Accident Investigation SCAT CHART

Accident Investigation SCAT CHART

Diunggah oleh

Fahmi NoviandriJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Accident Investigation SCAT CHART

Accident Investigation SCAT CHART

Diunggah oleh

Fahmi NoviandriHak Cipta:

Format Tersedia

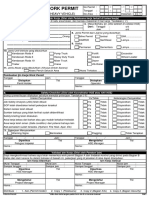

Diagram Sistematika Teknik Analisa Penyebab ( STAP )

URAIAN KEJADIAN KECELAKAAN

EVALUASI POTENSI KERUGIAN JIKA TIDAK DIKENDALIKAN

Potensial Parahnya Kerugian Kemungkinan Kejadian Kekerapan Kejadian

O Besar ( A ) O Sedang ( B ) O Ringan ( C ) O Sering ( A ) O Sedang ( B ) O Jarang ( C ) O Sering ( A ) O Sedang ( B ) O Jarang ( C )

Jenis Kontak atau Nyaris Kontak dengan Energi / Bahan

1 Menabrak (Lihat PL: 1, 2, 4, 5, 12, 14, 16, 17, 18, 19 26) 3 Jatuh dari ketinggian (Lihat PL : 3, 5, 6, 7, 11, 12, 13, 14, 15, 16, 17, 22) 5 Terjepit barang & barang berputar (lihat PL : 7 Terjepit diantara/d ibawah (remuk atau amputasi)

2 Ditabrak (Lihat PL : 1, 2, 4, 5 6, 9, 10, 12, 13, 14, 15, 16, 20, 26) 4 Jatuh pada permukaan sama (Terpeleset) 5, 6, 11, 13, 14, 15, 16, 18) (Lihat PL : 1, 2, 5, 6, 9,11, 12, 13, 14, 15, 16, 22, 28) 20, 21, 23, 24, 25, 27,28)

(Lihat PL : 4, 9, 13, 14, 15, 16, 19, 22, 26) 6 Terkena (Sobekan, tonjolan (Lihat PL : 8 Kontak dengan listrik, panas, dingin, radiasi, kaustik 9 Stress berlebihan, pengerahan berlebihan

2, 6, 11, 12, 13, 14, 15, 16, 18) racun, kebisingan (Lihat PL : 5, 6, 7, 11, 12, 13, 14, 15, 16, 17, 18 (Lihat PL : 8, 9, 10, 11, 13, 14, 15)

(PL) Penyebab Langsung

TINDAKAN YANG TIDAK AMAN 7 Gagal Menggunakan pelindung diri yang benar (Lihat PD : 2.3.4.5.7.8 13 Bergurau (Lihat PD : 2.3.4.5.7.8.13.15) 20 Sistem peringatan yang tak memadai (Lihat PD : 8.9.10.11.12.13)

1 Pengoperasian peralatan tanpa wewenang (Lihat PD : 10.12.13.15) 14 Pengaruh obat atau alkohol 21 Bahaya kebakaran & peledakan (Lihat PD : 5.6.7.8.9.10.11.12.13.15)

2. 4. 5. 7. 8. 12. 13. 15) 8 Pemuatan yang tak benar (Lihat PD : 1.2.3.4.5.6.7.8.9.12 (Lihat PD : 2.3.4.5.7.8.13.15) 22 Kebersihan & tata rumah tangga yang buruk (Lihat PD : 5.6.7.8.9.10.12.13.15)

2 Gagal memberi peringatan (Lihat PD : 1. 2. 3. 4. 5. 6. 7. 8. 9. 12. 13.15) 15 Menggunakan peralatan yang tidak benar : 23 Paparan keb. (Lihat PD : 5.6.7.8.9.10.11.12.13.14)

13. 15) 9 Penempatan yang tak Benar (Lihat P.D : 1.2.3.4.5.6.7.8.9 (1.2.3.4.5.6.7.8.9.10.12.13.15) 24 Paparan radiasi (Lihat PD : 5.6.7.8.9.10.11.12.13)

3 Gagal mengamankan (Lihat PD : 2.3.4.5.6.7.8.9.12.13.150 12.13.15) 16 Pelindung tak memadai (Lihat PD : 25 Suhu yang berlebihan (Lihat PD : 1.2.3.8.9.11.12)

4 Mengoperasikan dengan kecepatan tidak memadai 10 Pengangkatan yang tak benar (Lihat PD : 1.2.3.4.5.6.7.8.9.12.13 5.7.8.9.10.11.12.13.15) 26 Suhu berlebihan (Lihat PD : 8.9.10.11.12.13)

(Lihat PD : 2. 3. 4. 5. 6. 7. 8) 15) 17 Peralatan pelindung tak memadai 27 Ventilasi tak memadai (Lihat PD : 8.9.10.11.12)

5 Membuat peralatan pengaman tidak berfungsi (Lihat PD : 11 Posisi melakukan pekerjaan yang tak benar (Lihat PD : 1.2.3.4.5.6 (Lihat PD : 5.7.8.9.10.12.13) 28 Kondisi lingkungan yang berbahaya (Lihat PD : 8.9.10.11.12.13)

2.3.4.5.6.7.8.9.12.13.15) 7.8.9.12.13.15) 18 Peralatan/material yang rusak (Lihat

6 Menggunakan peralatan yang rusak/ salah (lihat PD : 2.3.4.5.6 12 Menservis peralatan yang sedang jalan (Lihat PD : 2.3.4.5 PD : 8.9.10.11.12.13.14.15)

7.8.9.10.11.12.13.14.15) 6.7.8.9.12.13.15) 19 Tindakan yang terbatas/kongesti (Lihat PD : 8.9.13)

(PD) Penyebab Dasar

FAKTOR MANUSIA

1 Kemampuan fisik tak memadai 4 Stress mental 7.11 Contoh kepemimpinan yang tak benar 10 Pembelian tak memadai 13 Standard kerja tak memadai

(Lihat DTP : 6.9.12.15.18) (Lihat DTP : 1.4.5.6.10.11.12.15.16.18.20) 7.12 Umpan balik penampilan yang tak memadai (Lihat DTP : 1.3.4.6.9.12.13.14.15.19) (Lihat DTP : 1.2.3.4.5.6.7.8.9.10.11.

1.1 Tinggi, berat ukuran, kekuatan, jangkauan 4.1 Emosional yang berlebihan 7.13 Dukungan tingkah laku yang tak memadai 10.1 Spesifikasi permintaan tak memadai 12.13.14.15.16.19)

yg tidak sesuai, dsb 4.2 Kelelahan karena beban kerja mental 7.14 Insentif produksi yang tak benar 10.2 Penelitian material/peralt yg tak memadai 13.1 Pengembangan standard tak memadai untuk :

1.2 Pergerakan yg terbatas 4.3 Pertimbangan yang ekstrem 10.3 Spesifikasi dari vendor tak memadai 13.1.1 Investarisasi & evaluasi keterpaparan

1.3 Kemampuan yg tak terbatas utk menunjang badan 4.4 Rutin, monoton dan kebosanan FAKTOR PEKERJAAN 10.4 Bentuk/rute pengiriman tak memadai 13.1.2 Koordinasi dengan desain proses

1.4 Sensitif atau alergi terhadap bahan 4.5 Konsentrasi yang berlebihan 8 Kepemimpinan/pengawasan yg tak memadai 10.5 Pemeriksaan & penerimaan yang tak 13.1.3 Keterlibatan karyawan

