SCAT Accident

Diunggah oleh

Jonathan BerylDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

SCAT Accident

Diunggah oleh

Jonathan BerylHak Cipta:

Format Tersedia

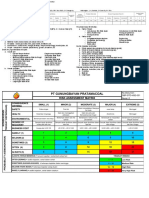

SCAT Chart - Systematic Cause Analysis technique - SCAT Chart

JELASKAN KEJADIAN KECELAKAAN

EVALUASI POTENSI KERUGIAN JIKA TDK DIKENDALIKAN

O Jarang ( C )

Potensi Keparahan Kerugian Probabilitas Kejadian Frekuensi Paparan

O Mayor ( a ) O Serius ( B ) O Minor ( C ) O Tinggi ( A ) O Sedang ( B ) O Jarang ( C ) O Tinggi ( A ) O Sedang ( B )

Jenis Contact atau hampir Kontak dengan Energi atau Zat

1 Menabrak/bentur benda diam/bergerak (See I.C's: 3 Jatuh dari tempat yang lebih tinggi 5 Tusuk, jepit, cubit benda runcing 7 Terperangkap diantra atau dibawah (Hancur Or diamputasi)

1,2,4,5,12,14,16,17,18,19,26) (See I.C's:3,5,6,7,11,12,13,14,

15,16,17,22) (see I.C's:

5,6,11,13,14,15,16,18) (See I.C's: 1,2,5,6,9,11,12,13,14,15,16,22,28)

2 Terpukul/tabrak oleh benda bergerak 4 Jatuh di tempat yang datar 6 Terjepit,tangkap,jebak diantara obyek besar 8 Kontak dengan (Listrik, Panas, Dingin, Radiasi, Kaustik,

(See I.C's: 1,2,4,5,

6,9,10,12,13,14,15,16,20,26) See I.C's: 4,9,13,14,15,16,19,22,26) (See I.C's:

5,6,11,12,13,14,15,16,18) Racun, Bising)(See I.C's:5,6,7,11,12,13,14,15,16,17,18,

(IC's) Immediate/Direct Causes (IC's)

SUBSTANDARD/UNSAFE ACTS 7 Kegagalan menggunakan APD secara tepat(See B.C's: 2,3,4,5,7,8 13 Bersenda gurau (See B.C's:2,3,4,5,7,8,13,15) 20 Sistem peringatan yang tidak memadai (See B.C's:8,9,10,11

1 Mengoperasikan Peralatan Tanpa Authority (See B.C's 10,12,13,15) 14 Dibawah pengaruh alkohol dan obat yang lainnya 21 Bahaya kebakaran dan ledakan (See B.C's:5,6,7,8,9,10,11,12,

2,4,5,7,8,12,13,15) 8 Beban tidak sesuai (See B.C's:1,2,3,4,5,6,7,8,9,12 (See B.C's:2,3,4,5,7,8,13,15) 13,15)

2 Gagal untuk meperingatkan (See B.C's: 1,2,3,4,5,6,7,8,9,12, 13,15) 15 Menggunakan peralatan secara tdk tepat (See B.C's: 22 Housekeeping yang buruk/berantakan (See B.C's: 5,6,7,8,9,10,11

13,15) 9 Penempatan tidak tepat (See B.C's: 1,2,3,4,5,6,7,8,9, 1,2,3,4,5,6,7,8,9,10,12,13,15) 12,13,15)

3 Kegagalan untuk mengamankan (See B.C's:2,3,4,5,6,7,8,9,12 12,13,15) 16 Pengaman atau penghalang yang tidak memadai (See B.C's 23 Paparan kebisingan (See B.C's: 5,6,7,8,9,10,11,12,13,14)

13,15) 10 Mengangkat tidak tepat (See B.C's:1,2,3,4,5,6,7,8,9,12,13 5,7,8,9,10,11,12,13,15) 24 Paparan radiasi (See B.C's: 5,6,7,8,9,10,11,12,13,14)

4 Mengoperasikan pada kecepatan yang tdk sesuai (See B.C's:2,3,4 15) 17 Peralatan pelindung yang tdk memadai atau tdk sesuai.

