode FMEARilly PangkeregoBelum ada peringkat

- Analisa Risiko Dengan Metode FMEA Arjaty 2019ppt PDFDokumen22 halamanAnalisa Risiko Dengan Metode FMEA Arjaty 2019ppt PDFNikmah's Dentist LifeBelum ada peringkat

- Makalah Materi FmeaDokumen17 halamanMakalah Materi Fmeaagus100% (1)

- FMEADokumen11 halamanFMEADitta Nur apriantyBelum ada peringkat

- Panduan FmeaDokumen23 halamanPanduan Fmeatheresia_tiara_putriBelum ada peringkat

- Akreditasi Kiat ParipurnaDokumen110 halamanAkreditasi Kiat ParipurnaJose MillerBelum ada peringkat

- Kiat Dan Teknik Mengelola Perubahan Perilaku Staf Klinis Dalam AkreditasiDokumen35 halamanKiat Dan Teknik Mengelola Perubahan Perilaku Staf Klinis Dalam AkreditasiJose MillerBelum ada peringkat

- 2 Bimb APDokumen62 halaman2 Bimb APJose MillerBelum ada peringkat

- Presentasi Peran Direktur Dalam Persiapan Akreditasi Jan 2016pptDokumen35 halamanPresentasi Peran Direktur Dalam Persiapan Akreditasi Jan 2016pptJose MillerBelum ada peringkat

- Tata Laksana Pengisian Self-Assessment Pada Sistem Akreditasi RS Secara OnlineDokumen33 halamanTata Laksana Pengisian Self-Assessment Pada Sistem Akreditasi RS Secara OnlineMdl BojonegoroBelum ada peringkat

- Materi Tata Laksana Aplikasi Survei - Diyurman Gea (Compatibility Mode)Dokumen31 halamanMateri Tata Laksana Aplikasi Survei - Diyurman Gea (Compatibility Mode)Anonymous KWxYXbBelum ada peringkat

- DrNico-Peran Pimp U. Pelayanan Medis Jan16Dokumen130 halamanDrNico-Peran Pimp U. Pelayanan Medis Jan16Jose Miller100% (1)

- Akreditasi MKI PPKDokumen83 halamanAkreditasi MKI PPKJose Miller100% (2)

- Presentasi Peran Direktur Dalam Persiapan Akreditasi Jan 2016pptDokumen35 halamanPresentasi Peran Direktur Dalam Persiapan Akreditasi Jan 2016pptJose MillerBelum ada peringkat

- LATIHAN Risk Register 09-2014Dokumen4 halamanLATIHAN Risk Register 09-2014Jose Miller100% (6)

- 4 Bimb PABDokumen28 halaman4 Bimb PABJose MillerBelum ada peringkat

- Buku Saku Obgin PDFDokumen382 halamanBuku Saku Obgin PDFAnty Dewi Sarty RanyabarBelum ada peringkat

- 4 Bimb PABDokumen28 halaman4 Bimb PABJose MillerBelum ada peringkat

- DrNico Praktek Manajemen Risiko RS 09 14Dokumen29 halamanDrNico Praktek Manajemen Risiko RS 09 14IrawanBelum ada peringkat

- Buku Ontogram Terbaru 2014Dokumen37 halamanBuku Ontogram Terbaru 2014Basma RosandiBelum ada peringkat

- Buku Kodepoi PaboiDokumen74 halamanBuku Kodepoi Paboiheru124Belum ada peringkat

- Hak Dan Kewajiban Dokter Dan PasienDokumen7 halamanHak Dan Kewajiban Dokter Dan PasienSilviana FassicaBelum ada peringkat

- Systemic Inflammatory Response SyndromeDokumen5 halamanSystemic Inflammatory Response SyndromeSyahrurrahman BokowBelum ada peringkat

- Surveilans Infeksi NosokomialDokumen14 halamanSurveilans Infeksi NosokomialHotma Uli SiahaanBelum ada peringkat

- Kode Etik Kedokteran Indonesia Dan Pedoman Pelaksanaan Kode Etik Kedokteran Indonesia 2004Dokumen83 halamanKode Etik Kedokteran Indonesia Dan Pedoman Pelaksanaan Kode Etik Kedokteran Indonesia 2004Martin Susanto, MDBelum ada peringkat

- PPI GilutDokumen71 halamanPPI GilutJose Miller100% (1)

- Hak Dan Kewajiban PasienDokumen7 halamanHak Dan Kewajiban PasienRirin Halimatus Sa'diah100% (2)

- Hak Dan Kewajiban Pasien Dalam Pelayanan KesehatanDokumen29 halamanHak Dan Kewajiban Pasien Dalam Pelayanan KesehatanHassan As 'AriBelum ada peringkat

- Manajemen Pencegahan Surveilans Untuk Infeksi Nosokomial 4Dokumen14 halamanManajemen Pencegahan Surveilans Untuk Infeksi Nosokomial 4Lucas TobingBelum ada peringkat

- Pedoman Teknis Tata Udara RsDokumen89 halamanPedoman Teknis Tata Udara Rsbung_tomo2013100% (5)

- Permenkes 161Dokumen17 halamanPermenkes 161ZaenuriBelum ada peringkat

- PBM Menteri Dalam Negeri Dan MENKES No. 162 TTG Pelaporan Kematian Dan Penyebab KematianDokumen5 halamanPBM Menteri Dalam Negeri Dan MENKES No. 162 TTG Pelaporan Kematian Dan Penyebab KematiankrisnandarBelum ada peringkat

- Guideline Infection Surv Hospital BahasaDokumen25 halamanGuideline Infection Surv Hospital BahasamasmblinkBelum ada peringkat

- Hak Dan Kewajiban Pasien Dalam Pelayanan KesehatanDokumen29 halamanHak Dan Kewajiban Pasien Dalam Pelayanan KesehatanHassan As 'AriBelum ada peringkat