1.5 Sensitif terhadap keadaan yg berlebihan 4.6 Kegiatan yang menurun (Lihat DTP : 1.2.3.4.5.6.8.9.10.11.12.13.14.15.16.17.18) memadai 13.1.4 Peraturan/orosedur

(temperatur, suara, dsb) 4.7 Pimpinan/petunjuk yg membingungkan 8.1 Hubungan pelaporan yang tidak jelas 10.6 Pemberitahuan & data K3 yg tak memadai

1.6 Kurang penglihatan 4.8 Pimpinan/petunjuk yg bertentangan 8.2 Punugasan & tanggung jawab yg tidak jelas & bertentangan 10.7 Penangan barang yg tak benar 13.2 Komunikasi standard tak memadai untuk :

1.7 Kurang pendengaran 4.9 Keasyikan dengan masalah-masalah 8.3 Penyerahan tugas tak jelas & bertentangan 10.8 Penyimpanan barang yg tak benar 13.2.1 Publikasi

1.8 Kurang kepekaan lainnya (berasa, 4.10 Frustasi 8.4 Pemberian pekerjaan, cara, petunjuk yang tak memadai 10.9 Transportasi barang yg tak benar 13.2.2 Distribusi

penciuman, keseimbangan dsb) 4.11 Sakit mental 8.5 Penentuan tujuan, gol/sasaran atau stand yg bertentangan 10.10 Identifikasi barang berbahaya tak memadai 13.2.3 Terelemahan bahasa

1.9 Gangguan pernafasan 8.6 Rencana/program kerja yang tak memadai 10.11 Penangan & pembuangan sampah yg 13.2.4 Pelatihan

1.10 Kemampuan fisik 5 Kurang pengetahuan 8.7 Instruksi, orientasi atau pelatihan yg tak memadai tak benar 13.2.5 Pelaksanaan tanda, kode warna & alat bantu

1.11 Ketidakmampuan sementara (Lihat DTP : 2.4.5.6.7.8.9.10.11.12.13.15.16.18.20) 8.8 Penyediaan dokumen referensi, publikasi petunjuk 10.12 Pemilihan kontraktor yg tak benar

5.1 Kurang pengalaman tak memadai 13.3 Pemeliharaan standard tak memadai untuk :

2 Kemampuan mental yg tak memadai 5.2 Orientasi tak memadai 8.9 Identifikasi & evaluasi kerugian yg mungkin timbul 11 Pemeliharaan tidak layak 13.3.1 Menyelusuri alur kerja

(Lihat DTP : 6.9.10.15.18) 5.3 Pelatihan tak memadai tak memadai (Lihat DTP : 1.3.4.5.9.10.13.15.19) 13.3.2 Yang terbaru

2.1 Ketakutan & pobi 5.4 Pelatihan mutakhir tak memadai 8.10 Kurangnya pengetahuan tentang fungsi 11.1 Preventive yg tak memadai 13.3.3 Pemantauan penggunaan prosedur

2.2 Gangguan emosional 5.5 Tidak mengerti petunjuk pengawas 11.1.1 Penaksiran kebutuhan

2.3 Sakit mental 8.11 Ketidak sesuaian kemampuan seseorang & tugas yang 11.1.2 Pelumasan dan servis 13.4 Pemantauan pemenuhan tak memadai

2.4 Tingkat intelegensi 6 Kurang trampil dikehendaki 11.1.3 Penyesuaian/pemasangan

2.5 Ketidakmampuan untuk memahami (Lihat DTP : 2.4.5.6.7.9.10.13.15.18) 8.12 Tolak ukur dan evaluasi penampilan yang tak 11.1.4 Pembersihan 14 Kerusakan dan keausan

2.6 Pertimbangan yang kurang 6.1 Instruksi awal tak memadai memadai 11.2 Perbaikan yg tak memadai (Lihat DTP : 3.4.6.9.10.13.14.15)

2.7 Koordinasi yang kurang baik 6.2 Praktek tak memadai 8.13 Umpan balik perbuatan yang tak memadai & tak benar 11.2.1 Kebutuhan komunikasi 14.1 Perencanaan & penggunaan tak memadai

2.8 Lambat bereaksi 6.3 Penampilan tak memadai 11.2.2 Jadwal pekerjaan 14.2 Perpanjangan waktu pakai tak tepat

2.9 Kecerdasan yang kurang 6.4 Kurang pelatihan 9 Rekayasa tidak layak 11.2.3 Pemeriksaan unit 14.3 Inspeksi & monitoring tak memadai

2.10 Ketangkasan belajar yang kurang 6.5 Tinjauan instruksi tak memadai (Lihat DTP : 1.2.3.4.9.12.13.14) 11.2.4 Penggantian bagian 14.4 Pemusatan/jumlah pengunaan tak benar

2.11 Daya ingatan yang kurang 9.1 Penilaian kerugian yang tak memadai 14.5 Pemeliharaan yang tak memadai

7 Motivasi tak benar 9.2 Pertimbangan ergonomi/faktor manusia 12 Peralatan & alat-alat tak memadai 14.6 digunakan orang yg tidak ahli

3 Stress fisik (Lihat DTP : 1.2.4.5.6.8.10.11.13.15.17.18) yang tak memadai (Lihat DTP : 1.3.4.6.7.9.11.12.13.14.15.19) 14.7 Penggunaan utk keperluan yg salah

(Lihat DTP : 4.6.9.11.12.13.15.18.20) 7.1 Penampilan yang tak benar dipuji 9.3 Standard, spesifikasi/kriteria rancang bangun 12.1 Penaksiran keb & resiko tak memadai

3.1 Sakit 7.2 Penampilan yang tak benar dimarahi tak memadai 12.2 Pertimbangan ergonomi tak memadai 15 Penyelewengan & penyalahgunaan

3.2 Kelelahan karena beban/lamanya kerja 7.3 Kurang insentive 9.4 Pemantauan konstruksi yang tak memadai 12.3 Standard/spesifikasi tak standard 15.1 Dibiarkan oleh supervisornya

3.3 Kelelahan karena kurang istirahat 7.4 Frustasi yang berlebihan 9.5 Penaksiran kesiapan operasi yang 12.4 Penyediaan alat tak memadai 15.1.1 Disengaja

3.4 Kelelahan karena indera kelebihan beban 7.5 Agresi yang tak sesuai tak memadai 12.5 Perbaikan tak memadai 15.1.2 Tidak disengaja

3.5 Terpapar pada bahaya kesehatan 7.6 Usaha untuk menghemat waktu yang tak benar 9.6 Pengendalian yang tak benra/tak memadai 12.6 Pengamanan kembali tak memadai 15.2 Tak dibiarkan oleh Supervisornya

3.6 Terpapar pada suhu yang berlebihan 7.7 Usaha menghilangkan ketidak tenangan 9.7 Pemantauan operasi awal tak memadai 12.7 Pengambilan & penggantian barang yg 15.2.1 Disengaja

3.7 Kurang Oksigen 7.8 Usaha mendapatkan perhatian 9.8 Evaluasi perubahan yang tak memadai tak sesuai tak memadai. 15.2.2 Tidak disengaja