5,6,7,8,) 11 Posisi tugas tdk tepat (See B.C's: 1,2,3,4,5,6 (See B.C's: 5,7,8,9,10,12,13) 25 Temperature Extremes (See B.C's: 1,2,3,8,9,11,12

5 Membuat peralatan pengaman tdk berfungsi (See B.C's 7,8,9,12,13,15) 18 Bahan, peralatan atau tools dalam kondisi rusak (See

2,3,4,5,6,7,8,9,12,13,15) 12 Menservis peralatan dalam kondisi beroperasi (See B.C's:2,3,4,5 B.C's: 8,9,10,11,12,13,14,15)

6 Menggunakan peralatan rusak (See B'C's: 2,3,4,5,6 6,7,8,9,12,13,15) 19 Kemacetan atau tindakan terbatas (See B.C's:

7,8,9,10,11,12,13,14,15) 8,9,13)

(BC's) Basic / Underlying Causes (BC's)

PERSONAL FACTORS

1 Kemampuan Fisik / Fisiologis tdk memadai 4 Mental atau psikologis Stres 7.11. Contoh dari supervisor yg tdk benar 10 Pembelian yang tdk Memadai

(See CAN: 6,9,12,15,18) (See CAN: 1,4,5,6,10,11,12,15,16,18,20) 7.12. Feedback (umpan balik) kinerja yg tdk tepat (See CAN: 1,3,4,6,9,12,13,14,15,19)

1.1 Tinggi, berat, ukuran, kekuatan, pencapaian, dll 4.1 Kelebihan beban emosional 7.13. Kurangnya penekanan pada perilaku yg benar 10.1

tdk memadai 4.2 Kelelahan mental karena beban tugas 7.14. Insentif produksi yg kurang memadai 10.2

1.2 Keterbatasan gerak badan 4.3 Tuntutan penilaian / keputusan yang ekstrim 10.3

1.3 Keterbatasan kemampuan untuk mempertahankan posisi tubuh 4.4 Rutin, monoton, penjagaan membosankan Faktor Pekerjaan 10.4

1.4 Alergi atau sensitif terhadap bahan kimia 8 Kepemimpinan/supervisi yang tidak memadai 10.5

1.5 Sensivitas yang ekstrem dari sistem sensorik 4.5 Tuntutan konsentrasi / persepsi yang ekstrim 8.1 Sistem pelaporan yang tidak jelas atau bertentangan

(temperature, suara, etc) 4.6 Aktivitas tdk berarti atau menurun 8.2 Penugasan atau tanggung jawab yang tdk jelas atau bertentangan 10.6

1.6 Defisiensi penglihatan 4.7 Arahan / tuntutan yang membingungkan 8.3 Pendelegasi yang tidak benar atau tidak memadai

1.7 Defisiensi pendengaran 4.8 Tuntutan/arahan yang bertentangan 8.4 Kebijakan, prosedur, praktek, guideline 10.7

1.8 Defisiensi sistem sensor yang lain (raba, 4.9 Penuh dengan masalah yang tdk memadai 10.8

rasa, bau, keseimbangan) 4.10. Frustasi 8.5 Memberikan target, sasaran, tujuan atau standar yang konflik 10.9

1.9 Ketidakmampuan sistem pernapasan 4.11. Sakit mental 8.6 Program atau perencanaan kerja yang tdk memadai 10.10.

1.10. Ketidakmampuan permanen fisik lainnya 8.7 Training, orientasi dan instruksi yang tdk memadai

1.11. Cacat sementara 5 Lack of Knowledge 8.8 Dokumen referensi, peraturan, petunjuk 10.11

(See CAN:2,4,5,6,7,8,9,10,11,12,13,15,16,18,20) yang tdk memadai 10.12

2 Kemampuan mental/psikologis yang tdk memadai 5.1 Kurang pengalaman 8.9 Identifikasi dan evaluasi paparan kerugian

(See CAN: 6,9,10,15,18) 5.2 Orientasi tdk mencukupi yang tdk memadai 11 Perawatan yg tdk memadai

2.1 Ketakutan dan probias 5.3 Training awal tdk memadai 8.10. Kekurangan dalam hal pengetahuan manajemen pekerjaan ( See CAN: 1,3,4,5,9,10,13,15,19)