3.8 Tekanan udara yang bervariasi 7.9 Kedisiplinan yang tak memadai

3.9 Gula darah yang tidak cukup 7.10 Tekanan kawan sekerja yang tak memadai

3.10 Mabuk

Diperlukan Tindakan Pengendalian ( DTP )

1 KEPEMIMPINAN & ADMINISTRATION 5 PROGRAM PENYELIDIKAN KECELAKAAN 10 PELATIHAN KARYAWAN 16 PERTEMUAN KELOMPOK

Pengadaan Program (P), Standard (S), Pemenuhan (P) P S P Peng program (P), Standard (S), Pemenuhan (P) P S P Peng program (P), Standard (S), Pemenuhan (P) P S P Peng program (P), Standard (S), Pemenuhan (P) P S P

1.1 Kebijakan umum 5.1 Prosedure Penyelidikan Kecelakaan 10.1 Analisa kebutuhan pelatihan 16.1 Pelaksanaan rapat kelompok

1.2 Koordinator program 5.2 Penetapan lingkup Penyidikan 10.2 Program pelatihan karyawan 16.2 Dokumen tentang pers. Peserta, alat bantu

1.3 Partisipasi Senior & Manajemen menengah 5.3 Tindakan perbaikan & tindak lanjut 10.3 Evaluasi program pelatihan yg dibicarakan

1.4 Standard Kemampuan manajemen 5.4 Kecelakaan besar 16.3 Keterlibatan manajemen menengah & atas

1.5 Partisipasi Manajemen 5.5 Informal Potensi kejadian yg tinggi 11 ALAT PELINDUNG DIRI 16.4 Program pemantauan berkala

1.6 Pertemuan presentasi manajemen 5.6 Partisipasi manajemen operasi Peng program (P), Standard (S), Pemenuhan (P) P S P

1.7 Manual referensi manajemen 5.7 Pelaporan penyidikan kecelakaan 11.1 Standard alat pelindung diri 17 PROMOSI UMUM

1.8 Melakukan audit manajemen 5.8 Pemeliharaan laporan kecelakaan 11.2 Dokumentasi & catatan Peng program (P), Standard (S), Pemenuhan (P) P S P

1.9 Penetapan sasaran K3 & Perwakilan dalam 5.9 Pemantauan program secara berkala alat pelindung diri 17.1 Papan pengumuman K3

Panitia K3 11.3 Pelaksanaan standard 17.2 Penggunaan program statistik

1.10 Penetapan K3 6 TUGAS OBSERVASI 11.4 Pemantauan program secara berkala 17.3 Promosi pokok persoalan yg kritis

Sasaran pengendalian kerugian Peng program (P), Standard (S), Pemenuhan (P) P S P 17.4 Menggunakan hadiah atau penghargaan

1.11 Panitia K3 & Perwakilan dalam 6.1 Petunjuk manajemen pd hal-hal yg penting 12 PENGENDALIAN KESEHATAN 17.5 Publikasi program informasi

Perwakilan Panitia K3 6.2 Program observasi tugas semua tingkat Peng program (P), Standard (S), Pemenuhan (P) P S P 17.6 Promosi penampilan kelompok

1.12 Penolakan kerja bahaya K3 6.3 Observasi tugas semua tingkat 12.1 Identifikasi bahaya kesehatan 17.7 Promosi kebersihan

Procedure bahaya kesehatan 6.4 Program observasi perbagian 12.2 Pengendalian bahaya kesehata 17.8 Dokumen kegiatan program komisi

1.13 Referensi perpustakaan 6.5 Analisa observasi perbagian 12.3 Informasi/pelatihan/pendidikan

6.6 Program pemantauan secara berkala 12.4 Pemantauan secara berkala 18 PEREKRUTAN & PENGGANTIAN ORANG

2 PELATIHAN MANAGEMEN 12.5 Program pemeliharaan kesehatan Peng program (P), Standard (S), Pemenuhan (P) P S P

Pengadaan prog (P), Standard (S), Pemenuhan (P) P S P 7 KESIAGAAN DARURAT 12.6 Bantuan paramedik yg professional 18.1 Analisa kemampuan fisik

2.1 Program orientasi manajemen Peng program (P), Standard (S), Pemenuhan (P) P S P 12.7 Komunikasi keselamatan pada karyawan 18.2 Pemeriksaan fisik sebelum diangkat

2.2 Pelatihan resmi awal bagi anggota 7.1 Penunjukan koordinator 12.8 Pemeliharaan catatan 18.3 Program orientasi kerja secara umum

manajemen 7.2 Perencanaan darurat secara tertulis 18.4 Pengecekan kwalitas sebelum diangkat

2.3 Tinjauan & pelatihan terbaru resmi 7.3 Pelatihan P3K bagi Supervisor 13 SISTEM PROGRAM EVALUASI ditempatkan

bagi anggota manajemen 7.4 Pelatihan K3 bagi Karyawan Peng program (P), Standard (S), Pemenuhan (P) P S P

2.4 Pelatihan resmi awal bagi supervisor 7.5 Penerangan darurat yang 13.1 Audit pemenuhan standard program 19 PENGENDALIAN PEMBELIAN

manajemen menengah memadai secara luas Peng program (P), Standard (S), Pemenuhan (P) P S P

2.5 Tinjauan & pelatihan terbaru resmi 7.6 Sistim kontrol kode warna 13.2 Audit pemenuhan standard 19.1 Pembelian K3 termasuk spesifikasi

Supervisor dan manajemen menengah dan label kondisi fisik pengadaan

personnel 7.7 Peralatan pelindung & penyelamat 13.3 Audit pemenuhan standard pencegahan 19.2 Menyeleksi dan mengontrol kontraktor

2.6 Koordinator program training 7.8 Pelatihan team darurat dan pengendalian kebakaran

7.9 Petugas P3K yang terdidik 13.4 Audit pemenuhan standard 20 KESELAMATAN DILUAR JAM KERJA

3 RENCANA INSPEKSI 7.10 Pengorganisasian pertolongan dari kesehatan kerja Peng program (P), Standard (S), Pemenuhan (P) P S P

Peng program (P), Standard (S), Pemenuhan (P) P S P luar 13.5 Dokumen catatan sistem evaluasi 20.1 Penetapan sistem pelaporan dan

3.1 Inspeksi umum terencana 7.11 Dokumen pelindung yang vital program analisa statistik

3.2 Prosedur tindak lanjut 7.12 Perencanaan setelah kejadian 20.2 Komunikasi informasi keselamatan

3.3 Analisa laporan inspeksi 7.13 Menetapkan kumunikasi darurat 14 PENGENDALIAN REKAYASA diluar tugas

3.4 Program inspeksi barang/part yang kritis 7.14 Kumunikasi kes kpd umum yg terencana Peng program (P), Standard (S), Pemenuhan (P) P S P

3.5 Program Pencegahan Perawatan 14.1 Pertimbangan design Engineering K3

3.6 Inspeksi awal Peng Peralt mobil/alat 8 PERATURAN ORGANISASI pada konsepsi dan design

pengangkat dsb. Peng program (P), Standard (S), Pemenuhan (P) P S P 14.2 Pertimbangan proses Engineering K3