2.2 Gangguan Emosional 5.4 Update training tdk memadai dan pengawasan. 11.1

2.3 Sakit Mental 5.5 Kesalahpahaman thd arahan / instruksi 8.11 Kualifikasi pekerja yg tdk cocok dengan persyaratan

2.4 Tingkat intelenjensia pekerjaan atau tugas

2.5 Ketidakmampuan untuk memahami 6 Lack of Skill 8.12 Evaluasi dan pengukuran kinerja pekerja

2.6 Penilaian yg buruk (See CAN: 2,4,5,6,7,9,10,13,15,18) yang tdk memadai

2.7 Koordinasi yg buruk 6.1 Instruksi awal tidak memadai 8.13 Umpan balik kinerja yang tdk memadai dan tdk benar 11.2

2.8 Waktu reaksi yg lambat 6.2 Praktek tdk memadai

2.9 Bakat mekanik rendah 6.3 Kinerja rendah 9 System Engineering yg tdk memadai

2.10. Bakat belajar rendah 6.4 Kurang pengawasan/bimbingan (See CAN: 1,2,3,4,9,12,13,14)

2.11. Kegagalan ingatan 6.5 Peninjaun intsruksi tdk memadai 9.1 Penilaian potensi kerugian paparan yg tdk memadai

9.2 Pertimbangan faktor manusia atau ergonomik

3 Stres fisik atau fisiologis 7 Motivasi yang tidak benar yg tdk memadai 12 Peralatan dan tools yg tdk memadai

(See CAN: 4,6,9,11,12,13,15,18,20) (See CAN: 1,2,4,5,6,8,10,11,13,15,17,18) 9.3 Standar, spesifikasi atau kriteria disain (See CAN: 1,3,4,6,7,9,11,12,13,14,15,19)

3.1 Cedera penyakit 7.1 Kinerja yg tdk benar dihargai yg tdk memadai 12.1

3.2 Kelelahan karena beban tugas atau durasi 7.2 Kinerja yang tidak benar dihukum 9.4 Monitoring konstruksi yg tdk memadai

3.3 Kelelahan karena kurang istirahat 7.3 Insentive kurang 9.5 Penilaian kesiapan pengoperasian yg tdk memadai 12.2

3.4 Kelelahan karena overload sensorik 7.4 Frustasi yang berlebihan

3.5 Paparan bahaya kesehatan 7.5 Agresi yg tdk pantas 9.6 Kontrol yg tdk tepat atau tdk memadai 12.3

3.6 Paparan suhu ekstrim 7.6 Upaya yang tidak benar untuk menghemat waktu atau usaha 9.7 Monitoring awal pengoperasian yg tdk memadai 12.4

3.7 Kekurangan oksigen 7.7 Upaya yang tidak benar untuk menghindari ketidaknyamanan 9.8 Evaluasi perubahan yg tdk memadai 12.5

3.8 Variasi tekanan atmosfer 7.8 Upaya yang tidak tepat untuk mendapatkan perhatian 12.6

3.9 Insufisiensi gula darah 7.9 Disiplin yang tidak memadai 12.7

3.10. Obat-obatan 7.10. Tekanan dari rekan kerja yang tdk benar

(CAN) Control Action Needs (CAN)

1 LEADERSHIP AND ADMINISTRATION 5 ACCIDENT AND INCIDENT INVESTIGATION 10 EMPLOYEE TRAINING 16 GROUP MEETING

Program Present (P), Standards (S), Compliance ( C ) Program Present (P), Standards (S), Compliance ( C ) P S C Program Present (P), Standards (S), Compliance ( C ) P S C Program Present (P), Standards (S), Compliance ( C )

P S C

1.1 General Policy 5.1 Accident/Incident Investigation Procedure 10.1 Training Needs Analysis 16.1

1.2 Program Coordinator 5.2 Scope of Investigations Established 10.2 Employee Training Program 16.2

1.3 Senior and Middle Management Participation 5.3 Remedial Follow-up and Action 10.3 Training Program evaluation

1.4 Management Performance Standards 5.4 Major Accident Announcement Used 16.3

1.5 Management Participation 5.5 High Potential Incident Information Used 11 PERSONAL PROTECTIVE EQUIPMENT 16.4

1.6 Presentation at Management Meeting 5.6 Operating management Participation Program Present (P), Standards (S), Compliance ( C ) P S C

1.7 Management Reference Manual 5.7 Incident Reporting and Investigation 11.1 Personal Protective Equipment Standards 17. GENERAL PROMOTION

1.8 Management Audits Conducted 5.8 Accident/Incident Report Maintenance 11.2 Personal Protective Equipment Program Present (P), Standards (S), Compliance ( C )

1.9 Individual Responsibility for Safety and health 5.9 Regular Program Monitoring Recordkeeping 17.1

/Loss Control Objectives 11.3 Enforcement of Standards 17.2

1.10. Establishment of Annual Safety and Health 6 TASK OBSERVATION 11.4 Regular Program Monitoring 17.3

/Loss Control Objectives Program Present (P), Standards (S), Compliance ( C ) P S C 17.4

1.11 Joint safety & Health Committees and/or 6.1 Management Directive on Importance 12 HEALTH CONTROL 17.5

Safety and Health Representatives 6.2 Complete Task Observation Program Program Present (P), Standards (S), Compliance ( C ) P S C 17.6

1.12 Refusal to Work on Grounds of safety & 6.3 Level of Complete Task Observations 12.1 Health Hazard Identification 17.7

Health Hazard (s) procedure 6.4 Partial Task Observation Program 12.2 Health hazard Control 17.8

1.13 reference Library 6.5 Task Observation Report Analysis 12.3 Information/Training/education

6.6 Regular Program Monitoring 12.4 Industrial Hygiene Monitoring 18 HIRING AND PLACEMENT

2 MANAGEMENT TRAINING 12.5 Health Maintenance program Program Present (P), Standards (S), Compliance ( C )

Program Present (P), Standards (S), Compliance ( C ) P S C 7 EMERGENCY PREPAREDNESS 12.6 Professional Medical Assistance 18.1

2.1 Management Orientation/Induction Program Program Present (P), Standards (S), Compliance ( C ) P S C 12.7 Health Communications to Worker 18.2

2.2 Formal Initial Training of Senior Management 7.1 Coordinator Appointed 12.8 Record Maintenance 18.3

personnel 7.2 emergency Plan in Writing 18.4

2.3 Formal Review and update Training of senior 7.3 Supervisory Training in First Aid 13 PROGRAM EVALUATION SYSTEM

P S C

Management Personnel 7.4 Employee Training in First Aid (10%) Program Present (P), Standards (S), Compliance ( C )

2.4 Formal iInitial Training of Supervisory and 7.5 Emergency Lighting and Power 13.1 Comprehensive Audit of Compliance with 19 PURCHASING CONTROLS

Middle Management Personnel Adequate Program standards Program Present (P), Standards (S), Compliance ( C )

2.5 Formal Review and Update Training of 7.6 Master Controls Color Coded and 13.2 Comprehensive Audit of Compliance with 19.1

Supervisory and Middle Management Labeled Physical Conditions standards

personnel 7.7 Protective and Rescue Equipment 13.3 Comprehensive Audit of Compliance with 19.2

2.6 Formal Training of program coordinator 7.8 Emergency Team Training and Drills Fire Prevention and Control Standards

7.9 Qualified First Aid Attendants 13.4 Comprehensive Audit of Compliance with 20 OFF-THE-JOB SAFETY

3 PLANNED INSPECTIONS 7.10. Organized Outside Help and Mutual Occupational Health Standards Program Present (P), Standards (S), Compliance ( C )

Program Present (P), Standards (S), Compliance ( C ) P S C Aid 13.5 Program Evaluation Systems Record 20.1

3.1 Planned General Inspections 7.11 Protection of Vital Records Keeping

3.2 Follow-up Procedures 7.12 Post Event Planning 20.2

3.3 Inspection report Analysis 7.13 Emergency Communication Provided 14 ENGINEERING CONTROL

3.4 Critical Parts/Items Inspection Program 7.14 Public Safety Communications Planned Program Present (P), Standards (S), Compliance ( C ) P S C

3.5 Preventive Maintenance Program 14.1 Design Engineering Safety and Health Con-

3.6 Mobile and Material-Handling Pre-Use 8 ORGANIZATIONAL RULES siderations at conception and Design

Equipment Inspections Program Present (P), Standards (S), Compliance ( C ) P S C 14.2 process Engineeing Safety and Health

3.7 Alternative Conditions Reporting System 8.1 General safety and Health Rules Consideration at Conception and Design LEGEND

3.8 Planned general Inspection Report 8.2 Specialized Work Rules 14.3 Regular Program Monitoring

Maintenance 8.3 Work Permit and specialized procedures P

3.9 regular Program Monitoring Systems 15 PERSONAL COMMUNICATIONS

P S C

8.4 Rule education and Review Program Program Present (P), Standards (S), Compliance ( C ) S

4 TASK ANALYSIS AND PROCEDURES 8.5 Rule Compliance Effort 15.1 Training in Personal Communication

Program Present (P), Standards (S), Compliance ( C ) P S C 8.6 Use of Educational Signs and Color Technique C