3.7 Sistem laporan kondisi 8.1 Peraturan Umum K3 pada konsepsi dan design

3.8 Pemeliharaan Laporan Inspeksi 8.2 Peraturan pekerjaan khusu 14.3 Pemantauan program secara berkala

Umum 8.3 Surat ijin kerja &

3.9 Pemantauan Program prosedur khusus 15 KOMUNIKASI PERSEORANGAN

8.4 Pendidikan tentang peraturan & tinjauan prog Peng program (P), Standard (S), Pemenuhan (P) P S P

4 PROSEDUR & ANALISA TUGAS 8.5 Upaya memenuhi peraturan 15.1 Pelatihan dalam teknik komunikasi SINGKATAN

Peng program (P), Standard (S), Pemenuhan (P) P S P 8.6 Penggunaan sistem warna perseorangan P Apakah mempunyai program standard untuk aktifitas ini ? (V)

4.1 Petunjuk manajemen pada hal-hal yg penting dan kode warna 15.2 Orientasi kerja pegawai/karyawan

4.2 Inventarisasi tugas-tugas yang kritis 8.7 Pemantauan program secara berkala baru S Apaka standard yang ada sudah cukup ? (V)

4.3 Sasaran analisa dan 15.3 Pelatihan & peng instruksi kerja yg benar

prosedur tugas 9 ANALISA KECELAKAAN 15.4 Program kontak pribadi yang terencana P Apaka semua sudah memenuhi standard ? (V)

4.4 Analisa dan prosedur bagi tugas Peng program (P), Standard (S), Pemenuhan (P) P S P 15.5 Pemantauan program secara berencana

yang kritis secara lengkap diperbaharuhi 9.1 Pelaksanaan penghitungan statistik & gunanya

Update 9.2 Analisa cidera & sakit akibat kerja 1 = 20% 2 = 40% 3 = 60%

4.5 Bahaya K3 dalam analisa 9.3 Identifikasi & analisa kerusakan barang

prosedure tugas 9.4 Analisa nyaris celaka atau kejadian 4 = 80% 5 = 100%

4.6 Pemantauan program 9.5 Analisa incident

SCAT Chart - Systematic Cause Analysis Technique - SCAT Chart

DESCRIPTION OF ACCIDENT OR INCIDENT

EVALUATION OF LOSS IF NOT CONTROLLED

Loss Severity Potential Probability of Occurrence Frequency of Exposure

O Major ( A ) O Serious ( B ) O Minor ( C ) O High ( A ) O Moderate ( B ) O Rare ( C ) O Extensive ( A ) O Moderate ( B ) O Low ( C )

Type of Contact or Near Contact with Energy or Substance

1 Struck against (Running & Bumping into) 3 Fall to Lower Level (see 1. IC's : 3, 5, 6, 7, 11, 12, 13, 14, 5 Caught in (Pinch and Nip Points (See 1. IC's : 7 Caught Between Or Under (Crushed Or amputated)

See IC's 1, 2, 4, 5, 12, 14, 16, 17, 18, 19 26) 15, 16, 17, 22) 5, 6, 11, 13, 14, 15, 16, 18) (See IC's : 1, 2, 5, 6, 9,11, 12, 13, 14, 15, 16, 22, 28) 20, 21, 23, 24, 25, 27,28)

2 Struck by (Hit by Moving Object) (See IC's : 1, 2, 4, 5 4 Fell on Same level (Slip and fall, Trip Over) 6 Caught On (Snagged, Hung) See IC's : 8 Contact with (Electricity, Heat, Cold, Radiation, Caustics 9 Overstress, Overexertion, Overhead

6, 9, 10, 12, 13, 14, 15, 16, 20, 26) (See IC's: 4, 9, 13, 14, 15, 16, 19, 22, 26) 2, 6, 11, 12, 13, 14, 15, 16, 18) Toxics, Noise) (See IC's : 5, 6, 7, 11, 12, 13, 14, 15, 16, 17, 18 (See IC's : 8, 9, 10, 11, 13, 14, 15)

(IC's) Immediate/Direct Causes (IC's)

SUBSTANDARD/UNSAFE ACTS 7 Failing to Use PPE Property (See BC's : 2.3.4.5.7.8 13 Horseplay (See BC's : 2.3.4.5.7.8.13.15) 20 Inadequate warning System (See BC's : 8.9.10.11.12.13) 26 Inadequate or Excess Illumination

1 Operating Equipment Without Authority (See BC's 10.12.13.15) 14 Under Influence of Alcohol and/or Other 21 Fire & explosion Hazards (See BC's : 8.9.10.11.12.13)

2. 4. 5. 7. 8. 12. 13. 15) 8 Improper Loading (See BC's : 1.2.3.4.5.6.7.8.9.12 Drugs (See BC's : 2.3.4.5.7.8.13.15) (See BC's : 5.6.7.8.9.10.11.12.13.15) 27 Inadequate Ventilation

2 Faiture to Warn (See BC's : 1. 2. 3. 4. 5. 6. 7. 8. 9. 12. 13.15) 15 Using Equipment Improperty (See BC's : 22 Poor Housekeeping/Disorder (See BC's : 8.9.10.11.12)

13. 15) 9 Improper Placement (See BC's : 1.2.3.4.5.6.7.8.9 (1.2.3.4.5.6.7.8.9.10.12.13.15) (See BC's : 5.6.7.8.9.10.12.13.15) 28 Hazardous Environmetal Conditions

3 Faiture to Secure (See BC's : 2.3.4.5.6.7.8.9.12 12.13.15) 16 Inadequate Guards or Bariers (See BC's : 23 Noise Exposure (See BC's : 5.6.7.8.9.10.11.12.13.14) (See BC's : 8.9.10.11.12.13)

13.15) 10 Improper Lifting (See BC's : 1.2.3.4.5.6.7.8.9.12.13 5.7.8.9.10.11.12.13.15) 24 Radiation Exposure

4 Operating at Improper Speed 15) 17 Inadequate or Improper Protective Equipment (See BC's : 5.6.7.8.9.10.11.12.13)

(See BC's : 2. 3. 4. 5. 6. 7. 8) 11 Improper Position for Task (See BC's : 1.2.3.4.5.6 (See BC's : 5.7.8.9.10.12.13) 25 Temperature Extremes (See BC's : 1.2.3.8.9.11.12)

5 Making Safety Davices Inoperative (See BC's : 7.8.9.12.13.15) 18 Defective Tools, Equipment or Materials (See

2.3.4.5.6.7.8.9.12.13.15) 12 Servicing Equipment in Operation (See BC's : 2.3.4.5 BC's : 8.9.10.11.12.13.14.15)

6 Using Defactive/ wrong Equipment (See BC's : 2.3.4.5.6 6.7.8.9.12.13.15) 19 Congestion or Restricted Action (See BC's :

7.8.9.10.11.12.13.14.15) 8.9.13)

(BC's) Basic / Underlying Cause

PERSONAL FACTORS

1 Inadequate Physical/Physiological Capabillity 4 Mental or Psychological Stress 7.11 Improper supervisory example 10 Inadequate Purchasing 13 Inadequate Work Standard

(See CAN : 6.9.12.15.18) (See CAN : 1.4.5.6.10.11.12.15.16.18.20) 7.12 Inadequate performance feedback (See CAN : 1.3.4.6.9.12.13.14.15.19) (See CAN : 1.2.3.4.5.6.7.8.9.10.11. 12.13.14.15.16.19)