4.1 Management Directive on Importance Codes 15.2 Job Orientation/Induction New/Transferred

4.2 Critical Task Inventory 8.7 Regular program Monitoring People

4.3 Task Analysis and Task Procedure 15.3 Proper Task Instruction Traning and Use

Objectives 9 ACCIDENT/INCIDENT ANALYSIS 15.4 Planned Personal Contact Program

4.4 Task Analysis and Procedures for Program Present (P), Standards (S), Compliance ( C ) P S C 15.5 Regular Program Monitoring

Critical Task Completed and regularly 9.1 performance statistics Computed and used

Updated 9.2 Occupational Injury and Illness Analysis

4.5 Safety and Health Hazards in Critical 9.3 Property and Equipment Damage

task Analyses and procedures Identification and analysis

4.6 Regular program Monitoring 9.4 Problem Solving project Teams

ran

O Sedang ( B ) O Rendah( C )

Terperangkap diantra atau dibawah (Hancur Or diamputasi)

(See I.C's: 1,2,5,6,9,11,12,13,14,15,16,22,28) 20,21,23,24,25,27,28)

Kontak dengan (Listrik, Panas, Dingin, Radiasi, Kaustik, 9 Tekanan berlebih, Kelelahan

Racun, Bising)(See I.C's:5,6,7,11,12,13,14,15,16,17,18, (See I.C's:8,9,10,11,13,14,15)

Sistem peringatan yang tidak memadai (See B.C's:8,9,10,11 26 Penerangan yang tidak memadai atau berlebihan

Bahaya kebakaran dan ledakan (See B.C's:5,6,7,8,9,10,11,12, (See B.C's:8,9,10,11,12,13)

27 Ventilasi tdk memadai (see B.C's:)

Housekeeping yang buruk/berantakan (See B.C's: 5,6,7,8,9,10,11 8,9,10,11,12)

12,13,15) 28 Kondisi lingkungan yang berbahaya

Paparan kebisingan (See B.C's: 5,6,7,8,9,10,11,12,13,14) (See B.C's:8,9,10,11,12,13)

Paparan radiasi (See B.C's: 5,6,7,8,9,10,11,12,13,14)

Temperature Extremes (See B.C's: 1,2,3,8,9,11,12

Pembelian yang tdk Memadai 13 Standar Kerja Tdk Memadai

(See CAN: 1,3,4,6,9,12,13,14,15,19) (See CAN: 1,2,3,4,5,6,7,8,9,10,11,

Spesifikasi yg tdk sesuai permintaan 12,13,14,15,16,19)

Penelitian yang tidak memadai pada bahan / perala 13.1 Pengembangan standar yg tdk memadai;

Spesifikasi tdk memadai untuk vendor 13.1.1. Evaluasi dan inventory dari

Mode atau rute pengiriman yg tdk memadai kebutuhan dan paparan

Inspeksi penerimaan yang tidak memadai 13.1.2. Koordinasi disain proses

13.1.3. Keterlibatan karyawan

Komunikasi data keselamatan dan kesehatan 13.1.4. Procedures/practices/rules

yang tdk memadai 13.2 Komunikasi standar yg tdk memadai;

Penanganan material yg tdk tepat 13.2.1. Publikasi

Penyimpanan Material yg tdk tepat 13.2.2. Distribusi

Pengiriman material yg tdk tepat 13.2.3. Terjemahan untuk bahasa

Identifikasi item-item berbahaya yg tdk memadai yg sesuai

items 13.2.4. Training

Penyelamatan atau pembuangan limbah yg tdk tepat 13.2.5. Memperkuat dengan tanda, warna,

Pemilihan kontraktor yg tdk tepat kode dan alat bantu pekerjaan

13.3 Standar perawatan tdk memadai;

Perawatan yg tdk memadai 13.3.1. Penelusuran alur kerja

( See CAN: 1,3,4,5,9,10,13,15,19) 13.3.2. Memperbarui/update

Pencegahan yg tdk memadai 13.3.3. Memonitor penggunaan prosedur/

11.1.1. Penilaian kebutuhan peraturan atau praktek kerja.

11.1.2. Lubrikasi and servis 13.4 Monitoring kepatuhan tdk memadai

11.1.3. Penyesuaian / perakitan

11.1.4. Pembersihan 14 Exercise Wear and Tear

Perbaikan yg tdk memadai (See CAN: 3,4,6,9,10,13,14,15)

11.2.1. Komunikasi kebutuhan 14.1 Perencanaan penggunaan yg tdk memadai

11.2.2. Jadual pekerjaan 14.2 Perpanjangan waktu service yg tdk tepat

11.2.3. Pengujian unit 14.3 Inspeksi atau monitor yg tdk memadai

11.2.3. Pengantian part 14.4 Beban atau tingkat pengunaan yg tdk tepat

14.5 Perawatan yg tdk memadai

Peralatan dan tools yg tdk memadai 14.6 Digunakan oleh orang yg tdk ditraining

(See CAN: 1,3,4,6,7,9,11,12,13,14,15,19) 14.7 Digunakan utk tujuan yg salah

Penilain kebutuhan dan risiko

yg tdk memadai 15 Penyalahgunaan

Pertimbangan faktor kesalahan manusia 15.1 Perilaku yang tidak benar yang dibiarkan

/ergonomik yg tdk memadai 15.1.1. Sengaja

Standar atau spesifikasi yg tdk memadai 15.1.2. Tdk Sengaja

Ketersediaan yg tdk memadai 15.2 Perilaku yang tidak benar yang tydk dibiarkan

Perawatan / penyesuaian yg tdk memadai 15.2.1. Sengaja

Reklamasi dan penyelamatan yg tdk memadai 15.2.2. Tdk Sengaja

Penggantian dan pemindahan item-item

yg cocok tdk memadai

GROUP MEETING

Program Present (P), Standards (S), Compliance ( C ) P S C

Group Meeting Held

Record of Subject, Visual Aid, Attendance,

Problems Discussed

Middle and Top Management Involvement

Regular Program Monitoring

7. GENERAL PROMOTION

Program Present (P), Standards (S), Compliance ( C ) P S C

safety Bulletin Board Program

Use of program statistics and facts

Critical Topic Promotion

Use of Awards or Recognition

Program Information Publication

Group Performance Promotion

Housekeeping Promotion

Records of Program Promotion Activities

HIRING AND PLACEMENT

Program Present (P), Standards (S), Compliance ( C ) P S C

Physical Capability Analyses

Pre-Employment Physical examination

General Orientation/Induction Program

Pre-Employment/Pre-Placement Qualifica-

tion Checks

PURCHASING CONTROLS

P S C

Program Present (P), Standards (S), Compliance ( C )

Purchasing Includes safety and health in

Specifications and Procurement

Selection and Control of Contractor

OFF-THE-JOB SAFETY

Program Present (P), Standards (S), Compliance ( C ) P S C

Reporting System Established and statistics

Analyzed

Off-the-job safety Information Communi-

cated

LEGEND

Do we have program standards for this activity?

Are existing standards adequate?

Is there full compliance with standards?

Anda mungkin juga menyukai

- SCAT Analysis - Revisi InshaAllah BenerDokumen1 halamanSCAT Analysis - Revisi InshaAllah BenerHisyam SyafiqBelum ada peringkat

- F FDH Epc 012 Tabel Cat IndoDokumen7 halamanF FDH Epc 012 Tabel Cat IndoHANIF AKBARBelum ada peringkat

- SCAT Accident INDONESIADokumen2 halamanSCAT Accident INDONESIAAnisful Lailil MunawarohBelum ada peringkat

- SCAT Versi LamaDokumen15 halamanSCAT Versi LamaagustiawanBelum ada peringkat

- 4 - 2 - Systematic Cause Analysis TechniqueDokumen3 halaman4 - 2 - Systematic Cause Analysis TechniqueGusriantoBelum ada peringkat

- SCAT IndonesiaDokumen3 halamanSCAT IndonesiaAndri San100% (3)

- SCAT Formulir TerbaruDokumen3 halamanSCAT Formulir Terbaruryan chirillaBelum ada peringkat

- 06.2. SCAT Indonesia (Color)Dokumen3 halaman06.2. SCAT Indonesia (Color)BerlyYanuariNoerPrasusi100% (3)

- SCATDokumen12 halamanSCATDiyan M RamdaniBelum ada peringkat

- Scat IndonesiaDokumen3 halamanScat IndonesiaindraBelum ada peringkat

- SCAT Accident AnalisisDokumen16 halamanSCAT Accident Analisisnovy nur kusumawardhaniBelum ada peringkat

- Potensi Kecelakaan KerjaDokumen57 halamanPotensi Kecelakaan Kerjaheri100% (1)

- Analisa Ikp - RcaDokumen58 halamanAnalisa Ikp - RcaWilly Damas DzakiBelum ada peringkat