1.1 Inappropriate, height, weight,size,strength 4.1 Emotional overload 7.13 Inadequate reinforcement of proper behavoir 10.1 Inadequate specifications on requisitions

reach, etc. 4.2 Fatique due to mental task load or speed 7.14 Improper production incentives 10.2 Inadequate research on materials/equipment 13.1 Inadeguate development of standard for ;

1.2 Pestriated range of body movement 4.3 Extreme judgment/decision demands 10.3 Inadequate specifications to vendors 13.1.1 Inventory and evaluation of

1.3 Limited ability to sustain body positions 4.4 Routine, monotory, demand for uneventful vigilance JOB FACTORS 10.4 Inadequate mode or route of shipment exposures and needs

1.4 Substance sensitivities or ellergies 4.5 Extreme concentration/perception demands 8 Inadequate Loadership and/or Supervison 10.5 Inadequate receiving inspection and 13.1.2 Coordination pocess design

1.5 Sensitivities to sensory axtramas 4.6 Meaningless or degrading activities (See CAN : 1.2.3.4.5.6.8.9.10.11.12.13.14.15.16.17.18) acceptance 13.1.3 Employee involment

(temperature, sound, etc) 4.7 Confusing directions/demands 8.1 Unclear or conflicting reporting relationships 10.6 Inadequate communication of safety 13.1.4 Procedures/practices/rules

1.6 Vislea deficiency 4.8 Conflicting demands/directions 8.2 Unclear or conflicting assigment of responsibility and health data 13.2 Inadequate communication of standards for ;

1.7 Hearing deficiency 4.9 Preoccupation with problems 8.3 Improper or insufficient delegation 10.7 Improper handling of materials 13.2.1 Publication

1.8 Other sensory deficiency (touch, 4.10 Frustasion 8.4 Giving inadeguate policy, procedure, practices 10.8 Improper storage of materials 13.2.2 Distribution

taste, small, balance) 4.11 Mental illness or guidelines 10.9 Improper transporting of materials 13.2.3 Translation to appropriate

1.9 Respiratory incapability 8.5 Giving objectives, goals, or standard that conflict 10.10 Inadequate identification of hazardous languages

1.10 Other parmanent physical capability 5 Lack of Knowledge 8.6 Inadequate work planing or programming items 13.2.4 Training

1.11 Temporary disabilities (See CAN : 2.4.5.6.7.8.9.10.11.12.13.15.16.18.20) 8.7 Inadequate instructions, orientation and or train 10.11 Improper salvage and/or waste disposal 13.2.5 Reinforcing with sign, color

5.1 Lack of experience 8.8 Providing inadequate reference documents 10.12 Inadequate contractor selection codes and jobs aids

2 Inadequate mental/Psychological Capability 5.2 Inadequate orientation directives and guidance publications 13.3 Indequate maintenance of standard for :

(See CAN : 6.9.10.15.18) 5.3 Inadequate initial training 8.9 Inadequate identification and evaluation of 11 Inadequate Maintenance 13.3.1 Tracking of work flow

2.1 Fears and probias 5.4 Inadequate update training loss exposure (See CAN : 1.3.4.5.9.10.13.15.19) 13.3.2 Updating

2.2 Emotional disturbance 5.5 Misunderstood directions 8.10 Lack of supervisory / management job 11.1 Inadequate preventive 13.3.3 Monitoring use of prosedure

2.3 Mental illness knowledge 11.1.1 Assessment of needs or practices/rules

2.4 Intelligence level 6 Lack of Skill 8.11 Inadequate matching of individual qualifications 11.1.2 Lubrication and servicing 13.4 Inadequate monitoring of compliance

2.5 Inability to comprohead (See CAN : 2.4.5.6.7.9.10.13.15.18) and job / task requirement 11.1.3 Adjusment/assembly

2.6 Poor judgment 6.1 Inadequate initial instruction 8.12 Inadequate performance measurement and 11.1.4 Cleaning or resurfacing 14 Exercise Wear and Tear

2.7 Poor coordination 6.2 Inadequate prectice evaluation 11.2 Inadequate repairative (See CAN : 3.4.6.9.10.13.14.15)

2.8 Slow reaction time 6.3 Infrequent performance 8.13 Inadequate or incorrect performance feedback 11.2.1 Communication of needs 14.1 Inadequate planning of use

2.9 Low mechanical aptitude 6.4 Lack of Coaching 11.2.2 Scheduling of work 14.2 Improper extension of service life

2.10 Low learning aptitude 6.5 Inadequate review instruction 9 Inadequate Engineering 11.2.3 Examination of units 14.3 Inadequate Inspection and/or monitor

2.11 Memory failure (See CAN : 1.2.3.4.9.12.13.14) 11.2.4 Part of substitution 14.4 Improper loading or rate of use

7 Impropar Motivation 9.1 Inadequate assessment of loss exposures 14.5 Inadequate maintenace

3 Physical or Physlological Stress (See CAN : 1.2.4.5.6.8.10.11.13.15.17.18) 9.2 Inadequate consideration of human factors 12 Inadequate Tools and equipment 14.6 Use by unqualified or untrained people

(See CAN : 4.6.9.11.12.13.15.18.20) 7.1 Improper performance is rewarding or ergonomic (See CAN : 1.3.4.6.7.9.11.12.13.14.15.19) 14.7 Use for wrong purpose

3.1 Injury illnass 7.2 Improper performance is punishing 9.3 Inadequate standards, specifications and or 12.1 Inadequate assessment of needs and

3.2 Fatique due to task load or duration 7.3 Lack of Incentives design centeriaInadequate monitoring of construction risks 15 Abuse or Misuse

3.3 Fatique due to lack of rest 7.4 Excessive frustation 9.4 Inadequate monitoring of construction 12.2 Inadequate human factors/ergonomics 15.1 Improper conduct that is condoned

3.4 Fatique due to sensory overload 7.5 Inappropriate agression 9.5 Inadequate assessment of operational considerations 15.1.1 Intentional

3.5 Exposure to health bazards 7.6 Impropar altempt to save time or effort readiness 12.3 Inadequate standards or specifications 15.1.2 Unintentional

3.6 Exposure to temperature extremes 7.7 Impropar altempt to avoid discomfort 9.6 Inadequate or improper controls 12.4 Inadequate availabilly 15.2 Improper conduct that is not condoned

3.7 Oxygen depciency 7.8 Improper attempt to gain attention 9.7 Inadequate monitoring of initial operation 12.5 Inadequate adjusment/maintenance 15.2.1 Intentional

3.8 Atmospheric pressure variation 7.9 Inadequate dicipline 9.8 Inadequate evaluation of changes 12.6 Inadequate salvage and reclamation 15.2.2 Unintentional

3.9 Blood sugar asulfigiency 7.10 Inappropriate pear pressure 12.7 Inadequate removal and replacement

3.10 Drugs of suitable items

Control of Action Needs ( CAN )

1 LEADERSHIP AND ADMINISTRATION 5 ACCIDENT AND INCIDENT INVESTIGATION 10 EMPLOYEE TRAINING 16 GROUP MEETING

Program Present (P), Standard (S), Compliance (C) P S C Program Present (P), Standard (S), Compliance ( C ) P S C Program Present (P), Standard (S), Compliance ( C ) P S C Program Present (P), Standard (S), Compliance ( C ) P S C