- Analisa Insiden Dengan RCA Labkesda Arjaty 2021Dokumen58 halamanAnalisa Insiden Dengan RCA Labkesda Arjaty 2021Ardi PutriBelum ada peringkat

- 01 - Petunjuk Pengisian Tabel HIRADC Dan Aspek DampakDokumen4 halaman01 - Petunjuk Pengisian Tabel HIRADC Dan Aspek DampakJohn ZebuaBelum ada peringkat

- By: Agus Triyono, M.KesDokumen33 halamanBy: Agus Triyono, M.KesivourwahBelum ada peringkat

- Risk Management - Form - ContohDokumen4 halamanRisk Management - Form - ContohnanoBelum ada peringkat

- Presentasi RcaDokumen79 halamanPresentasi RcaRumah Sakit SANSANIBelum ada peringkat

- LAPORAN KEJADIAN Pasien Di RsDokumen15 halamanLAPORAN KEJADIAN Pasien Di RsSuhendi Uciha MadaraBelum ada peringkat

- Register Rawat Jalan Balita Sakit (Revisi Final)Dokumen3 halamanRegister Rawat Jalan Balita Sakit (Revisi Final)winaBelum ada peringkat

- Indentifikasi, Analisis Dan Tindak Lanjut Manajemen Resiko Kia-KbDokumen10 halamanIndentifikasi, Analisis Dan Tindak Lanjut Manajemen Resiko Kia-KbMuhammad IRsan86% (7)

- RISK MANAGEMENT - BalancingDokumen11 halamanRISK MANAGEMENT - BalancingDenny Kurniawan PrawiraBelum ada peringkat

- RISK Register Unit Jenazah 2022Dokumen5 halamanRISK Register Unit Jenazah 2022yevi eryantiBelum ada peringkat

- Analisa Kecelakaan KerjaDokumen34 halamanAnalisa Kecelakaan KerjaKostan AbdillahBelum ada peringkat

- Checklist Harian AlkesDokumen5 halamanChecklist Harian AlkesLienaBelum ada peringkat

- Indentifikasi, Analisis Dan Tindak Lanjut Manajemen Resiko ImunisasiDokumen10 halamanIndentifikasi, Analisis Dan Tindak Lanjut Manajemen Resiko ImunisasiMuhammad IRsan75% (4)

- 1 Laporan Tahunan 2022 Risk RegisterDokumen13 halaman1 Laporan Tahunan 2022 Risk RegisterM Rivan AlentinoBelum ada peringkat

- Form Laporan PerkesmasDokumen47 halamanForm Laporan PerkesmasApihna Ad Id AnBelum ada peringkat

- Data Jumlah Unit Yang Belum Dan Sudah Direalkan (Agunan Dan Non Agunan)Dokumen2 halamanData Jumlah Unit Yang Belum Dan Sudah Direalkan (Agunan Dan Non Agunan)ariantoelmalikBelum ada peringkat

- Bab 9 GGDokumen14 halamanBab 9 GGTaufikurrachmanBelum ada peringkat

- Kelengkapan Berkas Klaim Bpjs Dan KisDokumen2 halamanKelengkapan Berkas Klaim Bpjs Dan KisrsudtengkusulungBelum ada peringkat

- Laporan Investigasi KecelakaanDokumen5 halamanLaporan Investigasi KecelakaanBondet CutaxBelum ada peringkat

- Buku Bantu Balita PDFDokumen1 halamanBuku Bantu Balita PDFBudi AstikaBelum ada peringkat

- Blanko Monitoring Oppe IccuDokumen3 halamanBlanko Monitoring Oppe Iccueen puriyatiBelum ada peringkat

- Contoh Form Penilaian Kinerja PrasaranaDokumen4 halamanContoh Form Penilaian Kinerja PrasaranaDhestiana SulistyaningsihBelum ada peringkat

- Proses Penilaian Bahaya Dan RisikoDokumen3 halamanProses Penilaian Bahaya Dan RisikoBlack Tirah TirahBelum ada peringkat

- Fm-Ibpe-Hse-043 Report Insident RendahDokumen6 halamanFm-Ibpe-Hse-043 Report Insident Rendahdwijaapriadyy14Belum ada peringkat

- Daftar MainriskDokumen211 halamanDaftar MainriskNila Permata SariBelum ada peringkat

- Checklist Supervisi Pengumpulan DataDokumen80 halamanChecklist Supervisi Pengumpulan DataDwi RahmaBelum ada peringkat