1.1 General Policy 5.1 Accident/Incident Investigation Procedure 10.1 Training Needs Analysis 16.1 Group Meeting Held

1.2 Program coordinator 5.2 Scope of Investigations Established 10.2 Employee Training Program 16.2 Record of Subject, Visual Aid, Attendance,

1.3 Senior and middle Management Participation 5.3 Remedial Follow-up and Action 10.3 Training Program Evaluation Problems Discussed

1.4 Management Performance Standards 5.4 Major Accident Announcement Used 16.3 Middle and Top Management Involvement

1.5 Management Participation 5.5 High Poiential Incident Information Used 11 PERSONAL PROTECTIVE EQUIPMENT 16.4 Regular Program Monitoring

1.6 Preparatation of management Meeting 5.6 Operating Management Participation Program Present (P), Standard (S), Compliance ( C ) P S C

1.7 Management Referance Manual 5.7 Incident Reporting and Investigation 11.1 Personal Protective Equipment Standards 17 GENERAL PROMOTION

1.8 Management Audits Conducted 5.8 Accident/Incident Report Maintenance 11.2 Personal Protective Equipment Program Present (P), Standard (S), Compliance ( C ) P S C

1.9 Individual Responsibility for Safety and Health 5.9 Regular Program Monitoring Recordkeeping 17.1 Safety Bulletin Board Program

/loss Control Objectives 11.3 Enforcement of Standards 17.2 Use of program statistic and facts

1.10 Estabishment of Annual Safety and Health 6 TASK OBSERVATION 11.4 Regular Program Monitoring 17.3 Critical Topic Promotion

/loss Control Objectives Program Present (P), Standard (S), Compliance ( C ) P S C 17.4 Use of Awards or Recognition

1.11 Joint Safety & Health Commonittess and/or 6.1 Management Directive on Importance 12 HEALTH CONTROL 17.5 Program Information Publication

Safety and Health Representatives 6.2 Complete Task Observation Program Program Present (P), Standard (S), Compliance ( C ) P S C 17.6 Group Performance Promotion

1.12 Refusal to Work on Grounds of Safety & 6.3 Level of Complete Task Observations 12.1 Health Hazard Identification 17.7 Housekeeping Promotion

Health hazard (s) procedure 6.4 Partial Task Observation Program 12.2 Health Hazard Control 17.8 Records of Program Promotion Activities

1.13 Reference Library 6.5 Task Observation Report Analysis 12.3 Information/Training/Education

6.6 Regular Program Monitoring 12.4 Industrial Hygiene Monitoring 18 HIRING AND PLACEMENT

2 Management Training 12.5 Health Maintenance Program Program Present (P), Standard (S), Compliance ( C ) P S C

Program Present (P), Standard (S), Compliance ( C ) P S C 7 EMERGENCY PREPAREDNESS 12.6 Professional Medical Assistance 18.1 Physical Capability Analyses

2.1 Management Orientation/Induction Program Program Present (P), Standard (S), Compliance ( C ) P S C 12.7 Health Communication to Worker 18.2 Pre-Employment Physical examination

2.2 Formal Initial Training of Senior Management 7.1 Coordinator Appointed 12.8 Record maintenance 18.3 General Orientation/Induction Program

personnel 7.2 Emergency Plan in Writing 18.4 Pre-Employment/Pre-Placement Qualifica-

2.3 Formal Review and Update Training of senior 7.3 Supervisory Training in First Aid 13 PROGRAM EVALUATION SYSTEM tion Checks

Management Personnel 7.4 Employee Training in First Aid ( 10% ) Program Present (P), Standard (S), Compliance ( C ) P S C

2.4 Formal Initial Training of Supervisory and 7.5 Emergency Lighting and Power 13.1 Comprehensive Audit of Compliance with 19 PURCHASING CONTROLS

Midle Management Personnel Adequate Program Standards Program Present (P), Standard (S), Compliance ( C ) P S C

2.5 Formal Review and Update Training of 7.6 Master Controls Color Coded and 13.2 Comprehensive Audit of Compliance with 19.1 Purchasing Includes Safety and Health in

Supervisory and Middle Management labeled Physical Conditions Standards Specifications and Procurement

personnel 7.7 Protective and Rescue Equipment 13.3 Comprehensive Audit of Compliance with 19.2 Selection and Control of Contractor

2.6 Format Training of program coordinator 7.8 Emergency team Training and Drills Fire Prevention and Control Standards

7.9 Qualified First Aid Attendants 13.4 Comprehensive Audit of Compliance with 20 OFF THE JOB SAFETY

3 PLANNED INSPECTIONS 7.10 Organized Outside Help and Mutual Occupational Health Standards Program Present (P), Standard (S), Compliance ( C ) P S C

Program Present (P), Standard (S), Compliance (C) P S C Aid 13.5 Program Evaluation System Record 20.1 Reporting System Established and statistics

3.1 Planned General Inspections 7.11 Protection of Vital Records Keeping Analyzed

3.2 Follow up Procedure 7.12 Post Event Planning 20.2 Off the job safety information Communi-

3.3 Inspection report Analyst 7.13 Emergency Communication Provided 14 ENGINEERING CONTROL cated

3.4 Critual Parts/items inspection Program 7.14 Public Safety Communication Planned Program Present (P), Standard (S), Compliance ( C ) P S C

3.5 Propentive maintenance Program 14.1 Design Engineering Safety and Health Con-

3.6 Mobile and Material-Handling Pra-Use 8 ORGANIZATION RULES siderations at conception and design

Equipment Inspection Program Present (P), Standard (S), Compliance ( C ) P S C 14.2 Process Engineering Safety and Health

3.7 Alternative Conditions Reporting System 8.1 General Safety and Health Rules Consideration at Conception and Design

3.8 Planned general Inspection Report 8.2 Specialized Work Rules 14.3 Regular Program Monitoring

Maintenance 8.3 Work Permit and Specialized Procedures

3.9 Regular Program Monitoring Systems 15 PERSONAL COMMUNICATIONS

8.4 Rule Education and Review Program Program Present (P), Standard (S), Compliance ( C ) P S C

4 TASK ANALYSIS AND PROCEDURES 8.5 Rule Compliance Effort 15.1 Training in Personal Communication LEGEND :

Program Present (P), Standard (S), Compliance ( C ) P S C 8.6 Use of Educational Signs and Color Code Technique

4.1 Management Directive on Importance 8.7 Regular Program Monitoring 15.2 Job Orientation/Instruction New/Transferred P Do we have program standards for this activity?

4.2 Critical Task Inventory People

4.3 Task Analysis and Task Procedure 15.3 Proper Task Instruction Training and Use S Are existing standards adequate?

Objectives 9 ACCIDENT/INCIDENT ANALYSIS 15.4 Planned Personal Contact Program

4.4 Task Analysis and Task Procedures for Program Present (P), Standard (S), Compliance ( C ) P S C 15.5 Regular Program Monitoring C Is there full compliance with standards?