- Tools Manajemen RisikoDokumen45 halamanTools Manajemen RisikoDewa OkaBelum ada peringkat

- Form Laporan STBMDokumen4 halamanForm Laporan STBMcut irnandaBelum ada peringkat

- Pelaporan IKP PuskesmasDokumen39 halamanPelaporan IKP Puskesmashening andityaBelum ada peringkat

- Template Manajemen ResikoDokumen30 halamanTemplate Manajemen ResikoMitha Aulia IIBelum ada peringkat

- Cek List Harian LINENDokumen4 halamanCek List Harian LINENSugiBelum ada peringkat

- Master Pd. KLP - PSN & RcaDokumen66 halamanMaster Pd. KLP - PSN & RcaPondok KelapaBelum ada peringkat

- Formulir Identifikasi BahayaDokumen3 halamanFormulir Identifikasi Bahayatitik sumartiniBelum ada peringkat

- Register Resiko Admen 2023Dokumen21 halamanRegister Resiko Admen 2023bangkit setyaBelum ada peringkat

- Tugas Manajemen Risiko Pelatihan Provinsi NTT 20 Oktober 2020 - MB Winda, PerkecilDokumen9 halamanTugas Manajemen Risiko Pelatihan Provinsi NTT 20 Oktober 2020 - MB Winda, PerkecilSri WatiBelum ada peringkat

- Draft HIRADC Dan Matriks TemplateDokumen3 halamanDraft HIRADC Dan Matriks Templatefirman2012Belum ada peringkat

- Praktek Demo 1Dokumen2 halamanPraktek Demo 1IrpandiBelum ada peringkat

- Pengendalian Potensi Bahaya BesarDokumen29 halamanPengendalian Potensi Bahaya BesarAbraham AlfanBelum ada peringkat

- Formulir Pemantau SuhuDokumen1 halamanFormulir Pemantau SuhuRinna TriyanaBelum ada peringkat

- Senarai Semak OSHWA - myKKP Jentera - Https - Mykkp - Dosh.gov - My - myKKPJentera - Semakan - SemakanOSHWADokumen6 halamanSenarai Semak OSHWA - myKKP Jentera - Https - Mykkp - Dosh.gov - My - myKKPJentera - Semakan - SemakanOSHWARedzwan Kadir100% (2)

- IBPR (Identifikasi Bahaya Dan Penilaian Resiko)Dokumen38 halamanIBPR (Identifikasi Bahaya Dan Penilaian Resiko)AF ArysandiBelum ada peringkat

- Kri Kku - Pemantauan Bulanan 2022Dokumen1 halamanKri Kku - Pemantauan Bulanan 2022Hendry LuaseBelum ada peringkat

- Pelaporan IKP Puskesmas (KAAKP 9 Sept 2021) ArjatyDokumen48 halamanPelaporan IKP Puskesmas (KAAKP 9 Sept 2021) ArjatyYoestysryBelum ada peringkat

- Dosis Pemberian Dopamin 200mgDokumen3 halamanDosis Pemberian Dopamin 200mgJoko Coldplay DhaniBelum ada peringkat

- PAK, KAK, CAKK, RCA, Manris 2019Dokumen42 halamanPAK, KAK, CAKK, RCA, Manris 2019AnnaBelum ada peringkat

- Resume Materi Kebijakan Dan Uu PDFDokumen2 halamanResume Materi Kebijakan Dan Uu PDFJonathan BerylBelum ada peringkat

- HSE Plan Tank Lirik UnlockedDokumen112 halamanHSE Plan Tank Lirik UnlockedJonathan BerylBelum ada peringkat

- Divisi KonsumsiDokumen2 halamanDivisi KonsumsiJonathan BerylBelum ada peringkat

- P2 TB Ak3u 2020Dokumen41 halamanP2 TB Ak3u 2020Jonathan BerylBelum ada peringkat

- Anggaran HSDokumen5 halamanAnggaran HSJonathan BerylBelum ada peringkat

- Pengawasan K3 Penanggulangan KebakaranDokumen78 halamanPengawasan K3 Penanggulangan KebakaranJonathan BerylBelum ada peringkat

- K3 ListrikDokumen117 halamanK3 ListrikJonathan BerylBelum ada peringkat

- Norma K3 Penanggulangan KebakaranDokumen27 halamanNorma K3 Penanggulangan KebakaranJonathan BerylBelum ada peringkat

- K3 LISTRIK KOnsDokumen72 halamanK3 LISTRIK KOnsJonathan BerylBelum ada peringkat