Critical Task Completed and Regulary 9.1 Performance Statistics Computed and used

Updated 9.2 Occupational injury and illness Analysis 1 = 20% 2 = 40% 3 = 60%

4.5 Safety and Health Hazards in Critical 9.3 Property and Equipment Damage

task Analyses and Procedures Identification and Analysis 4 = 80% 5= 100%

4.6 Regular Program Monitoring 9.4 Problem Solving Project Teams

Anda mungkin juga menyukai

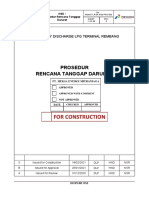

- Prosedur Tanggap DaruratDokumen13 halamanProsedur Tanggap DaruratIndah Khairun Nisa AzizBelum ada peringkat

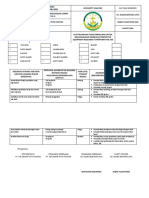

- Form Cek Tabung APIDokumen1 halamanForm Cek Tabung APItemter gandaBelum ada peringkat

- 3.1 Struktur Organisasi HseDokumen16 halaman3.1 Struktur Organisasi HseRahmat HidayatBelum ada peringkat

- K3 Lingker - Kita Kompeten - Industri - Peserta - UnlockedDokumen20 halamanK3 Lingker - Kita Kompeten - Industri - Peserta - Unlockedquality control pt dusBelum ada peringkat

- HIARO Indoor ActivityDokumen2 halamanHIARO Indoor ActivityHilman RadifanBelum ada peringkat

- Prosedur 7 Bekerja Di KetinggianDokumen9 halamanProsedur 7 Bekerja Di KetinggianRoyke Eryantho Anthonie-HontongBelum ada peringkat

- Anr Sop 12 Incident InvestigationDokumen5 halamanAnr Sop 12 Incident InvestigationRhudyRanBelum ada peringkat

- Proposal Hari K3Dokumen14 halamanProposal Hari K3yaaveaBelum ada peringkat

- HIRADC WarehouseDokumen18 halamanHIRADC WarehouseIrwan SuharwanBelum ada peringkat

- Hse Plan RJTDokumen43 halamanHse Plan RJTBayu PutraBelum ada peringkat

- Investigasi Kecelakaan KerjaDokumen35 halamanInvestigasi Kecelakaan KerjaAde Yusuf100% (1)

- Vehicle PermitDokumen1 halamanVehicle PermitRizqi NoviantBelum ada peringkat

- Topik 51 Jalan Pintas Tidaklah AmanDokumen1 halamanTopik 51 Jalan Pintas Tidaklah AmanFahmi NoviandriBelum ada peringkat

- Potensi BahayaDokumen15 halamanPotensi BahayaRahmatika IntianiBelum ada peringkat

- IBPR KiavannaDokumen42 halamanIBPR Kiavannaade. kiavannaBelum ada peringkat

- Basic Training Inspeksi K3Dokumen24 halamanBasic Training Inspeksi K3Ahmad FadillahBelum ada peringkat

- Accident - Incident Investigation Report (QF-HS-001 Rev.00)Dokumen3 halamanAccident - Incident Investigation Report (QF-HS-001 Rev.00)vannyBelum ada peringkat

- 24 - Program&Biaya K3Dokumen1 halaman24 - Program&Biaya K3Fahmi NoviandriBelum ada peringkat

- HIRADC Working at Height (Ketinggian)Dokumen2 halamanHIRADC Working at Height (Ketinggian)bayu arwiansyahBelum ada peringkat

- Sosialisasi Kebijakan - EPIK - CompressedDokumen53 halamanSosialisasi Kebijakan - EPIK - Compressedhsse perkasaBelum ada peringkat

- 01 Prosedur Statistik K3Dokumen5 halaman01 Prosedur Statistik K3CV. Abdi Energy SambojaBelum ada peringkat

- Hiradc ICBP BiskuitDokumen26 halamanHiradc ICBP Biskuitasep ewoxBelum ada peringkat

- Sop IbprDokumen11 halamanSop IbprGeon SatriaBelum ada peringkat

- LahanDokumen5 halamanLahanjordi100% (1)

- 00 Daftar Isi Check List Prakualifikasi CSMS PDFDokumen1 halaman00 Daftar Isi Check List Prakualifikasi CSMS PDFAdi SumarsonoBelum ada peringkat

- Struktur Organisasi Tanggap Darurat Pada Idi Dan KontraktorDokumen1 halamanStruktur Organisasi Tanggap Darurat Pada Idi Dan KontraktorFahmi100% (1)

- Matrix Medical CekupDokumen2 halamanMatrix Medical CekupFahmi NoviandriBelum ada peringkat

- SMKP Minerba - Elemen IV - AdrianusDokumen19 halamanSMKP Minerba - Elemen IV - AdrianusAndini Perwita SariBelum ada peringkat

- Safety Talk 16012018Dokumen3 halamanSafety Talk 16012018rougue arcaneBelum ada peringkat

- Contoh Ibpr Pengoperasian Gerinda TanganDokumen6 halamanContoh Ibpr Pengoperasian Gerinda TanganHendrikronaldo mdiBelum ada peringkat

- 029 - SOP Tanggap DaruratDokumen9 halaman029 - SOP Tanggap DaruratSuhendri JoelBelum ada peringkat

- Bpac-Sop-Ohse-002 - Commissioning - Atau - Kelayakan - Alat TambangDokumen7 halamanBpac-Sop-Ohse-002 - Commissioning - Atau - Kelayakan - Alat TambangFahmi NoviandriBelum ada peringkat

- HEMA-TLPGR-HSE-PRO-003-REV.0 - Prosedur Rencana Tanggap Darurat Fix Update 5 Sept 2021Dokumen28 halamanHEMA-TLPGR-HSE-PRO-003-REV.0 - Prosedur Rencana Tanggap Darurat Fix Update 5 Sept 2021Erwin P. AjaBelum ada peringkat

- CSMS 02 ApdDokumen5 halamanCSMS 02 ApdEthos SeptiansyahBelum ada peringkat

- LATIHAN Formulir Investigasi - Teori Domino & 5-WhyDokumen6 halamanLATIHAN Formulir Investigasi - Teori Domino & 5-WhyheryadiwijayaBelum ada peringkat

- Bpac-Sop-Ohse-003 - Prosedur Lalu - Lintas - TambangDokumen8 halamanBpac-Sop-Ohse-003 - Prosedur Lalu - Lintas - TambangFahmi NoviandriBelum ada peringkat

- 006 Pernyataan InduksiDokumen2 halaman006 Pernyataan InduksiFahmi Noviandri100% (1)

- 5.1 Form HIRA PengelasanDokumen1 halaman5.1 Form HIRA Pengelasanyoga kuncorojatiBelum ada peringkat

- Hygiene PerusahaanDokumen20 halamanHygiene Perusahaannadya maharaniBelum ada peringkat

- SSMM - HSE.Komunikasi K3LDokumen6 halamanSSMM - HSE.Komunikasi K3Lricho naiborhuBelum ada peringkat

- 03.prosedur Identifikasi UU & Peraturan K3LDokumen11 halaman03.prosedur Identifikasi UU & Peraturan K3LTirena PutriBelum ada peringkat

- 10.basic Safety & 5r-1Dokumen51 halaman10.basic Safety & 5r-1EgiBelum ada peringkat

- FM-00-SHE-040 Surat Pengangkatan Anggota SHE CommitteeDokumen1 halamanFM-00-SHE-040 Surat Pengangkatan Anggota SHE CommitteeFahmi NoviandriBelum ada peringkat

- 4 Langkah KeselamatanDokumen1 halaman4 Langkah KeselamatanArnoldo VipBelum ada peringkat

- Struktur Organisasi Komite Keselamatan PertambanganDokumen2 halamanStruktur Organisasi Komite Keselamatan PertambanganFahmi NoviandriBelum ada peringkat

- HIRADC-Analisa Resiko Poteasnsi Bahaya K3LL (09 Aug 2011)Dokumen9 halamanHIRADC-Analisa Resiko Poteasnsi Bahaya K3LL (09 Aug 2011)Imam PramudiBelum ada peringkat

- Matriks Penilaian SMLDokumen225 halamanMatriks Penilaian SMLFahmi NoviandriBelum ada peringkat

- 1.5 Program ProsedurDokumen13 halaman1.5 Program ProsedurAnwar Md100% (1)

- CSMSDokumen9 halamanCSMSbesolusi tekBelum ada peringkat

- 11 MMK3-PR-K-11 Prosedur Pengukuran Dan Inspeksi Mutu & K3Dokumen5 halaman11 MMK3-PR-K-11 Prosedur Pengukuran Dan Inspeksi Mutu & K3Obie BahhierBelum ada peringkat

- HSE PlanDokumen6 halamanHSE PlanYogi'eRachmanBelum ada peringkat

- Lab Pipa KAT19A SOP PELAPORAN BAHAYADokumen7 halamanLab Pipa KAT19A SOP PELAPORAN BAHAYAAulia AwekBelum ada peringkat

- Scat IndonesiaDokumen3 halamanScat IndonesiaindraBelum ada peringkat

- Contoh Isian Formulir InvestigasiDokumen9 halamanContoh Isian Formulir Investigasitanjungpinang tjpBelum ada peringkat

- Form Commisioning Alat BaruDokumen6 halamanForm Commisioning Alat Barusyamsiruddin. cakrabuanaproteksindoBelum ada peringkat

- Kartu Observasi Bahaya PDFDokumen1 halamanKartu Observasi Bahaya PDFMuhammadHafidhkBelum ada peringkat

- IK-SMK3-012-3 - Keadaan - Darurat - Ancaman - Bom - SMTDokumen1 halamanIK-SMK3-012-3 - Keadaan - Darurat - Ancaman - Bom - SMTDicky Nur AnharBelum ada peringkat

- Materi - Pemilihan Dan Pemakaian Alat Pelindung Diri (APD)Dokumen3 halamanMateri - Pemilihan Dan Pemakaian Alat Pelindung Diri (APD)Andy YanotBelum ada peringkat

- Daily Activity 2021 - HSEDokumen9 halamanDaily Activity 2021 - HSEAdityaBelum ada peringkat

- SM QTCDokumen5 halamanSM QTCzulkifly qolbun salimBelum ada peringkat

- Sop HiraDokumen11 halamanSop HiraSaf UdinBelum ada peringkat

- JSA N SOPDokumen21 halamanJSA N SOPJoko Ono0% (1)

- Contoh Program - Kerja - K3Dokumen7 halamanContoh Program - Kerja - K3Nur FitrahBelum ada peringkat

- HSE Bulletin - Gempa BumiDokumen1 halamanHSE Bulletin - Gempa BumiNashrullah JamilBelum ada peringkat

- JSA Pemasangan Lampu BuoyDokumen2 halamanJSA Pemasangan Lampu Buoymahar dhikaBelum ada peringkat

- Cv. Putra Pratama: No:016-REV/17 Rev: - Tnggl:05/06/17 Hr:SeninDokumen1 halamanCv. Putra Pratama: No:016-REV/17 Rev: - Tnggl:05/06/17 Hr:Seninyudi mansalaiBelum ada peringkat

- HSEBKU-JSA-09-Activity Geophysical LoggingDokumen2 halamanHSEBKU-JSA-09-Activity Geophysical Loggingboby dwiBelum ada peringkat

- Prosedur Insetigasi InsidenDokumen4 halamanProsedur Insetigasi InsidenRishamdi HSEBelum ada peringkat

- Topik 03 Hak Dan Kewajiban Tenaga KerjaDokumen1 halamanTopik 03 Hak Dan Kewajiban Tenaga KerjaFahmi NoviandriBelum ada peringkat

- Topik 06 Penyebab Dasar KecelakaanDokumen1 halamanTopik 06 Penyebab Dasar KecelakaanFahmi NoviandriBelum ada peringkat

- Kebisingan Dan Pemeliharaan PendengaranDokumen1 halamanKebisingan Dan Pemeliharaan PendengaranFahmi NoviandriBelum ada peringkat

- Topik 34 Alat Pelindung DiriDokumen2 halamanTopik 34 Alat Pelindung DiriFahmi NoviandriBelum ada peringkat

- Topik 08 Mengenal BahayaDokumen1 halamanTopik 08 Mengenal BahayaFahmi NoviandriBelum ada peringkat

- Topik 02 Dasar Hukum K3Dokumen1 halamanTopik 02 Dasar Hukum K3Fahmi NoviandriBelum ada peringkat

- Topik 32 Prosedur Re-FuelingDokumen1 halamanTopik 32 Prosedur Re-FuelingFahmi NoviandriBelum ada peringkat

- Topik 30 Bahan B3Dokumen1 halamanTopik 30 Bahan B3Fahmi NoviandriBelum ada peringkat

- BPAC FR OHSE 025 - Commisioning - COMPACTORDokumen2 halamanBPAC FR OHSE 025 - Commisioning - COMPACTORFahmi NoviandriBelum ada peringkat

- BPAC-FR-OHSE-023 Commisioning LIGHT VEHICLEDokumen1 halamanBPAC-FR-OHSE-023 Commisioning LIGHT VEHICLEFahmi NoviandriBelum ada peringkat

- FM-00-SHE-04 Surat Pengangkatan Anggota KKPDokumen1 halamanFM-00-SHE-04 Surat Pengangkatan Anggota KKPFahmi NoviandriBelum ada peringkat

- Gambar EwsDokumen2 halamanGambar EwsFahmi NoviandriBelum ada peringkat

- SMLDokumen1 halamanSMLFahmi NoviandriBelum ada peringkat

- Pt. BPDokumen1 halamanPt. BPFahmi NoviandriBelum ada peringkat

- RESPON MANAJEMEN Format 2Dokumen1 halamanRESPON MANAJEMEN Format 2Fahmi NoviandriBelum ada peringkat

- Curriculum VitaeDokumen4 halamanCurriculum VitaeFahmi NoviandriBelum ada peringkat

- Penawaran Harga Kapur Tohor - JPCDokumen1 halamanPenawaran Harga Kapur Tohor - JPCFahmi NoviandriBelum ada peringkat

- Sarana Dan Prasarana Pelayanan KesehatanDokumen2 halamanSarana Dan Prasarana Pelayanan KesehatanFahmi NoviandriBelum ada peringkat

- Rincian Biaya Pelatihan BasarnasDokumen1 halamanRincian Biaya Pelatihan BasarnasFahmi NoviandriBelum ada peringkat

- CV Ramadhan-LengkapDokumen10 halamanCV Ramadhan-LengkapFahmi NoviandriBelum ada peringkat

- Draft Persyaratan Commissioing DLL - 01 - 30jan23 - Rev0Dokumen11 halamanDraft Persyaratan Commissioing DLL - 01 - 30jan23 - Rev0Fahmi NoviandriBelum ada peringkat